Amorphous matrix composite material and preparation method thereof

A composite material and amorphous technology, applied in the field of new composite materials and their preparation, can solve the problems of non-wetting, difficulty in obtaining nano-oxide particles, large difference in specific gravity, etc., and achieve the effect of simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

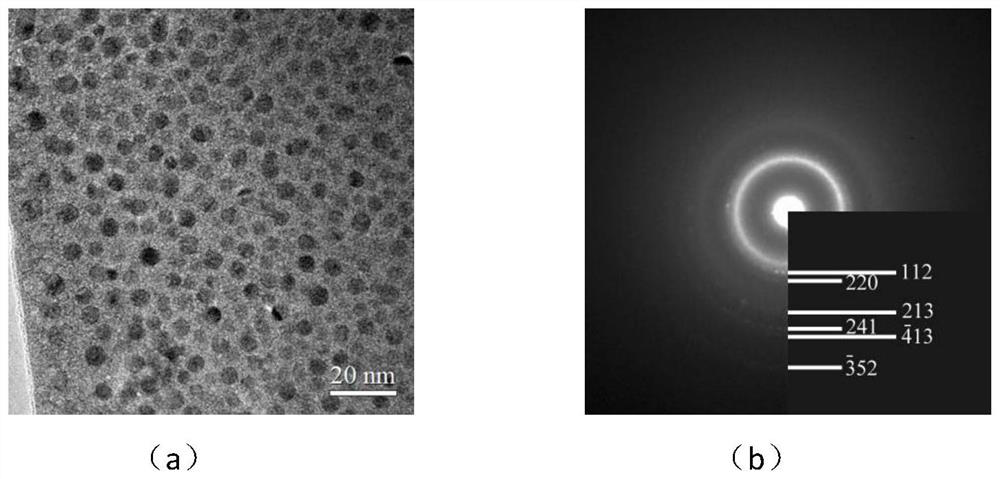

[0022] Example 1ZrO 2 Dispersed Cu-Zr Amorphous Matrix Composite (ETM=Zr)

[0023] Step 1. Preparation of Zr-O master alloy

[0024] Take Cu 50 Zr 50 30% volume fraction of ZrO distributed on the amorphous matrix 2 The precipitate is the target amorphous matrix composite material, and the atomic percentage content of the O component in the ETM-O master alloy is determined to be 35%, which is converted into a weight percentage. Using sponge Zr (>99%) and ZrO 2 (>99%) as raw material, weigh and prepare Zr-O master alloy. Mix the raw materials and place them in a water-cooled copper crucible of a non-consumable arc melting furnace, then evacuate to 10Pa, fill in an industrial pure Ar atmosphere of 0.01MPa for melting, and the working current of the arc melting is 100A; then put the alloy ingot up and down Flip over and repeat the smelting process for 3 times to obtain an intermediate alloy ingot with uniform composition. The weight loss rate of the alloy before and after sm...

Embodiment 2Z

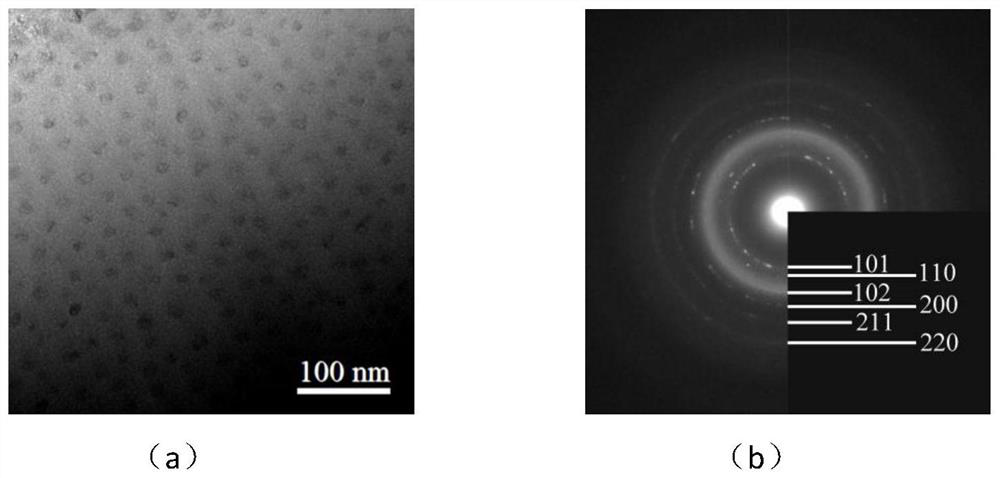

[0028] Example 2ZrO 2 Dispersed Zr-Cu-Al Amorphous Matrix Composite (ETM=Zr)

[0029] Step 1. Preparation of Zr-O master alloy

[0030] Take Cu 35 Al 15 Zr 50 15% volume fraction ZrO distributed on the amorphous matrix 2 The precipitate is the target amorphous matrix composite material, and the atomic percentage content of the O component in the ETM-O master alloy is determined to be 20%, which is converted into a weight percentage. Using sponge Zr (>99%) and ZrO 2(>99%) as raw material, weigh and prepare Zr-O master alloy. Mix the raw materials and place them in a water-cooled copper crucible of a non-consumable arc melting furnace, then evacuate to 10Pa, fill in an industrial pure Ar atmosphere of 0.01MPa for melting, and the working current of the arc melting is 100A; then put the alloy ingot up and down Flipping, repeated smelting in this way for 3 times, to obtain an intermediate alloy ingot with uniform composition, the weight loss of the alloy before and after sm...

Embodiment 3

[0034] Example 3HfO 2 Dispersed Hf-Cu Amorphous Matrix Composite (ETM=Hf)

[0035] Step 1. Preparation of Hf-O master alloy

[0036] Take CuHf 2 10% volume fraction of HfO distributed on the amorphous substrate 2 The precipitate is the target amorphous matrix composite material, and the atomic percentage content of the O component in the master alloy of the ETM-O combination is determined to be 25%, which is converted into a weight percentage. Using sponge Hf (>99%) and HfO 2 (>99%) as the raw material, weigh and prepare the Hf-O master alloy. Mix the raw materials and place them in a water-cooled copper crucible of a non-consumable arc melting furnace, then evacuate to 10Pa, fill in an industrial pure Ar atmosphere of 0.01MPa for melting, and the working current of the arc melting is 100A; then put the alloy ingot up and down Flipping, repeated smelting in this way for 3 times, to obtain an intermediate alloy ingot with uniform composition, the weight loss rate of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com