A kind of spandex with fatigue resistance and meltability and preparation method thereof

A fatigue-resistant and spandex technology, applied in the field of spandex fiber, can solve the problems of insufficient comprehensive performance and cumbersome polymerization process, and achieve the effect of improving aesthetics and comfort, excellent fatigue resistance, and excellent elastic function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of spandex with fatigue resistance and meltable properties of the present invention comprises the following steps:

[0022] 1) Perform chain growth reaction of IPDI and PCL in DMAC. When the viscosity reaches 100-600Pa·s at 25°C, terminate the reaction with neopentyl alcohol, and then add triethylene glycol ether-bis(3-tert-butyl-4 -Hydroxy-5-methylphenyl) propionate to obtain a component A stock solution with a solid content of 25% to 40%;

[0023] 2) Pre-polymerize 4,4'-MDI and PTMEG in DMAC, and then use ethylenediamine for chain extension reaction. When the viscosity reaches 100-600Pa·s at 25°C, stop the reaction with diethylamine, and finally add Bis(N,N-dimethylhydrazide amino 4-phenyl)methane to obtain a component B stock solution with a solid content of 25% to 40%;

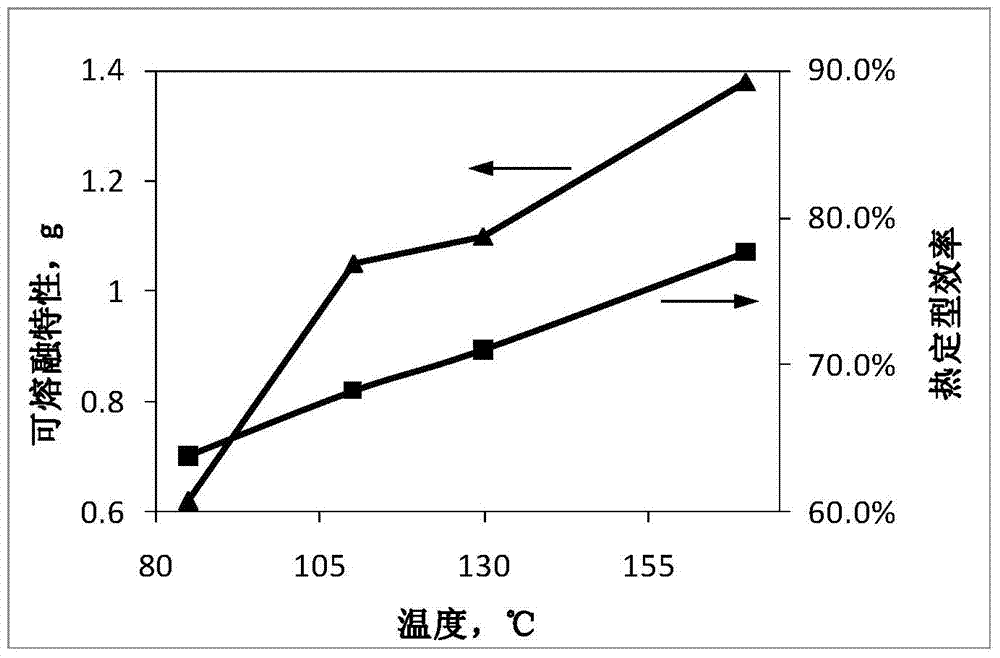

[0024] 3) fully mixing and aging the stock solution of component A containing 15% to 70% of component A and the stock solution of component B containing 30% to 85% of c...

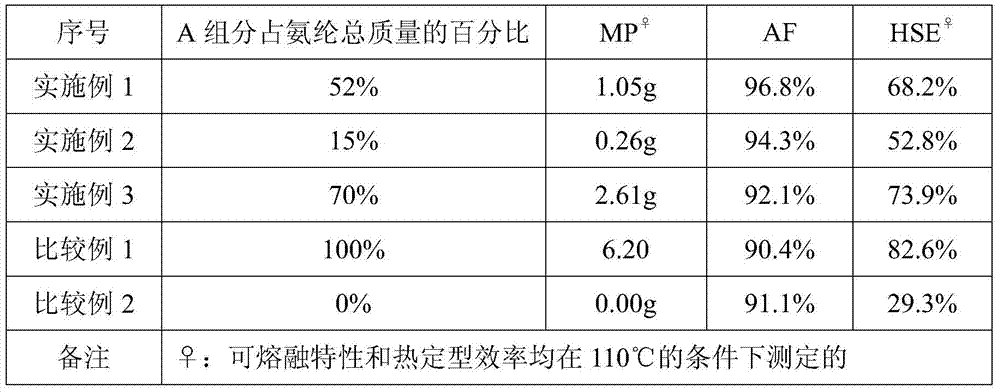

Embodiment 1

[0035]Preparation of component A stock solution (component A accounts for 52% of the total mass of spandex): 14.672kg of PCL with a molecular weight of 2000, 1.712kg of IPDI and 3.5g of benzoic acid are placed in 33.218kg of dimethylacetamide solution React at 50°C until the viscosity of the polymer reaches 25°C and 380Pa·s, immediately add 646.66g of 10% neopentyl alcohol solution, continue the reaction for 80min, then add 1.75kg of triethylene glycol ether-bis(3- tert-butyl-4-hydroxy-5-methylphenyl)propionate, stirred evenly, and matured to obtain the stock solution of component A, which was stored for future use.

[0036] Preparation of component B stock solution: 11.786kg of PTMEG with a molecular weight of 1810 and 3.337kg of 4,4'-MDI were reacted in 15.300kg of dimethylacetamide solution at 50°C for 120min to obtain isocyanate-terminated When the prepolymer is cooled to 6°C, add 13.638kg of ethylenediamine solution with a concentration of 2.8% under high-speed shear cond...

Embodiment 2

[0040] Spandex fibers were prepared according to the same method described in Example 1, except that the percentage of component A accounting for the total mass of spandex was 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com