High-wearing engine cylinder sleeve imitating desert lizard cuticle

An engine cylinder, high wear resistance technology, used in engine components, machines/engines, cylinders, etc., can solve problems such as poor wear resistance, reduced engine cylinder liner service life, engine cylinder liner wear, etc. The effect of abrasiveness, excellent anti-abrasive wear and anti-erosion wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

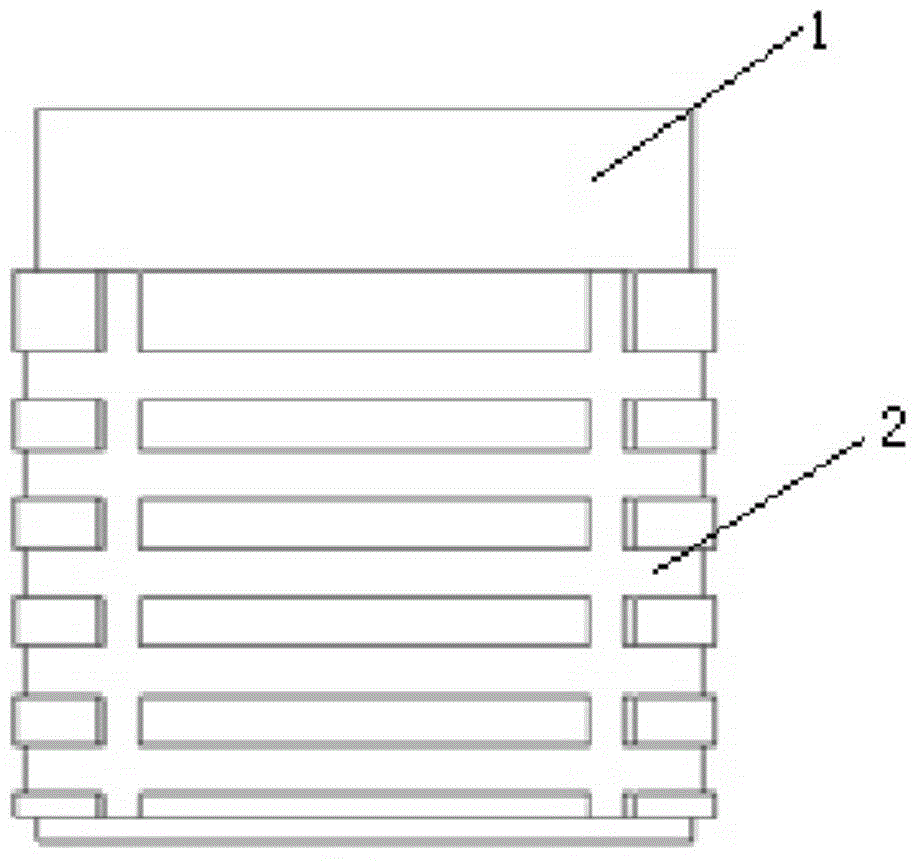

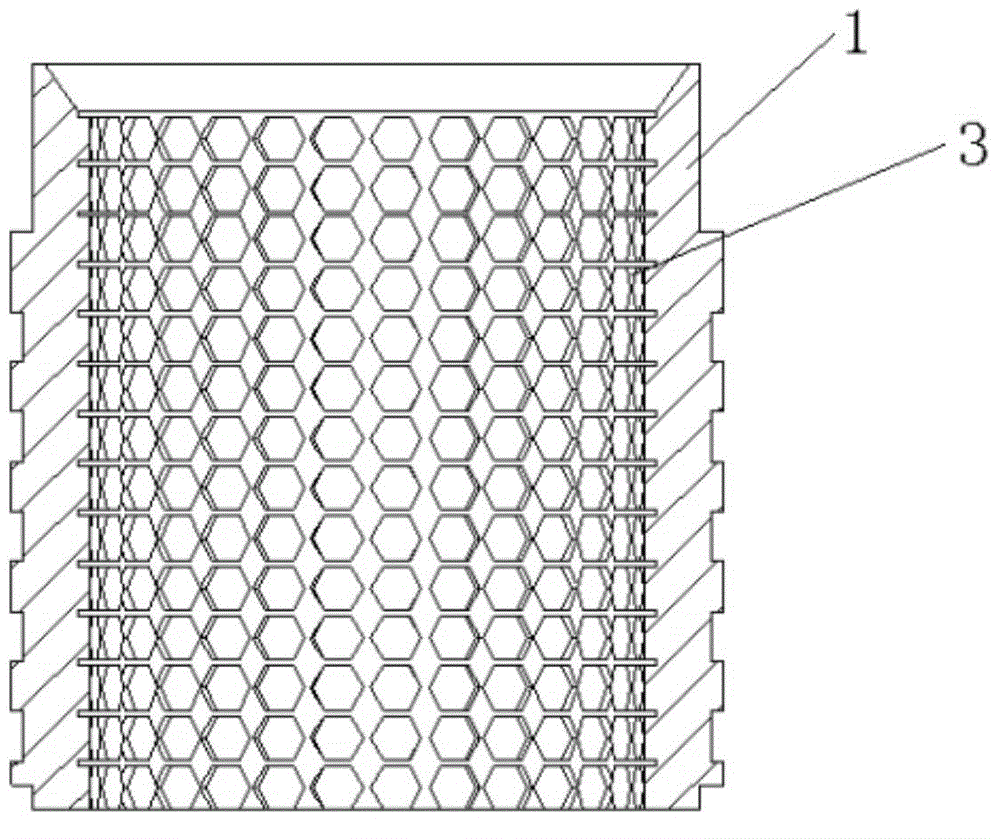

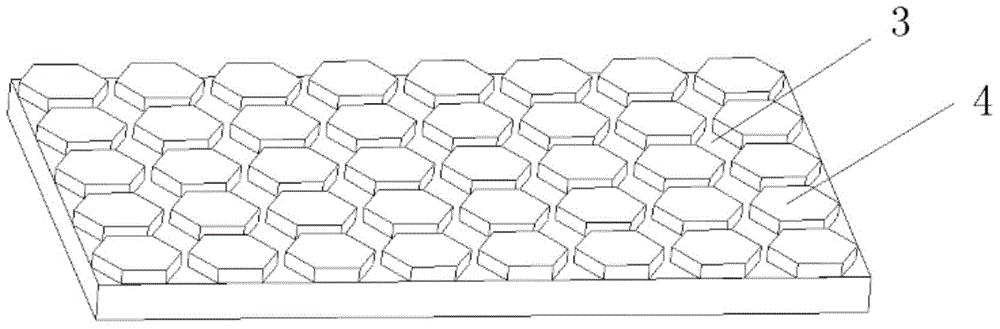

[0020] see Figure 1-Figure 5 Shown, a kind of highly wear-resistant engine cylinder liner imitating desert lizard epidermis, comprises engine liner body 1; The outer wall of described engine liner body is evenly distributed with some concave cut grooves 2, and the inner wall surface of engine liner body is attached with The wear-resistant layer imitating the desert lizard; the surface layer formed by the wear-resistant layer and the inner wall surface 3 of the engine cylinder liner body is concave-convex; Hexagonal projections (adjacent second hexagonal projections and the inner wall of the engine cylinder liner body surround a groove), and the second hexagonal protrusions form a hexagonal surface layer 6 with the inner wall of the engine cylinder liner body; The hexagonal surface layer is evenly distributed with some second spherical protrusions 7 at intervals; the second spherical protrusions are spherical protrusions of micronano scale (the shape and size of the first and ...

Embodiment 2

[0022] On the basis of Embodiment 1, the wear-resistant layer includes a plurality of first hexagonal protrusions 4 uniformly distributed on the inner wall surface of the engine cylinder liner body. The raised hexagonal structure on the inner wall of the engine cylinder liner body increases the connectivity of lubricating oil, promotes the lubrication of the piston and the cylinder liner, and reduces wear; specifically, the engine cylinder liner body other than the first hexagonal protrusion The various parts of the inner wall are connected, and the connection of lubricating oil can be realized on the macroscopic surface topography scale of the inner wall of the engine cylinder liner body, thereby ensuring the lubrication effect and effectively reducing the wear on the surface of the cylinder liner.

Embodiment 3

[0024] On the basis of Embodiment 1, the wear-resistant layer includes a plurality of first spherical protrusions 5 uniformly distributed on the inner wall surface of the engine cylinder liner body. The spherical protrusion structure on the inner wall of the engine cylinder liner body increases the connectivity of lubricating oil, promotes the lubrication of the piston and the cylinder liner, and reduces wear; specifically, all parts of the inner wall surface of the engine cylinder liner body other than the first spherical protrusion Connected, the macroscopic surface topography of the inner wall of the engine cylinder liner body can realize the communication of lubricating oil, thereby ensuring the lubrication effect and effectively reducing the wear of the cylinder liner surface; further, the friction between the piston and the inner wall surface of the engine cylinder liner body At the same time, because the top of the spherical protrusion is arc-shaped, it not only has stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com