Method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles

A technology of tungsten carbide ceramics and particle reinforcement, which is applied in the fields of electric power, machinery, metallurgy, and materials, and can solve the problem of not significantly improving the erosion and wear resistance and service life of the dry ash removal system, the dry ash removal technology of parts wear, and the impact on firepower Power plant operating efficiency, operating safety and power generation costs, etc., to achieve good self-fluxing and wettability, high hardness, and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

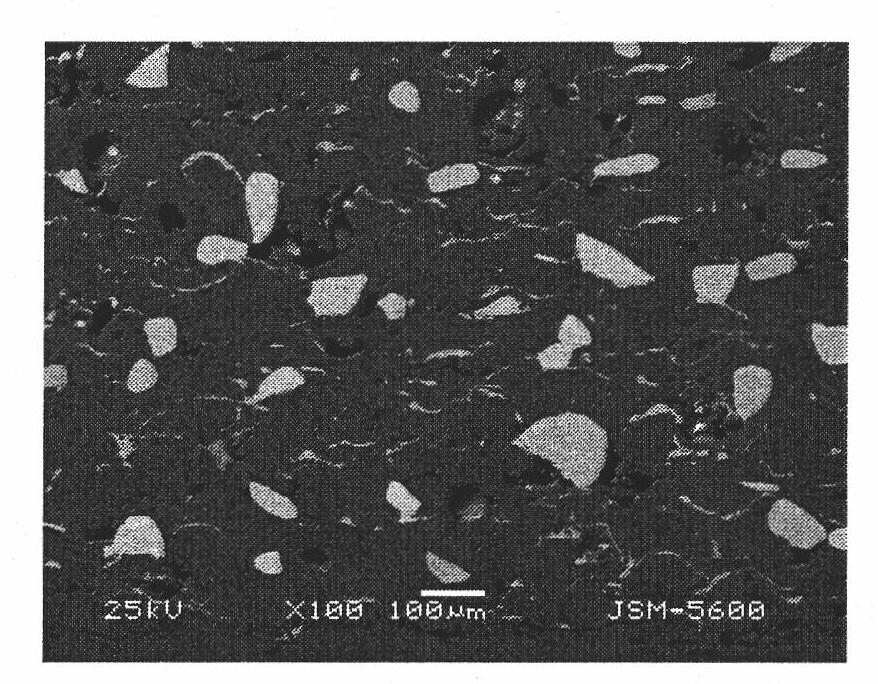

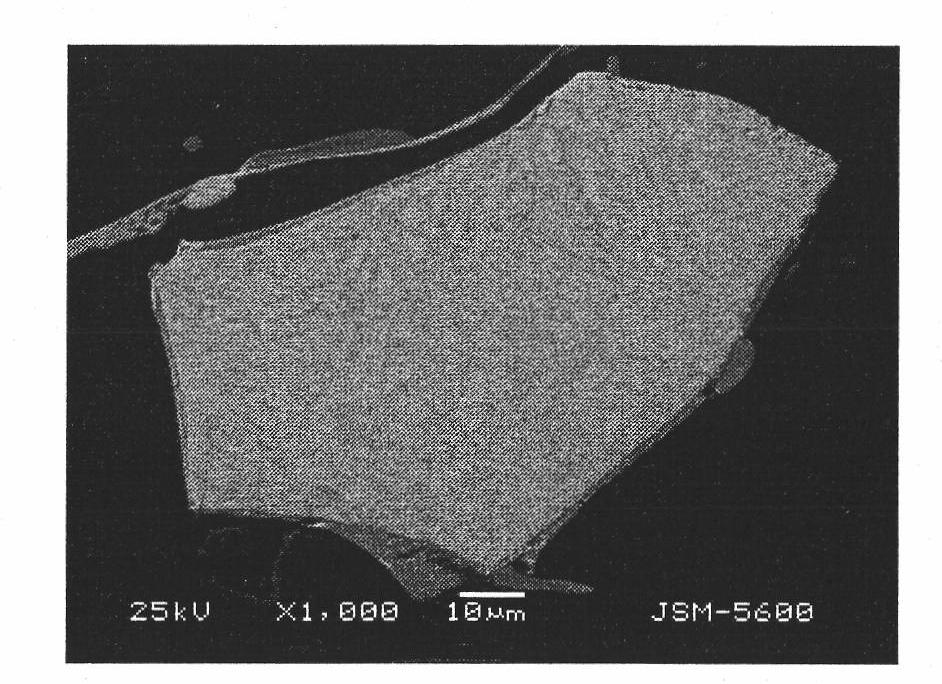

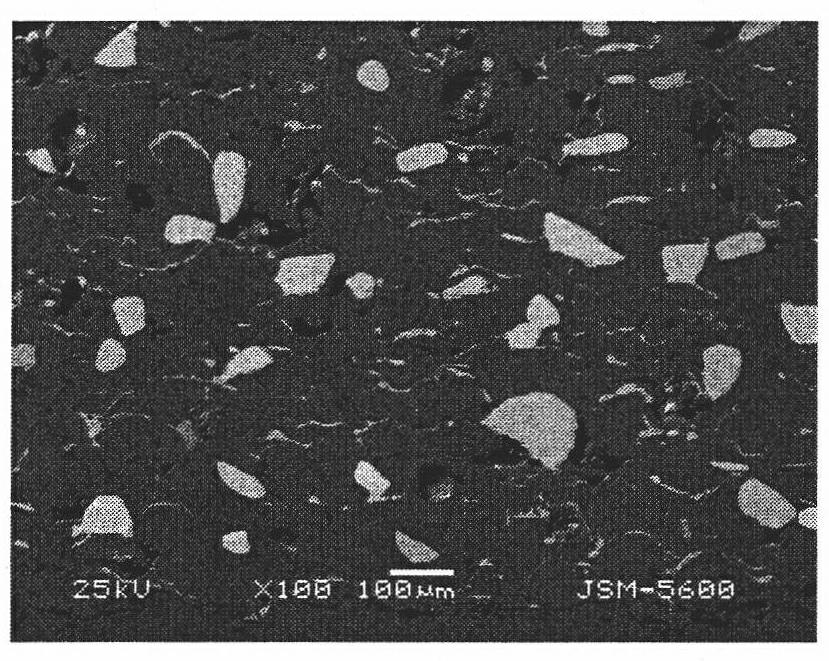

Image

Examples

Embodiment 1

[0021] Embodiment 1, adopt 35%WC+65%NiCrBSi mixed spraying powder, plasma spraying parameter is: electric current 410A; Voltage 49V; Primary gas (Ar) 46L / min; Secondary gas (H 2 ) 1.5L / min; powder feeding speed 32g / min; spraying distance 90mm; spraying speed 150mm / s, prepared WC P / NiCrBSi composite coating. WC P The erosion wear resistance rate of / NiCrBSi coating is 5.3×10 -3 mm 3 / g-5.6×10 -3 mm 3 / g; coating / substrate interface bonding strength is 30MPa-36MPa.

Embodiment 2

[0022] Embodiment 2, adopt 33%WC+67%NiCrBSi mixed spraying powder, plasma spraying parameter is: electric current 410A; Voltage 49V; Primary gas (Ar) 46L / min; Secondary gas (H 2) 1.5L / min; powder feeding speed 32g / min; spraying distance 90mm; spraying speed 150mm / s, prepared WC P / NiCrBSi composite coating. WC P The erosion wear resistance rate of / NiCrBSi coating is 5.5×10 -3 mm 3 / g-5.8×10 -3 mm 3 / g; coating / substrate interface bonding strength is 30MPa-37MPa.

Embodiment 3

[0023] Embodiment 3, adopt 37%WC+63%NiCrBSi mixed spraying powder, plasma spraying parameter is: electric current 410A; Voltage 49V; Primary gas (Ar) 46L / min; Secondary gas (H 2 ) 1.5L / min; powder feeding speed 32g / min; spraying distance 90mm; spraying speed 150mm / s, prepared WC P / NiCrBSi composite coating. WC P The erosion wear resistance rate of / NiCrBSi coating is 5.4×10 -3 mm 3 / g-5.8×10 -3 mm 3 / g; coating / substrate interface bonding strength is 26MPa-31MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com