A fabric setting machine and its process

A technology of setting machine and fabric, which is applied in the direction of thin material processing, fabric surface trimming, textile and papermaking, etc., can solve the problems of time-consuming and affect the heat-setting efficiency of fabrics, and achieve the effect of convenient feeding and improving heat-setting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

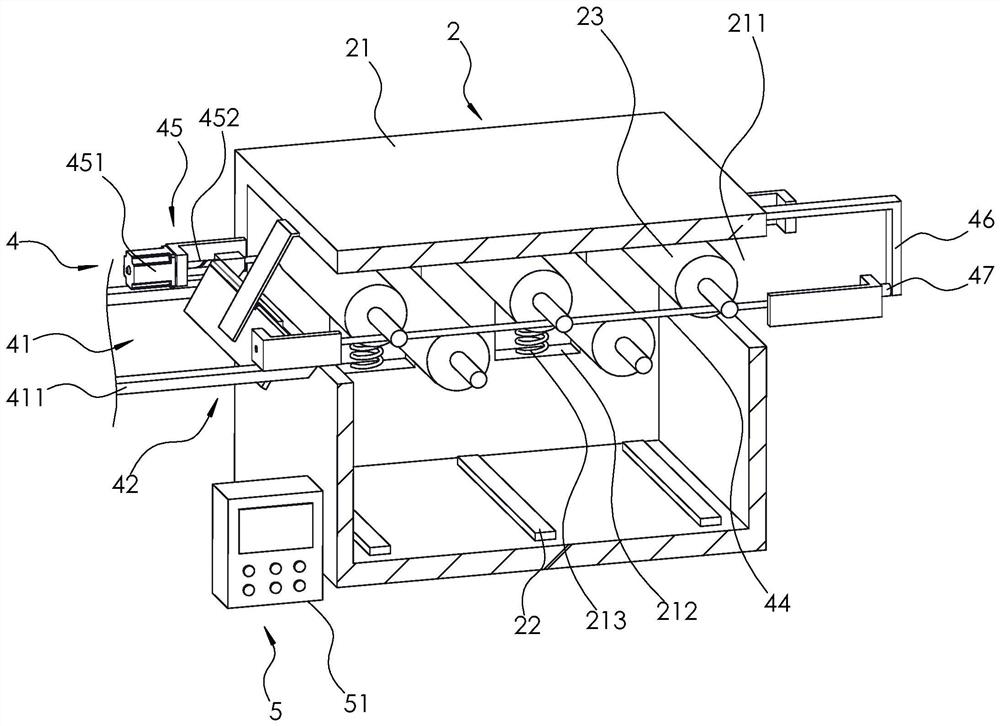

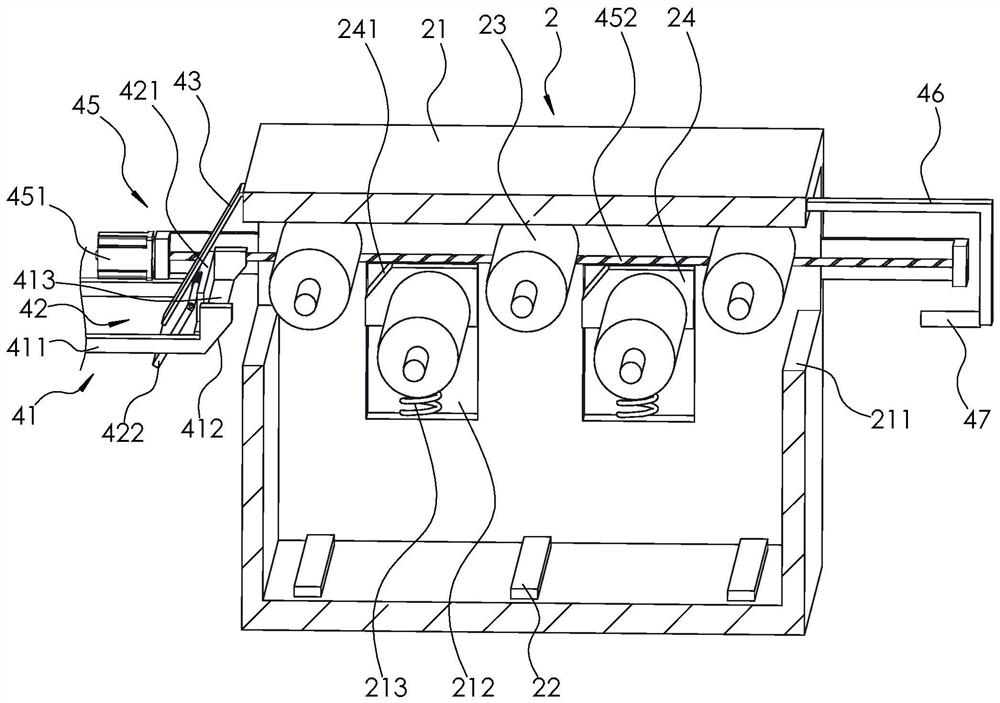

[0047] Attached to the following Figure 1-5 This application will be described in further detail.

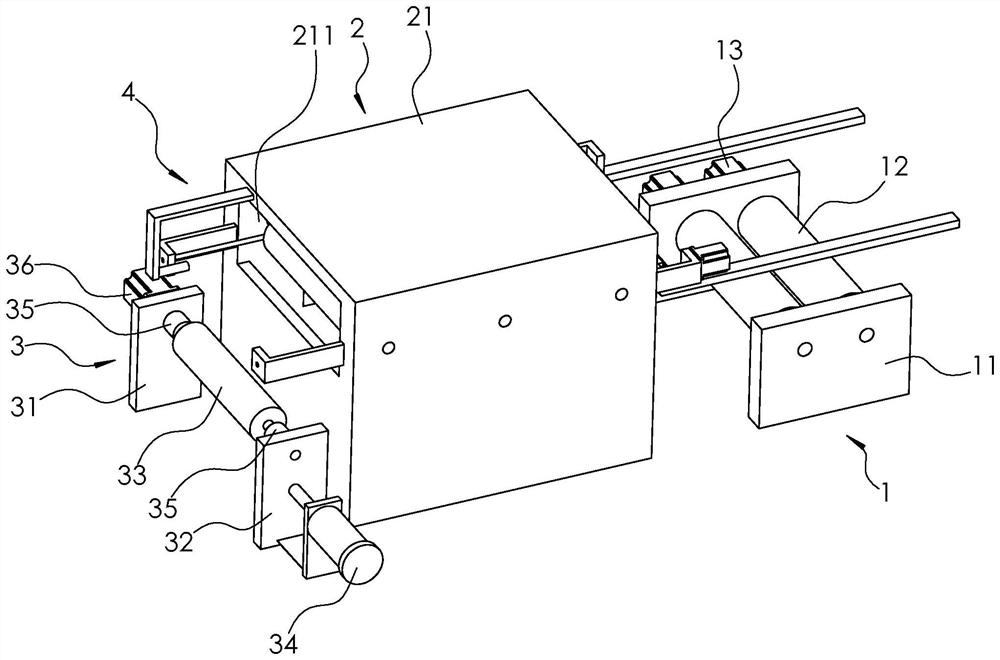

[0048] The embodiment of the present application discloses a fabric setting machine. like figure 1 As shown in the figure, a fabric setting machine includes an unwinding mechanism 1, a heat drying mechanism 2 and a winding mechanism 3 arranged in sequence, and the winding mechanism 3 is used for winding the fabric on the unwinding mechanism 1. The fabric is passed through the heat drying mechanism 2, and the heat drying mechanism 2 is used to heat-set the fabric.

[0049] like figure 1 As shown, the unwinding mechanism 1 includes a mounting frame 11 on which two horizontally arranged unwinding rollers 12 are rotatably connected; The output shafts are all fixedly connected to the corresponding unwinding rollers 12 . The fabric is placed in rolls on the two unwinding rollers 12. When the third motor 13 drives the unwinding roller 12 to rotate, the unwinding roller 12 will dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com