Production method of polyurethane urea elastic fiber with high heat setting efficiency

A polyurethane urea and elastic fiber technology, which is applied in the manufacturing field of polyurethane urea elastic fiber and polyurethane urea elastic fiber, can solve the problems of large negative impact on fiber elastic function and strength, decreased fiber setting efficiency, poor spinnability, etc., and achieves energy reduction. Consumption, improved setting efficiency, effect of high heat setting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

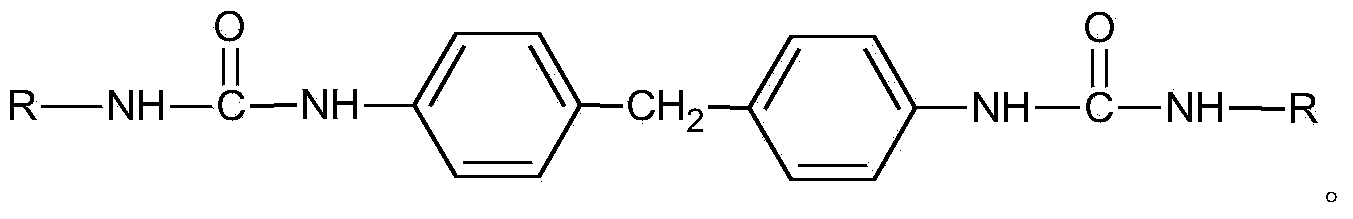

Method used

Image

Examples

Embodiment 1

[0059] Add 5.65 kg of DMAC and 9.5 kg of PTMEG with a number average molecular weight of 1810 into a polymerization reactor protected by a nitrogen atmosphere and stir well. Then add 3.120kg (95% equivalent) of 4,4'-MDI and 0.146kg (5% equivalent) of IPDI to the above system in a certain way and react at 42°C for 150min to obtain isocyanate-terminated polyurethane urea prepolymer . Then add 9.59 kg of DMAC to the prepolymer, continue to stir evenly, and lower the temperature to 17°C. At the same time, 523.42g (67% equivalent) of N,N'-dimethylpropylenediamine and 18.81g of isopropylamine were dissolved in 6.688kg of DMAC at a concentration of 7.5wt% to obtain a mixed amine chain extender solution for the first time , and added to the above-mentioned cooled prepolymer solution in a certain way to obtain polyurethane urea stock solution A.

[0060] Then 137.85g of ethylenediamine (30% equivalent), 26.65g of 2-methyl-1,5-pentanediamine (3% equivalent), and 8.06g of isopropylamin...

Embodiment 2 and 3

[0063] Polyurethane urea elastic fibers were prepared in the same manner as in Example 1, except that the molar ratio of 4,4'-MDI to IPDI was changed.

Embodiment 4~7

[0065] Polyurethane urea elastic fibers were prepared in the same manner as in Example 1, except that the molar ratio of dibasic secondary amines to dibasic primary amines was changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com