Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improve meltability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-dielectric-constant glass fiber and glass fiber fabric made thereof

InactiveUS20030054936A1Maintain good propertiesImprove meltabilityWoven fabricsCircuit susbtrate materialsProduction rateTO-18

Disclosed are a low-dielectric-constant glass fiber having a glass composition comprising, by weight %, 50 to 60% of SiO2, 10 to 18% of Al2O3, 14% to less than 20% of B2O3, 1% to less than 6% of MgO, 2 to 5% of CaO, 0.5 to 5% of TiO2, 0 to 0.3% of Li2O, 0 to 0.3% of Na2O, 0 to 0.5% of K2O and 0 to 2% of F2, the content of MgO+CaO being 4 to 11% and the content of Li2O+Na2O+K2O being 0 to 0.6%, and a glass fiber fabric made of the low-dielectric-constant glass fiber. The glass fiber of the present invention has a low dielectric constant and a low dielectric tangent, is excellent in productivity and workability and is also excellent in water resistance, and the glass fiber is suitable for reinforcing printed wiring boards for high-density circuits.

Owner:NITTO BOSEIKI CO LTD

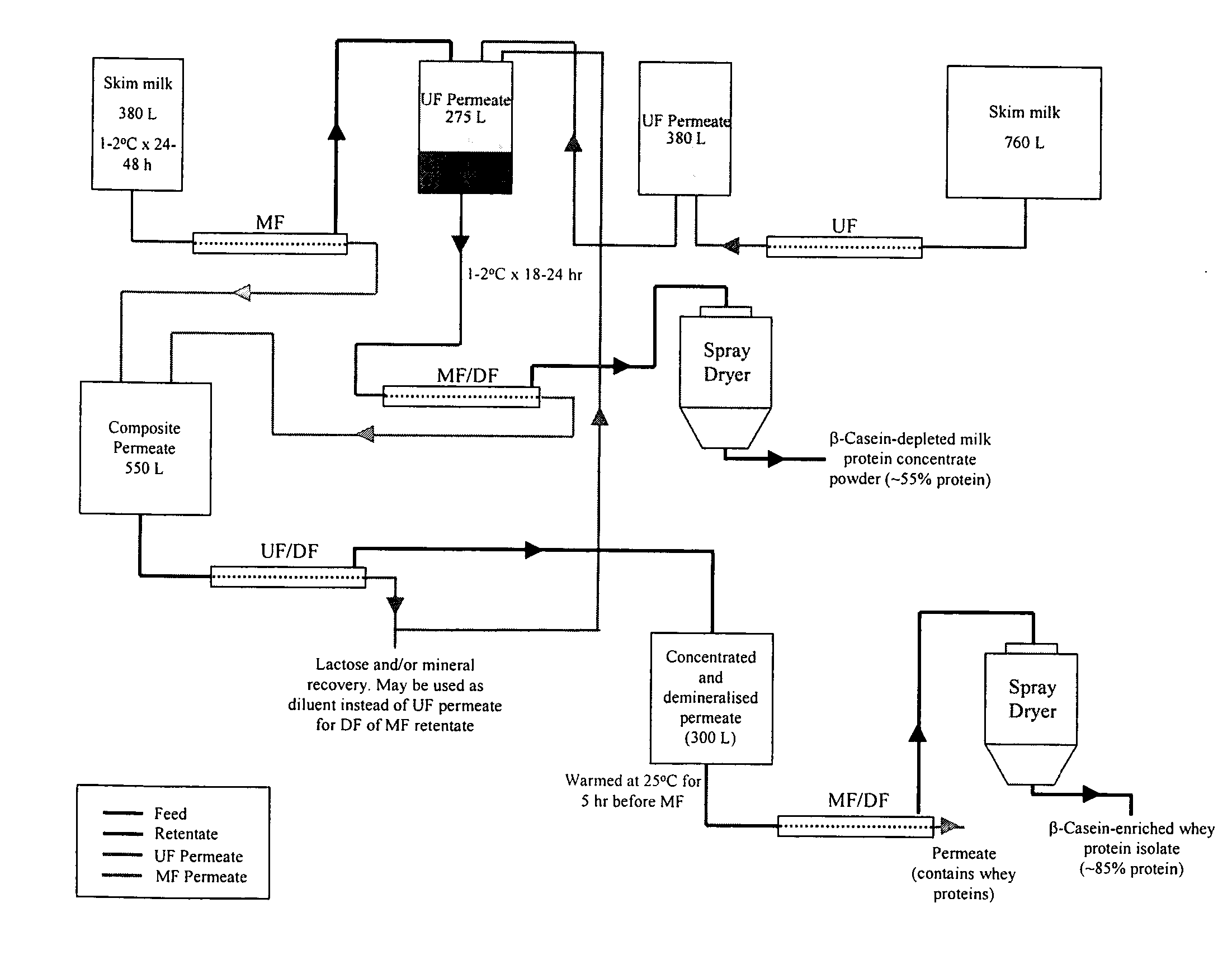

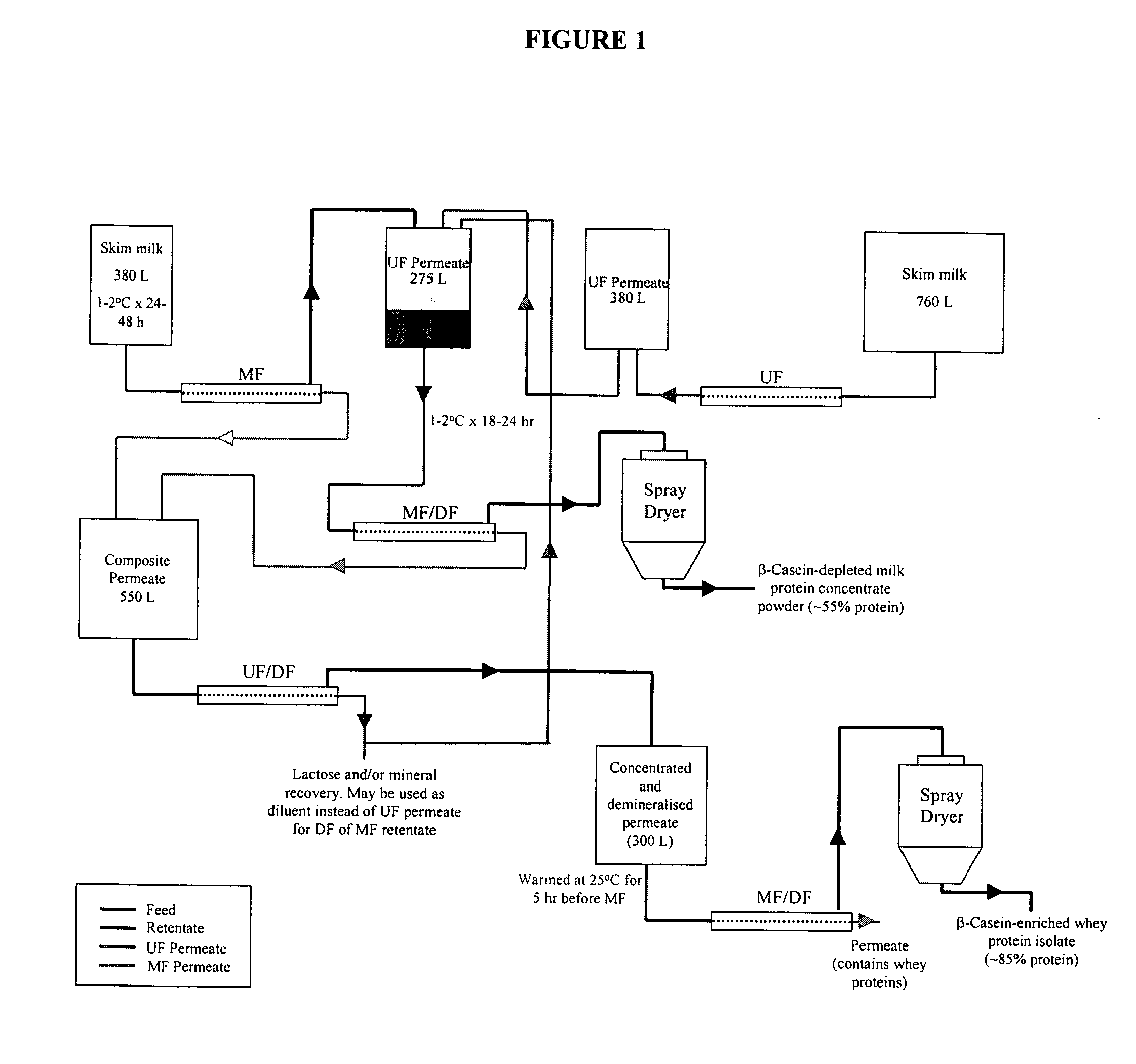

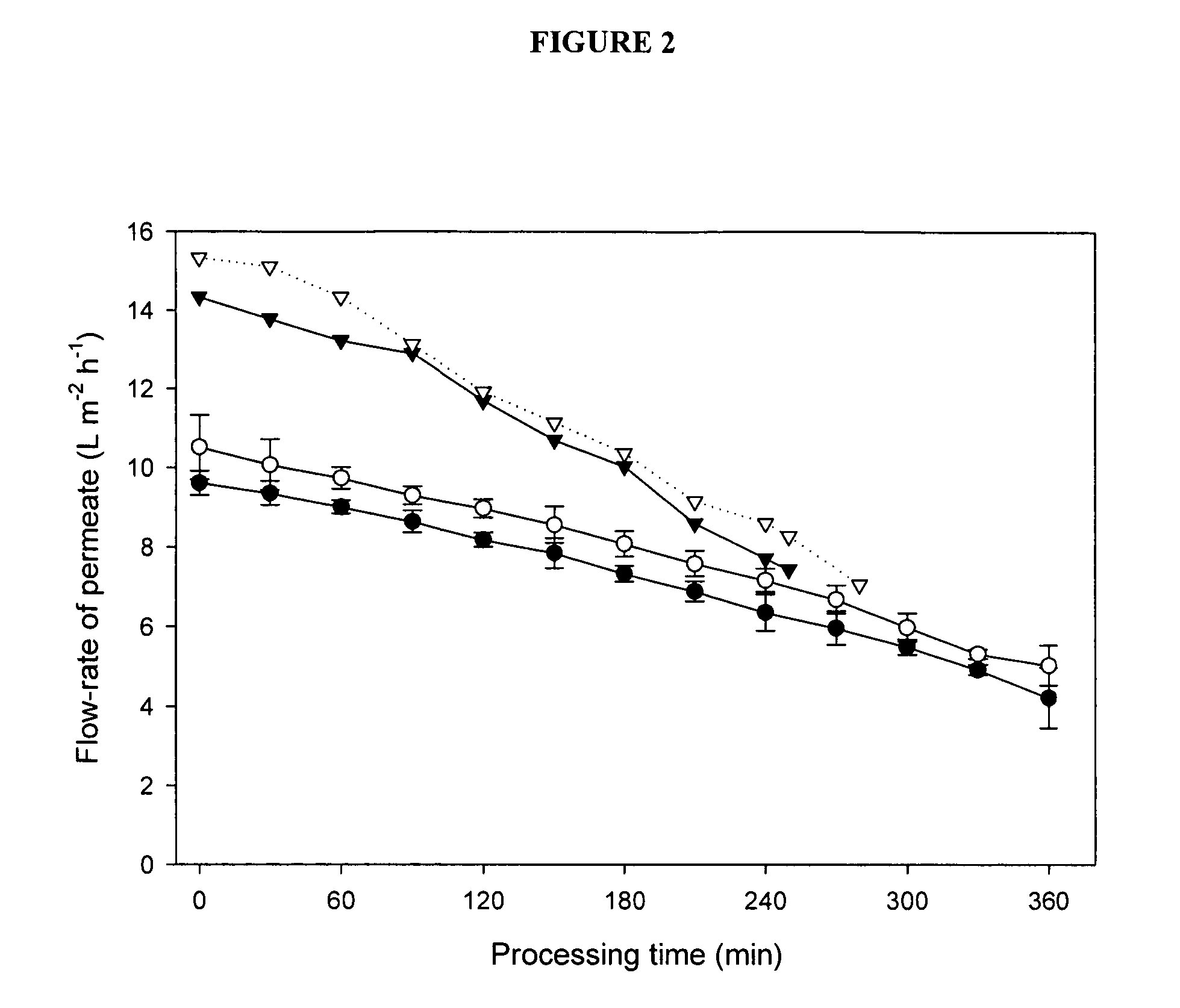

Purification of beta casein from milk

ActiveUS20070104847A1Without negatively impactingFunctionalMilk preparationFood membrane processMilk SerumMicrofiltration membrane

A method is provided for obtaining β-casein from skim milk. Purification of β-casein from milk is achieved through a process of microfiltration using cross-flow polymeric microfiltration membranes. Cooling of the milk prior to microfiltration results in improved separation of β-casein from the other milk serum proteins. Further filtration and demineralization of the microfiltered permeate results in enrichment of the fraction containing soluble β-casein. An integrated scheme that allows a dairy plant to continuously separate and purify β-casein is provided. Also provided is a method for obtaining cheese with improved meltability and reduced bitterness.

Owner:WISCONSIN ALUMNI RES FOUND

Low-dielectric-constant glass fiber and glass fiber fabric made thereof

InactiveUS6846761B2Maintain good propertiesImprove meltabilityWoven fabricsCircuit susbtrate materialsTO-18Glass fiber

Low-dielectric-constant glass fibers having a glass composition comprising, by weight %, 50 to 60% of SiO2, 10 to 18% of Al2O3, 14% to less than 20% of B2O3, 1% to less than 6% of MgO, 2 to 5% of CaO, 0.5 to 5% of TiO2, 0 to 0.3% of Li2O, 0 to 0.3% of Na2O, 0 to 0.5% of K2O and 0 to 2% of F2, the content of MgO+CaO being 4 to 11% and the content of Li2O+Na2O+K2O being 0 to 0.6%. The glass fiber has a low dielectric constant and a low dielectric tangent, is excellent in productivity and workability and is also excellent in water resistance, and the glass fiber is suitable for reinforcing printed wiring boards for high-density circuits.

Owner:NITTO BOSEIKI CO LTD

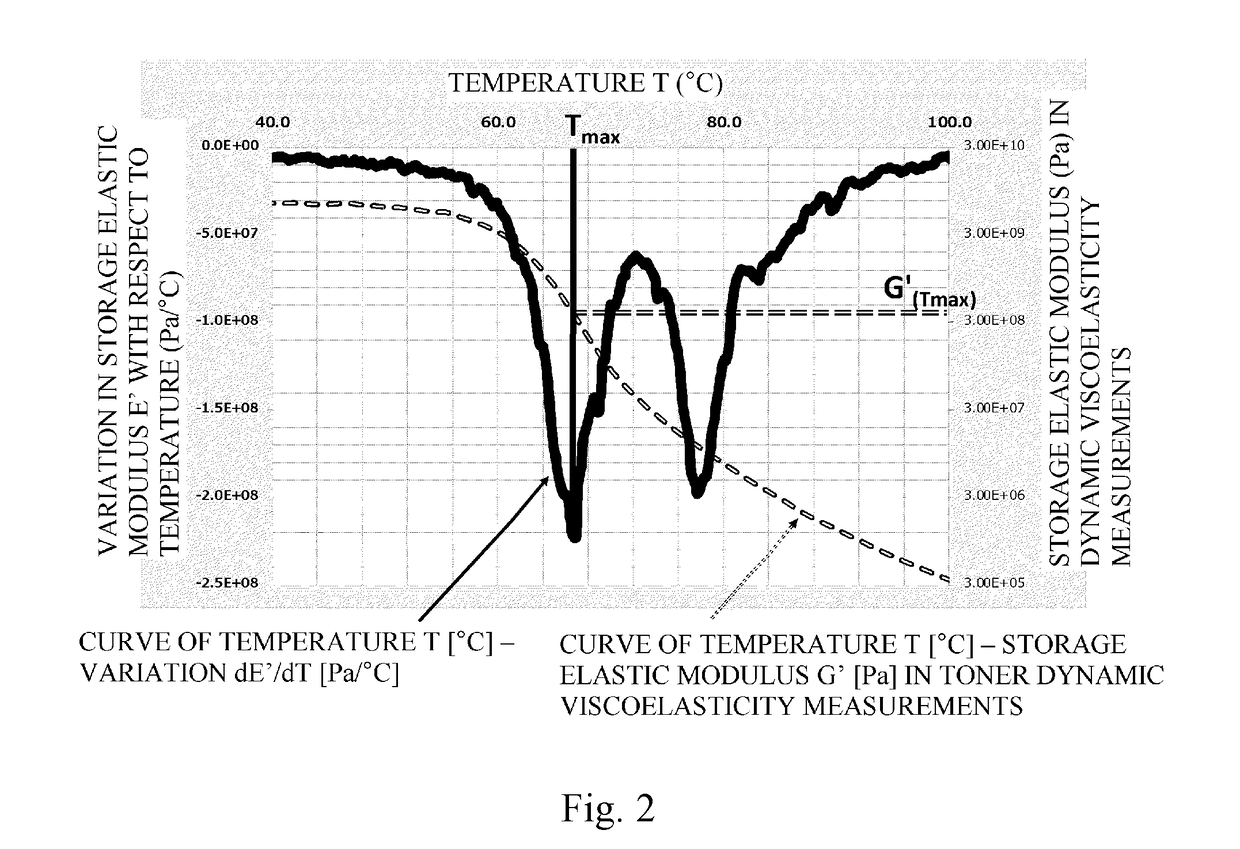

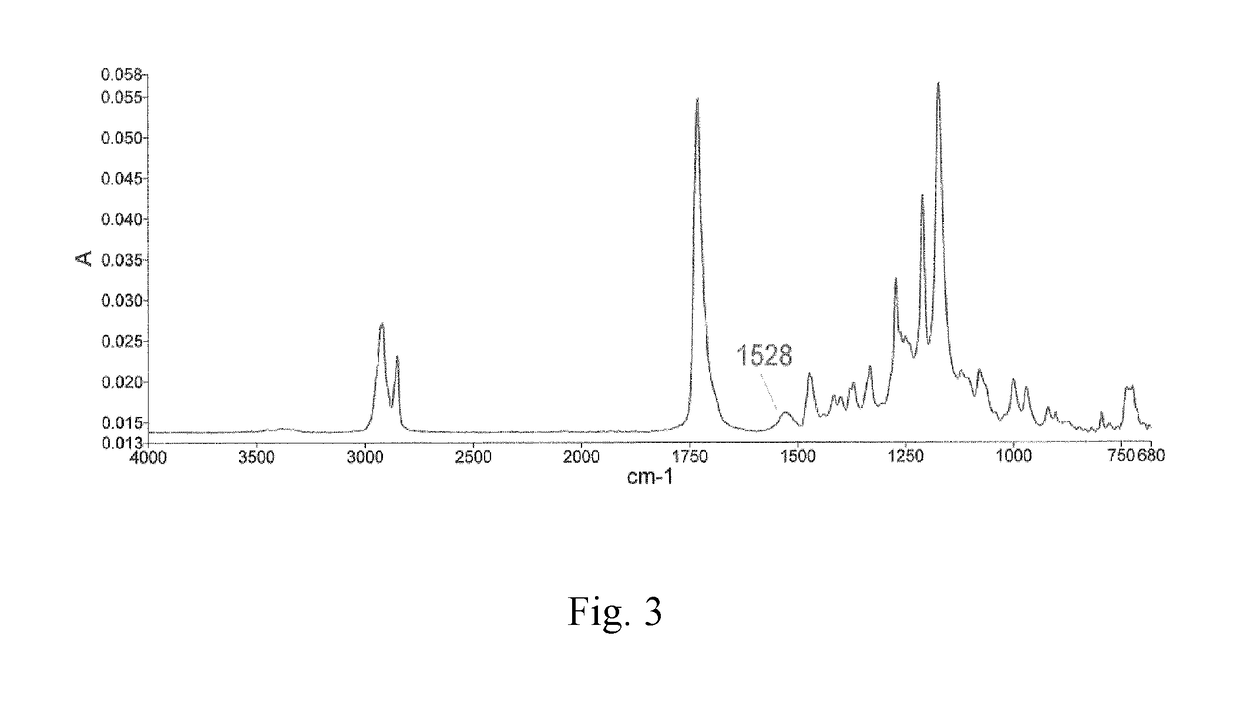

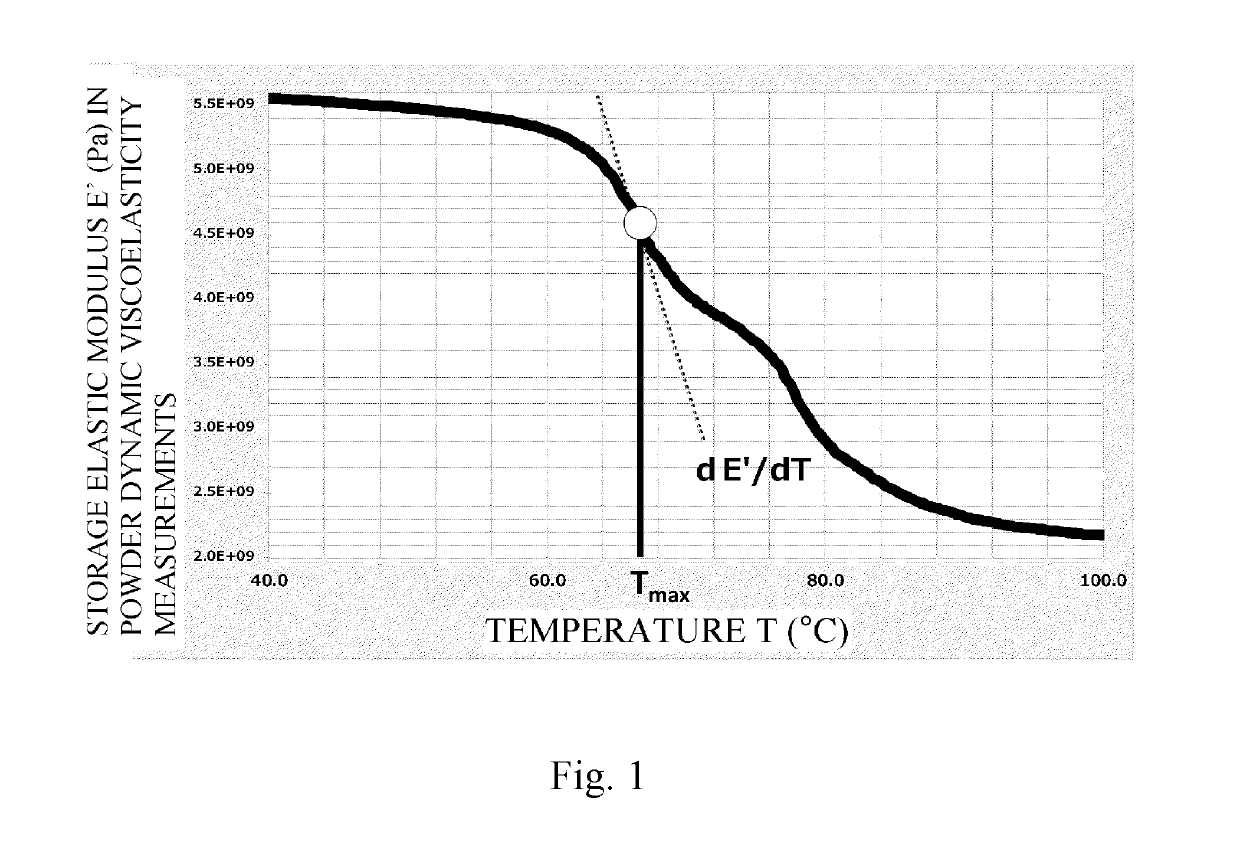

Toner, and external additive for toner

A toner comprising: a toner particle containing a binder resin and a colorant; and an external additive, wherein the external additive is a composite particle having an organic substance and an organosilicon polymer coating layer on the surface of the organic substance, and when a curve for the variation (dE′ / dT) in the storage elastic modulus E′ of the toner with respect to temperature T [° C.] is obtained on the basis of a curve of the temperature T—the storage elastic modulus E′ [Pa] of the toner, as determined by powder dynamic viscoelasticity measurements of the toner, the relative minimum value on the lowest temperature side between the onset temperature and 90° C. is −1.35×108 or less.

Owner:CANON KK

Toner, and external additive for toner

ActiveUS10241430B2Low temperature fixabilityLower performance requirementsDevelopersDynamic viscoelasticityPolymer coatings

Owner:CANON KK

Method for improving or maintaining physical properties of substance

InactiveUS20180325141A1Improve foam stabilityImprove retentionMilk preparationCosmetic preparationsMedicinePhysical property

Owner:SAN EI GEN F F I

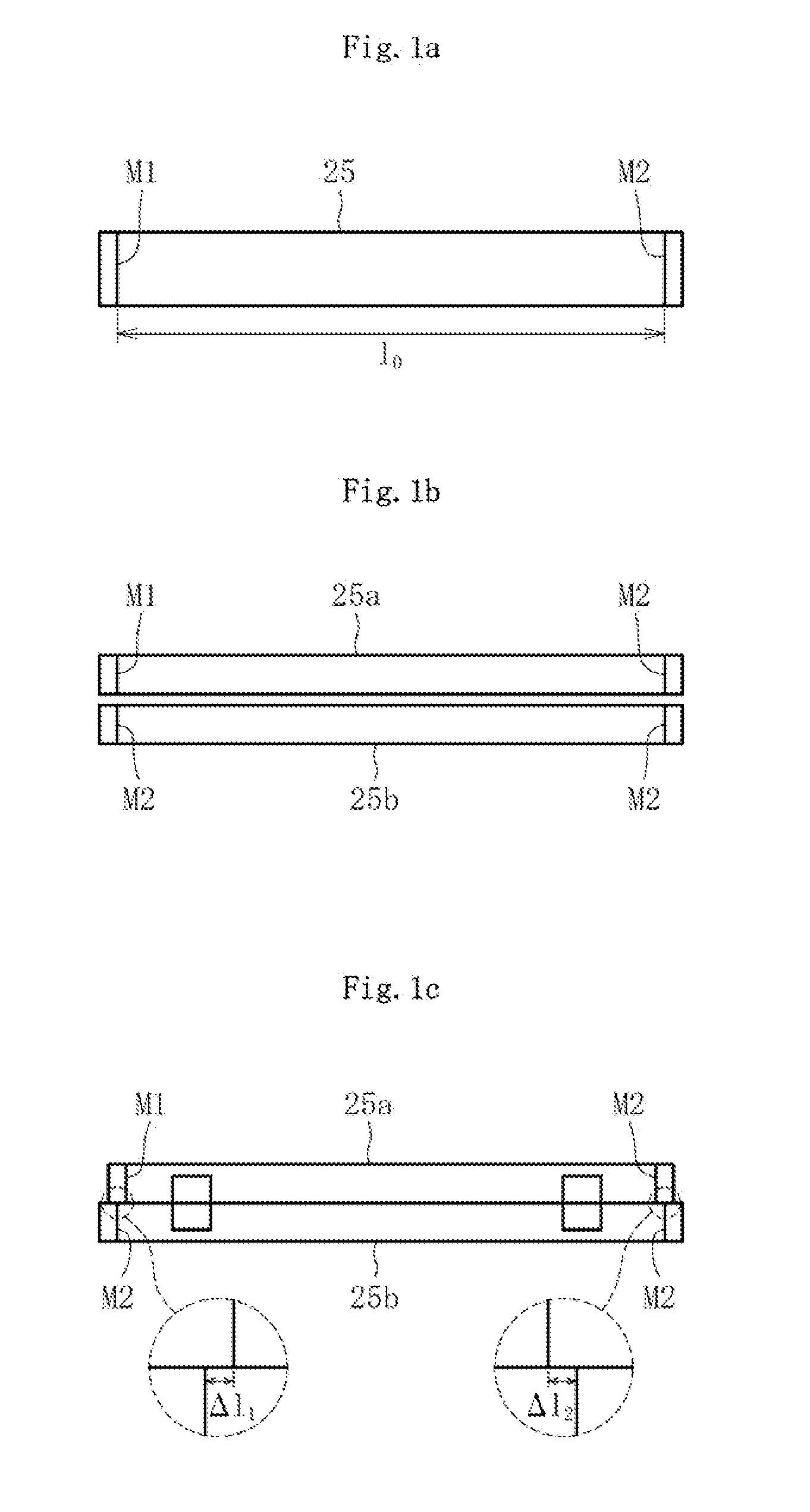

Thermosetting resin composition, cured product of the same, and interlaminar adhesive film used for printed wiring board

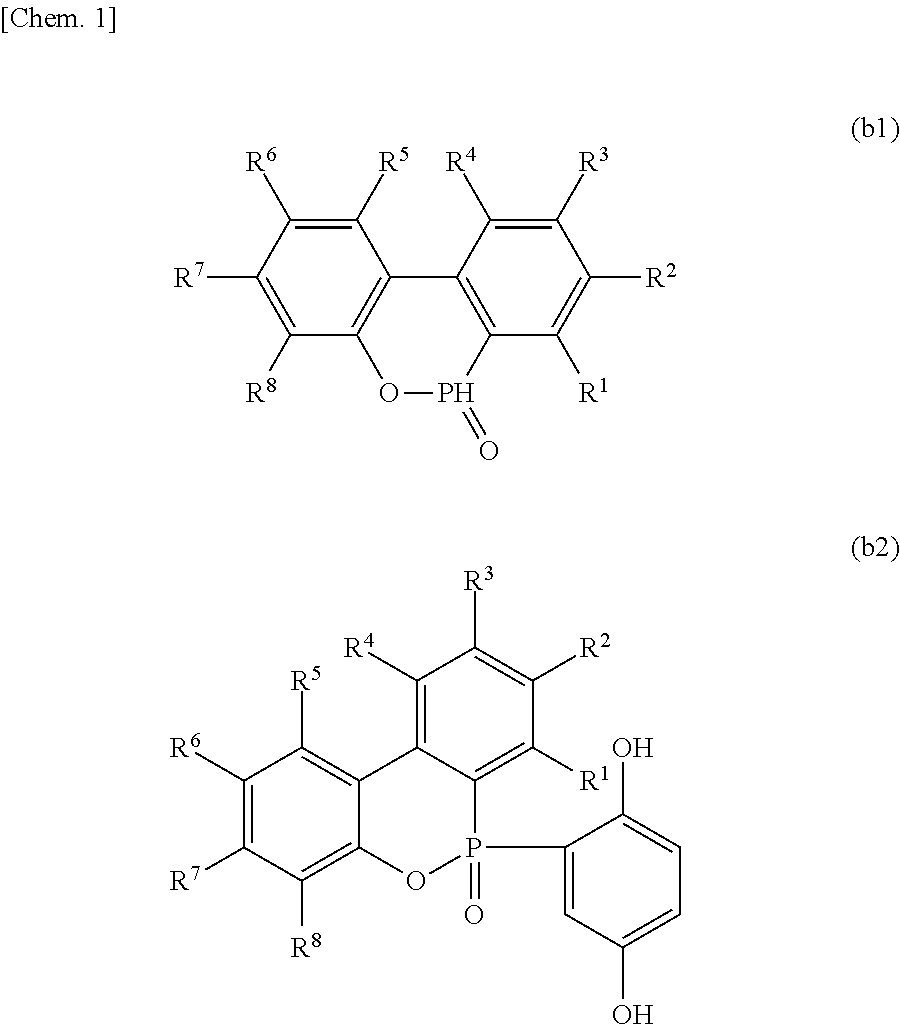

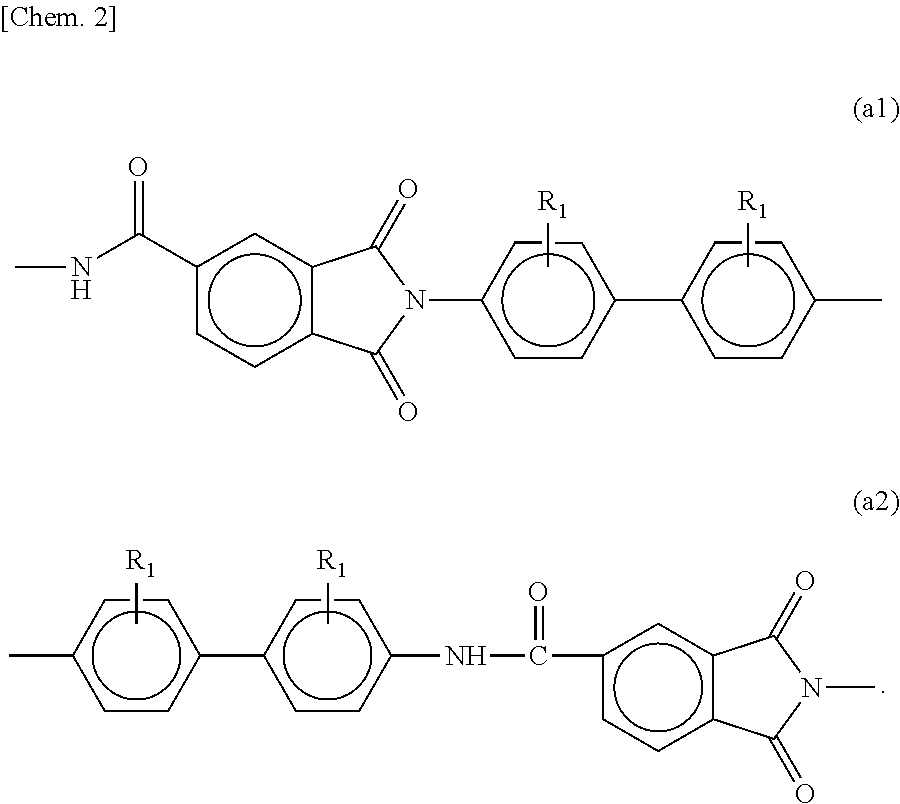

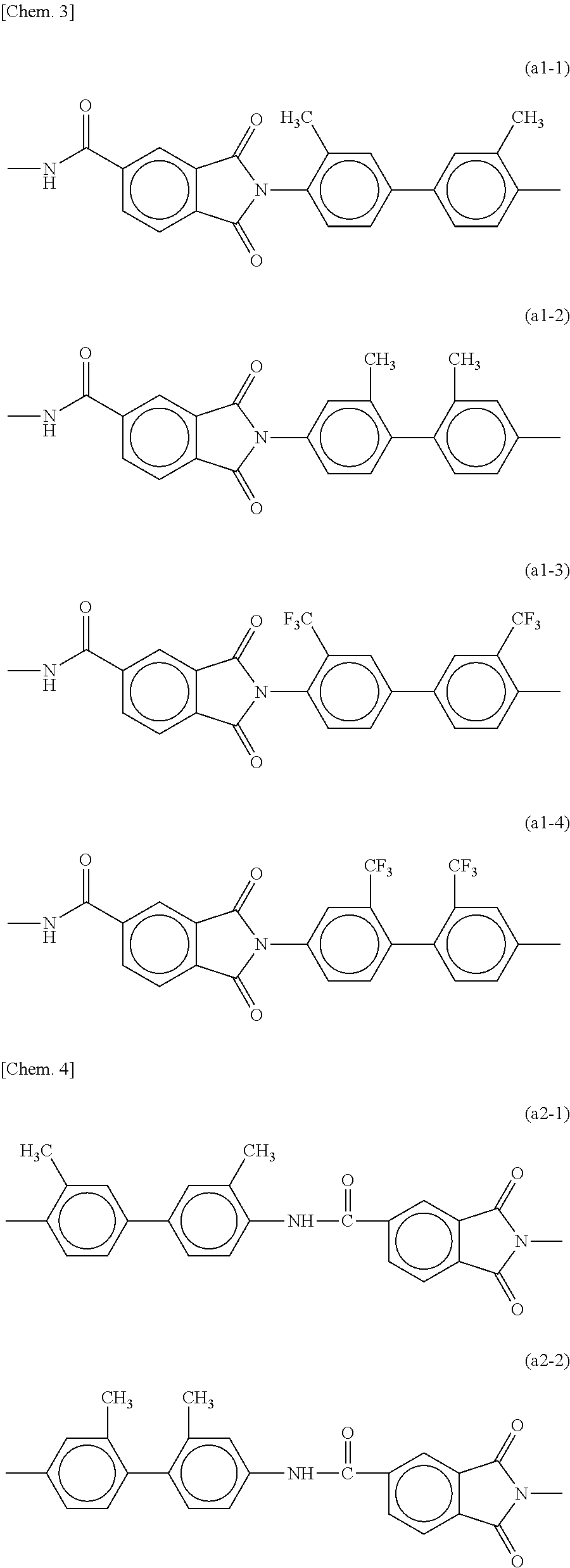

InactiveUS20130309489A1Improve melting effectReduction factorNon-macromolecular adhesive additivesGroup 5/15 element organic compoundsEpoxyImide

There is provided a thermosetting polyimide resin composition which enables production of a cured product exhibiting excellent dimensional stability and which exhibits excellent meltability; there are also provided a cured product of such a composition and an interlaminar adhesive film used for a printed wiring board, the interlaminar adhesive film being formed of the composition. In particular, there are provided a thermosetting polyimide resin composition containing a thermosetting polyimide resin (A) having a biphenyl backbone directly linked to a nitrogen atom of a five-membered cyclic imide backbone and a weight-average molecular weight (Mw) of 3,000 to 150,000, a phosphorus compound (B) represented by specific Formula (b1) or (b2), and an epoxy resin (C); a cured product of such a composition; and an interlaminar adhesive film used for a printed wiring board, the interlaminar adhesive film including a layer formed of the composition, the layer being formed on a carrier film.

Owner:DAINIPPON INK & CHEM INC

Repairing method for surface of draught fan blade

InactiveCN107254650ASolve lossSolve the problem of longevityMolten spray coatingCarbon compoundsPre treatmentMulti element

The invention discloses a repairing method for the surface of a draught fan blade and belongs to the technical field of draught fan repairing. According to the repairing method for the surface of the draught fan blade, the method comprises the steps of blade surface pre-treatment, preheating before spraying, preparation before material spraying, ultrasonic spraying and hole sealing treatment. According to a spraying material, an NiAl material is chosen and used to conduct bottoming, and the problem that the material thermal expansion coefficients of an abrasion-resisting work layer and a blade base layer are not matched can be solved, so that thermal stress caused by the fact that the expansion coefficients of the work layer and the blade base layer are not matched is reduced, and the mechanical matching and physical compatibility between the work layer and the blade base layer are improved. The work layer is a WC-12Co composite coating or an NiCr-Cr3C2 composite coating. According to the repairing method for the surface of the draught fan blade, by optimizing the repairing steps, multi-element alloy coating components and distribution, the good erosion and abrasion resistance performance is achieved, and the technical problem that the efficiency of a draught fan is affected due to draught fan blade erosion and abrasion is solved.

Owner:安徽威龙再制造科技股份有限公司

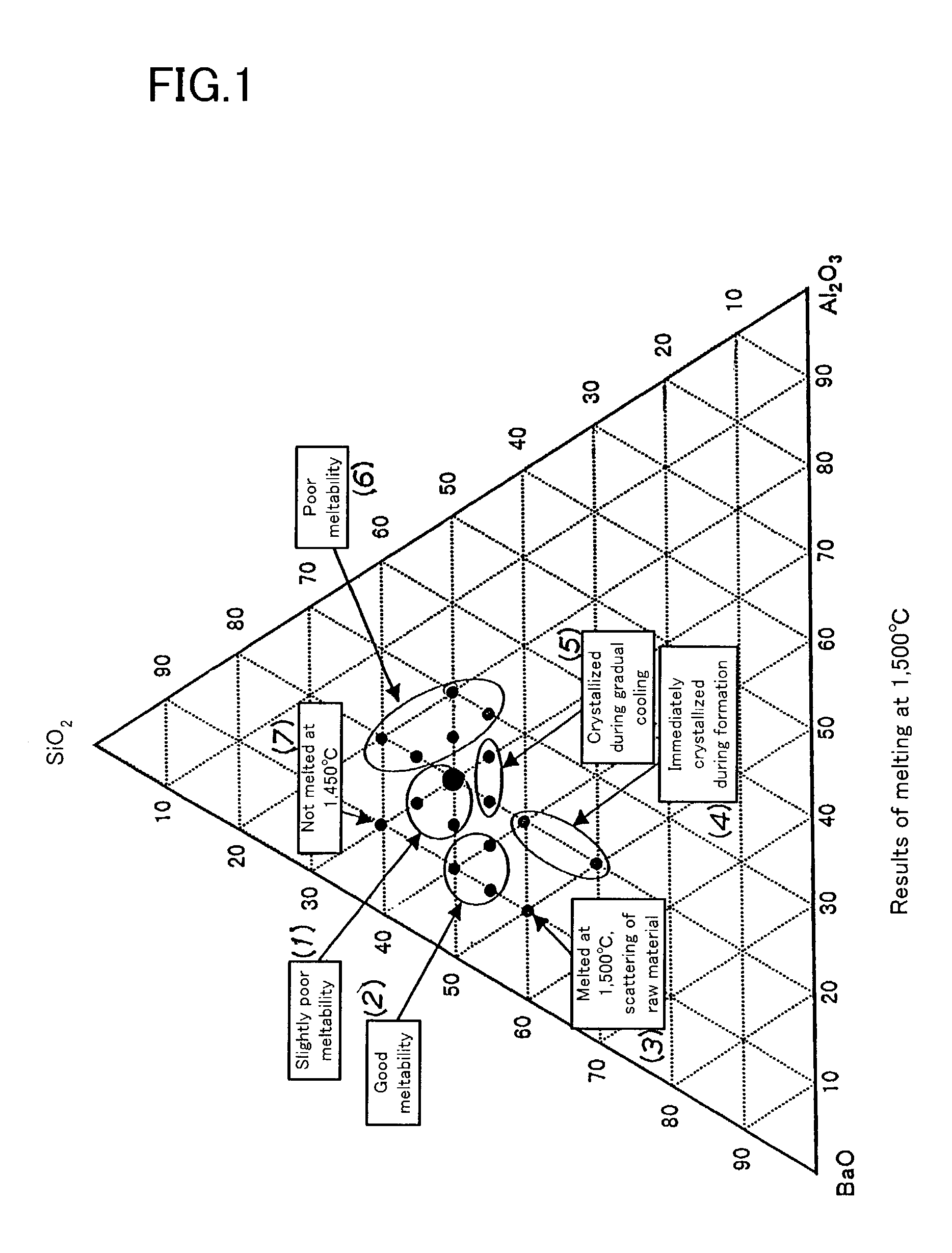

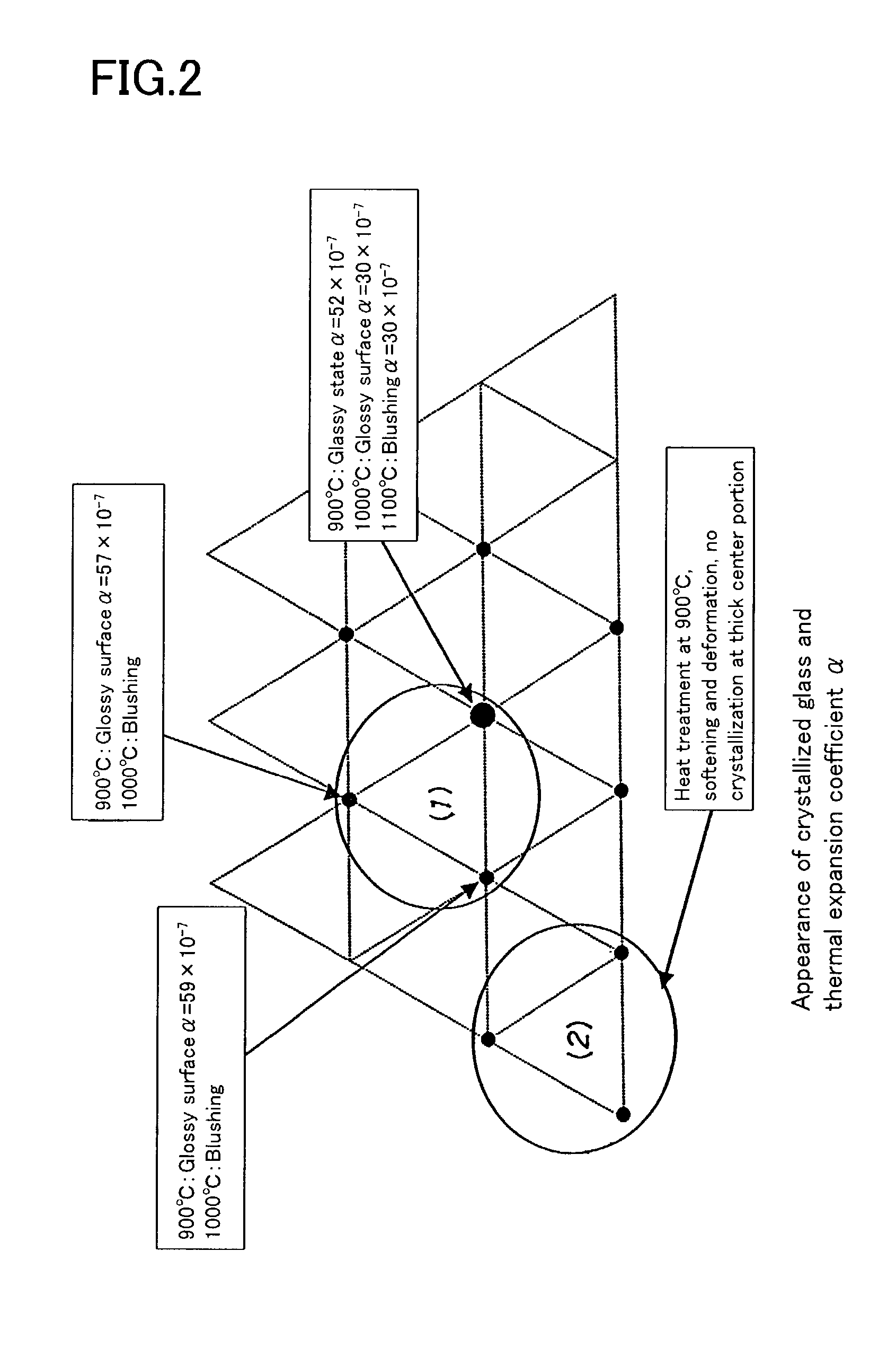

Glass-ceramic and reflecting mirror substrate

InactiveUS20030129414A1Improve meltabilityPromote precipitationGlass/slag layered productsMetal layered productsMetallurgyAlkali feldspar

An object of the present invention is to provide a glass-ceramic which is suitable as a material for forming a reflecting mirror substrate. The glass-ceramic has celsian as a primary crystal phase and contains SiO2, Al2O3, BaO, and TiO2 as primary components and Li2O as a modification component, wherein the amount of Li2O falls within a range of 0.05 to 1.0 wt. %. The glass-ceramic is substantially formed of a crystal phase of celsian alone.

Owner:NGK INSULATORS LTD +1

Glass and glass substrate

ActiveUS20150315065A1High strain pointSatisfactory chemical resistanceDevitrificationYoung's modulus

Devised are a glass and glass substrate, which contain an alkaline component at a low content, are low in density and thermal expansion coefficient, are high in strain point and Young's modulus, and are excellent in devitrification resistance, meltability, formability, and the like. That is, the glass of the present invention includes as a glass composition, in terms of mass %, 58 to 70% of SiO2, 16 to 25% of Al2O3, 3 to 8% of B2O3, 0 to 5% of MgO, 3 to 13% of CaO, 0 to 6% of SrO, 0 to 6% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, and 0 to 5% of P2O5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Alkali-free glass and alkali-free glass substrate

ActiveUS8455378B2Excellent devitrification resistanceImprove meltabilityNon-linear opticsAlkali freeAlkali metal oxide

An alkali-free glass characterized by having a glass composition being substantially free of an alkali metal oxide, As2O3 and Sb2O3 and including, in terms of mol %, 55 to 75% of SiO2, 7 to 15% of Al2O3, 7 to 12% of B2O3, 0 to 3% of MgO, 7 to 12% of CaO, 0 to 5% of SrO, 0 to 2% of BaO, 0 to 5% of ZnO and 0.01 to 1% of SnO2 and has a liquidus viscosity of 105.2 dPa·s or higher and a temperature corresponding to a viscosity of 102.5 dPa·s of 1,550° C. or lower.

Owner:NIPPON ELECTRIC GLASS CO LTD

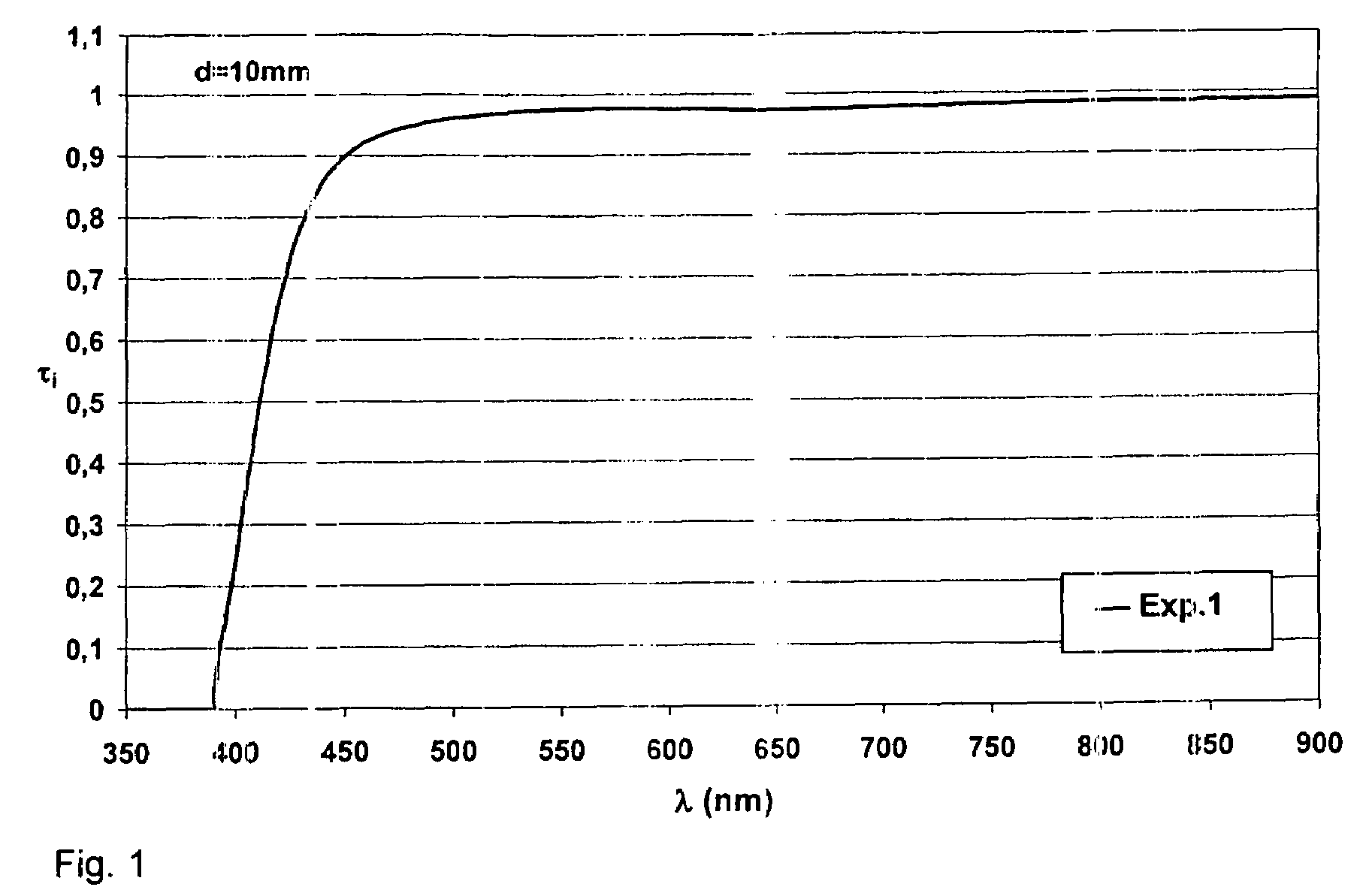

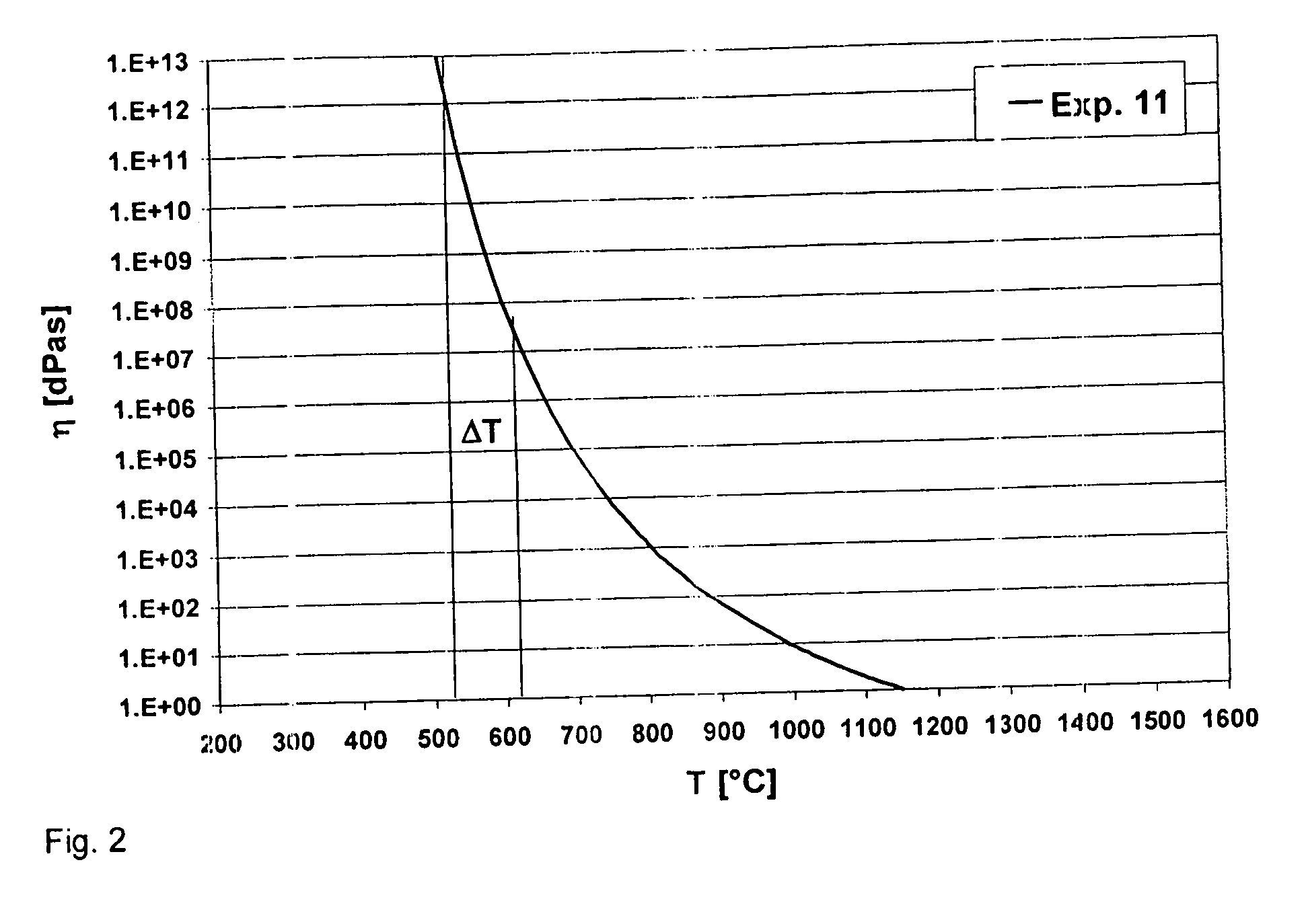

Lead-free and arsenic-free niobium phosphate optical glass

The lead-free, arsenic-free, preferably gadolinium-free and fluorine-free, optical glass has a refractive index of 1.86≦nd≦1.95, an Abbe number of 19≦vd≦24, a transformation temperature of ≦595° C., preferably ≦550° C., good crystallization stability, good processing properties and production properties. The optical glass is free of Na2O, frre of B2O3 and has a composition (based on oxide content in % by weight) of P2O5, 14-31; Nb2O5, 22-50; Bi2O3, 5-36; WO3, >10-25; GeO2, 0-14; Li2O, 0-6; K2O, 0-6; Cs2O, 1-7; MgO, 0-6; CaO, 0-6; SrO, 0-6; BaO, 0-6; ZnO, 0-6; TiO2, 0-4; Σ alkali oxides, 2-12; Σ alkaline earth oxides, 0-10; Σ Nb2O5, WO3, Bi2O3≦50 and fining agents, 0-2.

Owner:SCHOTT AG

Lead-free and arsenic-free niobium phosphate optical glass

The lead-free, arsenic-free, preferably gadolinium-free and fluorine-free, optical glass has a refractive index of 1.86≦nd≦1.95, an Abbe number of 19≦vd≦24, a transformation temperature of ≦595° C., preferably ≦550° C., good crystallization stability, good processing properties and production properties. The optical glass has a composition (based on oxide content in % by weight) of P2O5, 14-31; Nb2O5, 22-50; Bi2O3, 5-36; WO3, >10-25; GeO2, 0-14; Li2O, 0-6; K2O, 0-6; Cs2O, 0-7; MgO, 0-6; CaO, 0-6; SrO, 0-6; BaO, 0-6; ZnO, 0-6; TiO2, 0-4; Σ alkali oxides, 2-12; Σ alkaline earth oxides, 0-10; Σ Nb2O5, WO3, Bi2O3≦50 and fining agents, 0-2.

Owner:SCHOTT AG

Bearing seat inner hole abrasion remanufacturing spray repair method

ActiveCN107312995AGood resistance to high temperature oxidationImproved erosion and wear resistanceMolten spray coatingMaterials preparationSpray coating

The invention discloses a bearing seat inner hole abrasion remanufacturing spray repair method and belongs to the technical field of bearing seat repair. Through the steps of bearing seat inner hole surface pretreatment, preheating before spraying, spray material preparation, supersonic spraying and coating processing, a NiCr or NiAl material is selected for spray material priming, the problem that the material thermal expansion coefficients of an abrasion-resistant working layer and a bearing seat inner hole basic layer are not matched can be solved, thus, the thermal stress caused by mismatching of the expansion coefficients of the working layer and the bearing seat inner hole basic layer is reduced, and mechanical matching and physical compatibility of the working layer and the bearing seat inner hole basic layer are improved; and a WC-12Co composite coating or a NiCr-Cr3C2 composite coating is used as the working layer. Through repair step optimization, multicomponent alloy coating compositions and distribution, the good erosive abrasion resistance is achieved, and the problems of high mechanical repair cost of bearing seat abrasion and large shrinkage percentage of spraying coatings are solved.

Owner:济宁拓源精密机械股份有限公司

Optical glass

Owner:NIHON YAMAMURA GLASS CO LTD +1

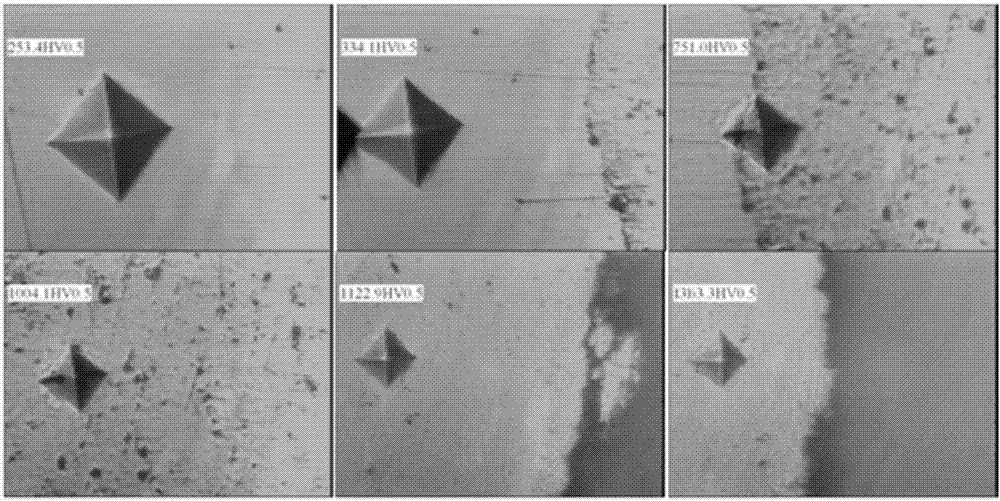

Inert dental glass

InactiveUS7264665B2Improve meltabilityImproves setting propertyImpression capsOther chemical processesPolyelectrolytePhysical chemistry

The invention relates to the use of ions of weakly basic oxides as linking ions for polyacids in cements, preferably polyelectrolyte cements. Suitable ions comprise elements of the scandium series, for example, Sc3+, Y3+, La3+, Ce4+ and all subsequent tri- and tetra-valent lanthanides and the ions Mg2+, Zn2+, Ga2+, In2+. The application of said ions permits a regulation of the cement reaction without surface treatment of the glass powder.

Owner:3M INNOVATIVE PROPERTIES CO

Optics horniness crown glass without lead and arsenical

The present invention relates to lead and arsenic-free optical hard crown glass with lower transition temperature (Tg≤520°C), characterized in that its optical range has a refractive index of 1.57≤nd≤1.61 and a refractive index of 56≤νd≤63 Dispersion coefficient. The glass has the following composition (in weight percentage): (see the above formula) wherein, ΣTiO2, ZrO2<0.9. Refining agents can be added as long as they do not contain arsenic.

Owner:SCHOTT AG

Glass and glass substrate

Devised are a glass and glass substrate, which contain an alkaline component at a low content, are low in density and thermal expansion coefficient, are high in strain point and Young's modulus, and are excellent in devitrification resistance, meltability, formability, and the like. That is, the glass of the present invention includes as a glass composition, in terms of mass %, 58 to 70% of SiO2, 16 to 25% of Al2O3, 3 to 8% of B2O3, 0 to 5% of MgO, 3 to 13% of CaO, 0 to 6% of SrO, 0 to 6% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, and 0 to 5% of P2O5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Oleaginous composition and oil-in-water type emulsifier containing oleaginous composition

ActiveUS20130078354A1Excellent meltabilityIncrease viscosityCream substitutesFood preparationIodine valueChemistry

Disclosed is a preferred oleaginous composition in an oil-in-water type emulsifier used as whipped cream mainly in confectionary and bread manufacturing. Use of the oleaginous composition suppresses whipped cream property changes that occur because of temperature changes, substantially without containing trans-fatty acid thereby providing an oil-in-water emulsifier with an excellent melt-in-the-mouth property. Disclosed is the manufacturing of an oil-in-water type emulsifier using an oleaginous composition containing a lauric acid content of 10-30% by weight and a triglyceride content of 30-55% by weight whose total carbon number is 44-48 of fatty-acid residue that composes the triglyceride, and containing a lauric-type oleo that contains interesterified fat with an iodine value of 30-50 and a lauric acid content of 40% by weight.

Owner:THE NISSHIN OILLIO GRP LTD

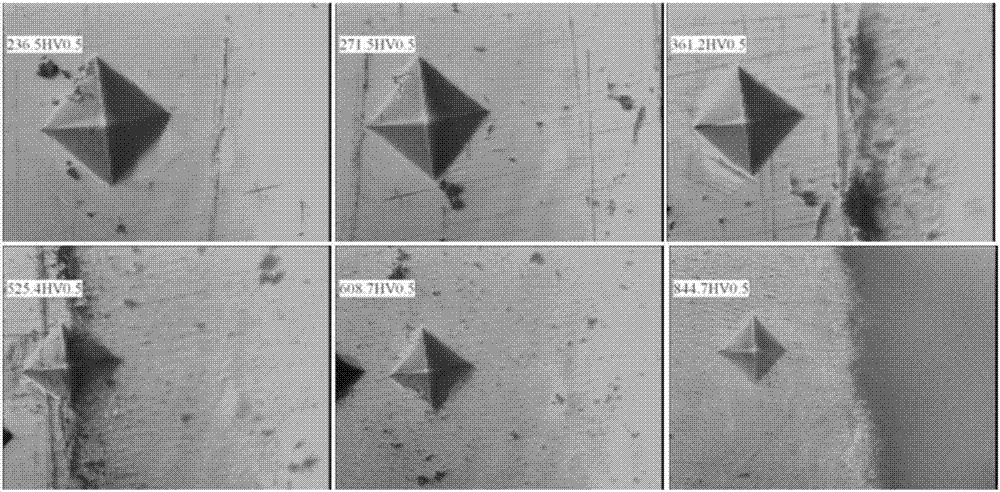

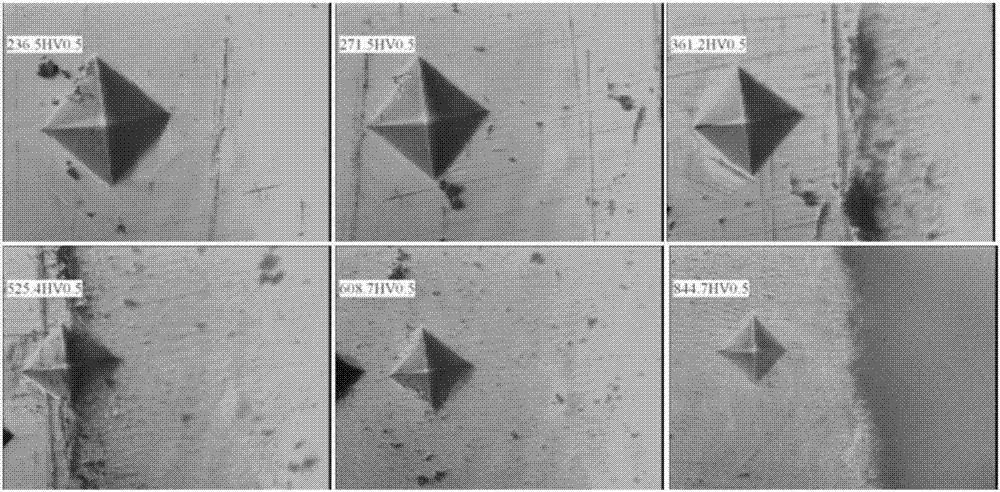

Sink roll multicomponent alloy coating and preparing and spraying method thereof

InactiveCN106929788AGood resistance to high temperature oxidationSolve lossMaterial nanotechnologyHot-dipping/immersion processesHeat resistanceHardness

The invention discloses a sink roll multicomponent alloy coating and a preparing and spraying method thereof, and belongs to the technical field of sink roll repair. The sink roll multicomponent alloy coating sequentially comprises a sink roll base layer, a transition layer and a work layer from inside to outside, the transition layer is a NiCrAlY spraying layer, NiCrAlY is sprayed to the sink roll base layer to serve as a metal bonding layer, that is the transition layer, and the problem of mismatching of material heat expansion coefficients between a wear-resisting heat-resisting work layer and the sink roll base layer can be solved; the work layer is the NiCr-Cr3C2 composite coating, the NiCr alloy has the excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties, Cr3C2 has the good high-temperature hardness and high-temperature oxidation resistance, the hard phase effect is achieved, the coating is not soluble in zinc liquid and is not wetted, coating peeling and even failures caused by heat impact can be greatly reduced, and the technical problems are solved.

Owner:安徽威龙再制造科技股份有限公司

Multicomponent alloy coating for hot rolling roll and preparation method and coating method of multicomponent alloy coating

InactiveCN107119250ASolve lossSolve the problem of longevityMolten spray coatingWear resistantSpray coating

The invention discloses a hot roll multi-element alloy coating and a preparation and spraying method thereof, belonging to the technical field of roll repair. A kind of hot roll multi-element alloy coating of the present invention, from inside to outside is hot roll base layer, transition layer and working layer successively, and transition layer is NiCr or NiCrAl spray coating, sprays NiCr or NiCrAl on hot roll base layer as metal bonding layer namely The transition layer can eliminate the problem of thermal expansion coefficient mismatch between the wear-resistant and heat-resistant working layer and the base layer of the hot roll; the working layer is NiCr‑Cr3C2 composite coating, and NiCr alloy has excellent heat resistance, corrosion resistance, high temperature oxidation resistance, etc. Performance, while Cr3C2 has good high temperature hardness and high temperature oxidation resistance, and acts as a hard phase. Moreover, NiCr-Cr3C2 has a linear expansion coefficient similar to that of hot rolling rolls, thereby greatly reducing the peeling or even failure of the coating caused by thermal shock, and solving the technical problem of the present invention.

Owner:安徽威龙再制造科技股份有限公司

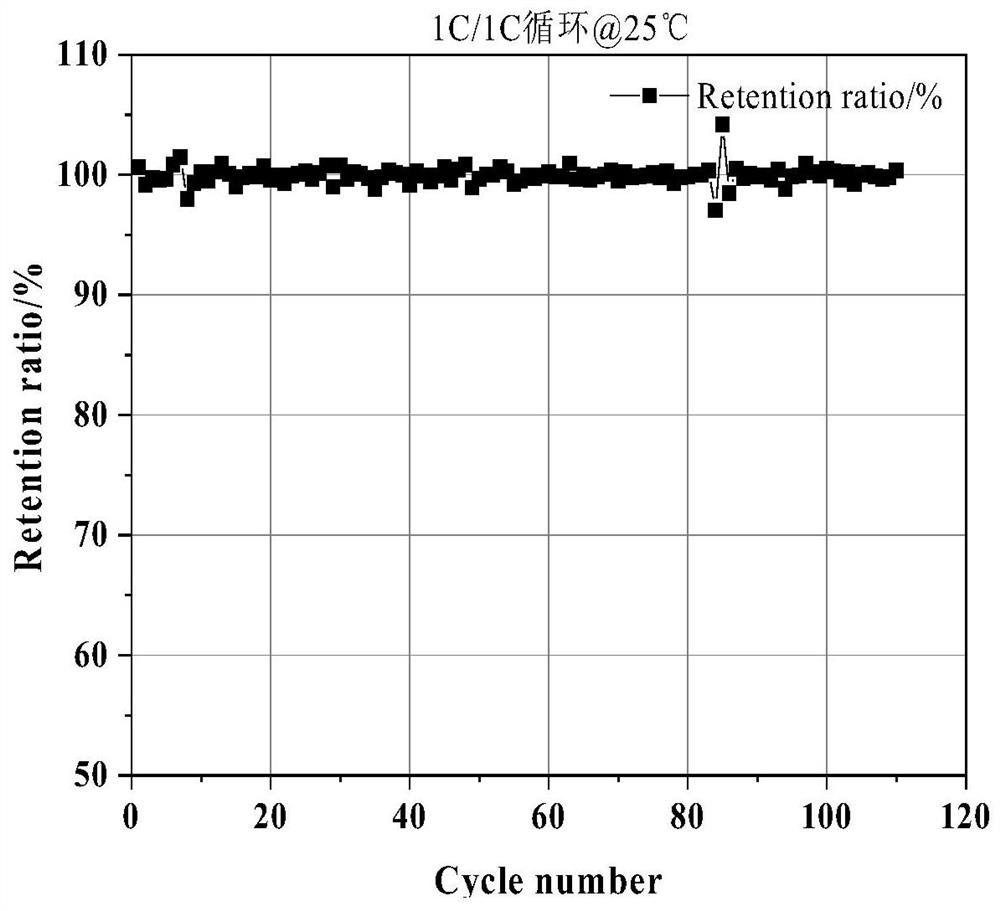

Lithium iron phosphate-boric acid co-coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

InactiveCN111653755ATotal base reductionEasy to processSecondary cellsPositive electrodesElectrolytic agentLithium iron phosphate

The invention discloses a lithium iron phosphate-boric acid co-coated lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. The preparation method comprises thefollowing steps: weighing a certain mass of a lithium nickel cobalt aluminate precursor, mixing lithium, sintering to obtain a lithium nickel cobalt aluminate primary sintered material, carrying outstirring and water washing on the lithium nickel cobalt aluminate primary sintered material, and carrying out vacuum drying to obtain a lithium nickel cobalt aluminate positive electrode material matrix; and mixing the matrix positive electrode material with a coating material lithium iron phosphate-boric acid, and carrying out high-temperature sintering to obtain the lithium iron phosphate-boricacid co-coated lithium nickel cobalt aluminate positive electrode material. The co-coated lithium nickel cobalt aluminate positive electrode material provided by the invention has good conductivity and a uniform coating layer, can prevent direct reaction between a positive electrode material matrix and an electrolytic solution, and effectively improves the cycle performance and safety performanceof the material. The method is simple in process, excellent in product performance, low in cost and suitable for large-scale industrial production.

Owner:SHAANXI COAL & CHEM TECH INST

Reflecting mirror

InactiveUS20060014026A1High forming precisionReduce the amount requiredGlass/slag layered productsCoatingsGas phaseTitanium dioxide

A reflecting mirror includes an uncrystallized glass substrate and thin multilayer reflective coatings formed on a surface of the glass substrate by vapor deposition. The glass substrate contains 53 to 64 percent by weight of SiO2, 10 to 23 percent by weight of Al2O3, ZnO and MgO each in an amount of not less than 3 percent by weight and in a total amount of 8 to 20 percent by weight, Na2O and K2O in a total amount of 0.2 to 2 percent by weight, 1 to 8 percent by weight of B2O3, 0 to 4% by weight of TiO2, and As2O3 and Sb2O3 in a total amount of not more than 2 percent by weight. The glass substrate has an average expansion coefficient of not more than 35, and a distortion point of not less than 640 degrees C. Thus, the reflecting mirror can withstand a temperature of 615 degrees C. on its inner surface even though the substrate contains only a small amount of TiO2.

Owner:OSAKA SPECIAL GLASS

Automatic-stirring smelting furnace

InactiveCN102679753AReduce heat lossReduce energy consumptionStirring devicesSurface layerTemperature difference

The invention discloses an automatic-stirring smelting furnace. The automatic-stirring smelting furnacecomprises a furnace body, wherein a feeding inlet and a discharging outlet are arranged on the furnace body; the bottom part of the furnace body is provided with a permanent magnet stirrer; the permanent magnet stirrer is mounted on the bottom part of a smelting furnace; and the stirring operation is performed by the permanent magnet technology. Compared with manual stirring, the automatic-stirring smelting furnace has the following advantages: 1, the operation is carried out without opening a furnace door, the heat consumption is reduced, and 20% of energy consumption can be saved; 2, since the components are even and the grains are refined, the best smelting effect is achieved; 3, non-direct-contact stirring is adopted so as to avoid artificial secondary pollution, and the generation of aluminum oxide slags is reduced; 4, the smelting speed of the smelting furnace is increased; 5, the temperature difference between the surface layer and the bottom part of a smelting body normally can be controlled within 5 DEG C so as to avoid the smelting body being overheated or being over-burnt locally; and 6, the operation is simple and the workload of workers is reduced greatly.

Owner:WUXI GREAT TECH

Optical glass

InactiveCN102050570AGood chemical stabilityImprove meltabilityGlass pressing apparatusOptical elementsRefractive indexOptical communication

The invention relates to precision moulding optical glass with high refractive index and low dispersion. With respect to application advantages, the optical glass can be used for producing optical parts and does not need to be polished, such as a lens for a digital camera. The optical parts produced through precision moulding can be used in the technical fields of imaging, projection, radio communication, optical communication engineering and laser.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Optical glass

A P2O5—BaO—ZnO—Nb2O5 type optical glass contains 25-50 wt. % P2O5, 15-35 wt. % BaO, 1-25 wt. ZnO, and 3-10 wt. % Nb2O5. The optical glass has a high refractive index (particularly preferably the refractive index nd of 1.6 or more), low dispersion (an Abbe number υd of 42 or more), a low deformation point, and improved resistance to devitrification upon molding, and is suitable for precision-mold press molding or other molding processes and also suitable for transfer of a fine structure.

Owner:NIHON YAMAMURA GLASS CO LTD +1

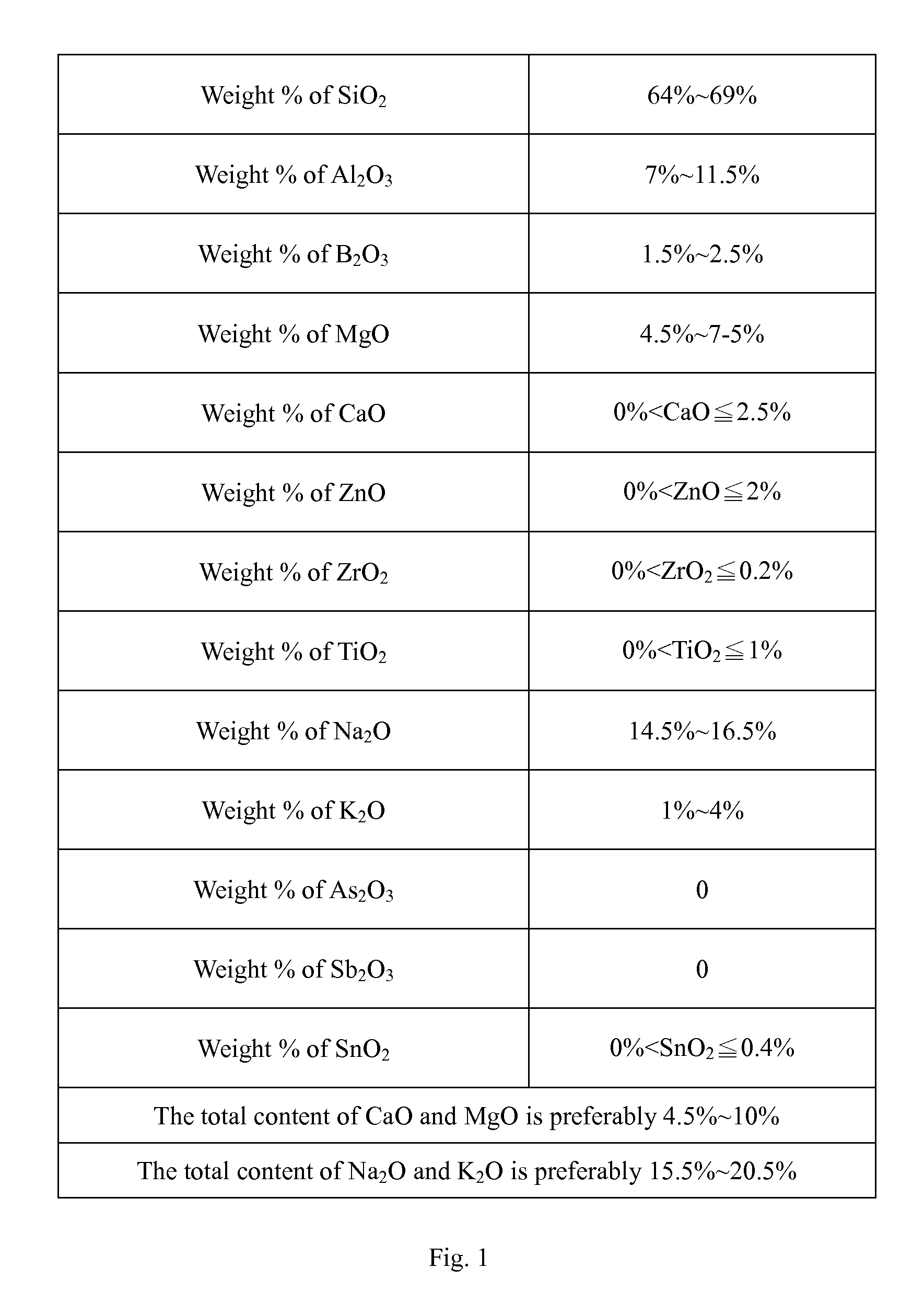

Constitution of Cover Glass

ActiveUS20140274655A1Devitrification resistanceSimple structureThin material handlingSurface layerPotassium ions

A constitution of cover glass, the compositions consist in terms of weight % on the oxide basis, of from 64 to 69 wt. % of SiO2; from 7 to 11.5 wt. % of Al2O3; from 1.5 to 2.5 wt. % of B2O3; from 4.5 to 7.5 wt. % of MgO; 0%<CaO≦2.5%; 0%<ZnO≦2%; 0%<ZrO2≦0.2%; 0%<TiO2≦1%; from 14.5 to 16.5 wt. % of Na2O; from 1 to 4 wt. % of K2O; and 0%<SnO2≦0.4%. The constitution then can be melted to form cover glass. Thereafter, the cover glass is dipped in KNO3 solution so that sodium ions, which is smaller in volume, contained in certain depth from the surface layer of the cover glass can be substituted by potassium ions, which is larger in volume. In this manner, squeezing effect is generated on the surface layer so as to form cover glass having high strength and resistance in both abrasion and scratch.

Owner:YU ALLEN

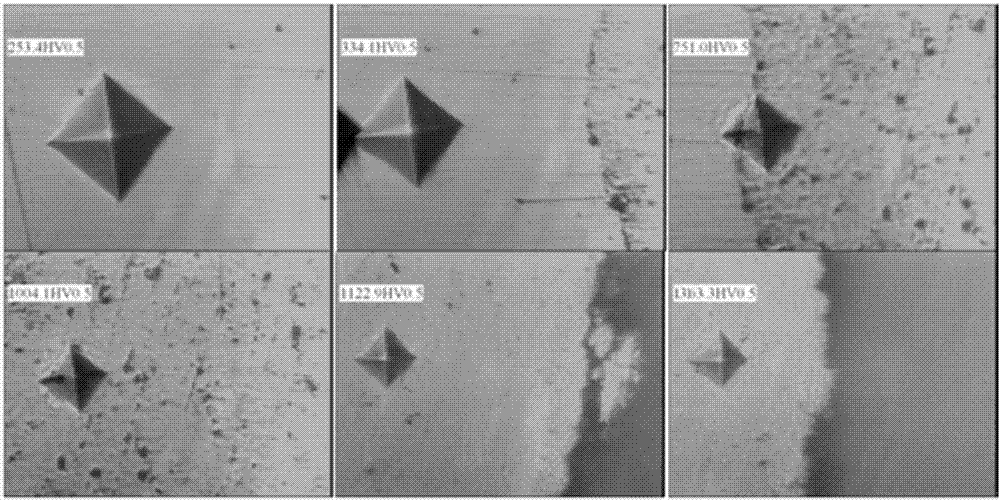

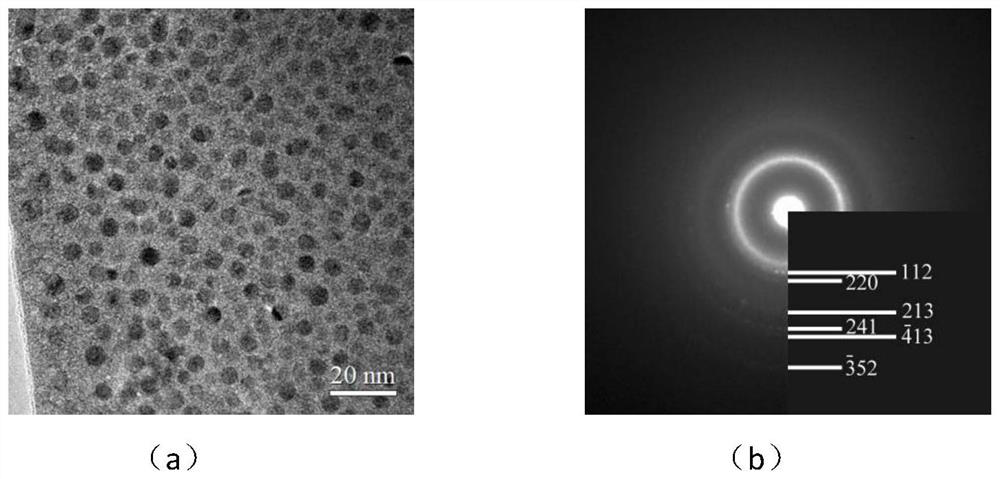

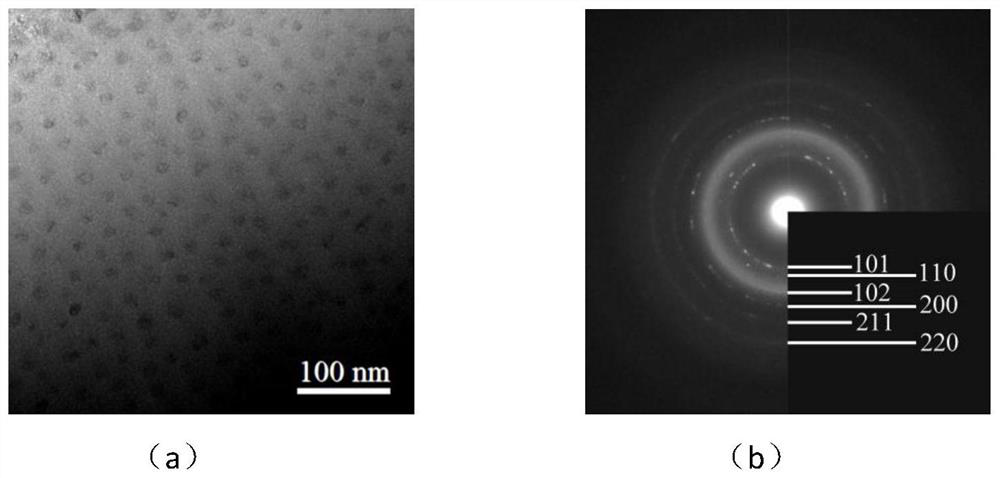

Amorphous matrix composite material and preparation method thereof

InactiveCN113322421ASimple preparation processEfficient preparation processAmorphous matrixQuenching

The invention discloses an amorphous matrix composite material and a preparation method thereof, and belongs to the technical field of new materials. The matrix of the amorphous matrix composite material is a Cu-ETM amorphous alloy; the Cu-ETM amorphous alloy comprises Cu and ETM (early transition metal) elements; the atomic percent chemical composition of the Cu-ETM amorphous alloy is Cu<100>--AlETM, wherein the value of a is more than or equal to 0 and less than or equal to 25, the value of b is more than or equal to 25 and less than or equal to 75, ETM is Zr<1-x-y>Hf<x>Ti<y>, the value of x is more than or equal to 0 and less than or equal to 1, and the value of y is more than or equal to 0 and less than 0.5. The preparation method of the amorphous matrix composite material comprises the following steps: firstly, preparing an ETM-O intermediate alloy; secondly, determining the chemical composition of the whole composite material with the aim that a Cu<100>--AlETM amorphous matrix contains ETMO<2> oxide precipitates with different volume fractions, preparing alloy raw materials with the ETM-O intermediate alloy, industrial pure ETM, Cu and Al as raw materials, and obtaining alloy ingots with uniform components through a non-consumable electric arc melting method; and finally, regulating and controlling nucleation and growth kinetics of an oxide precipitated phase by changing a cooling speed range by utilizing a melt rapid quenching and copper mold suction casting technology, so as to finally obtain the amorphous matrix composite material. Nanometer oxide particles with different densities and sizes are dispersed and distributed on the obtained amorphous matrix composite material, and the precipitate / matrix interface bonding is good.

Owner:DALIAN UNIV OF TECH

Optical toughened glass

The invention provides an optical toughened glass. The glass comprises SiO2, CaO, MgO, Al2O3, Na2O, B2O3, K2O, BaO, MoO3, CdO, La2O3, Gd2O3, Y2O3 and Yb2O3. After expensive Ta2O5 is discarded, the glass having excellent glass stability, high refractive index and low chromatic dispersion is obtained through adopting the co-existence form of the La2O3, Gd2O3, Y2O3 and Yb2O3, MoO3 can reduce the generation amount of nickel sulfide stones, and MoO3 and CdO are mixed to inhibit smoke generated in the glass production process, so the safety in the glass production process is ensured, and the self-explosion possibility of the glass is reduced.

Owner:重庆品信玻璃有限公司

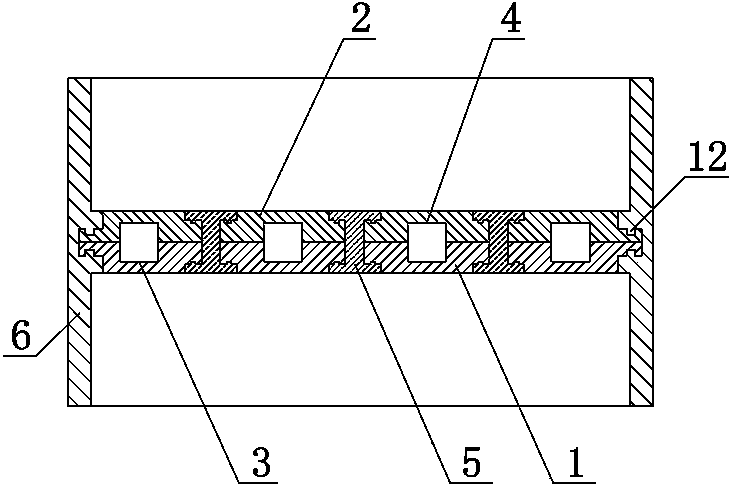

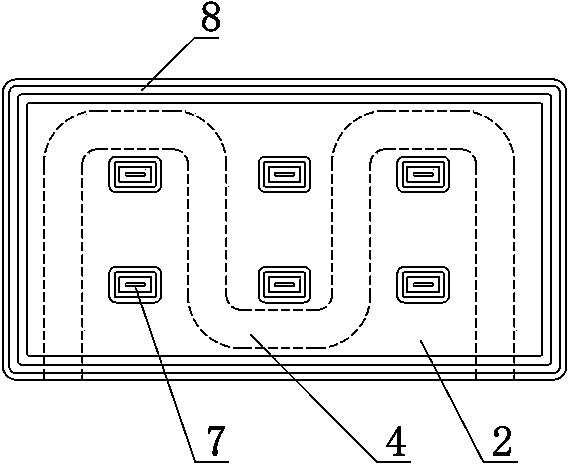

Totally-sealed cooling chamber

ActiveCN104334005APrevent "bulge" separation phenomenonImprove meltabilityCooling/ventilation/heating modificationsHigh volume manufacturingDie casting

The invention relates to a totally-sealed cooling chamber. The totally-sealed cooling chamber comprises a lower chamber (1), an upper chamber (2), a locking block (5) and a reinforcing coaming (6), wherein a lower chamber cooling channel (3) is formed in the lower chamber (1), while an upper chamber cooling channel (4) is formed in the upper chamber (2); the lower chamber cooling channel (3) and the upper chamber cooling channel (4) are combined to form a cooling channel; a plurality of T-shaped holes (7) are symmetrically formed in the lower chamber (1) and the upper chamber (2), respectively; the T-shaped holes (7) are filled with an aluminum alloy by use of a die-casting die and a die-casting process so that locking blocks (5) can be formed; the lower chamber (1) and the upper chamber (2) are integrally and closely locked together by use of the locking blocks (5); the reinforcing coaming (6) is die-casted on the edges of the four sides of the lower chamber (1) and the upper chamber (2) by use of the die-casting die and the die-casting process. The totally-sealed cooling chamber has the advantages of good sealing effect, good inter-fusibility, short production period and suitability for large-batch production.

Owner:CHENGDU TIGER MICROWAVE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com