Preparation method of hard particle reinforced impact-resistant and wear-resistant coating for machine-made sand

A hard particle, impact-resistant technology, used in coatings, metal material coating processes, liquid chemical plating, etc., can solve the problems of erosion wear, shortened life, and large coating brittleness, and achieve enhanced erosion resistance. Wear performance, improved service life, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

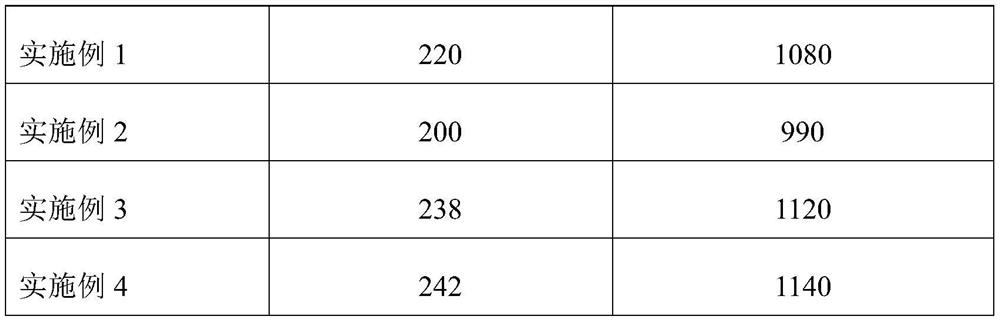

Embodiment 1

[0022] Step 1: Al 2 o 3 The raw powder is ball-milled with absolute ethanol to obtain the ball-milled Al 2 o 3 slurry, and after ball milling Al 2 o 3 Al in slurry 2 o 3 The particle size is less than 50nm; alumina or zirconia ceramic balls are used as medium balls during ball milling. The ball diameters of the medium balls are 1mm, 3mm, 5mm and 10mm. is 6:1;

[0023] Step 2: The Al after ball milling obtained in Step 1 2 o 3 The slurry is dried and sieved to obtain nano-Al after ball milling 2 o 3 powder spare;

[0024] Step 3: Ultrasonic cleaning the TiC powder in 6mol / L dilute HCl solution and 8mol / L dilute NaOH solution, followed by cleaning with deionized water, adding to the roughening solution to roughen the powder; the roughening The composition of the liquid consists of HF20mol / L, HNO 3 50mol / L and NH 4 F 1g / L mixed composition;

[0025] Step 4: Wash the roughened TiC powder with deionized water, then place it in the sensitization solution and activati...

Embodiment 2

[0030] Step 1: Al 2 o 3 The raw powder is ball-milled with absolute ethanol to obtain the ball-milled Al 2 o 3 slurry, and after ball milling Al 2 o 3 Al in slurry 2 o 3 The particle size is less than 50nm; alumina or zirconia ceramic balls are used as media balls during ball milling. The ball diameters of the media balls are 1mm, 3mm, 5mm and 10mm. is 7:1;

[0031] Step 2: The Al after ball milling obtained in Step 1 2 o 3 The slurry is dried and sieved to obtain nano-Al after ball milling 2 o 3 powder spare;

[0032] Step 3: ultrasonically clean the TiC powder in 8 mol / L dilute HCl solution and 7 mol / L dilute NaOH solution, then use deionized water to clean it, and add it to the roughening solution to roughen the powder; the roughening The composition of the liquid consists of HF40mol / L, HNO 3 70mol / L and NH 4 F 2g / L mixed composition;

[0033] Step 4: Wash the roughened TiC powder with deionized water, then place it in the sensitization solution and activati...

Embodiment 3

[0038] Step 1: Al 2 o 3 The raw powder is ball-milled with absolute ethanol to obtain the ball-milled Al 2 o 3 slurry, and after ball milling Al 2 o 3 Al in slurry 2 o 3 The particle size is less than 50nm; alumina or zirconia ceramic balls are used as media balls during ball milling. The ball diameters of the media balls are 1mm, 3mm, 5mm and 10mm. is 8:1;

[0039] Step 2: The Al after ball milling obtained in Step 1 2 o 3 The slurry is dried and sieved to obtain nano-Al after ball milling 2 o 3 powder spare;

[0040] Step 3: ultrasonically clean the TiC powder in 9 mol / L dilute HCl solution and 6 mol / L dilute NaOH solution, then use deionized water to clean it, and add it to the roughening solution to roughen the powder; the roughening The composition of the liquid consists of HF60mol / L, HNO 3 80mol / L and NH 4 F 3g / L mixed composition;

[0041] Step 4: Wash the roughened TiC powder with deionized water, then place it in the sensitization solution and activati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com