Shoe piece vision detection correcting ironing device and ironing method thereof

A technology for visual inspection and shoe pieces, applied in shoe uppers, footwear, insoles, etc., can solve the problems of difficulty in shrinking and shaping shape control, low efficiency, and high labor costs, reducing labor and time costs, reducing waste, and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

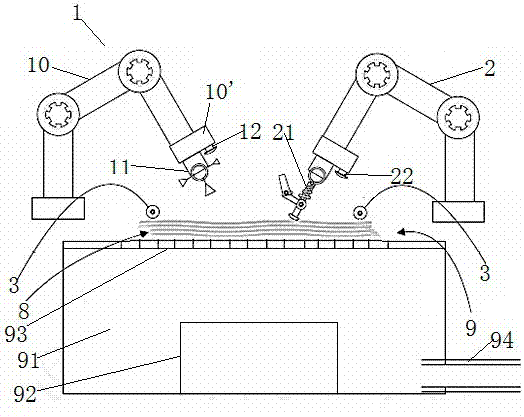

[0018] like figure 1 As shown, in one embodiment, the shoe piece visual inspection proofreading ironing device of the present invention mainly includes an ironing bed 9 for carrying the shoe piece 8, a controller (not shown) fixed on the ironing bed 9, a transmission device, A first manipulator 1 and a second manipulator 2 that can move freely above the ironing bed.

[0019] Wherein, the conveying device is used to convey the shoe pieces to be ironed to a predetermined area on the ironing bed 9, and may include a conveyor belt and a matching roller combination. figure 1 In the figure, only the pressure roller 3 for conveying and fixing the shoe piece arranged on the ironing bed is shown, and the conveyor belt and other roller devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com