Preparation method of magnetic boron nitride nanosheet/polyurethane composite material having ordered surface microstructure

A technology of composite materials and magnetic nanoparticles, which is applied in the field of preparation of magnetic boron nitride nanosheets/polyurethane composite materials, can solve the problems of polymers and their composite materials with less erosion and wear performance, complex formation mechanism, and many influencing factors , to achieve excellent erosion resistance, low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

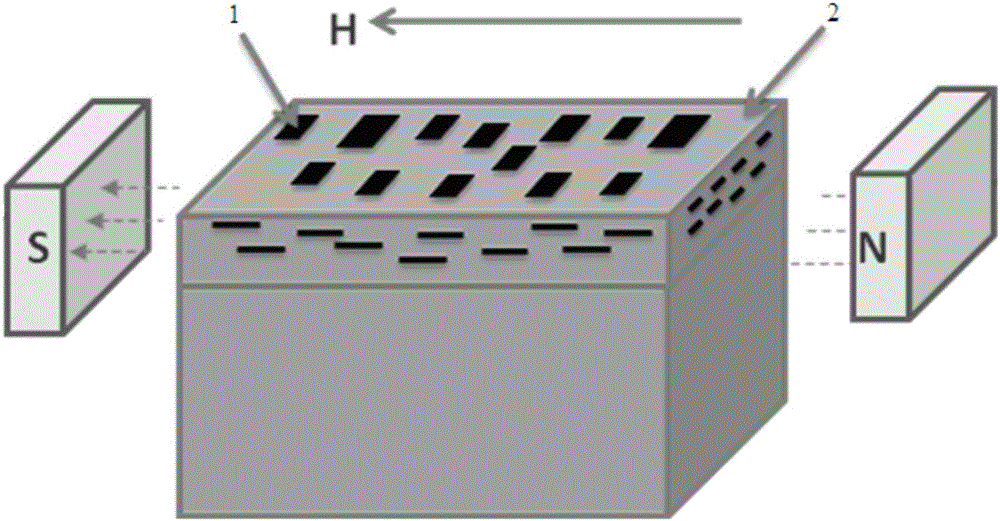

[0016] Embodiment 1: The preparation method of a magnetic boron nitride nanosheet / polyurethane composite material with an ordered surface microstructure in this embodiment is carried out according to the following steps:

[0017] 1. Add 2~6g of hexagonal boron nitride powder into 100mL~500mL of mixed acid, stir continuously for 10h~50h at a temperature of 30°C~100°C and a speed of 1000rpm~2000rpm, then cool and dilute with deionized water , repeated suction filtration and washing until the filtrate was neutral to obtain intercalated boron nitride; 2 SO 4 and concentrated HNO with a mass concentration of 95% 3 Composition by volume ratio of 1 to 3:1;

[0018] 2. Disperse the intercalated boron nitride obtained in step 1 in isopropanol, ultrasonically treat it for 10h~30h at room temperature, then centrifuge at 1500rpm~6000rpm for 15min~50min, take the supernatant, and use deionized Washing with water until neutral, drying the product at 80°C to 100°C to obtain boron nitride ...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the temperature is 60° C. and the rotation speed is 2000 rpm, and the stirring is continued for 30 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mixed acid described in step one is made of concentrated H with a mass concentration of 98%. 2 SO 4 and concentrated HNO with a mass concentration of 95% 3 Composition by volume ratio of 3:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com