Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Improved erosion and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

The invention relates to a preparation method of aluminum oxide metal ceramic reinforced iron-based composite, namely, aluminum-oxide-based metal ceramic is used as a structural framework and one of effective components to prepare metal ceramic iron-based composite, which is consistent in structure, even in metal phase distribution, high in mechanical performance, and high in wear resistance, under certain pressure by melt casting and further processing. The preparation method includes the steps of firstly, preparing aluminum oxide metal ceramic framework base pretreated by activated Si into surface-modified prefabricated ceramic part with a silk-screen-shaped pore structure by high-temperature sintering; secondly, preparing a pouring sand module; thirdly, placing the pouring sand module into a casting sand box for pretreating, pouring, vacuumizing, and allowing iron-based molten metal to fully permeate into pores of the prefabricated ceramic part to form a rigid integrity; and fourthly, performing heat treatment and air cooling to obtain the iron-based composite with closely combined aluminum oxide metal ceramic and iron base.

Owner:北京康盛宏达科技有限公司

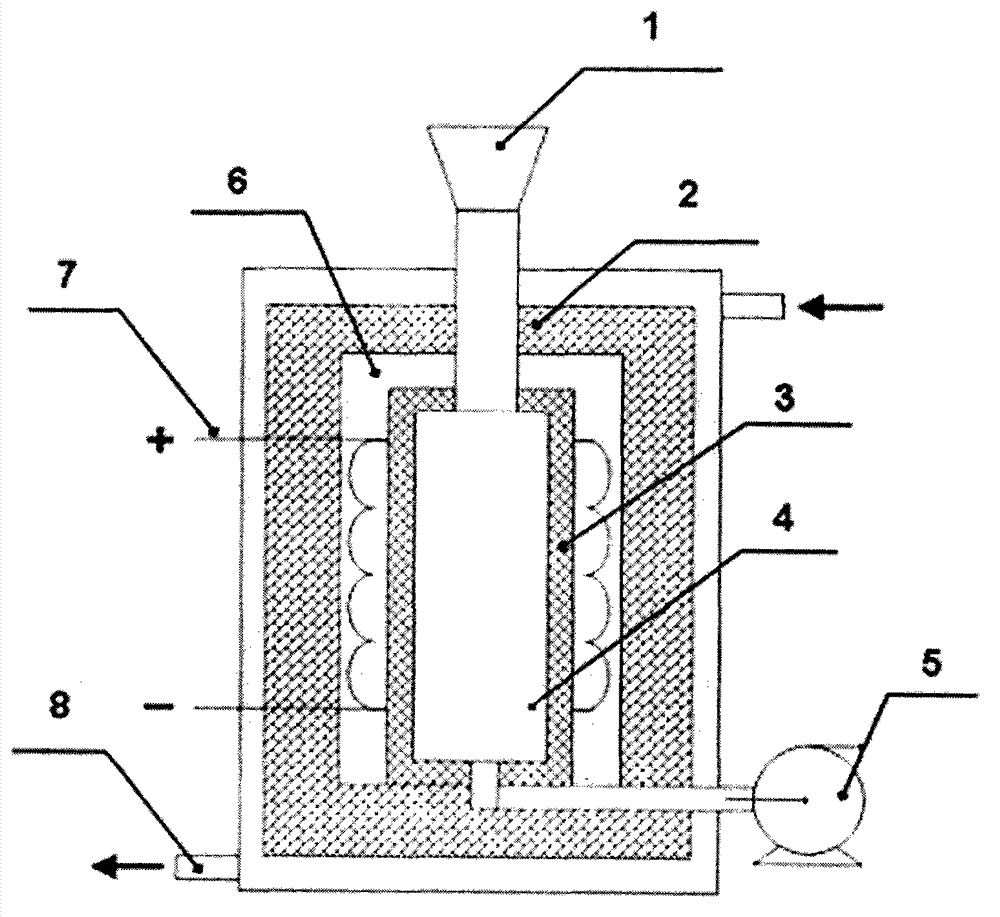

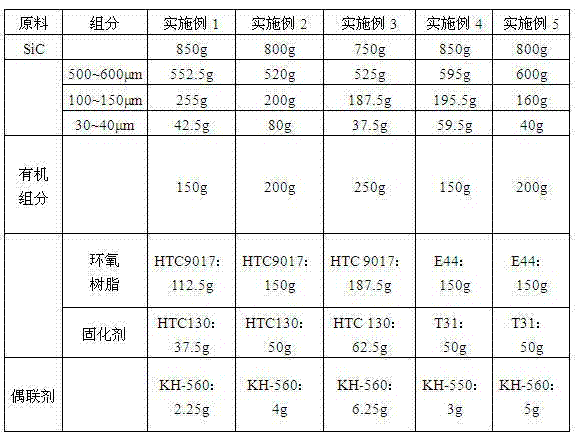

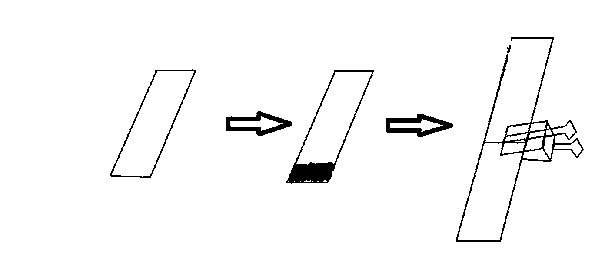

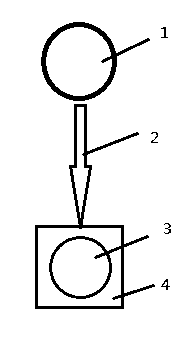

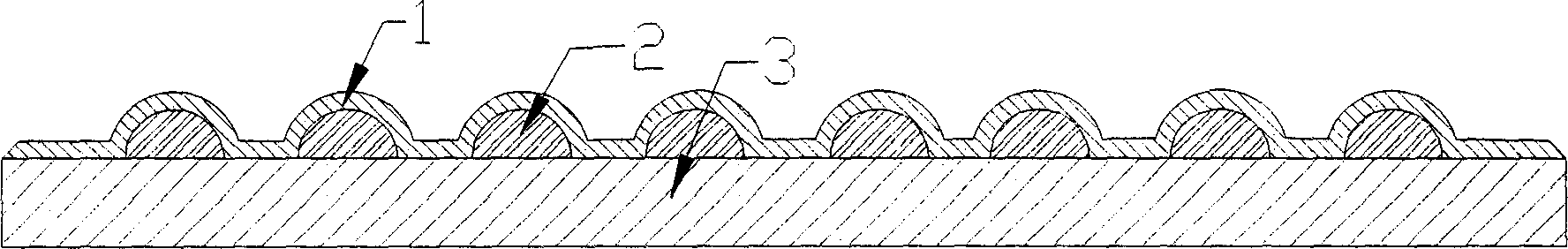

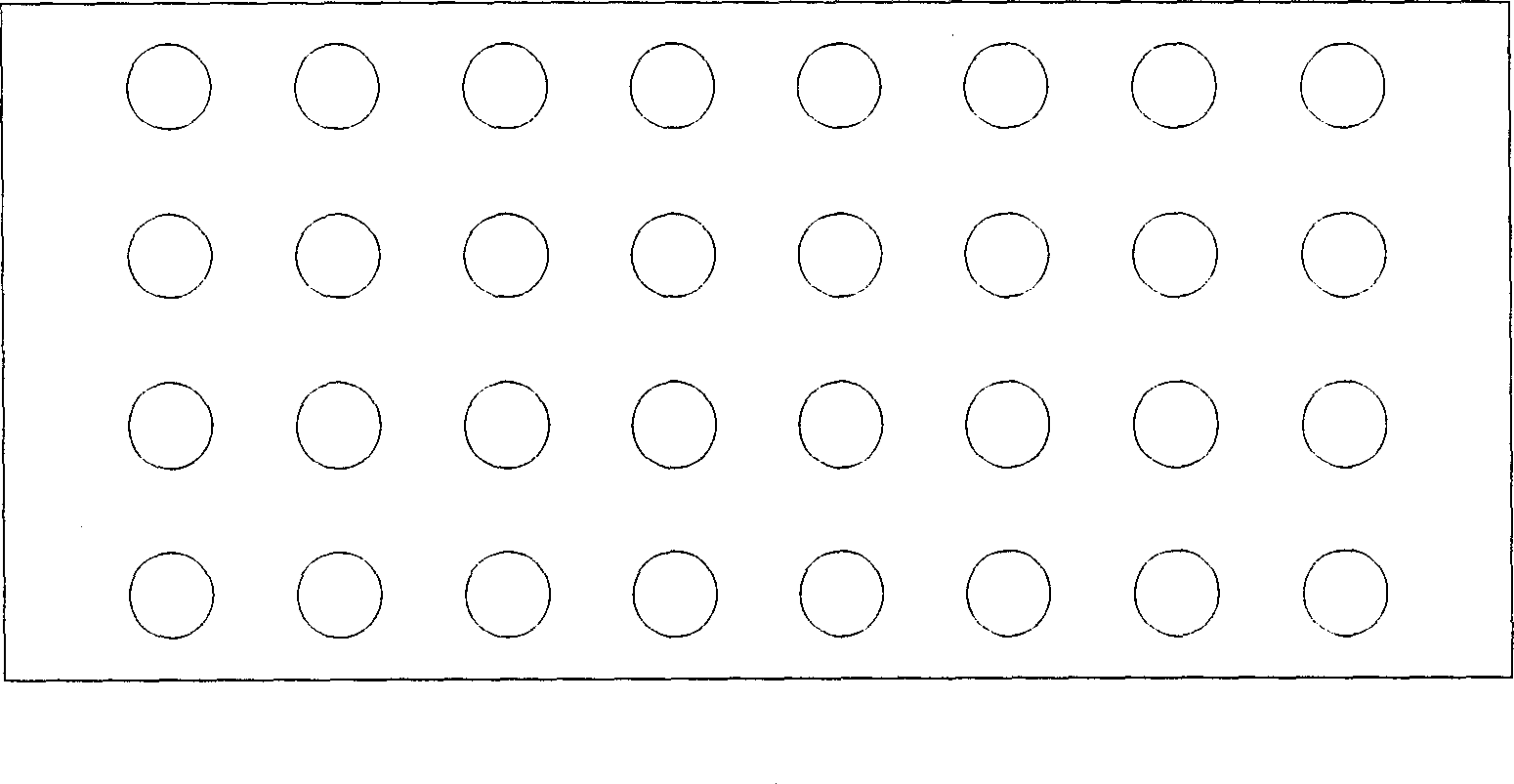

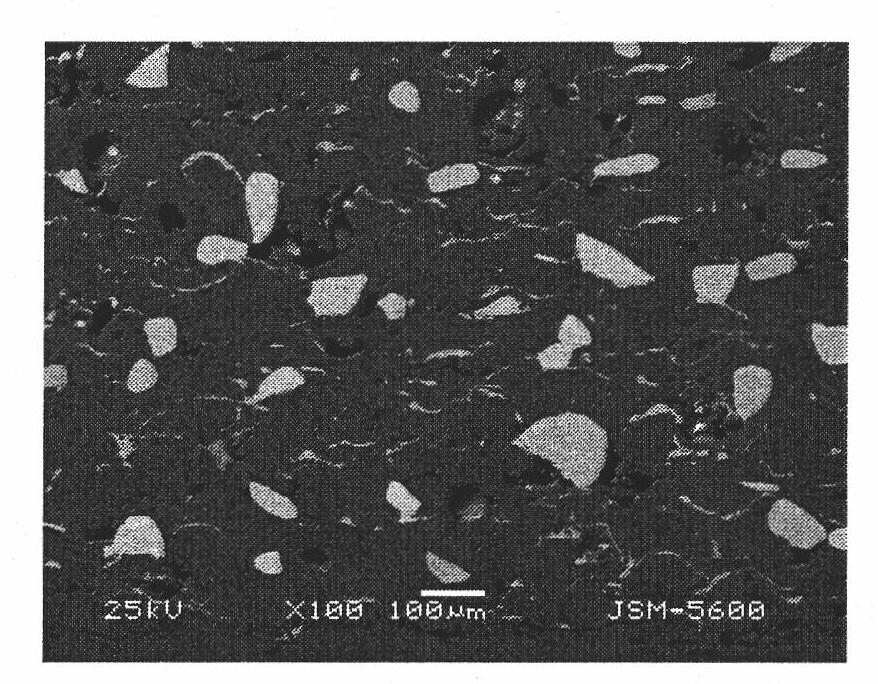

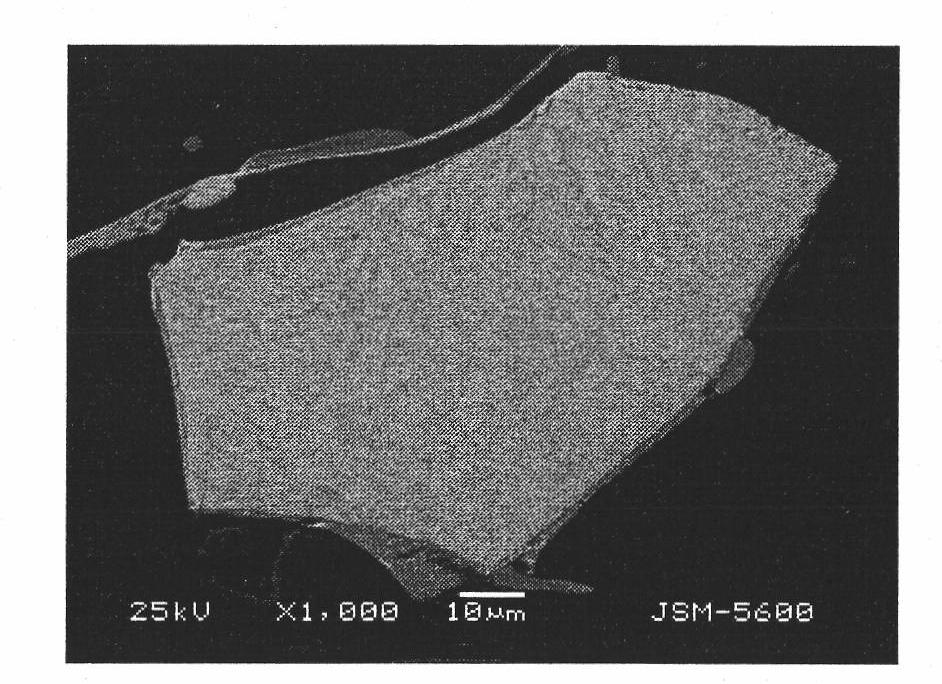

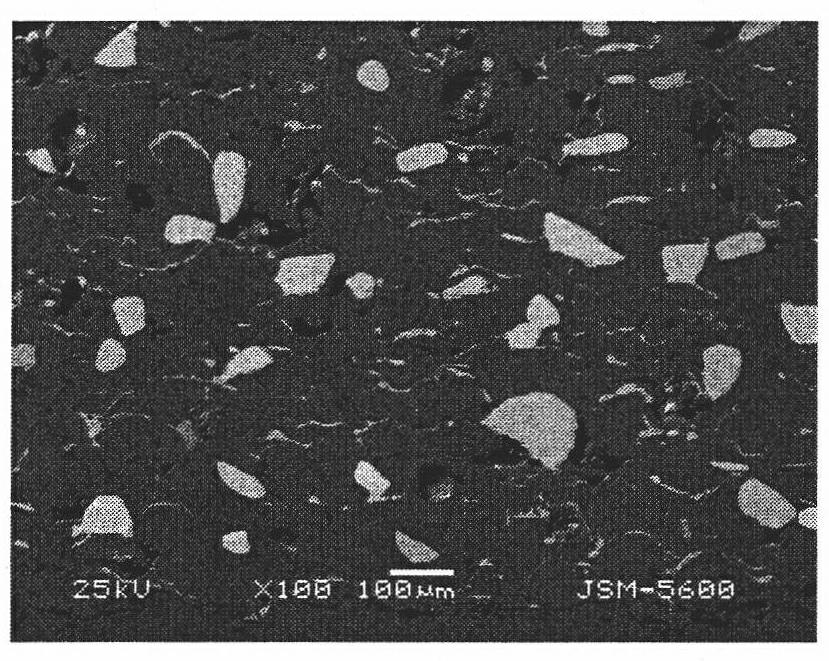

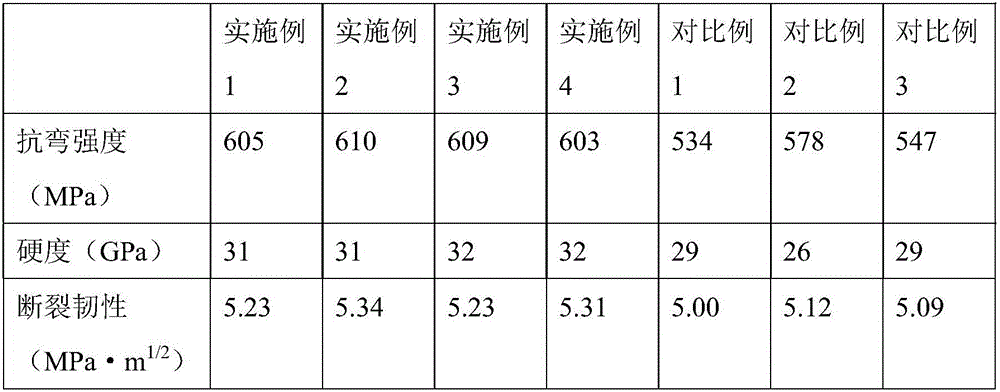

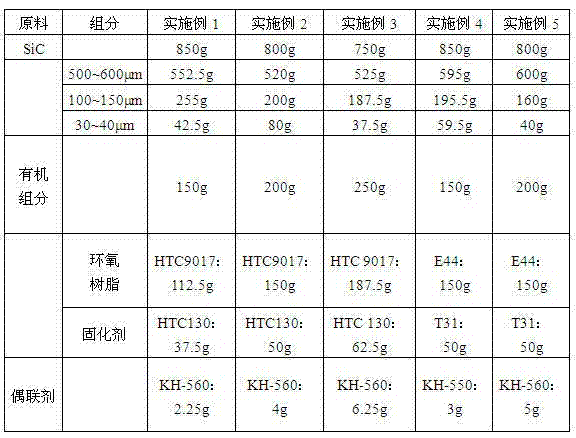

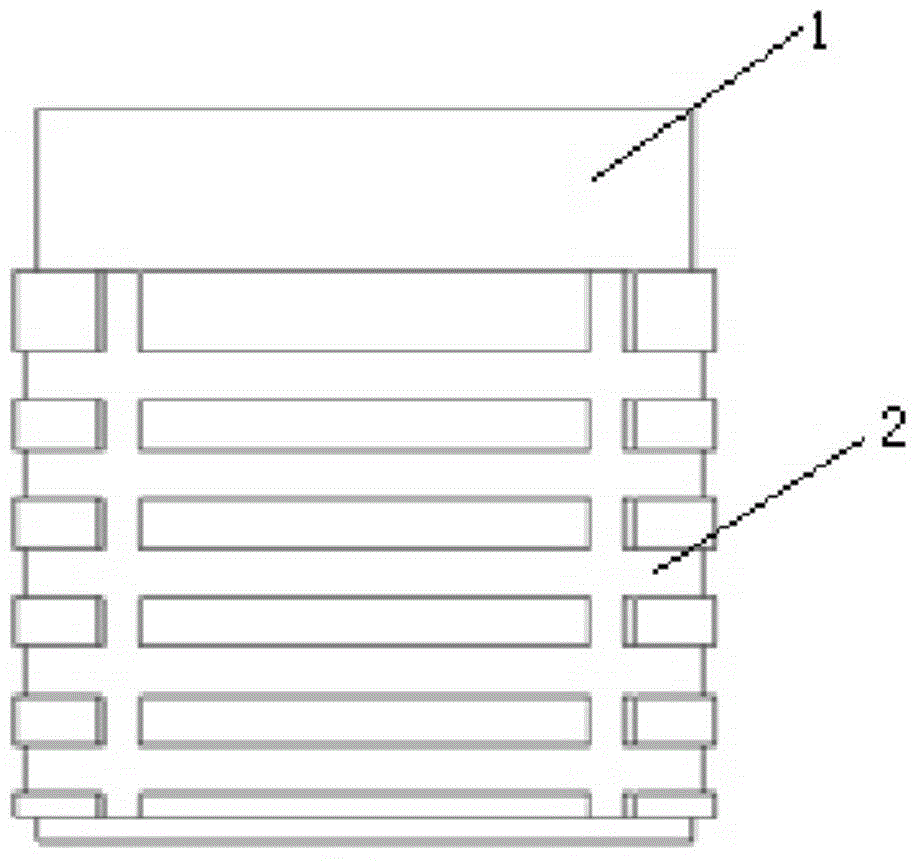

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Temperature-resistant wear-resistant coating and preparation method thereof

InactiveCN103834259AImprove temperature resistanceGood adhesionEpoxy resin coatingsWear resistantSlurry

The invention provides a temperature-resistant wear-resistant coating and a preparation method thereof, belongs to the technical field of two-component epoxy adhesives, and mainly solves the problems of poor temperature resistance and wear resistance of coatings in the prior art. The temperature-resistant wear-resistant coating is mainly composed of A and B two components, the component A comprises the following components: 10%-30% of epoxy resin, 5%-30% of modified epoxy resin, 3%-10% of a diluent, 10%-30% of silicon carbide, 1%-5% of fumed silica and 40%-70% of a high alumina ball; the component B comprises the following components: 20%-30% of a curing agent, 0%-3% of a promoter, 1%-5% of a silane coupling agent, 10%-30% of the silicon carbide, 1%-5% of the fumed silica and 40%-60% of the high alumina ball; the weight ratio of component A to component B is 4:1. The temperature-resistant wear-resistant coating has the advantages of good erosion wear resistance, simple coating process and low cost, is mainly used on the surface of a workpiece working in slurry erosion wear working conditions, and is also used in corrosion and wear surface repair.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Anticorrosion composite nano paint and its preparing process

InactiveCN1346860AHigh hardnessImprove mechanical propertiesCoatingsGranularityNanocomposite coating

An anticorrosion composite nano-paint contains film forming agent, dispersing liquid, antisticking agent and SiO2 colloid, where the granularity of SiO2 is 10-20 nm. Its coated layer is characterized by high hardness, adhesion and toughness, and excellent corrosion and abrasion resistance.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing Ni-based alloy-TiB2 nano coating

ActiveCN103589984AImprove and enhance the comprehensive performanceAccelerated corrosionMolten spray coatingNano structuringWear resistance

The invention discloses a method for preparing a Ni-based alloy-TiB2 nano coating. Powder is sprayed on a base material through supersonic speed flame so as to form a nano-structured coating, wherein the powder comprises two components, namely, 60-80 percent by weight of Ni-based alloy powder, and 20-40 percent by weight of TiB2. The nano coating prepared according to the technical scheme is dense in tissue and uniform in distribution, is of a certain flat layered distribution structure, and is not clear in boundary distribution amount spraying ions. In addition, the prepared nano coating further contains special or elliptical unmelted or semi-melted grains, and due to such a structure, the prepared nano coating has higher bonding strength and better abrasion resistance. Therefore, the comprehensive application property of the protection coating is improved, and the high-temperature corrosion resistance and the erosive wear resistance of 'four tubes' of a boiler are further improved.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Cobalt-based alloy powder for laser remanufacturing of housing of rolling mill

ActiveCN102220522ALow melting pointSolve and improve formabilityMetallic material coating processesLaser beam welding apparatusRolling millCorrosion

The invention discloses cobalt-based alloy powder for laser remanufacturing of the housing of a rolling mill, which is characterized by comprising the following components in percentage by mass: 0.8 to 1.4 percent of C, 26 to 32 percent of Cr, 3 to 6 percent of W, 0.6 to 1.4 percent of Mo, 1.2 to 1.8 percent of Ni, 0.2 to 0.6 percent of Mn, 0.8 to 2.4 percent of Si, 1.2 to 4.8 percent of Fe, 0.4 to 1.6 percent of B, 0.2 to 0.6 percent of Ce, 0.2 to 0.6 percent of Hf and the balance of Co. The cobalt-based alloy powder is suitable for the laser deposition of large-area ineffective working face of the housing of the rolling mill, and by depositing the alloy powder, the housing of the rolling mill can be reused and the oxidization resistance, corrosion resistance and washing corrosion resistance of the housing of the rolling mill are improved. The online repair problem of the housing of the rolling mill is solved effectively.

Owner:SHENYANG DALU LASER TECH

Method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles

InactiveCN101580939AImprove processing qualityImprove coating qualityMolten spray coatingHeat inorganic powder coatingSurface engineeringHardness

The invention relates to surface engineering technique in technical fields such as design materials, electrical power, metallurgy, machine and the like, in particular to a method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles. The metallic matrix composite coating reinforced with tungsten carbide ceramics particles (WCP / NiCrBSi) is prepared on the surface of mild steel base material based on the characteristics of high hardness, wear resistance, erosion resistance of the tungsten carbide ceramics material and fine self-fluxing nature, wettability and plasma spraying technology of the NiCrBSi alloy, and the property of wear and tarnish resistance is improved. The technique process of preparing WCP / NiCrBSi composite material coating is as follows: coating design; sifting dusty spray; mixing the powder according to certain ratio; superficial treatment of base material; controlling plasma spraying parameter; preparing WCP / NiCrBSi coating.

Owner:JILIN UNIV

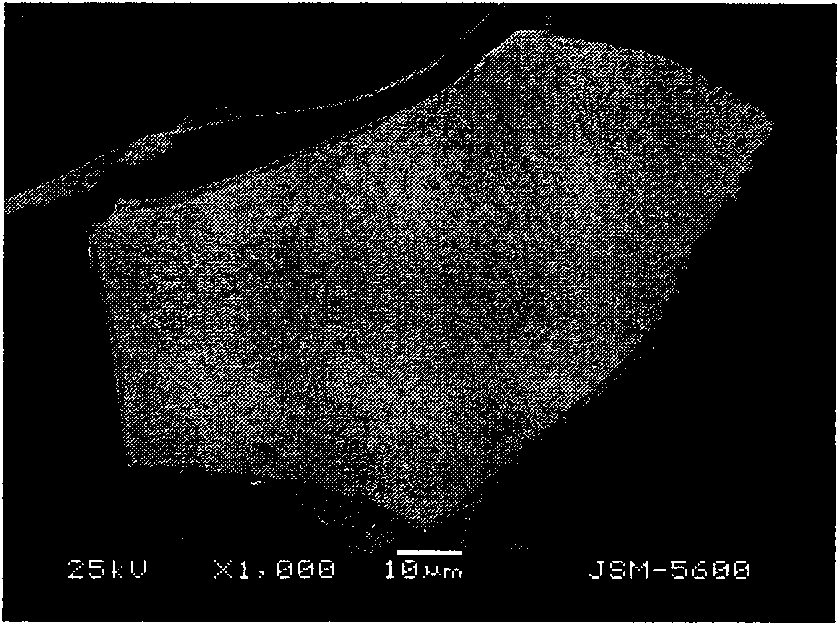

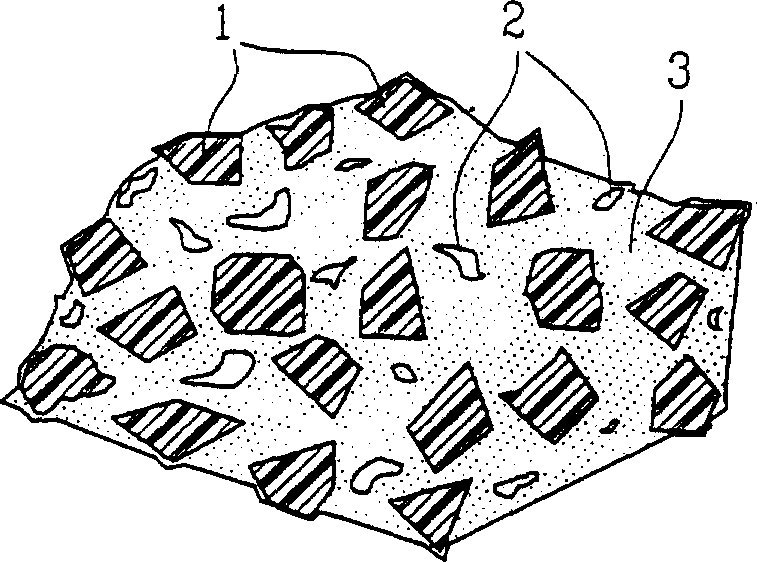

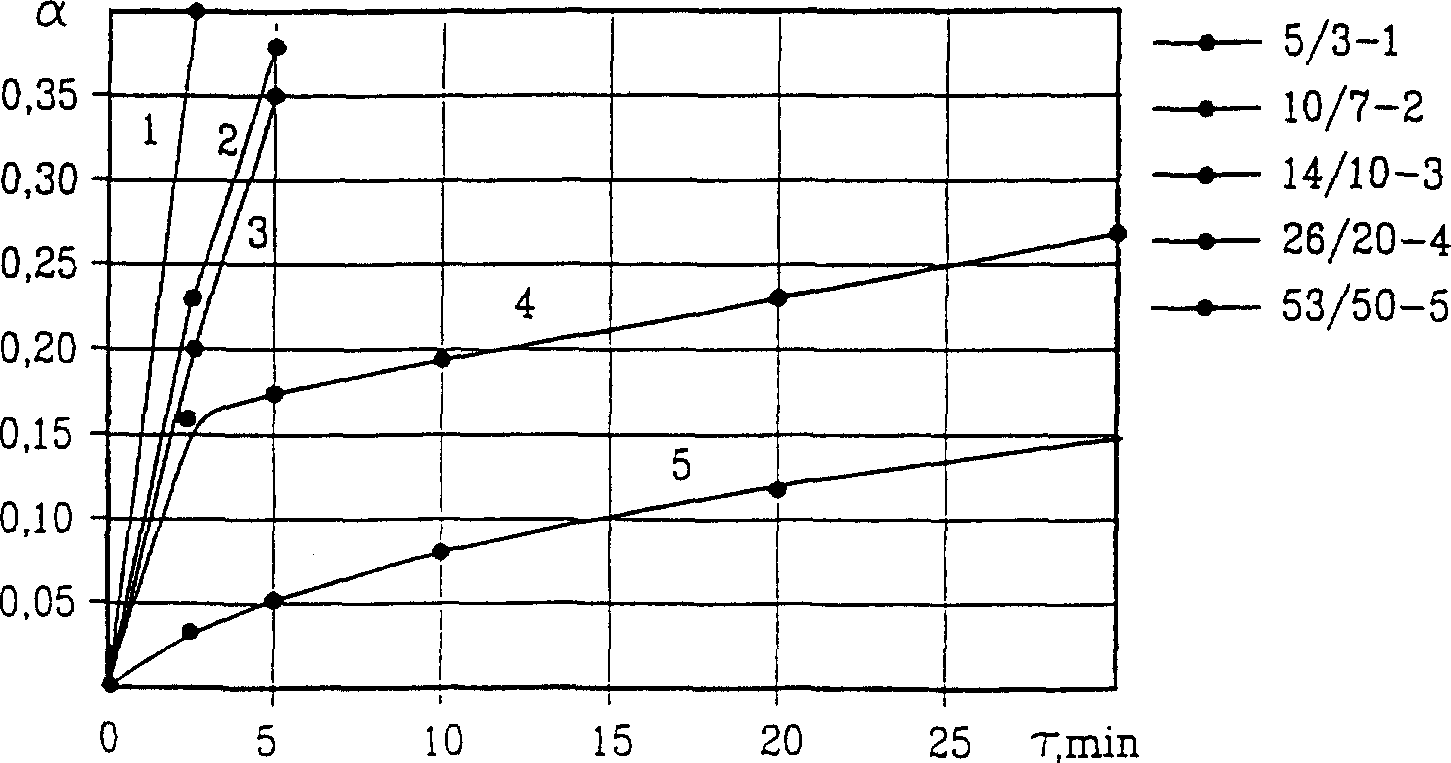

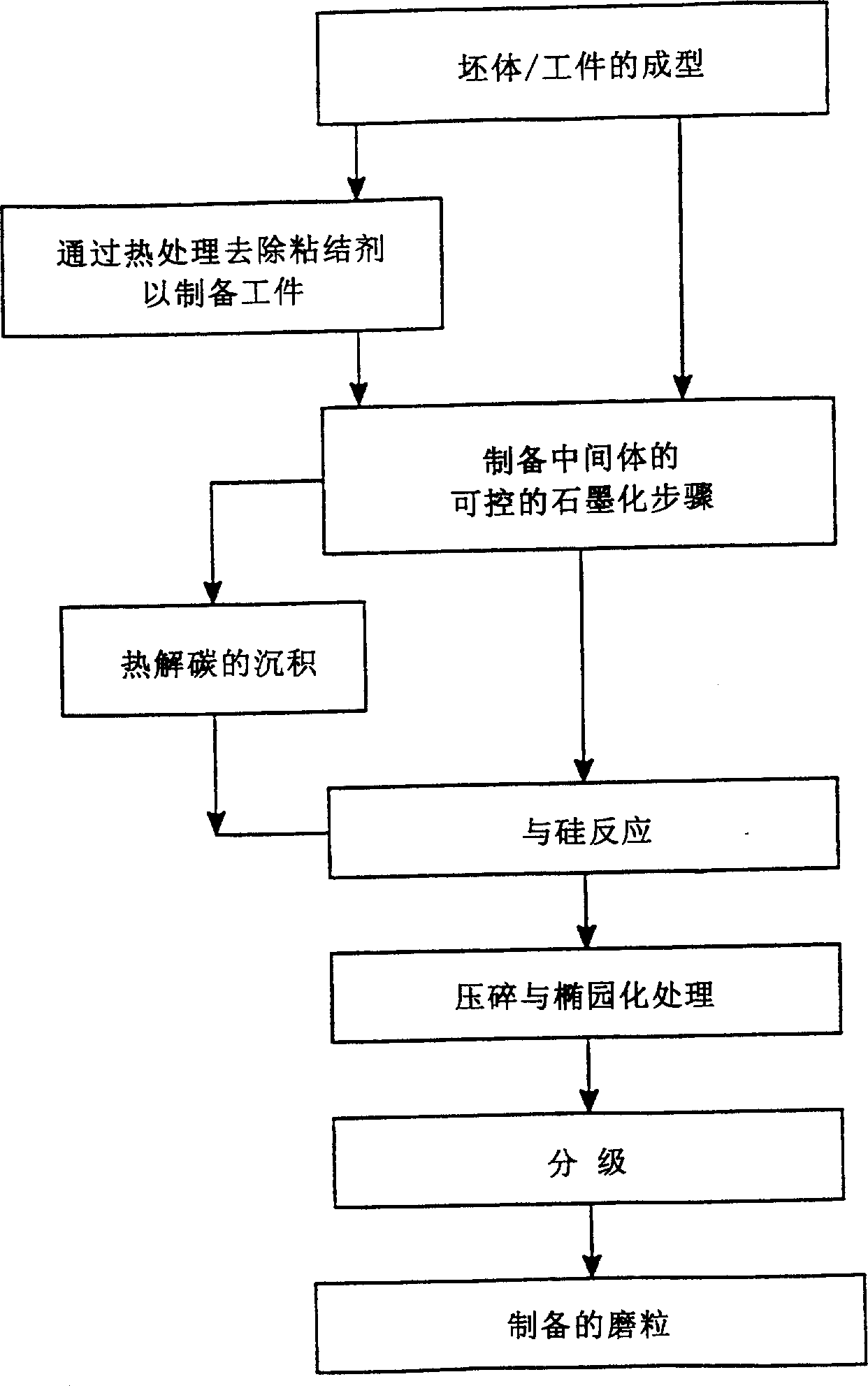

Method for producing abrasive grains and abrasive grains produced by this method

InactiveCN1272100AImprove wear resistanceHigh Young's modulusOther chemical processesBearing componentsCarbideSilicon

The present invention relates to a method for producing abrasive grains. According to the invention the method is characterised by the steps of manufacturing a polycrystalline body comprising diamond particles in a matrix of silicone carbide and silicon, and crushing the polycrystalline body into grains. The invention also relates to abrasive grains produced by the method.

Owner:FRENTON

Method for preparing erosion-wear-resisting composite coating

InactiveCN1814852AAvoid peelingExtended service lifeMolten spray coatingArc welding apparatusSurface engineeringAlloy

This invention relates to a surface engineering field used in the protection of power station boiler pipelines including: spot welding a layer of hardness alloy lattice on a cleaned metal matrix with self-protection metal core weld sticks, in which, the weld current is 180-220A, voltqge is 18-22V, welding point space is 2-5mm, diameter of the welding point is 4-5mm and the height is 2-3mm, the welded metal matrix is sprayed with sand to eliminate the oxidized skins, rust and the old coating and expose the metallic brightness then a compound layer of anti-erosion and anti-abrasion is sprayed on the matrix by an arc spraying method.

Owner:BEIJING UNIV OF TECH

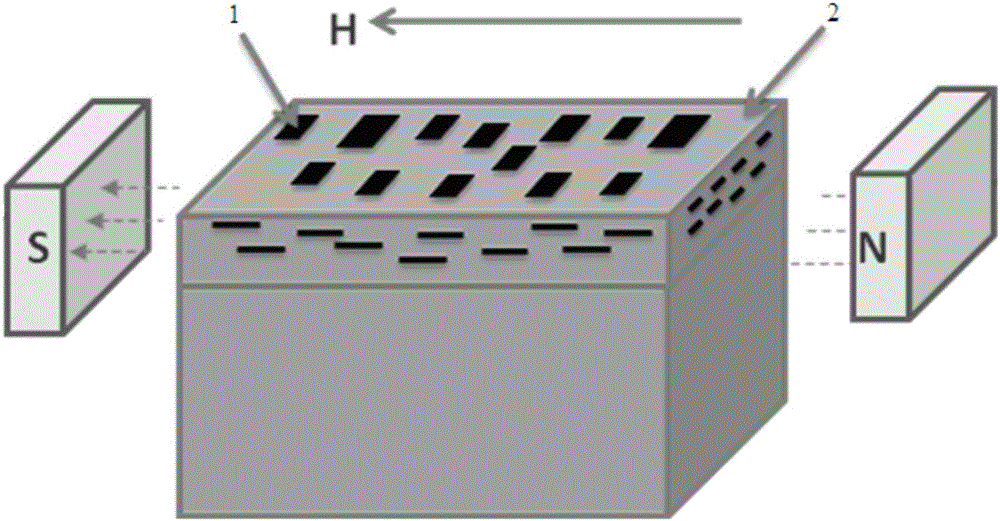

Preparation method of magnetic boron nitride nanosheet/polyurethane composite material having ordered surface microstructure

InactiveCN105111723AImproved erosion and wear resistanceSimple processMagnetite NanoparticlesBoron nitride

The invention relates to a preparation method of a magnetic boron nitride nanosheet / polyurethane composite material, in particular to a preparation method of magnetic boron nitride nanosheet / polyurethane composite material having an ordered surface microstructure. The invention aims to provide the preparation method of the magnetic boron nitride nanosheet / polyurethane composite material having the ordered surface microstructure. The preparation method includes: 1, preparing intercalation boron nitride; 2, preparing boron nitride nanosheets; 3, preparing boron nitride nanosheets, to the surface of each which ferroferric oxide magnetic nanoparticles are carried; and 4, preparing the magnetic boron nitride nanosheet / polyurethane composite material having the ordered surface microstructure. The ordered composite material has excellent erosion wear resistance; compared with disorder boron nitride / polyurethane composite materials and pure polyurethane, the magnetic boron nitride nanosheet / polyurethane composite material has erosion wear resistance increased by 31.9% and 51.5%, respectively and is applicable to anti-erosion protective coatings. The magnetic boron nitride nanosheet / polyurethane composite material is applicable to processing and application of nanomaterials.

Owner:HARBIN INST OF TECH

Preparation method of hard particle reinforced impact-resistant and wear-resistant coating for machine-made sand

ActiveCN113235036AEnhanced erosion and wear resistanceHigh hardnessMolten spray coatingLiquid/solution decomposition chemical coatingPelletizingBonding strength

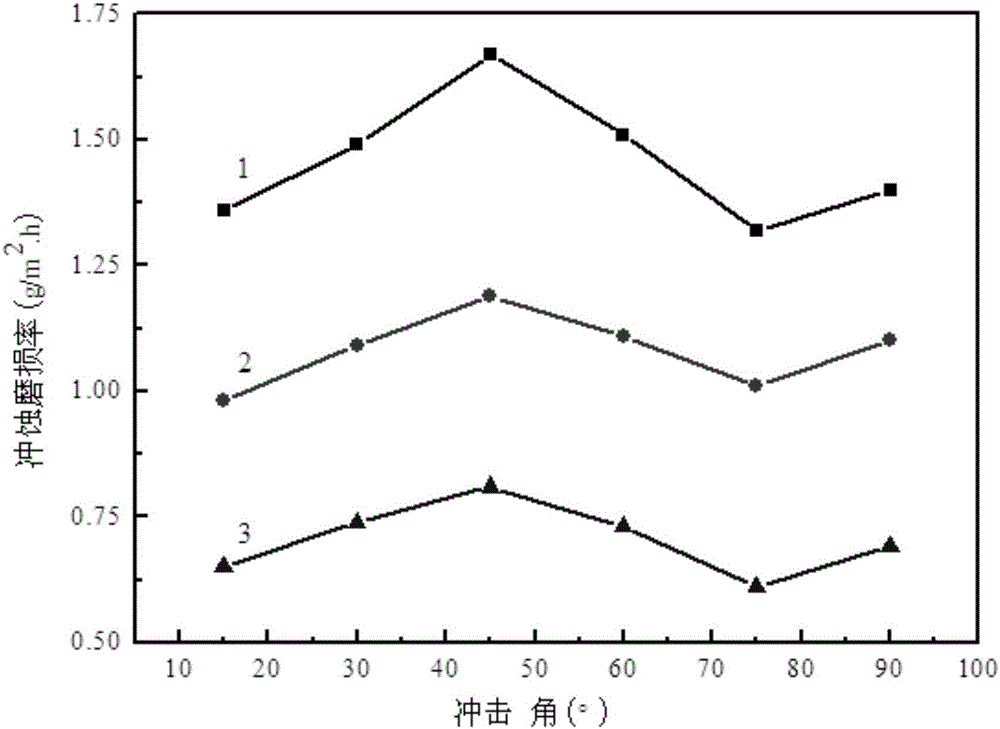

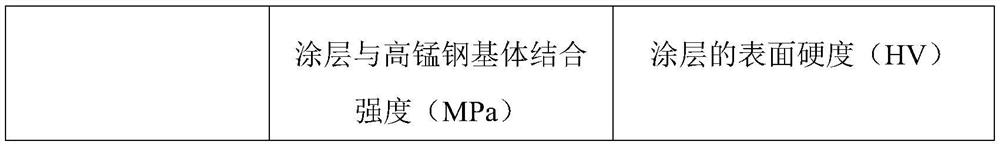

The invention discloses a preparation method of a hard particle reinforced impact-resistant and wear-resistant coating for machine-made sand, which comprises the following steps: firstly, preparing nano Al2O3 powder and pure Ni coated TiC powder, mixing NiCrBSi self-fluxing alloy powder, the nano Al2O3 powder and the pure Ni coated TiC powder through a plurality of additives to form mixed slurry, and then carrying out spray-drying granulation on the mixed slurry to obtain spherical granulated powder with the particle size of 30-120 [mu] m; and finally, coating the surface of a high manganese steel substrate with the granulated powder through a plasma spraying and laser remelting synchronous technology to form a wear-resistant coating through deposition, wherein pure Ni coated TiC is added into the NiCrBSi coating so as to enhance the erosive wear resistance of the coating. The nano Al2O3 is uniformly distributed on the whole of the coating by the method, so that the coating has higher hardness and better toughness at the same time; and the coating is prepared by the plasma spraying and laser remelting synchronous technology, so that the bonding strength between the coating and the substrate is relatively high.

Owner:江苏天沃重工科技有限公司 +1

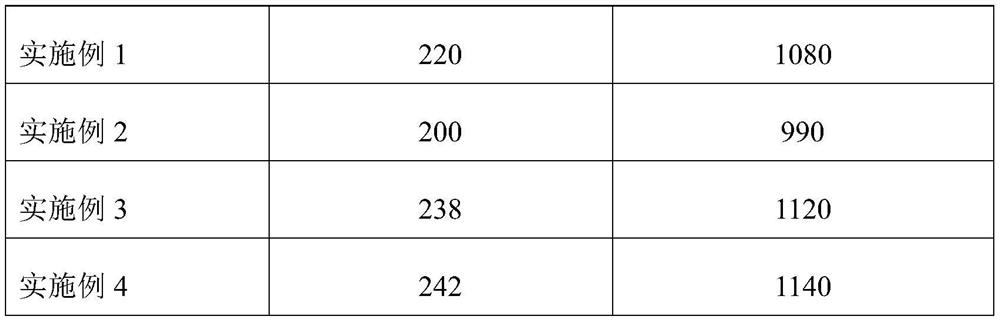

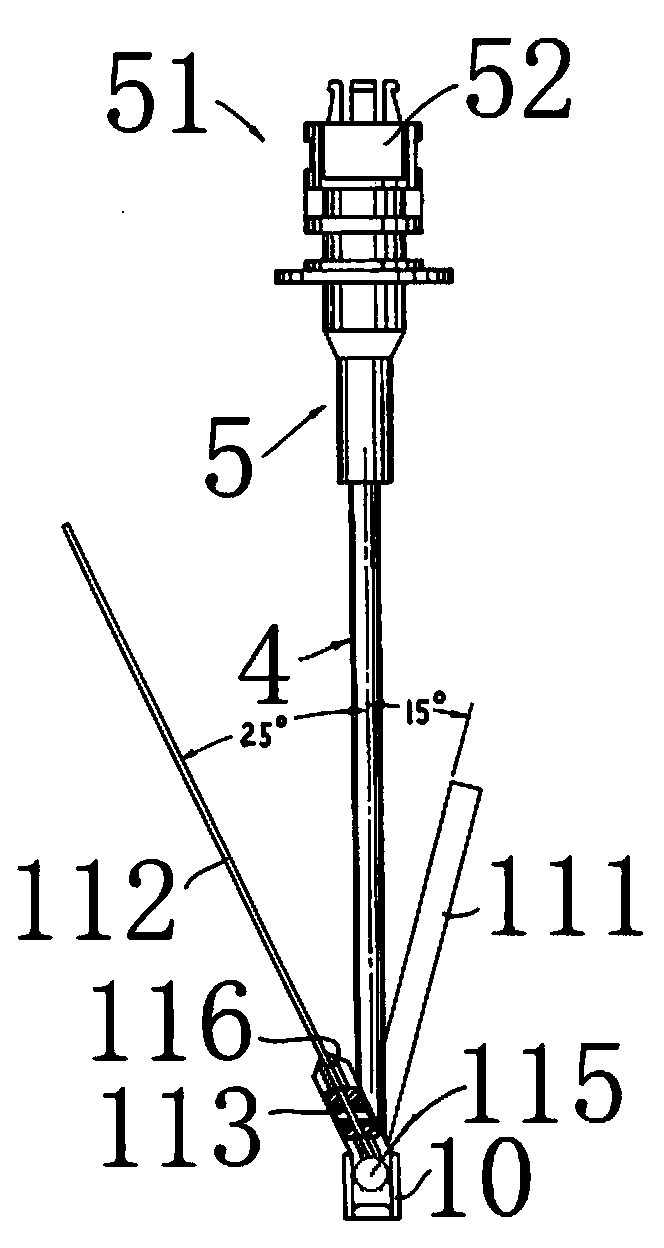

Method for manufacturing ceramic-based composite burners for field of coal chemical industry

The invention relates to a method for manufacturing ceramic-based composite burners for the field of coal chemical industry. The method includes: (1) design and machining of core moulds of ceramic burners; (2) structural design and shaping of prefabricated products of the ceramic burners; (3) preparation of interface layers of the prefabricated products of the ceramic burners; (4) densification of matrixes of the ceramic burners; (5) machining of the ceramic burners; (6) treatment of surface wear-resistant coatings of the ceramic burners. The method for manufacturing the ceramic-based composite burners for coal water slurry has the advantages of simple technical process, low cost and high rate of finished products. The burners manufactured according to the method have excellent erosion and abrasion resistance performance and are high in hardness, resistant to high temperature and high in toughness, and service lives of the burners are prolonged effectively.

Owner:XIAN AEROSPACE PROPULSION INST

Special cobalt-based wear-resistant alloy powder for laser remanufacture of drilling jar

ActiveCN102220580AImprove performanceHigh hardnessMetallic material coating processesLaser beam welding apparatusWear resistantAlloy

The invention relates to special cobalt-based wear-resistant alloy powder for laser remanufacture of a drilling jar. The powder is characterized by comprising the following components in percentage by weight: 0.6-1.0% of C, 32-36% of Cr, 7.5-9.5% of W, 3.0-3.6% of Mo, 0.8-1.2% of Ni, 0.2-0.6% of Mn, 2.0-2.4% of Si, 1.2-2.0% of Fe, 1.6-2.2% of B, 0.1-0.2% of Ce, 0.25-0.4% of Hf, 0.06-0.1% of Zr and the balance of Co. The cobalt-based wear-resistant alloy powder provided by the present invention is exclusively used in laser-cladding large-area failure working surfaces of the shaft journal of the drilling jar; and by cladding the alloy powder material, the drilling jar is restored to use, and the oxidation resistance, corrosion resistance and erosion and wear resistance are improved, thus effectively solving the difficulty in the repair of the failure shaft journal of the drilling jar.

Owner:上海大陆天瑞激光表面工程有限公司

High-oxidation-resistance non-cement bonded Al2O3-SiC-C refractory castable and preparation method thereof

ActiveCN112608138AReduce lossesImprove antioxidant capacityCeramic materials productionMetallic aluminumSlag

The invention discloses a high-oxidation-resistance non-cement-bonded Al2O3-SiC-C refractory castable and a preparation method thereof, and belongs to the field of amorphous refractory materials. The preparation method comprises the following steps: taking 50.0-60.0 wt% of brown fused alumina aggregate, 15.0-20.0 wt% of silicon carbide, 3.0-5.0 wt% of spherical asphalt, 5.0-10.0 wt% of corundum fine powder, 5.0-10.0 wt% of active alpha aluminum oxide micro powder, 3.0-5.0 wt% of mullite sol, 2.0-4.0 wt% of silicon micro powder, 0.5-2.0 wt% of lithium-containing aluminosilicate and 1.0-2.0 wt% of metal aluminum powder / monatomic silicon powder compound antioxidant as raw materials; and adding 0.20-0.30 wt% of a water reducing agent and 6-8wt% of water into the raw materials, carrying out stirring, pouring, molding, and subsequent heat treatment to obtain the high-oxidation-resistance non-cement-bonded Al2O3-SiC-C refractory castable for the large-scale blast furnace tapping channel. The prepared castable has extremely outstanding in oxidation resistance and excellent in normal-temperature / high-temperature mechanical property, thermal shock resistance and slag corrosion resistance, so that the safety coefficient and the service life of the tapping channel of the large blast furnace can be greatly improved, and the stable operation of the whole ironmaking process flow is guaranteed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

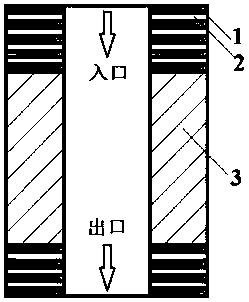

Method for preparing laminated ceramic nozzle based on stress wave theory

ActiveCN107586134AImprove erosion and wear resistanceGood erosion and wear resistanceBlast gunsYttriumTitanium carbide

The invention belongs to the technical field of nozzles, and in particular relates to a method for preparing a laminated ceramic nozzle based on a stress wave theory. The method is characterized in that the inlet of the nozzle comprises 9 layers of a laminated material, and the outlet of the nozzle comprises 7 layers of the laminated material. The laminated material comprises boron carbide, titanium carbide, aluminum oxide and yttrium oxide as raw materials, the mass of each the laminated material layer is calculated according to the mixed theoretic density and the thickness of the laminated material layer and the inner diameter and the outer diameter of the nozzle, the laminated material layers are spread in a graphite mould according to the laminating sequence and the number of the layers, the laminated material layers are prepressed layer by layer, and put into a vacuum sintering furnace, temperature is 1850-1900DEG C, pressure is 30-35MPa, and heat insulation time is 40-60min. Through the establishment of a mathematical model of the stress wave propagation theory, material parameters for reducing abrasive material impact can be selected, the anti erosion performance of the ceramic nozzle is improved, due to thermal expansion coefficient difference between the laminated layer at the inlet and the laminated layer at the outlet, residual compressive stress is formed at the outlet and the inlet of the nozzle after hot pressed sintering, and tensile stress of the nozzle during blasting process can be alleviated, so that the laminated ceramic nozzle prepared by the method hasgood erosive wear resistance and wear resistance, and the service life is greatly improved.

Owner:LUDONG UNIVERSITY

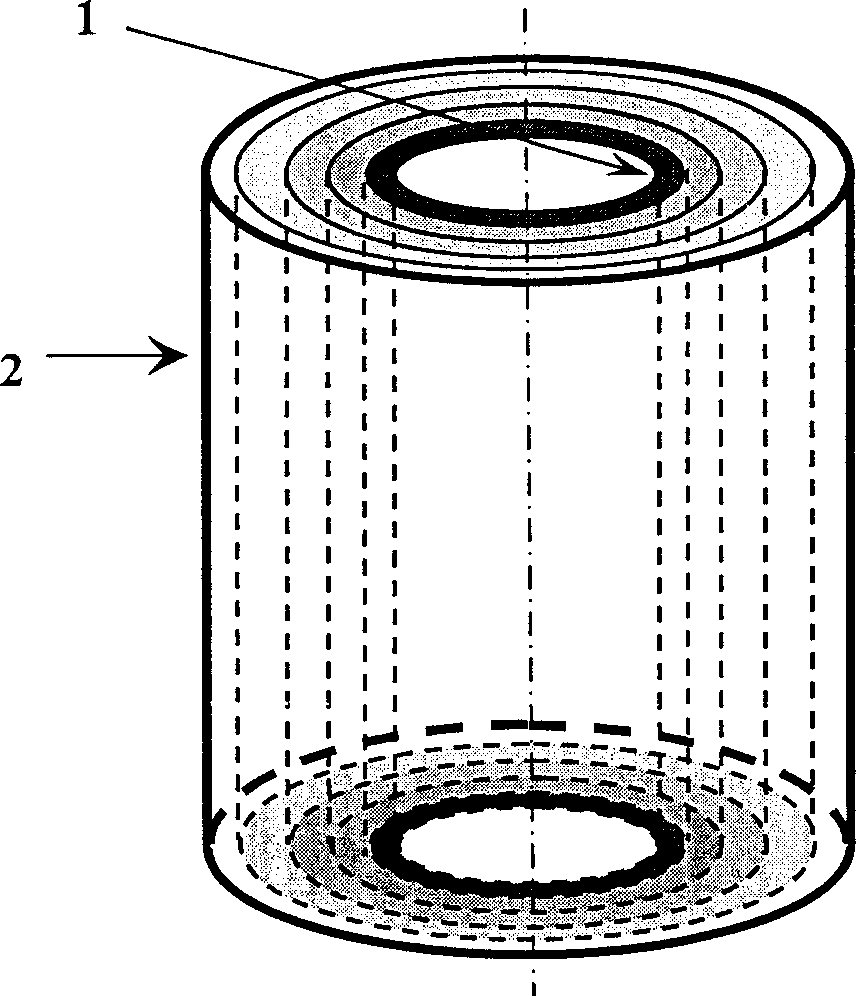

Radial gradient ceramic blast nozzle

InactiveCN1883882AImproved erosion and wear resistanceRelief of mechanical stressBlast gunsAbrasive blastingSolid solution

The invention relates to a radial gradient ceramic sandblast nozzle prepared by hot-pressing sintering process with SiC as matrix and (W, Ti)C solid solution as hardening constituent, which belongs to the field of advanced production technology. The radial gradient ceramic sandblast nozzle is multilayer structure, and the components change gradually along nozzle radial direction, that is: the content of (W, Ti)C solid solution increases gradually from the inner hole surface of sandblast nozzle to the external wall of sandblast nozzle. Because the radial gradient change of components in ceramic sandblast nozzle, residual compressive stress forms on the surface of inner hole, so that the stress on the surface of the inner hole is relieved, erosion-proof and wearable performance is improved, and service life is prolonged.

Owner:SHANDONG UNIV

Method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles

InactiveCN101580939BLow thermal conductivityEnhanced interface bindingMolten spray coatingHeat inorganic powder coatingSurface engineeringMetal matrix composite

The invention relates to surface engineering technique in technical fields such as materials, electrical power, metallurgy, machine and the like, in particular to a method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles. The metallic matrix composite coating reinforced with tungsten carbide ceramics particles (WCP / NiCrBSi) is prepared on the surface of mild steel base material based on the characteristics of high hardness, wear resistance, erosion resistance of the tungsten carbide ceramics material and fine self-fluxing nature, wettability and plasma spraying technology of the NiCrBSi alloy, and the property of wear and tarnish resistance is improved. The technique process of preparing WCP / NiCrBSi composite material coating is as follows: coating design; sifting dusty spray; mixing the powder according to certain ratio; superficial treatment of base material; controlling plasma spraying parameter; preparing WCP / NiCrBSi coating.

Owner:JILIN UNIV

Ceramic blast nozzle and preparing method thereof

A ceramic blast nozzle is produced by: using Al2O3 as basic material and (W, Ti) C solid solution as strengthening phase in thermal pressed sinteing process. It is gradient functional nozzle with multi-layered structure and gradient distribution of constituents. The content of the solid solution is reduced from inlet to outlet. Its mechanical performance is varied as the gradient distribution of constituents is regulated. The residual press stress at its inlet makes tension stress, which is caused by external loads, to be balanced. Through test, it is verified that the nozzle has more wear-resistant, longer service life, so that it can be widely used for surface treatment in machine building, petroleum, chemical, automobile, ship-building, metallurgical industries.

Owner:SHANDONG UNIV

Tube-like tungsten carbonate welding bar

InactiveCN1244431CImproved erosion and wear resistanceImprove wear resistanceArc welding apparatusWelding/cutting media/materialsAdhesiveAlloy

The present invention relates to a tungsten carbide electrode as wear-resisting surfacing material for strengthening tooth face and shirttail of steel tooth cone bit etc.. It includes electrode tube and filling material held in the electrode tube. The described filling material comprises sintered tungsten carbide granules in whnich its 20-30 mesh is 0-80% and 30-40 mesh is 20-100%, alloy powder and organic adhesive, and the cast tungsten carbide granules also can be added to the filling material, the filling material comprises 60-95% of sintered tungsten carbide granules, 0-35% of cast tungsten dcarbide granules, 2-6% of alloy powder and 0.5-2% of organic adhesive.

Owner:SINOPEC OILFIELD EQUIP CORP

Preparation method of titanium silicon carbide ceramic nozzle

The invention relates to a preparation method of a titanium silicon carbide ceramic nozzle. The preparation method comprises the following steps: optimizing raw materials of the titanium silicon carbide ceramic nozzle; using titanium silicon carbide powder and corundum as main raw materials; using Al-Ti alloy powder, phenolic resin, carbon tetraboride and silicon carbide as auxiliary materials. Meanwhile, in the process of preparation, large and small milling balls are used for mixed ball-milling; the suction filtration molding and a pre-boiling water quenching process are adopted to improve physical and chemical properties of prepared products; the prepared ceramic nozzle has good thermal stability, high compressive capacity, high corrosion resistance and difficult cracking.

Owner:CHENGDU YUYA TECH

Preparation method of integrated wear-resistant composite ceramic coal water slurry nozzle

ActiveCN103508725AHigh melting pointHigh hardnessGranular/pulverulent flues gasificationWear resistantComposite ceramic

The invention discloses an integrated wear-resistant composite ceramic coal water slurry nozzle. The integrated wear-resistant composite ceramic coal water slurry nozzle is made from following ingredients, by weight, 95 to 99 portions of Al2O3, 6 to 8 portions of TiC, 1 to 2 portions of WO3, 4 to 8 portions of a sintering aid, 0.1 to 0.2 portion of BeO, and 90 to 110 portion of absolute ethyl alcohol. A preparation method of the integrated wear-resistant composite ceramic coal water slurry nozzle comprises steps such as ball milling of raw materials, smashing and sieving, pressure forming, hot pressed sintering, and post processing. Formula of the integrated wear-resistant composite ceramic coal water slurry nozzle is reasonable; technology is advanced; erosive wear resistance of the ceramic coal water slurry nozzle is increased to more than 31 times larger than that of metal nozzles, and to more than 3 times larger than that of hard alloy nozzles; and thermal shock resistance of ceramic is improved. The integrated wear-resistant composite ceramic coal water slurry nozzle is capable of meeting with requirements of actual production preferably, service life of the integrated wear-resistant composite ceramic coal water slurry nozzle is longer than that of the metal nozzles and the hard alloy nozzles, and economic benefits of the integrated wear-resistant composite ceramic coal water slurry nozzle are higher than that of the metal nozzles and the hard alloy nozzles.

Owner:湖北群有长物环保科技有限公司

Epoxy resin coating layer having wear resistance and preparation method thereof

InactiveCN108300149AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsWear resistantNano al2o3

The invention aims to provide an epoxy resin coating layer having wear resistance and a preparation method thereof, wherein the wear-resistant epoxy resin coating layer is composed of a component A and a component B. The component A is composed of the following components in parts by weight: 30-60 parts of modified bisphenol A epoxy resin, 10-20 parts of an active diluent, 1-5 parts of nano alumina, 1-5 parts of nano titanium dioxide, 10-20 parts of silicon carbide and 0.5-1 part of a silane coupling agent; the component B is composed of the following components in parts by weight: 10-20 partsof a polyether amine curing agent, 5-10 parts of a polyamide curing agent, and 0.5-1 part of a curing accelerator.

Owner:河北清华发展研究院

Method for casting composite material inner cap

InactiveCN101274360AImproved erosion and wear resistanceEvenly distributedFoundry mouldsFoundry coresVacuum pressureSlurry

The invention provides a casting method of a composite internal cap, which relates to the casting method, in particular the casting method of a composite material which easily abrades transflux parts when transporting slag slurry. An intermediate frequency furnace is firstly used for smelting metal parent material to form molten metal, tungsten carbide and high carbon ferrochrome composite grains are evenly pre-arranged on the worn-out surface of the internal cap and then mold assembling and pumping for casting are carried out, and casting is carried out under 0.04 to 0.06 MPa of the vacuum pressure of a casting system. The working surface or the impact surface of the transflux parts prepared by the invention is the tungsten carbide grain reinforced composite material, while the non-working surface of the transflux parts is gray cast iron, low chromium cast iron, nodular cast iron or 35 cast steel, thereby having good impact resistant and abrasion resistant property; good metallurgical bonding is realized between the composite material layer and the interface of the metal matrix as well as the WC grains in the composite material layer and the interface of a basal body, and the distribution of the WC grains is even.

Owner:KUNMING UNIV OF SCI & TECH

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677BImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Freezing-tolerant crack-resistant coating for exhaust equipment

InactiveCN105949896AImprove hydrophobicityAccelerated corrosionAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a freezing-tolerant crack-resistant coating for exhaust equipment. The coating is made from the following raw materials: coal ash, an organosilicon-modified acrylic resin, toluene diisocyanate, zinc oxide, butyl cellulose, butyl acetate, an antifoaming agent BYK535, polyurethane, aluminium powder, silicon carbide powder, styrene, azodiisobutyronitrile, waterborne polyurethane, glycol, sodium dodecyl sulfate, a silane coupling agent a171, nanometer silica, a zirconia sol and a proper amount of absolute ethanol. The coating has preferable fouling resistance, alkali resistance, aging resistance and washing resistance, and has excellent freezing tolerance and crack resistance, and therefore can be used in the low-temperature environment. The equipment is protected, the service life of the equipment is prolonged, and thus the coating has high practical value.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

High-wearing engine cylinder sleeve imitating desert lizard cuticle

InactiveCN104963782AImproved erosion and wear resistanceImprove wear resistanceLayered productsCylinder headsSurface layerCuticle

The invention relates to the technical field of engine cylinder sleeve devices, and especially relates to a high-wearing engine cylinder sleeve imitating desert lizard cuticle. The cylinder sleeve comprises an engine cylinder sleeve body. The outer wall of the engine cylinder sleeve body is uniformly distributed with a plurality of concave cutting grooves. The inner wall surface of the engine cylinder sleeve body is adhered to a wearing layer. The surface layer formed by the wearing layer and the inner wall surface of the engine cylinder sleeve body is in a concave-convex shape. The high-wearing engine cylinder sleeve imitating desert lizard cuticle has high wear resistance.

Owner:泰州扬子江车辆部件有限公司

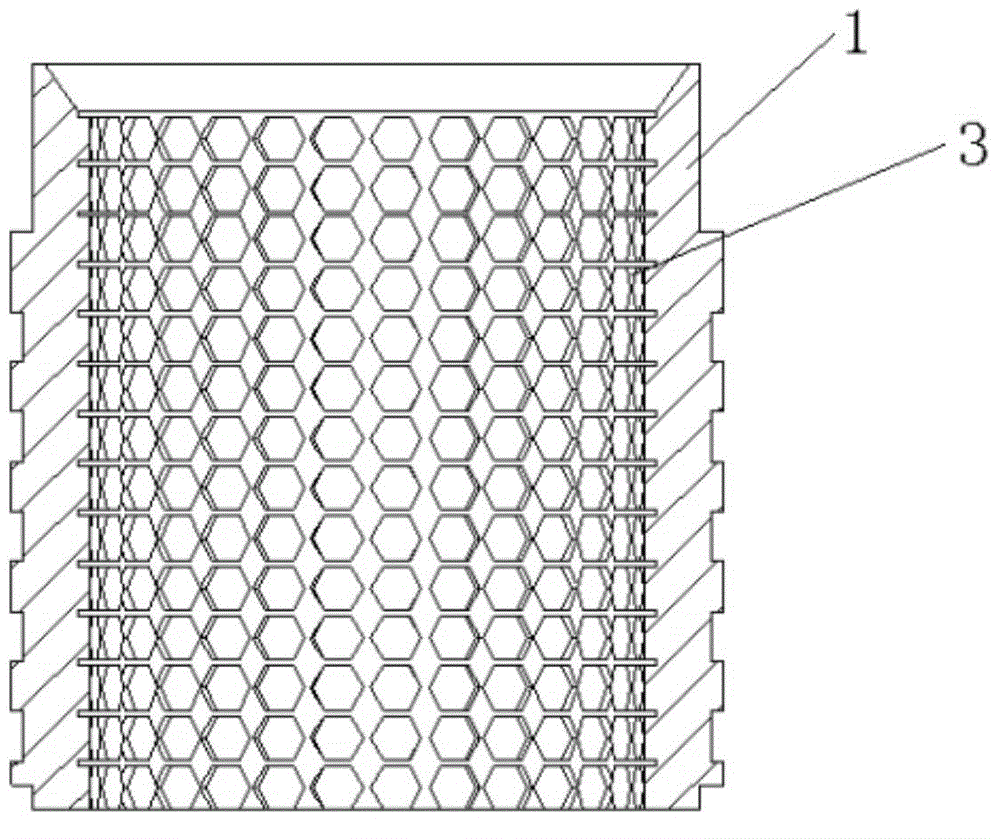

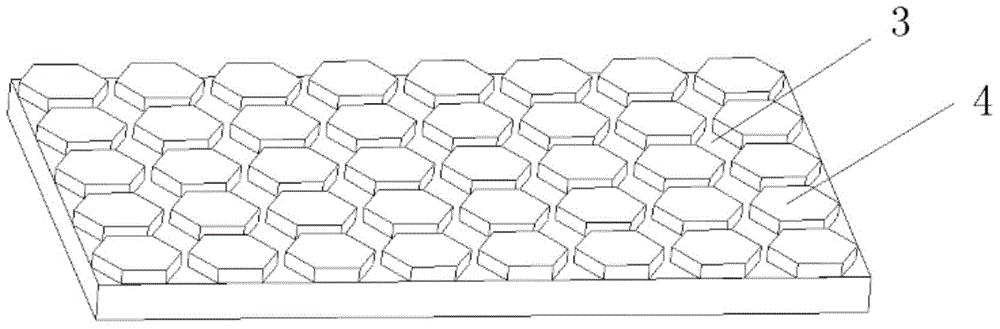

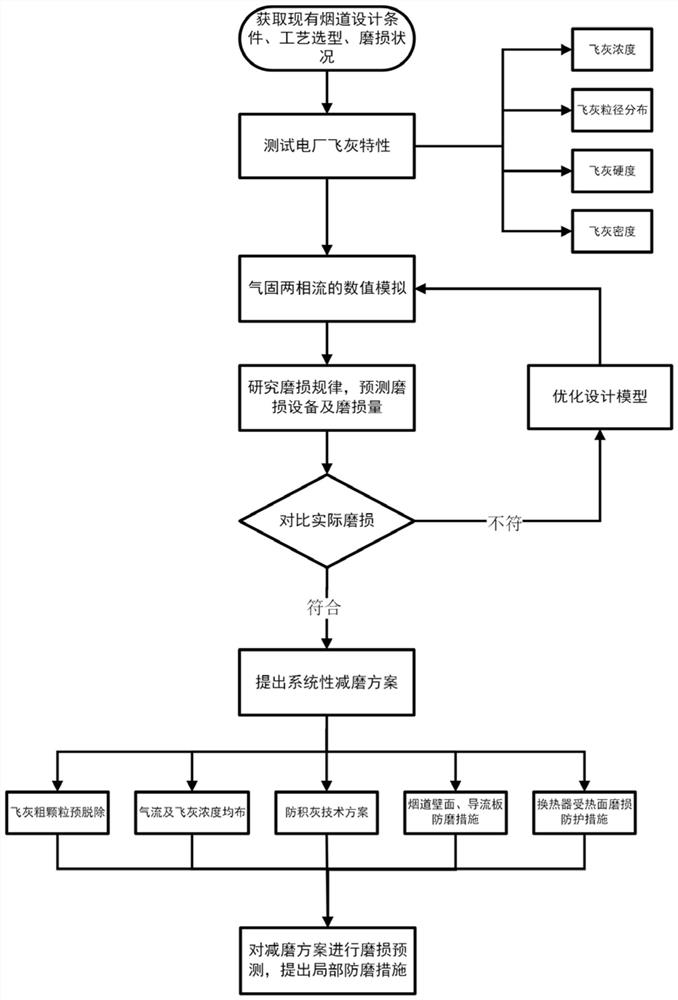

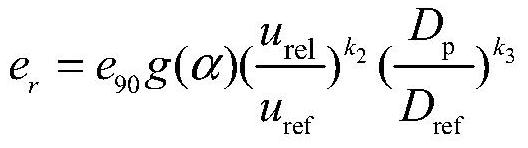

Method for solving boiler tail flue abrasion based on gas-solid two-phase flow numerical research

PendingCN112528547ASolve common wear and tear problemsImproved erosion and wear resistanceDesign optimisation/simulationCAD numerical modellingThermodynamicsProcess engineering

The invention discloses a method for solving boiler tail flue abrasion based on gas-solid two-phase flow numerical research, which comprises the following steps: S1, acquiring coal-fired power plant flue design conditions, process type selection and abrasion conditions, and adopting a abrasion model suitable for a coal-fired power plant boiler tail flue according to the numerical simulation research of gas-solid two-phase flow and fly ash characteristic test data; s2, based on the abrasion model suitable for the tail flue of the coal-fired power plant boiler, obtaining the abrasion rule of flue internal parts and equipment, determining the abrasion part and abrasion loss, and predicting the service life of materials and the service life of the equipment; and S3, proposing a systematic abrasion treatment scheme for the wear rules of the internal parts and equipment of the tail flue of each coal-fired power plant. The invention provides a method for systematically treating the abrasion of the tail flue of the boiler of the coal-fired power plant. Original passive anti-abrasion measures are changed into active anti-abrasion treatment, the workload and cost of maintenance and overhaulof a power plant are effectively reduced, the erosion and abrasion resistance of a boiler tail flue system is improved, and the safety and reliability of a tail flue and equipment are improved.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

Preparation method of epoxy resin wear-resistant composite material

InactiveCN111154232AImproved erosion and wear resistanceImprove corrosion resistanceFirming agentMegasonic cleaning

The invention discloses a preparation method of an epoxy resin wear-resistant composite material, wherein the preparation method comprises the following steps: (1) raw material pretreatment: a, respectively carrying out clear water cleaning and acetone solution ultrasonic cleaning on SiC particles, and finally drying; b, drying a stirrer and a mold, so as to prevent water from being brought in; (2) stirring and mixing: uniformly stirring E44 type epoxy resin and E51 type epoxy resin, adding a toughening agent, a coupling agent and an organic silicon oil defoaming agent, and adding the pretreated SiC particles while stirring; and (3) curing molding: adding a curing agent and a curing accelerator while stirring, injecting into a mold coated with a release agent, curing at normal temperature,curing in an oven, and curing at room temperature to finally obtain the finished product. The preparation operation is simple, the materials are easy to obtain, the reaction conditions are easy to achieve, and the prepared epoxy resin wear-resistant composite material has excellent erosive wear resistance, corrosion resistance and good tensile strength.

Owner:易士森

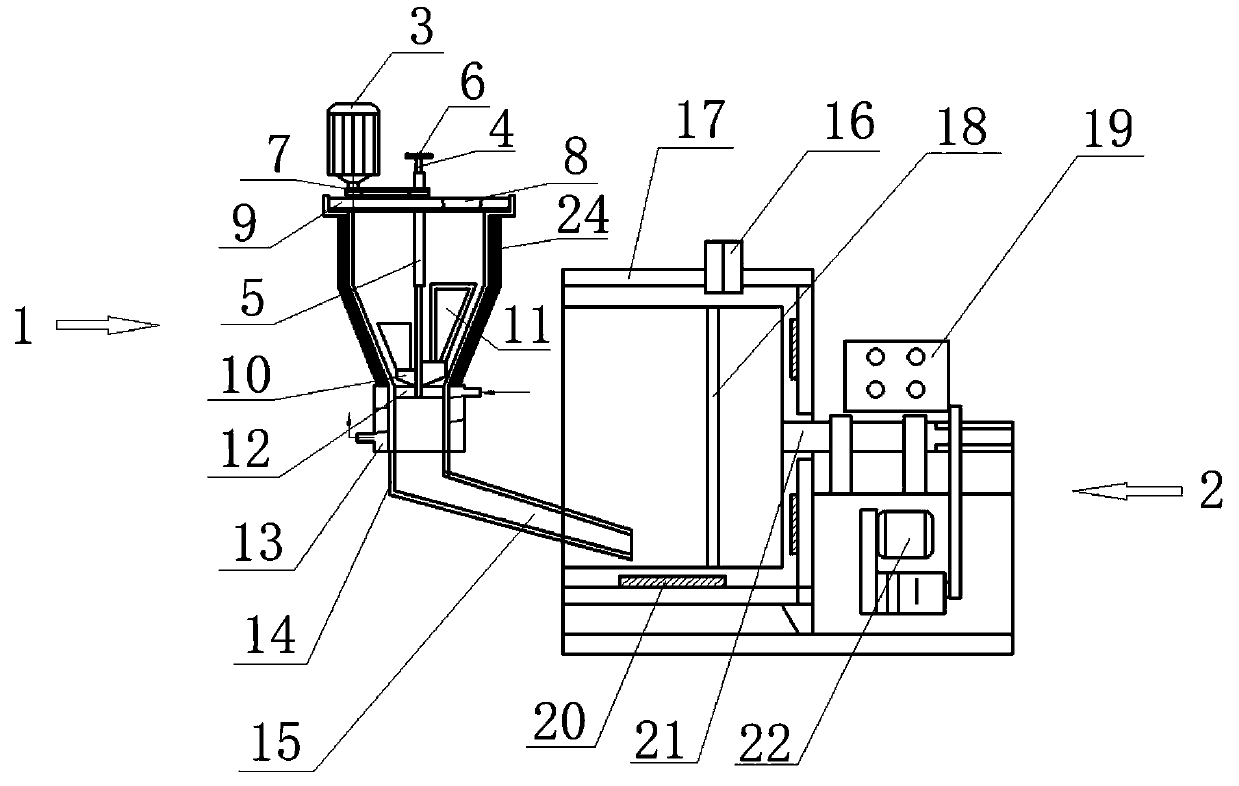

Conveying belt skirt side manufacturing system and method

InactiveCN110978357AReduce volumeImproved erosion and wear resistanceDomestic articlesCoatingsMechanical engineeringManufacturing systems

The invention provides a conveying belt skirt side manufacturing system and method. The system comprises a mixing device and a centrifugal forming device. The end, located on the centrifugal forming device, of the mixing device is vertically located on the upper stream, the mixing device is used for mixing a raw material used for manufacturing a conveying belt skirt side, the centrifugal formingdevice is arranged on the lower stream of the mixing device, and the centrifugal forming device is used for centrifugally forming the mixed raw material into the conveying belt skirt side. The conveying belt skirt side manufacturing system is designed, particularly, through structural design of the mixing device, an end cover assembly is arranged, one-instruction one-moving type mixing of the workmode of the centrifugal forming device can be matched, the size of the mixing device is reduced, through a paddle assembly, a stirring paddle is subjected to structural reasonable design, the mixingefficiency is greatly improved, the economic effect is obvious, and the conveying belt skirt side produced through the method is free of appearance defect, low in cost and quite high in product yield.

Owner:REMA TIPTOP TIANJIN RUBBER TECH

Nano-carbon-containing refractory castable for desulfurization stirrer and preparation method of nano-carbon-containing refractory castable

PendingCN111689783AImprove performanceImprove dispersion uniformityRotary stirring mixersTransportation and packagingCarbon filmMullite

The invention discloses a nano-carbon-containing refractory castable for a desulfurization stirrer. The castable comprises raw materials with the particle size being 1 mm or above, raw materials withthe particle size being larger than or equal to 0.1 mm and smaller than 0.1 mm and raw materials with the particle size being smaller than 0.1 mm. The raw materials with the particle size being smaller than 0.1 mm are prepared from pure fused mullite with the particle size being 325 mesh and dense corundum fine powder with the particle size being 325 mesh. The 325-mesh pure fused mullite and the 325-mesh dense corundum fine powder are carbon film nano-coated pure fused mullite and carbon film nano-coated dense corundum fine powder respectively. The invention also discloses a preparation methodof the castable. According to the castable disclosed by the invention, the thermal shock stability and the slag and molten iron erosion penetration resistance of the castable are improved, so that the castable is good in comprehensive performance and low in raw material cost, and a prepared stirrer is long in service life and low in consumption cost.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com