Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about "Monocomponent polyureas artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

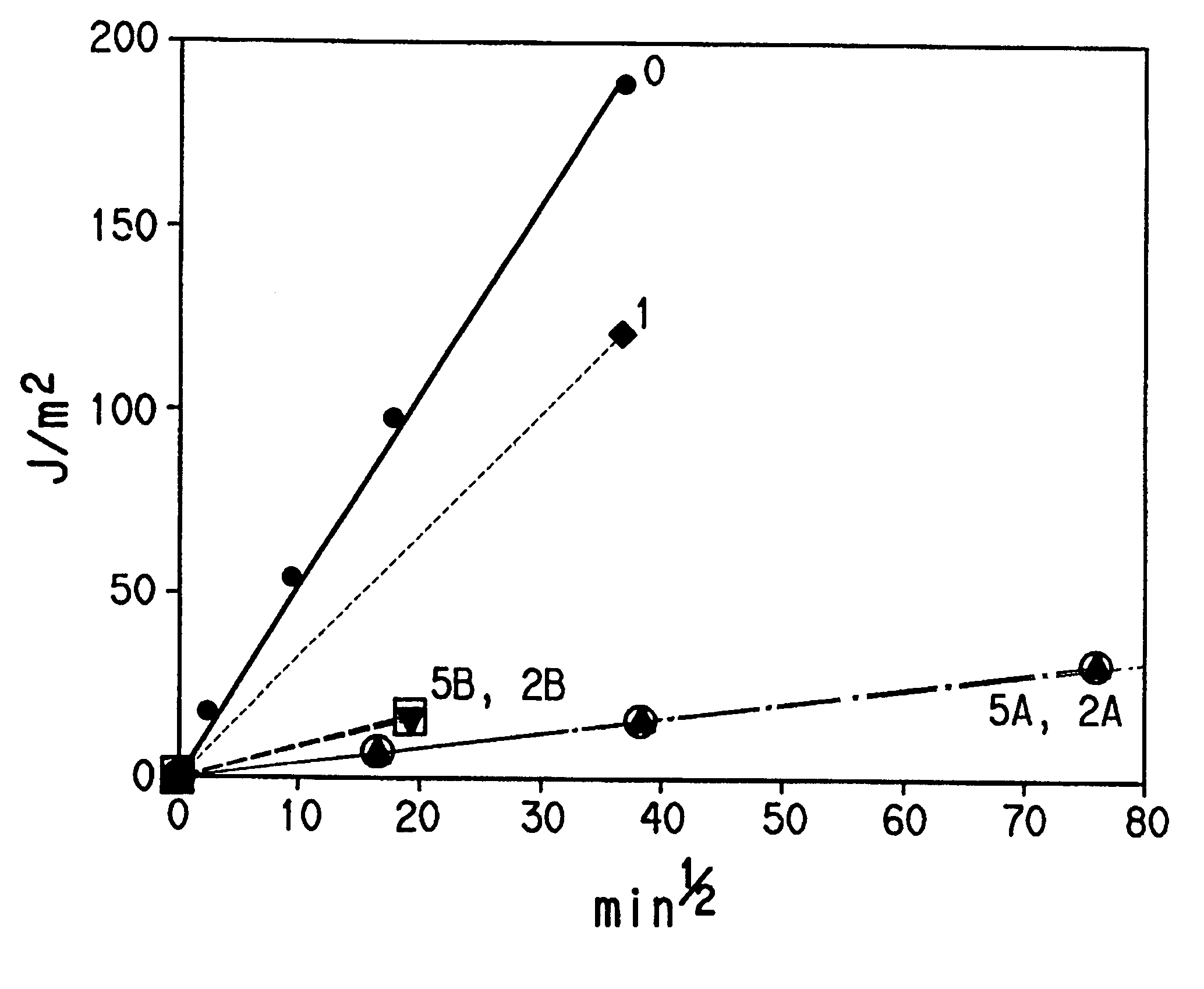

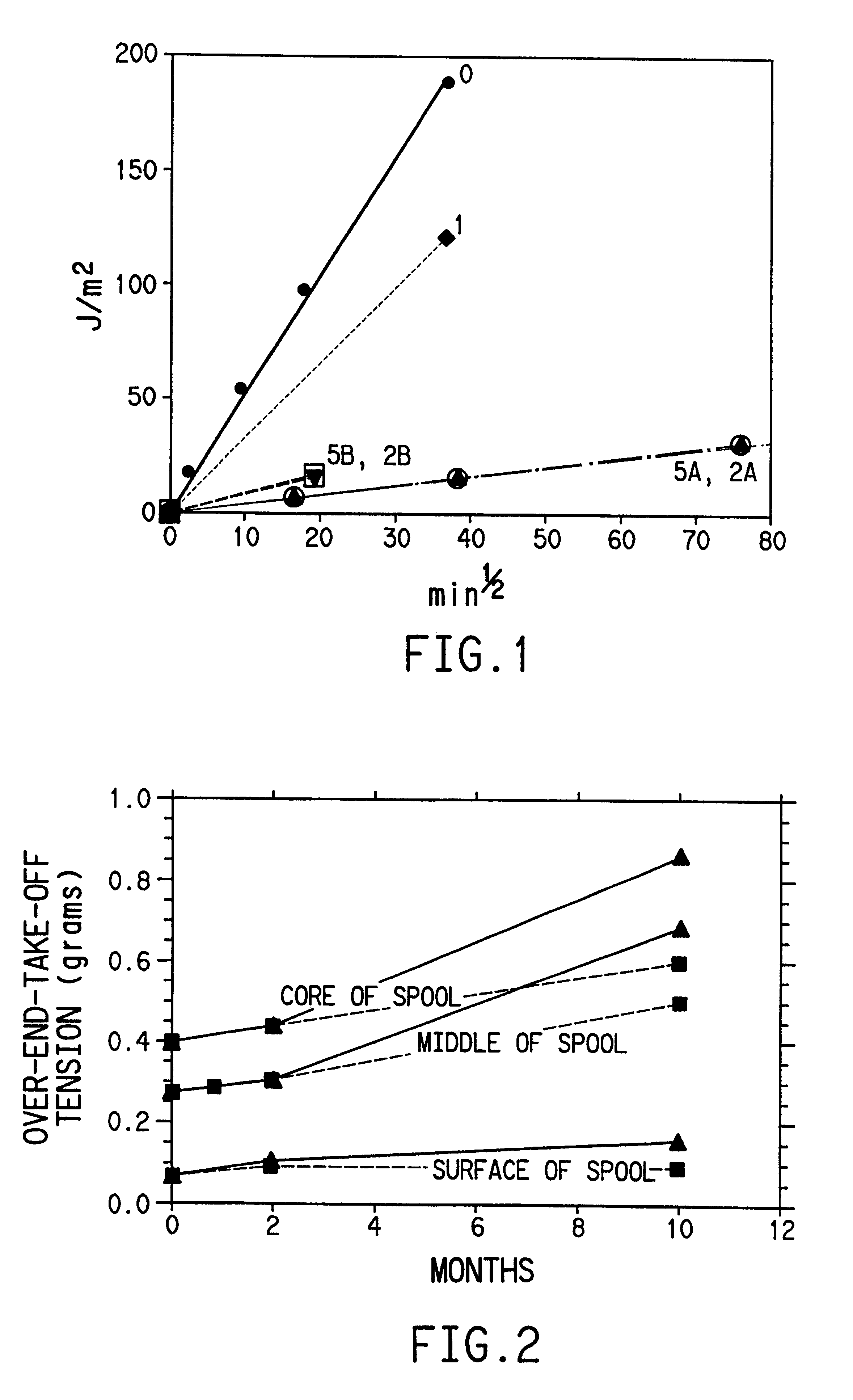

Polyurethane fibers and films

InactiveUS6203901B1Monocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolyurethane

Owner:INVISTA NORTH AMERICA R L

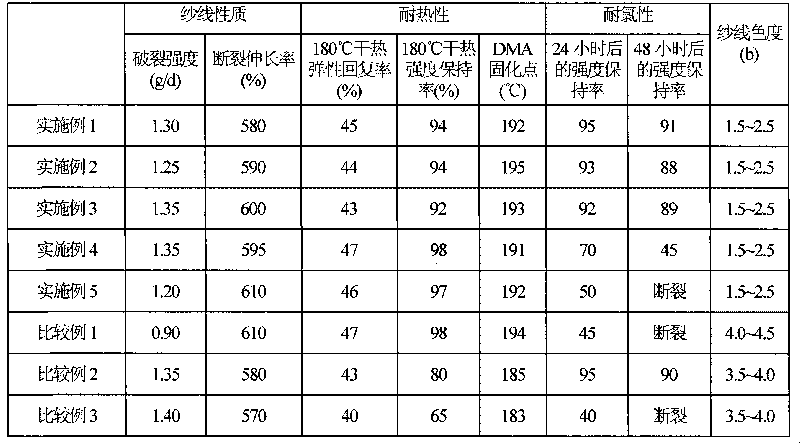

High heat and chlorine resistant polyurethaneurea elastic fiber and preparation of thereof

ActiveCN101724936AImprove heat resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolyester

Owner:TAEKWANG IND CO LTD

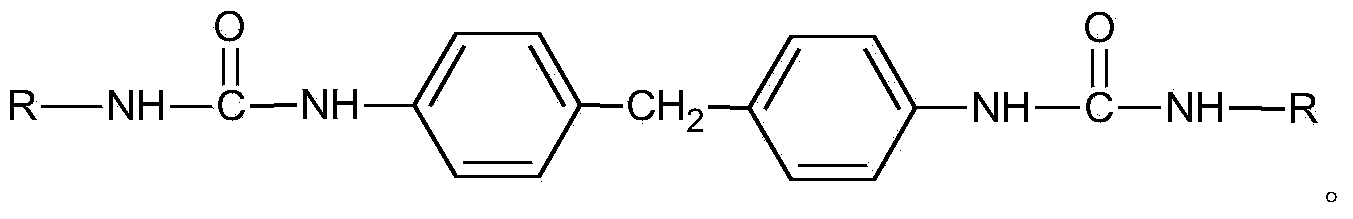

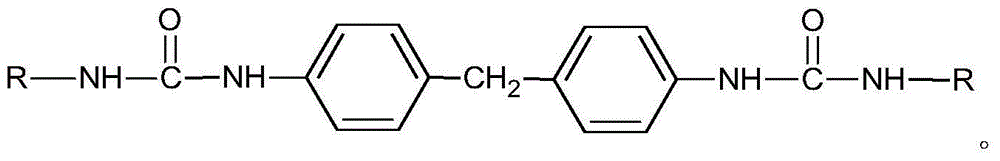

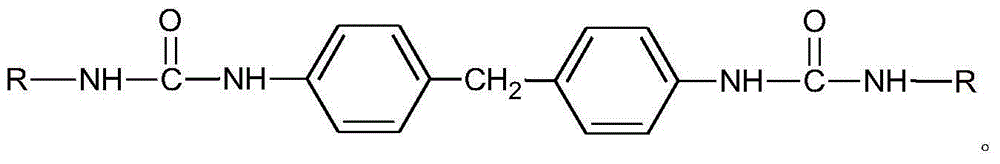

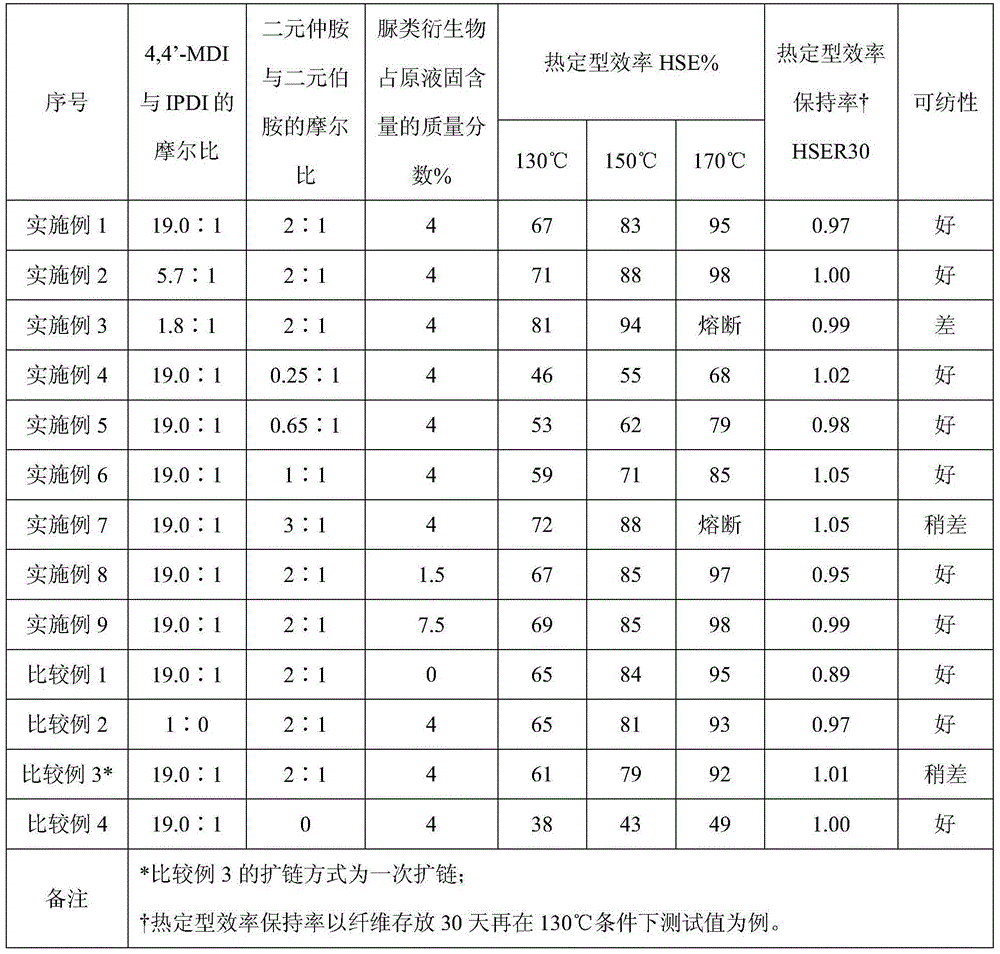

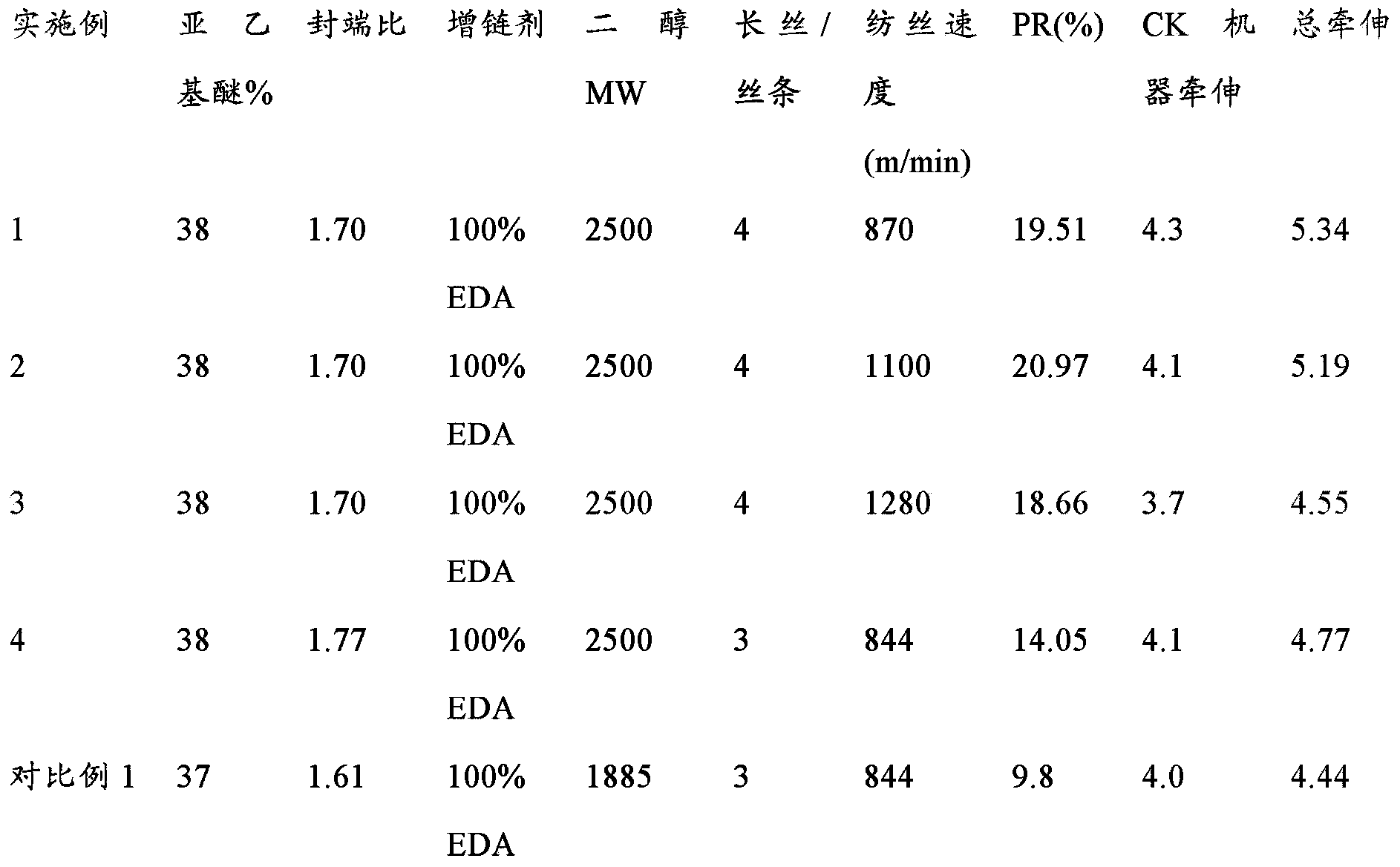

Production method of polyurethane urea elastic fiber with high heat setting efficiency

ActiveCN103469341AImprove heat setting efficiencyReduce consumptionMonocomponent polyureas artificial filamentUrea derivativesDiphenylmethane

The invention relates to a production method of polyurethane urea elastic fiber with high heat setting efficiency. The method comprises the steps of: reacting with polytetramethylene ether glycol, 4,4'diphenylmethane diisocyanate and isophorone diisocyanate in solvent to obtain isocyanate-terminated prepolymer; adding monamine compound and bis(secondary amine) compound mixed amine organic amide solution into the prepolymer for performing first chain extension, and then adding monamine compound and bis(primary amine) compound mixed amine organic amide solution for performing second chain extension to obtain polyurethane urea solution, and finally adding properly organic amide solution with low-volatile diamine and / or triamine compound into the stock solution; finally, adding 4,4'diphenylmethane urea derivatives into the generated stock solution with excessive amine; agitating the polyurethane urea stock solution at low speed and curing, then performing dry-process spinning to obtain polyurethane urea elastic fiber. According to the production method, the requirement on the setting efficiency of the polyurethane urea elastic fiber in the special fields can be met.

Owner:ZHEJIANG HUAFENG SPANDEX

Spandex from high molecular weight poly (tetramethylene-co-ethyleneether) glycols

InactiveUS20070117951A1Monocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolymer chemistry

The invention provides polyurethaneurea compositions comprising poly(tetramethylene-co-ethyleneether) glycol having high number average molecular weight, from about 1900 to about 4000 Dalton. The invention further relates to the use of high number average molecular weight poly(tetramethylene-co-ethyleneether) glycol as the soft segment base material in spandex compositions. The invention also relates to new polyurethane compositions comprising poly(tetramethylene-co-ethyleneether) glycols with such high number average molecular weight, from about 1900 to about 4000 Dalton, and their use in spandex.

Owner:THE LYCRA CO LLC

Carbon dioxide based polyurea and preparation method and application thereof

ActiveCN104592512ANo pollutionImprove performanceMonocomponent polyureas artificial filamentReaction temperatureHigh pressure

The invention discloses carbon dioxide based polyurea and a preparation method and application thereof, belongs to the technical field of macromolecular materials, and solves the technical problem in the prior art that the molecular weight of the carbon dioxide based polyurea prepared by the preparation method of the carbon dioxide based polyurea is low, so that the carbon dioxide based polyurea cannot be further applied. The method comprises the following steps: adding a prepolymer or a sliced prepolymer in a reaction device, then continuously blowing carbon dioxide into the reaction device, and completely reacting amino in the prepolymer so as to generate the carbon dioxide based polyurea, wherein the reaction temperature is 120-400 DEG C, the reaction pressure is 0.1-20 MPa, and the reaction time is 0.5-50h. The carbon dioxide which is continuously blown in the method not only can take away a by-product, water, which is not eliminated in the polymerization of the carbon dioxide under a high pressure but also can be inserted into a reaction system, the average molecular weight of the prepared polyurea is between 5000-50000, and the properties are excellent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method of preparing elastic spandex fibers for paper diapers

InactiveCN103422189AReduce slipImprove adhesionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolymer science

The invention discloses a method of preparing elastic spandex fibers for paper diapers. The method comprises the following steps that (1) polyether diol and diisocyanate are mixed and react to produce prepolymers; (2) the prepolymers are dissolved through dimethylacetamide, then mixed amine is added for chain growth reaction, and segmented copolymer solution is formed; (3) polymer dope is made by mixing, balancing and filtering the segmented copolymer solution; (4) under the continuous action of a certain amount of pressure, the polymer dope is uniformly and quantitatively pressed in a spinning head through a metering pump, and then is squeezed out of pores in a spinneret plate to form a filament trickle, and the filament trickle enters a passageway filled with hot air; (5) the dimethylacetamide in the filament trickle is removed in a volatilization mode, therefore, the concentration of the filament trickle is increased continuously until the filament trickle is solidified, and meanwhile a winding roller operates to enable the filament trickle to be pulled to be thinned and form spandex filaments; (6) the spandex filaments are wound to form elastic spandex fiber products.

Owner:厦门力隆氨纶有限公司

Thermoplastic polyurethane resin for melt spinning

InactiveCN1331764AMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolyolHeat resistance

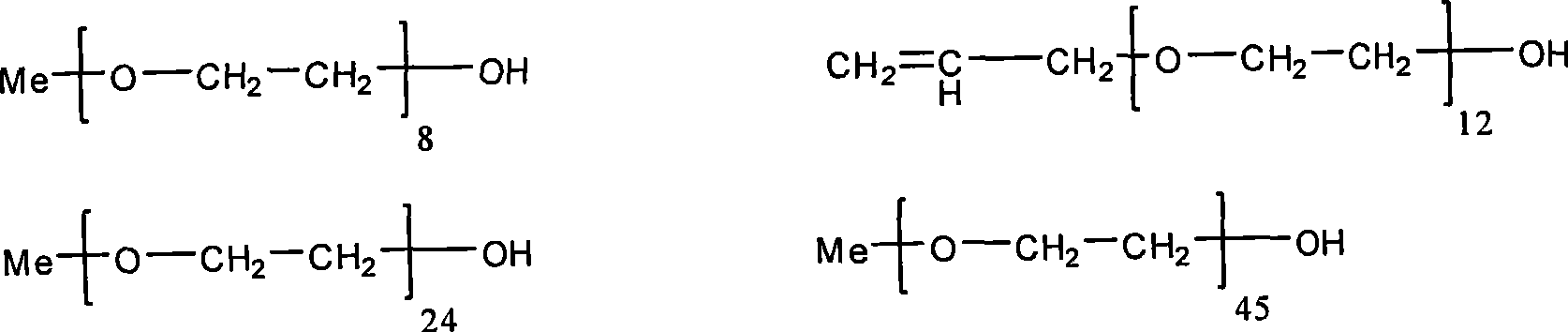

There is disclosed a polyurethaneurea resin consisting of a polymer represented by the following chemical formula (I): [A-O-(O)C-NH-D-NH-C(O)-NH-D-NH-C(O)-O]n wherein A represents an organopolyol residue having a number average molecular weight of approximately 500 to 5,000 and a weight average molecular weight / number average molecular weight (MW / MN) of 1.5 to 2.5 with the number of functional groups ranging from 1.8 to 2.2, D represents an aromatic organodiisocyanate residue ranging, in the number of functional groups, from 1.8 to 2.2, and n represents the number of repeat units. This resin is superior in thermal resistance and elastic recovery, so that it is suitable to melt spinning to make useful elastic fibers.

Owner:SK CHEM CO LTD

New types of compatibilising agents for improving the storage stability of polyol mixtures

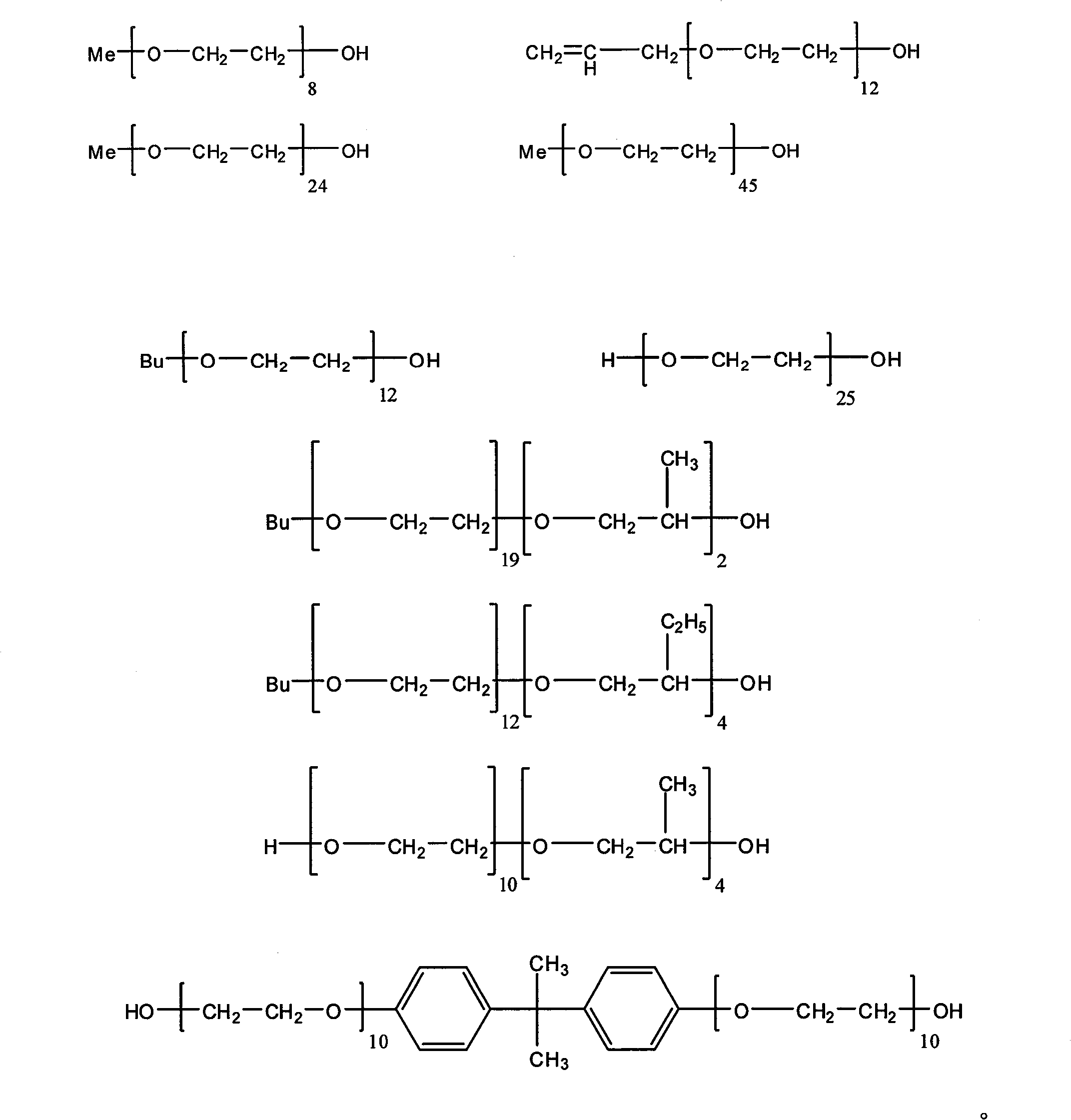

InactiveCN101503566AMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolyolCarbamate

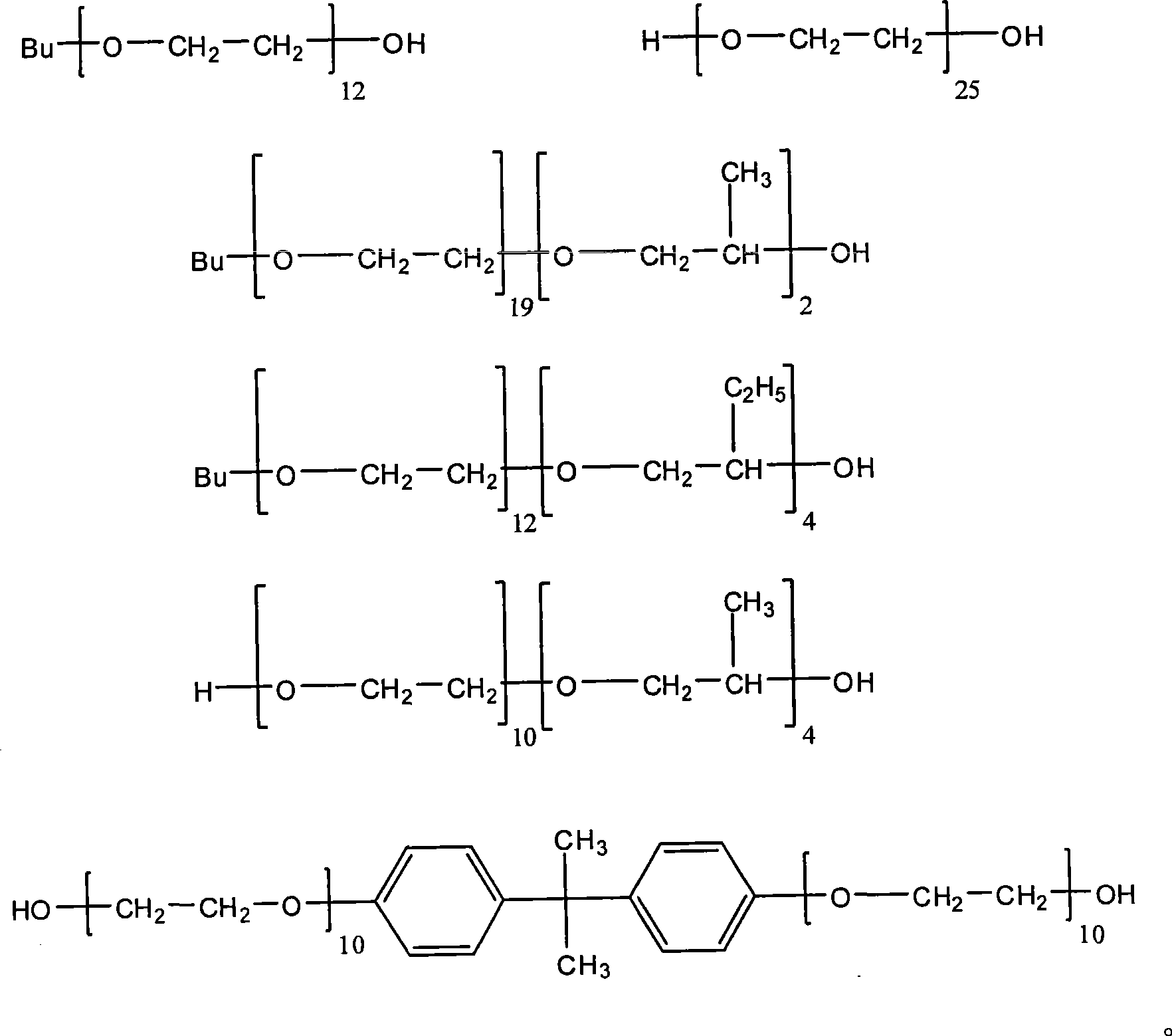

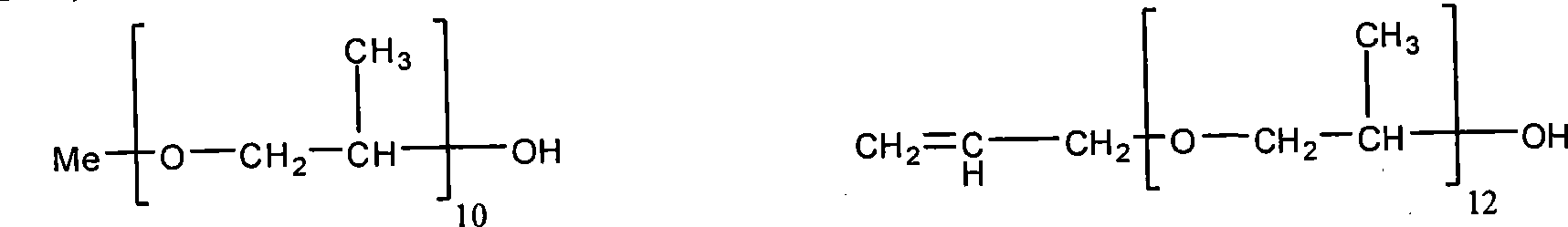

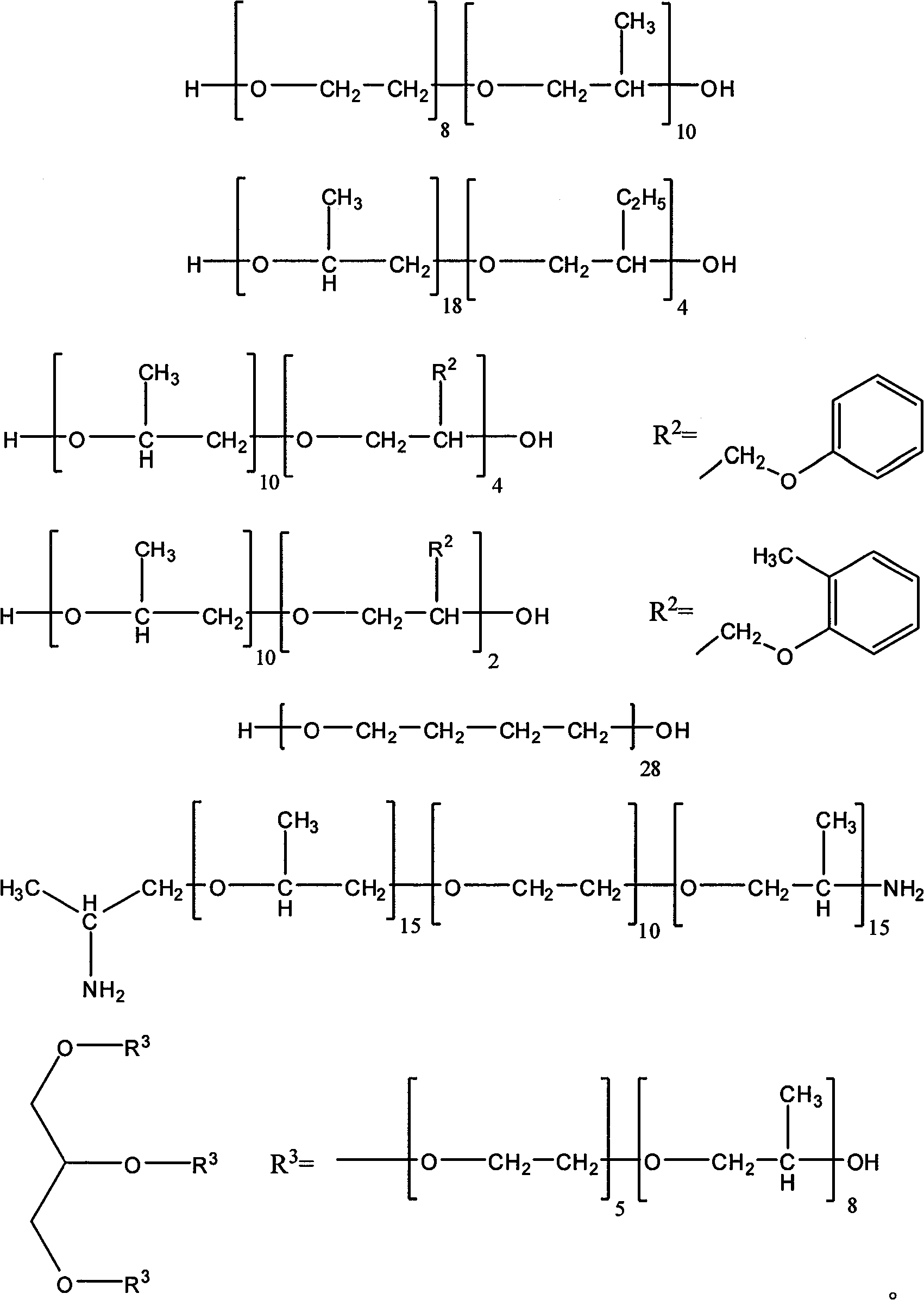

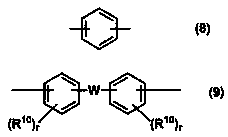

The invention relates to polyethers containing urethane or urea groups as compatibilising agents, their preparation and use, obtained by the reaction of A. at least one di- and / or polyisocyanate with B. (a) at least one hydrophilic polyether which randomly carries at least one OH and / or NH2 and / or NH function and (b) at least one hydrophobic polyether which randomly comprises at least one OH and / or NH2 and / or NH function and (c) optionally further compounds which carry at least one OH and / or NH2 and / or NH function and / or other isocyanate-reactive groups such as carboxylic acid or epoxide functions, and with the proviso that at least one isocyanate A is difunctional or multifunctional.

Owner:EVONIK OPERATIONS GMBH

A polyurethaneurea elastic fiber, and a process of preparing the same

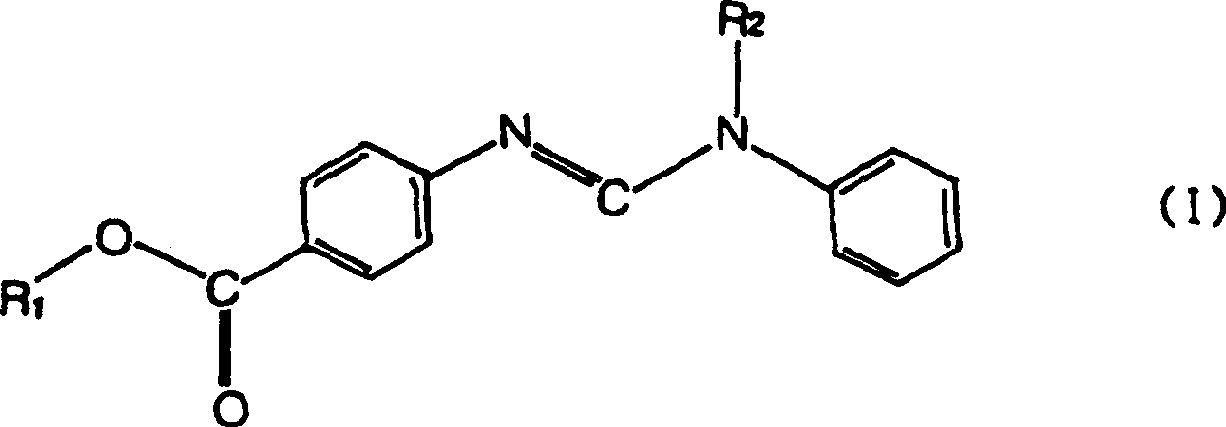

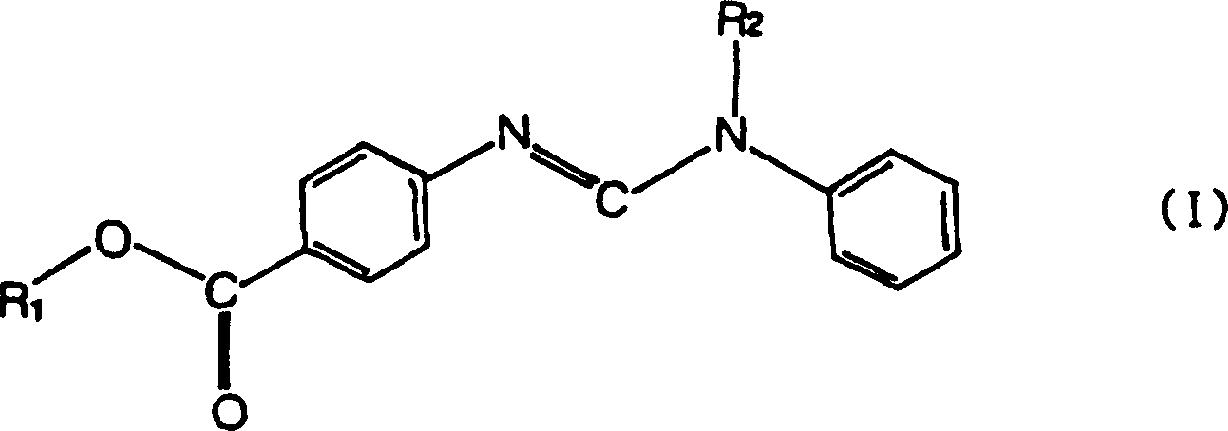

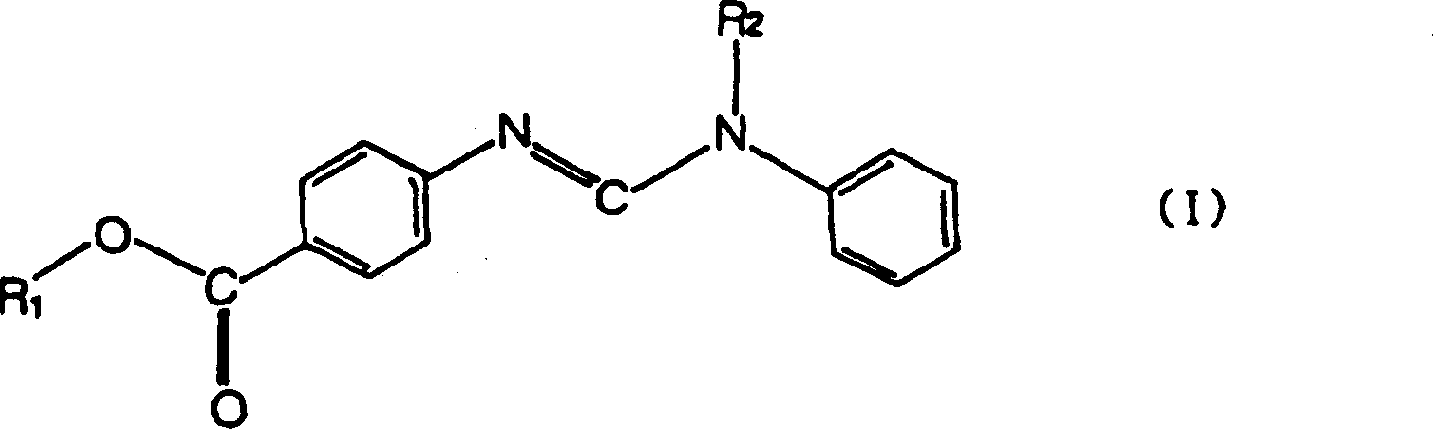

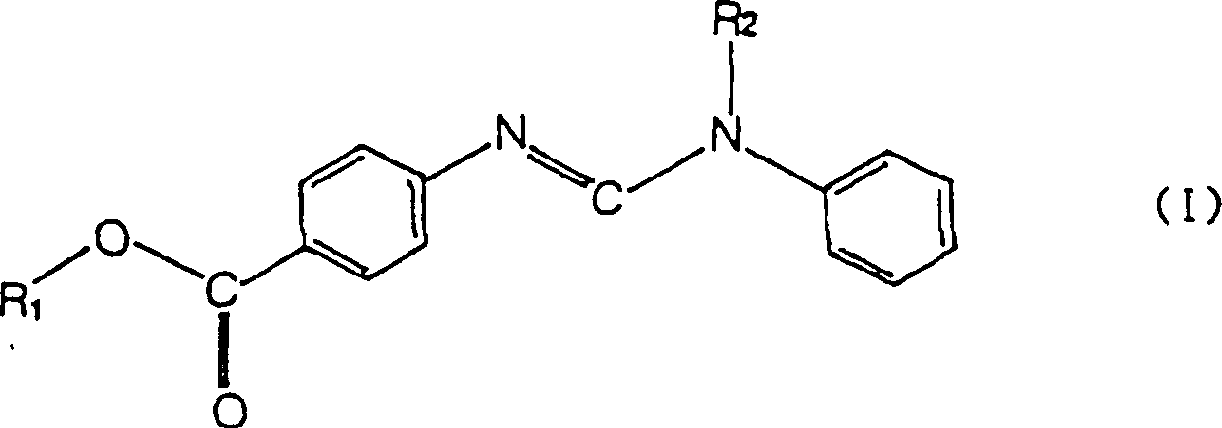

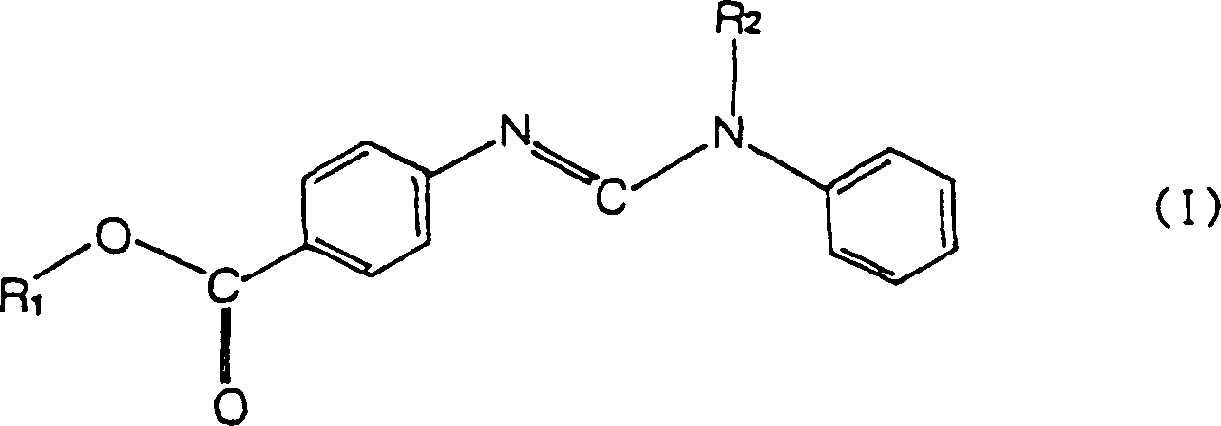

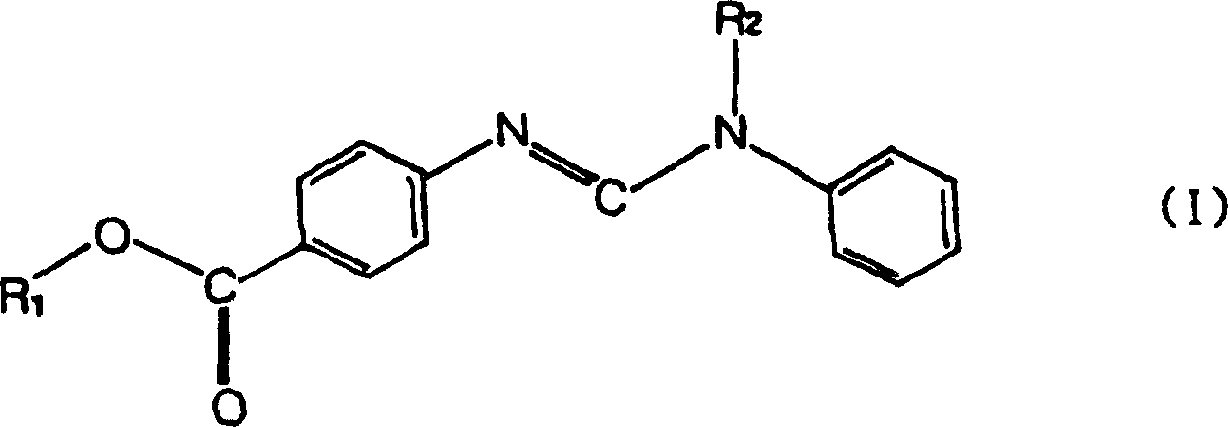

InactiveCN1310772AImprove heat resistanceImproves UV protectionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberUltraviolet

This invention relates to a polyurethaneurea elastic fiber of which the weatherability is excellent and the preparing method thereof. The invention prepares the polyurethaneurea elastic fiber by adding the formamidine type ultraviolet absorber of formula I to the spinning dope and the strength maintenance rate of the polyurethaneurea elastic fiber is over 90 % after being left for 24 hours at the Fade-O-Meter in which the sunshine carbon arc is installed, wherein, R1 and R2 represent an each alkyl group of 1 to 5 carbon atoms.

Owner:KOLON IND INC

A kind of production method of polyurethane urea elastic fiber with high heat setting efficiency

ActiveCN103469341BImprove heat setting efficiencyReduce consumptionMonocomponent polyureas artificial filamentDiphenylmethaneFiber

Owner:ZHEJIANG HUAFENG SPANDEX

Spandex fibers for enhanced bonding

InactiveUS20160194787A1Low costImprove bindingMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolystyreneNonwoven fabric

An elastic fiber is provided that includes polyurethane and / or polyurethaneurea and an additive such as polystyrene, an acrylic polymer, polyvinylpyrrolidone, copolymers thereof, derivatives thereof, and combinations thereof. The elastic fiber is useful in laminate structures, such as disposable hygiene articles as wells as in knit, woven and nonwoven fabric constructions.

Owner:INVISTA NORTH AMERICA R L

Polyurethane-urea elastomeric fiber with low-temperature workability

InactiveCN107002299AImprove uniformityEasy to processMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolymer sciencePolyol

The present invention relates to polyurethane-urea elastomeric fiber with low-temperature workability, and more specifically to polyurethane-urea elastomeric fiber prepared by forming a prepolymer by means of a primary polymerization of polyol and diisocyanate, and then a secondary polymerization of the prepolymer, a first chain extender, and a second chain extender, wherein the first chain extender is one or more types selected from among aromatic, aliphatic and alicyclic amines, and the second chain extender is one or more types selected from among aromatic, aliphatic and low molecular-weight diols. The polyurethane-urea elastomeric fiber according to the present invention has improved fiber uniformity and workability and enhanced heat-set efficiency, thus allowing heat-setting to be carried out at a low temperature to keep thermal embrittlement from occurring to the fiber under treatment, and therefore the touch of the fabric can be improved and the edge-curling of the processed fabric can be prevented.

Owner:HYOSUNG CORP

High Heat and Chlorine Resistant Polyurethaneurea Elastic Fiber and Preparation of Thereof

ActiveUS20110092628A1Excellent chlorine-resistanceExcellent heat-resistanceMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolyesterFiber

The present invention relates to a preparation method of polyurethaneurea elastic fiber, particularly a preparation method of high heat-resistant elastic fiber which retains unique physical properties of elastic fiber under the high temperature process. The polyurethaneurea elastic fiber of the present invention is characteristically prepared without using 1 functional mono-alcohol generally used to regulate the reaction speed and side-reaction during the prepolymer reaction to produce elastic fiber having excellent heat-resistance particularly for the dyeing processing or re-dyeing of polyester but using ethylenediamine alone as a chain extender for the polymerization. To reduce gel formation in polymer after the secondary polymerization and to regulate change of viscosity in the course of process, the ratio of the chain extender amine to the terminal group of prepolymer of the first polymerization is increased.

Owner:TAE GWANG IND CO LTD

Spandex from high molecular weight poly (tetramethylene-co-ethyleneether) glycols

InactiveCN104387545AMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolymer chemistry

Owner:INVISTA TECHNOLOG IES S A R L

Preparation method of spandex with durable resistance to aging

ActiveCN110241473AImprove heat resistanceImprove water resistanceMonocomponent polyureas artificial filamentTextile/flexible product manufactureCross-linkFiber

The invention relates to a preparation method of spandex with durable resistance to aging. The preparation method of the spandex comprises the following steps that 1, polyether diol and hydroxyl-terminated polyolefin are blended in a certain proportion and then react with a mixture isocyanate for a pre-polymerization reaction; 2, a prepolymer is cooled to about 6-12 DEG C, a chain extender, a cross-linking agent and a chain terminator solution are slowly added for a reaction, and a polyurethane-urea solution is formed; 3, a functional auxiliary material additive is added, and even stirring and curing are conducted; 4, by means of a dry-method spinning technology, through a spinning channel, twisting, oil agent application and formation are conducted, and the spandex with excellent aging-resistance performance is formed through spinning. The prepared spandex has excellent light stability, heat resistance, yellowing resistance and weather resistance, the damage caused in the storage and application processes of spandex fibers can be reduced, and the service life of the fabric with the spandex is prolonged.

Owner:ZHEJIANG HUAFENG SPANDEX

Carbon dioxide-based polyurea and its preparation method and application

ActiveCN104592512BNo pollutionImprove performanceMonocomponent polyureas artificial filamentReaction temperatureHigh pressure

The invention discloses carbon dioxide based polyurea and a preparation method and application thereof, belongs to the technical field of macromolecular materials, and solves the technical problem in the prior art that the molecular weight of the carbon dioxide based polyurea prepared by the preparation method of the carbon dioxide based polyurea is low, so that the carbon dioxide based polyurea cannot be further applied. The method comprises the following steps: adding a prepolymer or a sliced prepolymer in a reaction device, then continuously blowing carbon dioxide into the reaction device, and completely reacting amino in the prepolymer so as to generate the carbon dioxide based polyurea, wherein the reaction temperature is 120-400 DEG C, the reaction pressure is 0.1-20 MPa, and the reaction time is 0.5-50h. The carbon dioxide which is continuously blown in the method not only can take away a by-product, water, which is not eliminated in the polymerization of the carbon dioxide under a high pressure but also can be inserted into a reaction system, the average molecular weight of the prepared polyurea is between 5000-50000, and the properties are excellent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Dye composition and dyeing method for elastic fabric

ActiveUS11198970B2Way of increaseAlleviates barrieMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberElastic fibre

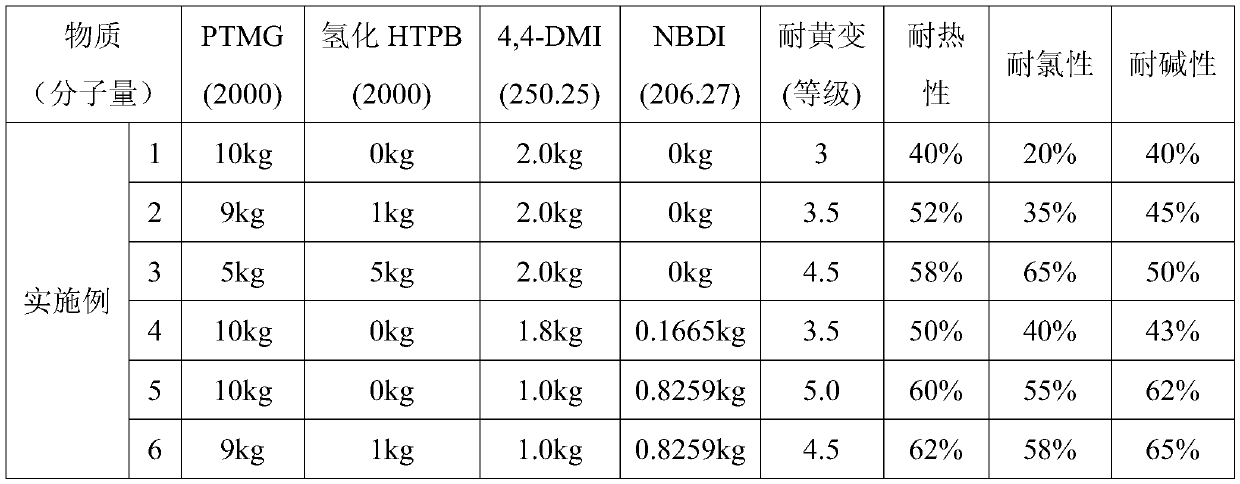

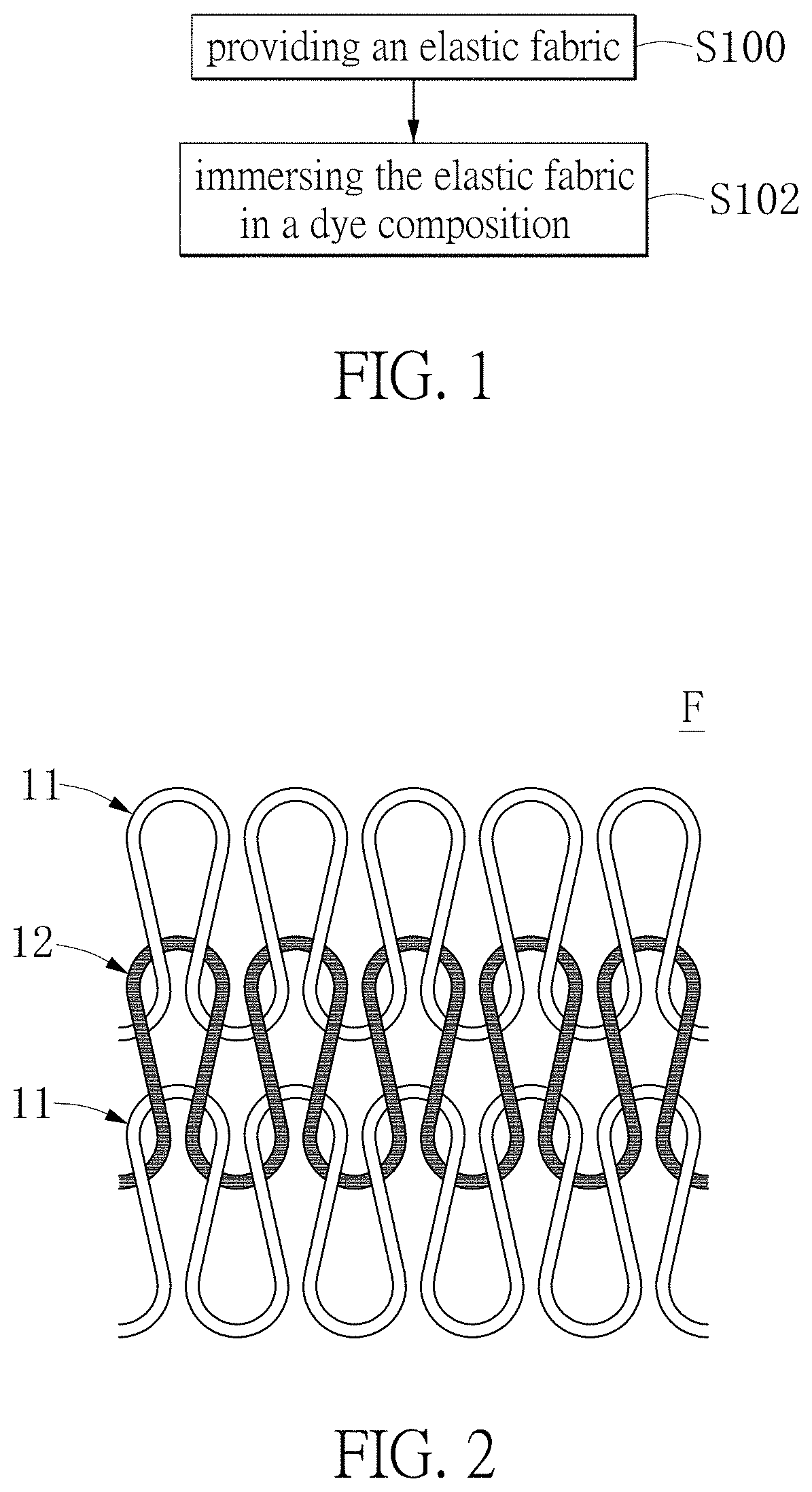

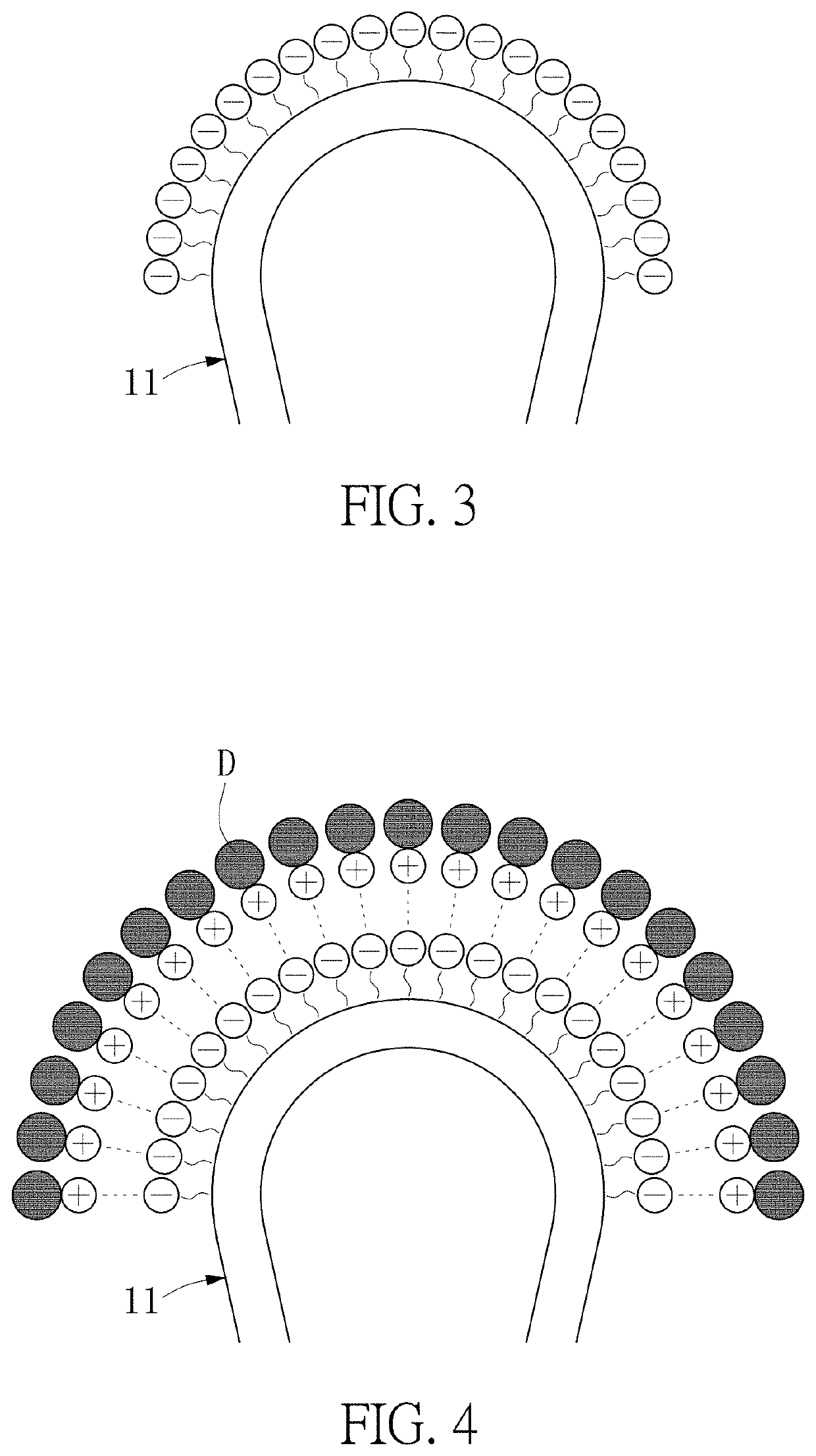

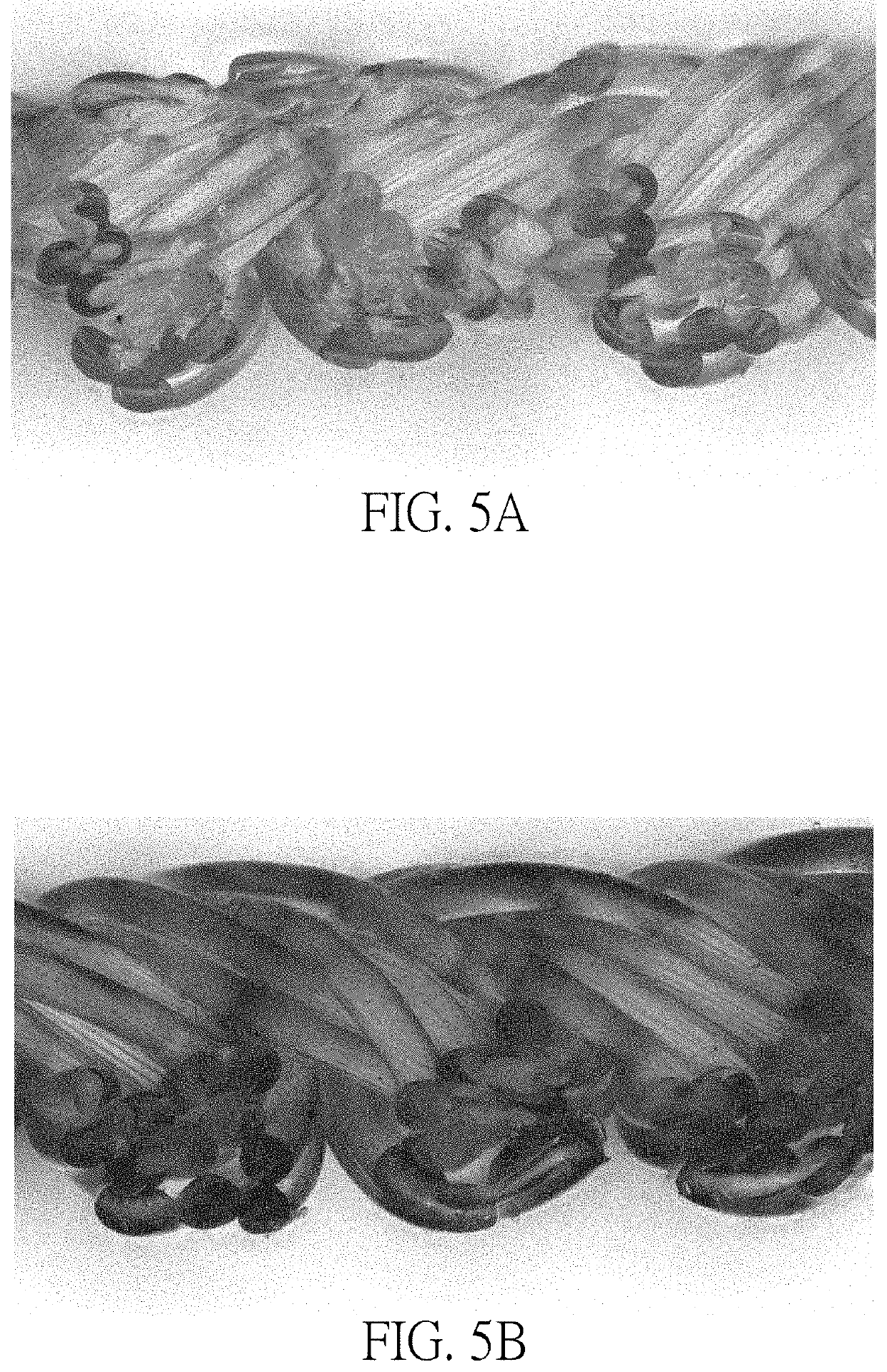

A dye composition and a dyeing method for an elastic fabric are provided. The dyeing method includes: (a) providing an elastic fabric which includes an elastic fiber; and (b) immersing the elastic fabric in a dye composition. The dye composition includes an ion modifier and a dye. The elastic fiber of the elastic fabric has a first ion by contacting the ion modifier, and the first ion has a first charge; the dye has a second ion, and the second ion has a second charge opposite to the first charge. The first ion of the elastic fiber and the second ion of the dye together form an ionic bonding.

Owner:TEX TILE ENTERPRISE CO LTD

Resin, resin composition, nonwoven fabric using same, fiber product, separator, secondary battery and electric double layer capacitor, and method for producing nonwoven fabric

InactiveUS20200131366A1Gas-filled discharge tubesMonocomponent polyureas artificial filamentElectrospinningWoven fabric

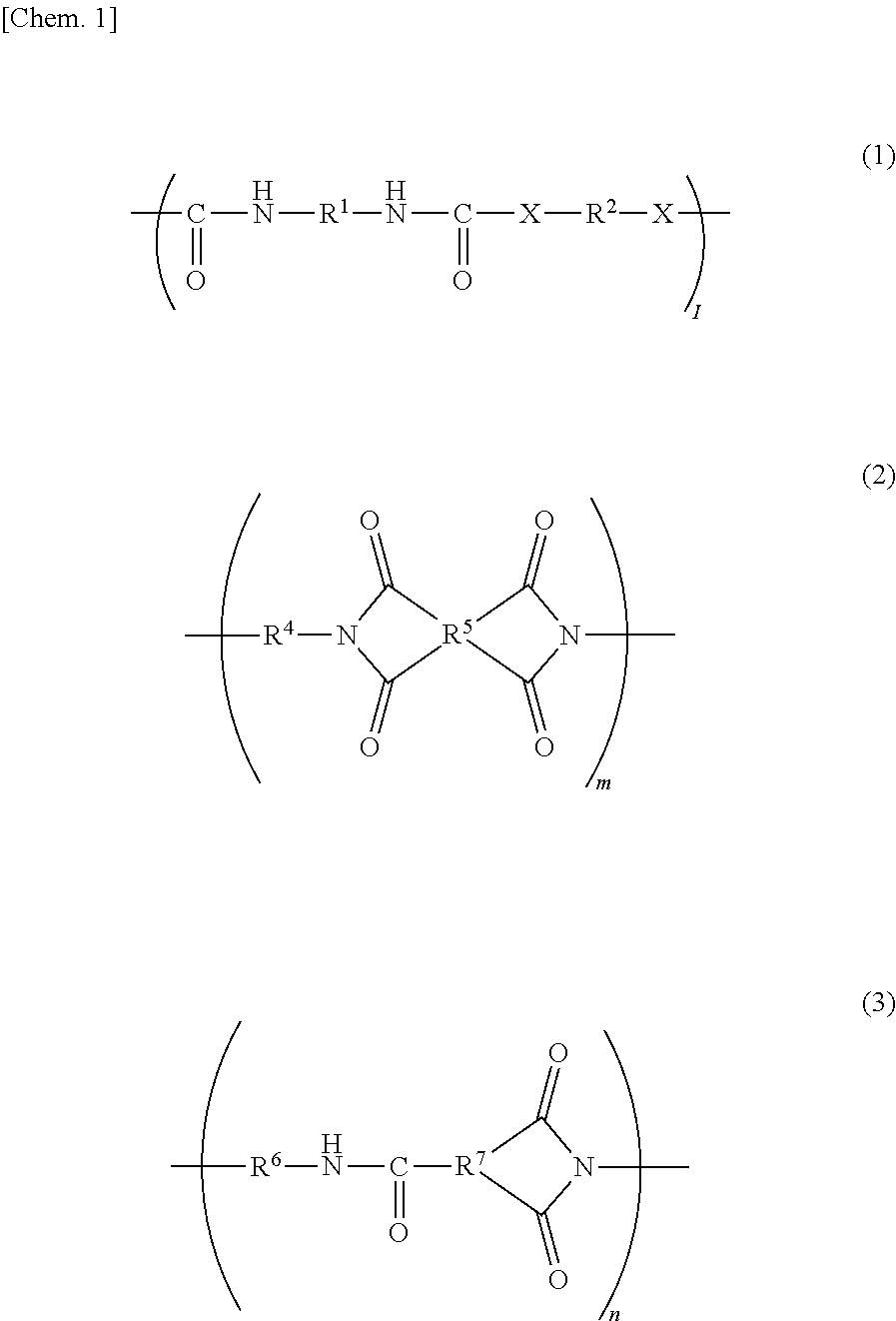

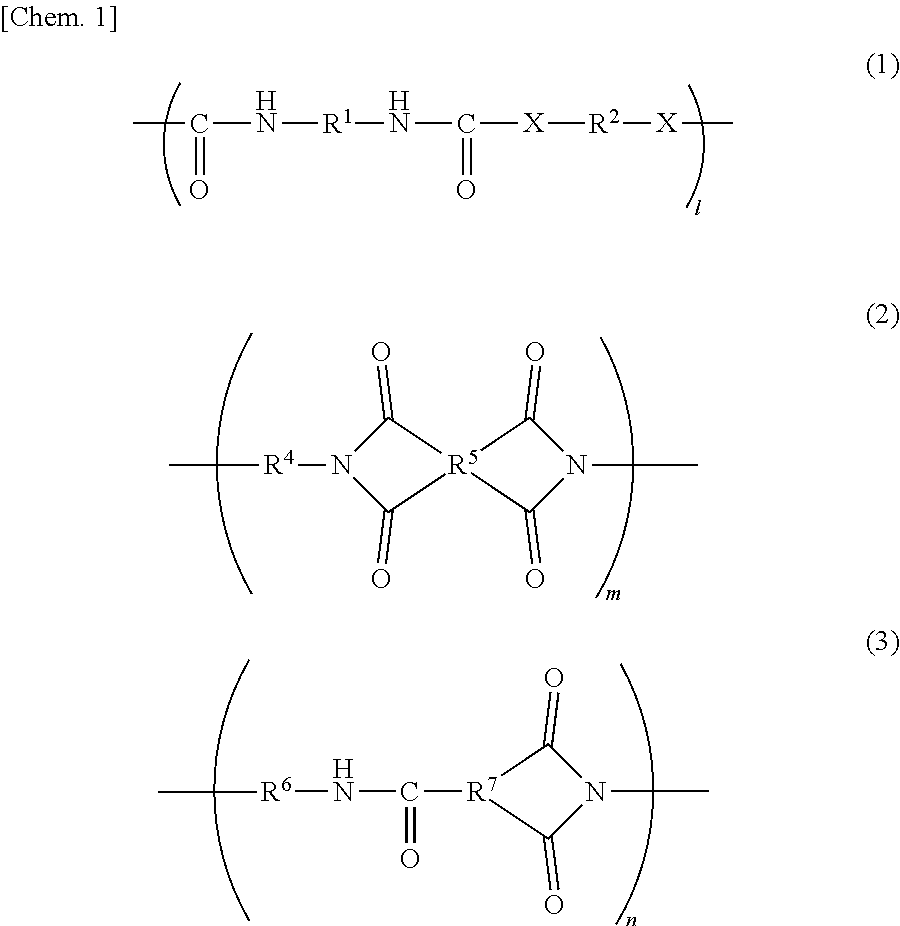

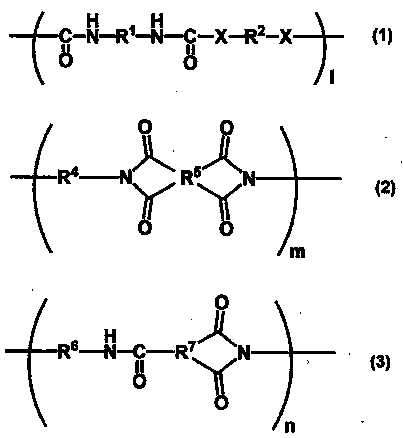

A problem addressed by the present invention is to provide a resin out of which a heat-resistant non-woven fabric having a fine fiber diameter can be made by an electrospinning method. A main object of the present invention is to provide a resin, including a structure(s) represented by at least one selected from the group consisting of the following general formulae (1) to (3), wherein an end of the main-chain of the resin has at least one selected from alkyl groups having 10 or more carbon atoms and fluoroalkyl groups having 4 or more carbon atoms;(wherein, in the general formula (1), X independently represents a single bond or —NR3—; R1 and R2 independently represent a C4-C30 bivalent organic group; R3 represents a hydrogen atom or a C1-C10 monovalent organic group; in the general formula (2), R4 represents a C4-C30 bivalent organic group; R5 represents a C4-C30 tetravalent organic group; in the general formula (3), R6 represents a C4-C30 bivalent organic group; R7 represents a C4-C30 trivalent organic group; l, m, and n are each an integer of 0 or greater with the proviso that l+m+n=10 or greater; and wherein the structures represented by the general formulae (1) to (3) do not necessarily need to be consecutively present.)

Owner:TORAY IND INC

Preparation method of colored polyurethane urea elastic fiber

ActiveCN109825893BImprove spin performanceHigh fastnessMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberElastic fiber

The present invention provides a novel preparation method of colored polyurethaneurea elastic fibers. And, the colored polyurethaneurea elastic fiber produced by the above-mentioned production method of the present invention is provided.

Owner:TAEKWANG IND CO LTD

Spandex from high molecular weight poly (tetramethylene-co-ethyleneether) glycols

InactiveUS9441314B2Monocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolymer chemistry

The invention provides polyurethaneurea compositions comprising poly(tetramethylene-co-ethyleneether) glycol having high number average molecular weight, from about 1900 to about 4000 Dalton. The invention further relates to the use of high number average molecular weight poly(tetramethylene-co-ethyleneether) glycol as the soft segment base material in spandex compositions. The invention also relates to new polyurethane compositions comprising poly(tetramethylene-co-ethyleneether) glycols with such high number average molecular weight, from about 1900 to about 4000 Dalton, and their use in spandex.

Owner:THE LYCRA CO LLC

Polyurethane urea elastic fibre and its preparation method

InactiveCN1536108AImprove heat resistanceImproves UV protectionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberUltraviolet

Owner:KOLON IND INC

Polyurethane urea elastic fibre and its preparation method

InactiveCN1268796CImprove heat resistanceImproves UV protectionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberUltraviolet

This invention relates to a polyurethaneurea elastic fiber of which the weatherability is excellent and the preparing method thereof. The invention prepares the polyurethaneurea elastic fiber by adding the formamidine type ultraviolet absorber of formula I to the spinning dope and the strength maintenance rate of the polyurethaneurea elastic fiber is over 90 % after being left for 24 hours at the Fade-O-Meter in which the sunshine carbon arc is installed, wherein, R1 and R2 represent an each alkyl group of 1 to 5 carbon atoms.

Owner:KOLON IND INC

A kind of method of making spandex elastic fiber for diapers

InactiveCN103422189BReduce slipImprove adhesionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberDiol

The invention discloses a method of preparing elastic spandex fibers for paper diapers. The method comprises the following steps that (1) polyether diol and diisocyanate are mixed and react to produce prepolymers; (2) the prepolymers are dissolved through dimethylacetamide, then mixed amine is added for chain growth reaction, and segmented copolymer solution is formed; (3) polymer dope is made by mixing, balancing and filtering the segmented copolymer solution; (4) under the continuous action of a certain amount of pressure, the polymer dope is uniformly and quantitatively pressed in a spinning head through a metering pump, and then is squeezed out of pores in a spinneret plate to form a filament trickle, and the filament trickle enters a passageway filled with hot air; (5) the dimethylacetamide in the filament trickle is removed in a volatilization mode, therefore, the concentration of the filament trickle is increased continuously until the filament trickle is solidified, and meanwhile a winding roller operates to enable the filament trickle to be pulled to be thinned and form spandex filaments; (6) the spandex filaments are wound to form elastic spandex fiber products.

Owner:厦门力隆氨纶有限公司

New types of compatibilising agents for improving the storage stability of polyol mixtures

InactiveCN101503566BMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolymer scienceCarbamate

Use of urethane or urea group containing polyether compound as a compatibility agent for a polyol composition containing at least two immiscible polyols, is claimed, where the polyether is obtained by reacting at least a di- and / or polyisocyanate (a) with at least a hydrophilic polyether and at least a hydrophobic polyether (b) (both statistically containing at least one hydroxyl, amide and / or imine function), and optionally further compound (c) containing at least one hydroxyl, amide and / or imine function and / or another isocyanate reactive group and carboxylic acid or epoxide function. Use of urethane or urea group containing polyether compound as a compatibility agent for a polyol composition containing at least two immiscible polyols, is claimed, where: the polyether is obtained by reacting at least a di- and / or polyisocyanate (a) with at least a hydrophilic polyether statistically containing at least one hydroxyl, amide and / or imine function, at least a hydrophobic polyether (b) statistically containing at least one hydroxyl, amide and / or imine function, and optionally further compound (c) containing at least one hydroxyl, amide and / or imine function and / or another isocyanate reactive group and carboxylic acid or epoxide function; and (a) is difunctional or polyfunctional. Independent claims are included for: (1) a polyol mixture comprising the compatibility agent and further auxiliary material and additives; (2) a reactive mixture comprising a homogeneous polyol mixture and optionally further auxiliary material and additives, and one or more isocyanates; and (3) the urethane or urea group containing polyether compound.

Owner:EVONIK OPERATIONS GMBH

A polyurethaneurea elastic fiber, and a process of preparing the same

InactiveCN1170966CImprove heat resistanceImproves UV protectionMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberUltraviolet

Owner:KOLON IND INC

Reactive dye dyeable polyurethane urea elastic yarn and manufacturing method thereof

ActiveCN114286876AAchieve dyeabilityGreat tasteMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentYarnFiber

Disclosed is a reactive dye dyeable polyurethane urea elastic yarn comprising a reaction product of two or more polyols, one of which is polyethylene glycol and is contained in an amount of 20 to 30.0 mol% with respect to the total polyol, a diisocyanate compound, a diamine chain extender, an amine chain terminator, and a diethylenetriamine compound, the polyurethane-urea polymer comprises 10 meq / kg to 45 meq / kg of a primary amine end base, the blocking ratio (CR) of the two polyols to the diisocyanate is 1.8 to 2.0, the polyurethane-urea elastic yarn of the present invention can be dyed by a reactive dye and can improve the ground color external penetration phenomenon when a blended product of cellulose-based fibers and polyurethane is dyed, and the polyurethane-urea elastic yarn can be dyed by a reactive dye. According to the present invention, the use range of a polyurethane-urea elastic yarn can be expanded by improving the transfer fastness without impairing the inherent physical properties of the polyurethane-urea elastic yarn, such as tensile properties and heat resistance.

Owner:HYOSUNG CORP

Spandex fibers for enhanced bonding

PendingUS20200308728A1No change in spandex fiber performanceLow melting pointMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolymer sciencePolystyrene

An elastic fiber is provided that includes polyurethane and / or polyurethaneurea and an additive such as polystyrene, an acrylic polymer, polyvinylpyrrolidone, copolymers thereof, derivatives thereof, and combinations thereof. The elastic fiber is useful in laminate structures, such as disposable hygiene articles as wells as in knit, woven and nonwoven fabric constructions.

Owner:THE LYCRA CO

High heat and chlorine resistant polyurethaneurea elastic fiber and preparation of thereof

ActiveUS8623950B2Excellent chlorine-resistanceExcellent heat-resistanceMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentPolyesterFiber

Owner:TAEKWANG IND CO LTD

Fluorescent polymer cored yarn and producing method thereof

The present invention is a fluorescent elastic yarn and method for producing the same. The fluorescent elastic yarn can fluoresce sufficiently to allow a thin elastic yarn to be seen by the naked eye when ultraviolet light is irradiated to the fluorescent elastic yarn by adding a novel organic additive to a polymer or a spinfinish. Therefore, the fluorescent elastic yarn of the present invention is advantageous in that production of inferior covered yarns is prevented.

Owner:HYOSUNG CORP

Resin, resin composition, nonwoven fabric using same, fiber product, separator, secondary battery, and method for producing electric double layer capacitor and nonwoven fabric

ActiveCN110799559AMonocomponent polyureas artificial filamentGas-filled discharge tubesCarbon numberPolymer science

The present invention addresses the problem of providing a resin with which a heat resistant nonwoven fabric having a fine fiber diameter can be produced by an electrospinning method. The purpose of the present invention is to provide a resin having a structure represented by at least one selected from the group consisting of general formulae (1)-(3), and containing, at the terminal of the main chain, at least one selected from among an alkyl group having 10 or more carbon atoms and a fluoroalkyl group having 4 or more carbon atoms. In general formula (1), each X independently represents a single bond or -NR3-, R1 and R2 each independently represent a C4-30 divalent organic group, and R3 represents a hydrogen atom or a C1-10 monovalent organic group. In general formula (2), R4 represents aC4-30 divalent organic group, and R5 represents a C4-30 tetravalent organic group. In general formula (3), R6 represents a C4-30 divalent organic group, R7 represents a C4-30 trivalent organic group,l, m, and n are each an integer of 0 or more, and 1+m+n is 10 or more. In addition, the structures represented by general formulae (1)-(3) do not necessarily appear in succession.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com