Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "High strain point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali free glass

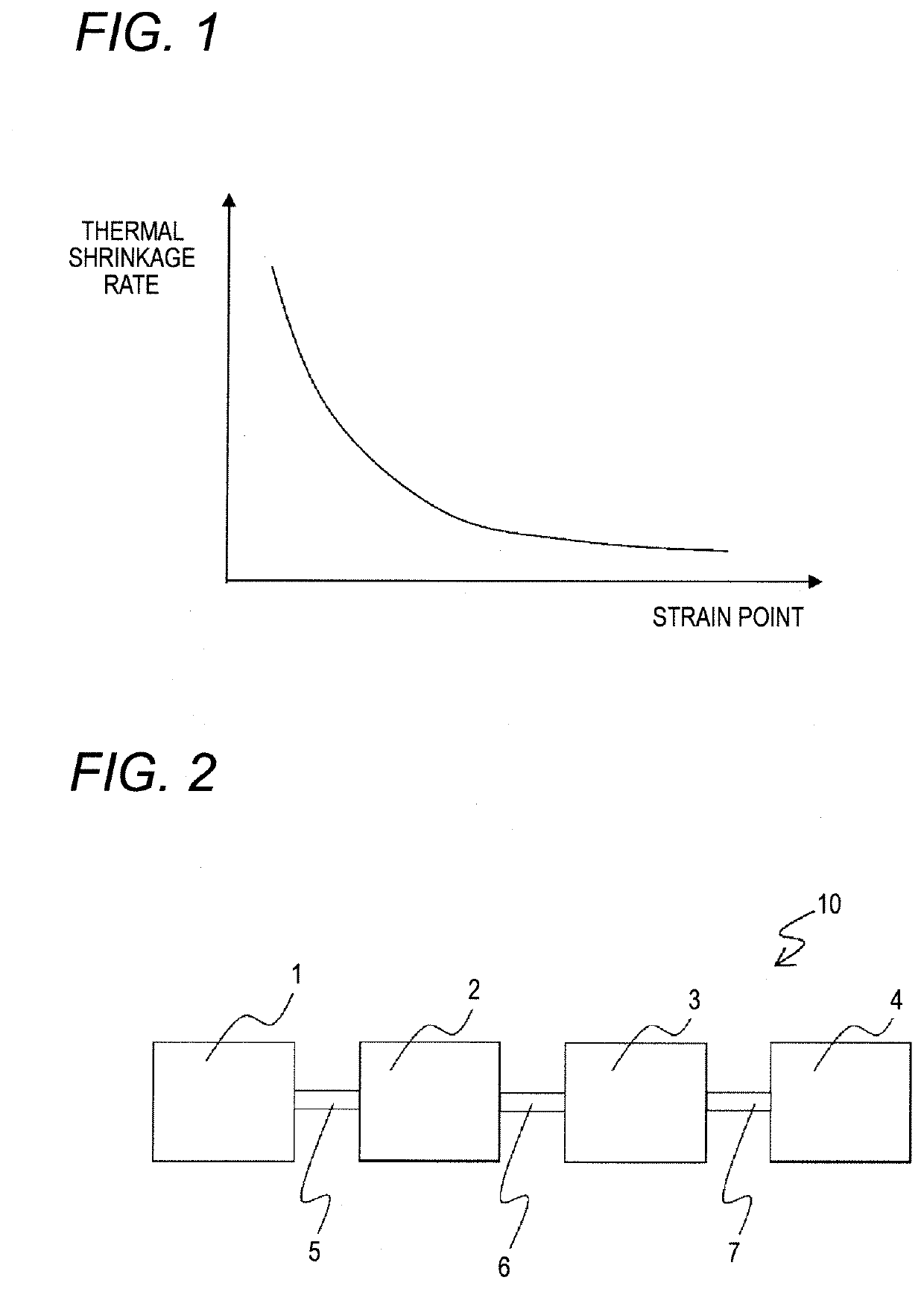

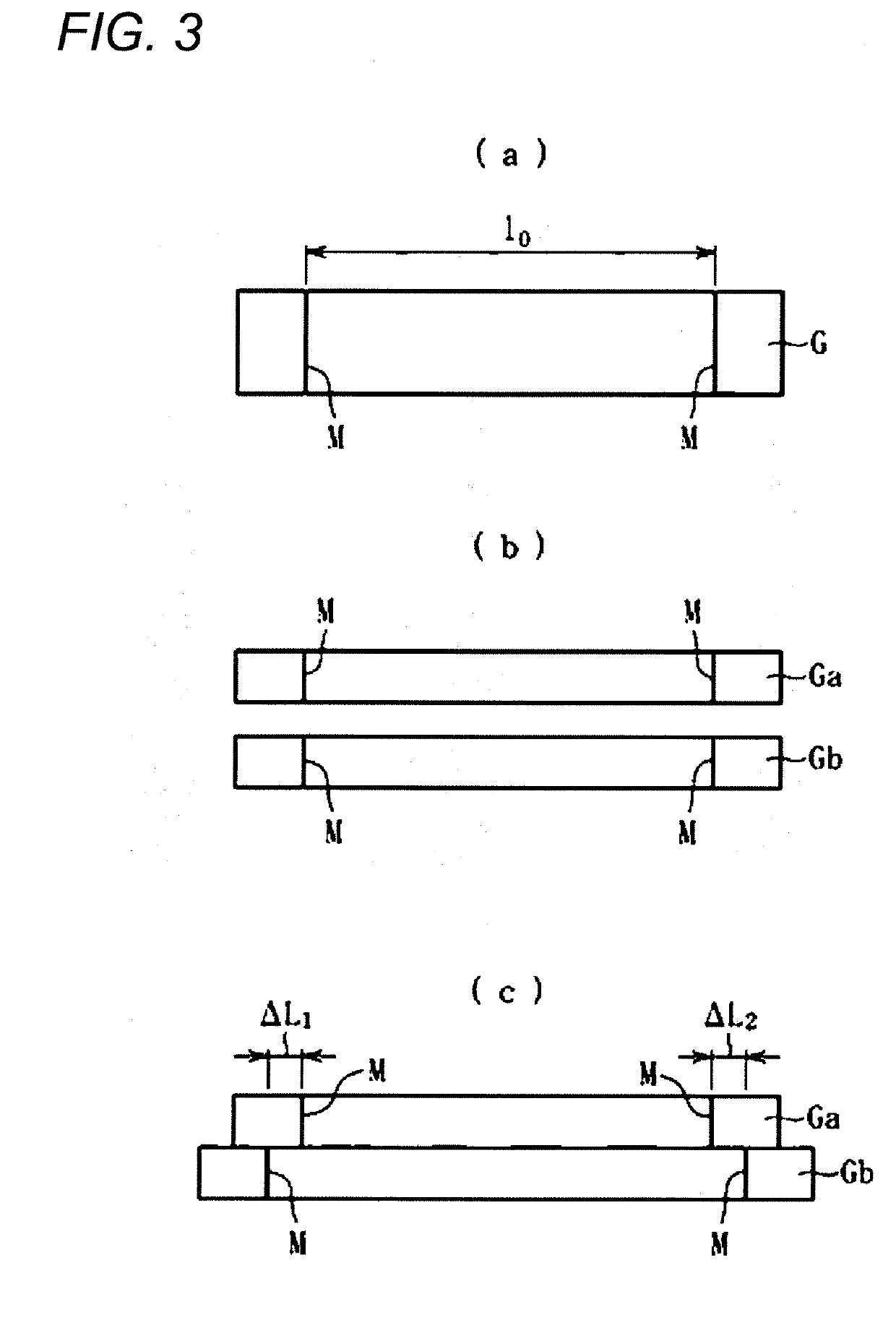

InactiveUS20060003884A1Reduce compactionIncreasing strain pointChemistryLinear expansion coefficient

To present an alkali free glass capable of reducing compaction caused by heat treatment, without significantly increasing the strain point. An alkali free glass characterized in that the ratio (Δan-st / α50-350) of the equilibrium density curve gradient Δan-st (ppm / ° C.) in a temperature range of from about the annealing point (Tan) to about the strain point (Tst) to the average linear expansion coefficient α50-350 (×10−6 / ° C.) in a range of from 50 to 350° C., is at least 0 and less than 3.64.

Owner:ASAHI GLASS CO LTD

Tempered glass and method for producing same

InactiveUS20140170380A1Efficiently provideImprove surface qualityRecord information storageMagnetic recordingMetallurgyCompression stress

A tempered glass of the present invention is a tempered glass having a compression stress layer in a surface thereof, the tempered glass comprising, as a glass composition in terms of mol %, 45 to 75% of SiO2, 3 to 15% of Al2O3, 0 to 12% of Li2O, 0.3 to 20% of Na2O, 0 to 10% of K2O, and 1 to 15% of MgO+CaO, and having a molar ratio (Al2O3+Na2O+P2O5) / SiO2 of 0.1 to 1, a molar ratio (B2O3+Na2O) / SiO2 of 0.1 to 1, a molar ratio P2O5 / SiO2 of 0 to 1, a molar ratio Al2O3 / SiO2 of 0.01 to 1, and a molar ratio Na2O / Al2O3 of 0.1 to 5, characterized in that the surface or an end surface of the tempered glass is etched after tempering treatment.

Owner:NIPPON ELECTRIC GLASS CO LTD

Glass for display substrate

ActiveUS20050209084A1Low densityReduce bloatVehicle body stabilisationGlass furnace apparatusThermal expansionPoise

A glass having a SiO2—Al2O3—B2O3—RO (RO is at least one of MgO, CaO, BaO, SrO and ZnO) based composition, a temperature corresponding to 102.5 poise being 1570° C. or higher and an alkali content of 0.01 to 0.2% and a ZrO2 content of 0.01 to 0.3%, as expressed in % by mass. And, a glass having a SiO2—Al2O3—B2O3—RO (RO is at least one of MgO, CaO, BaO, SrO and ZnO) based composition, a density of 2.5 g / cm3 or less, an average thermal expansion coefficient of 25 to 36×10−7 / ° C. in a temperature range of 30 to 380° C., a strain point of 640° C. or higher and an alkali content of 0.01 to 0.2% and a ZrO2 content of not less than 0.01% and less than 0.4%, as expressed in % by mass.

Owner:NIPPON ELECTRIC GLASS CO LTD

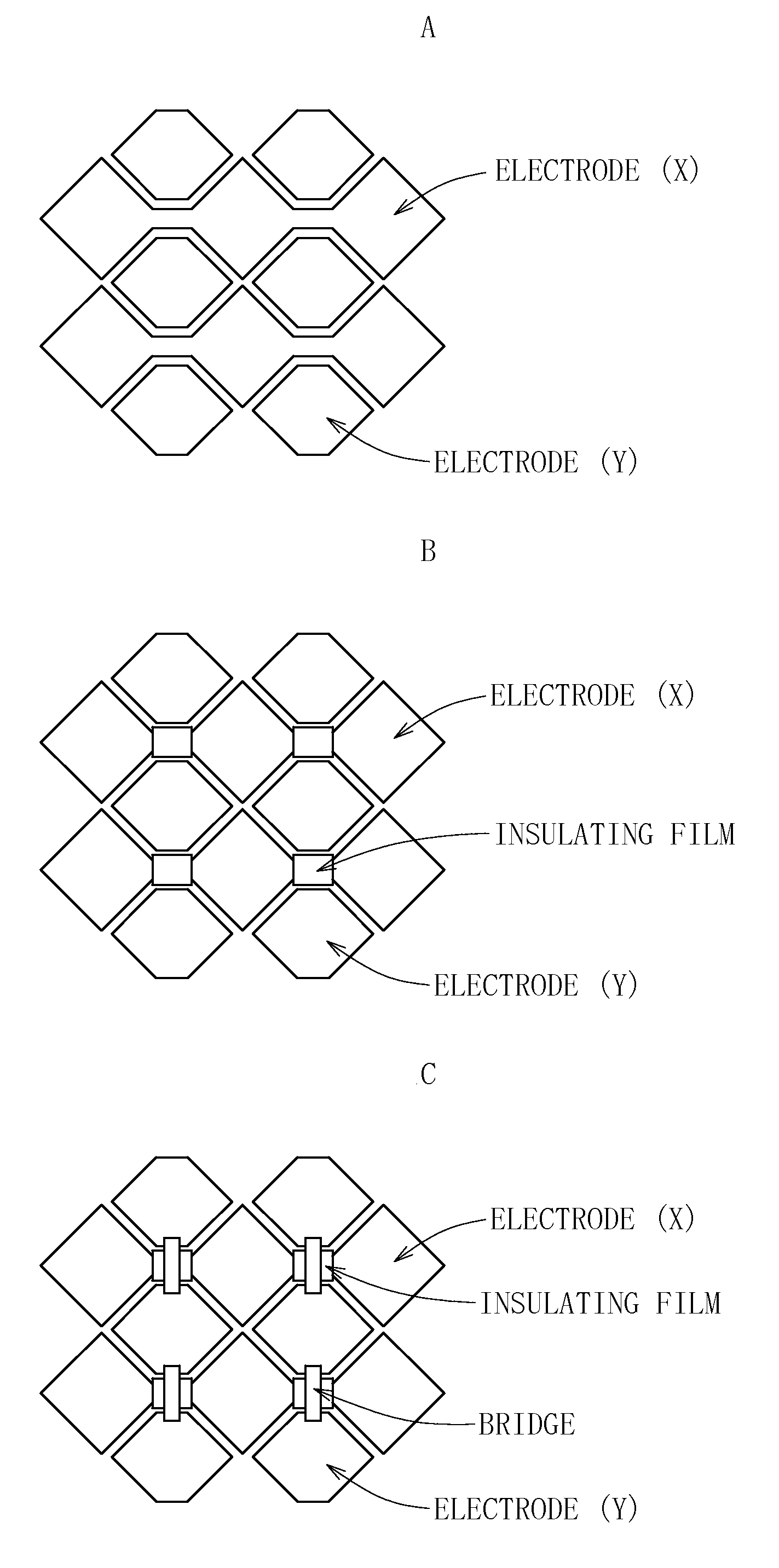

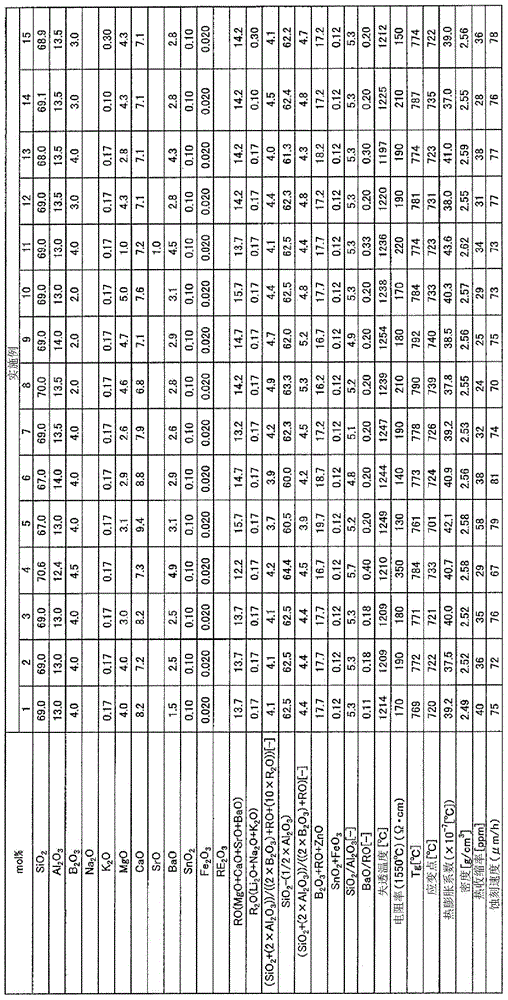

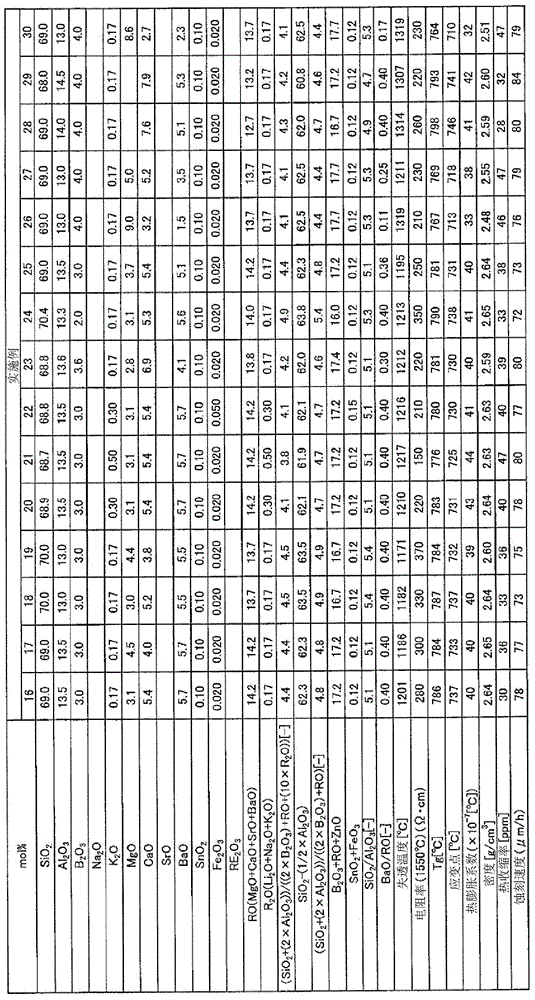

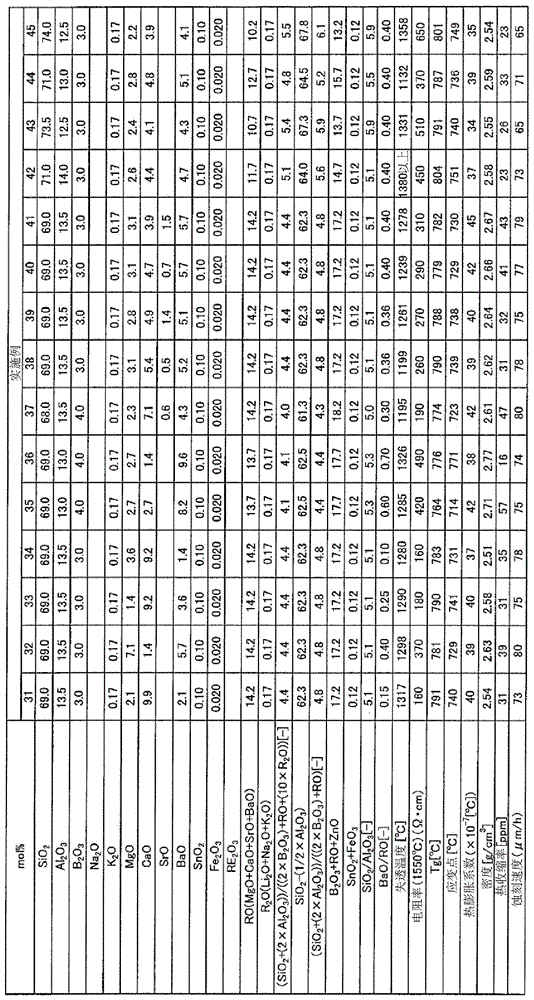

Glass substrate for display device and method for manufacturing same

ActiveCN103910487AInhibit or avoid melt lossInhibit devitrificationGlass productionDevitrificationMelting tank

The invention relates to a glass substrate for display device and a method for manufacturing same and provides a glass substrate which is high in strain point and capable of preventing a melting tank from melting loss, a glass substrate which is high in strain point and capable of suppressing devitrification, a glass substrate which is high in strain point and etching speed, and a method for manufacturing the glass substrate. The glass substrate contains Sio2 and Al2O3, 0-8% of B2O3, 0.01-0.8 % of R2O, and 0.05-1 of BaO / RO in mol%, and the strain point is over 670 DEG C. The glass substrate may contain Sio2, Al2O3 and MgO, 0.1-0.9 of MgO / (RO+ZnO), the strain point is over 700 DEG C, and the contraction rate is 5ppm-75ppm. The glass substrate may contain Sio2, Al2O3 and BaO, 0-7% of B2O3, 1-15% of BaO, and less than 6.0 of Sio2 / Al2O3, and the strain point is over 700 DEG C. RO represents (MgO+CaO+SrO+BaO), and R2O represents (Li2O+Na2O+K2O).

Owner:AVANSTRATE INC

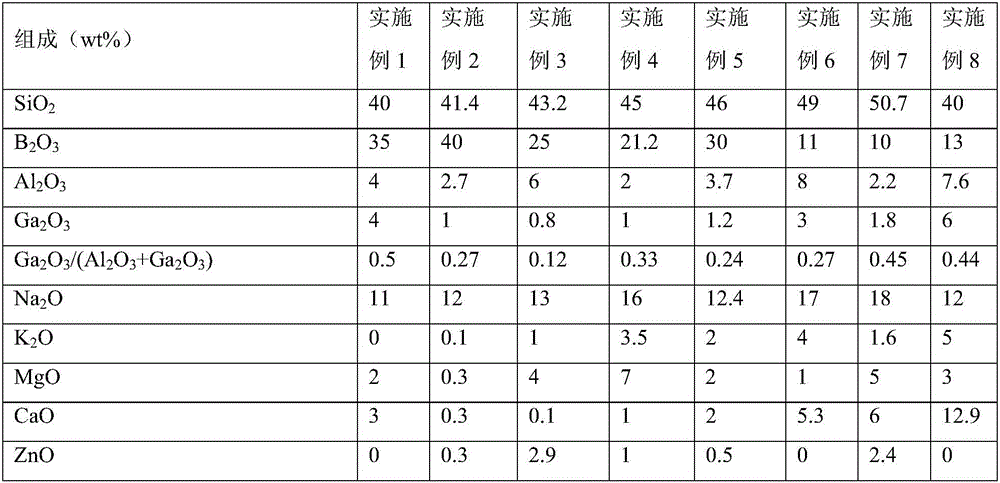

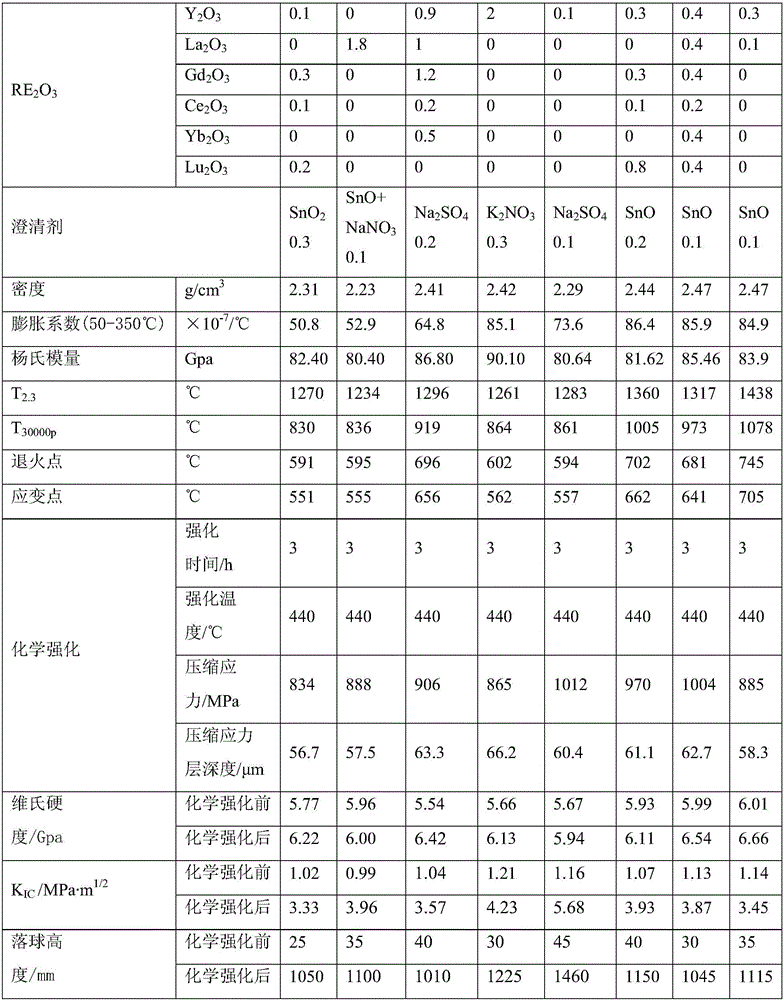

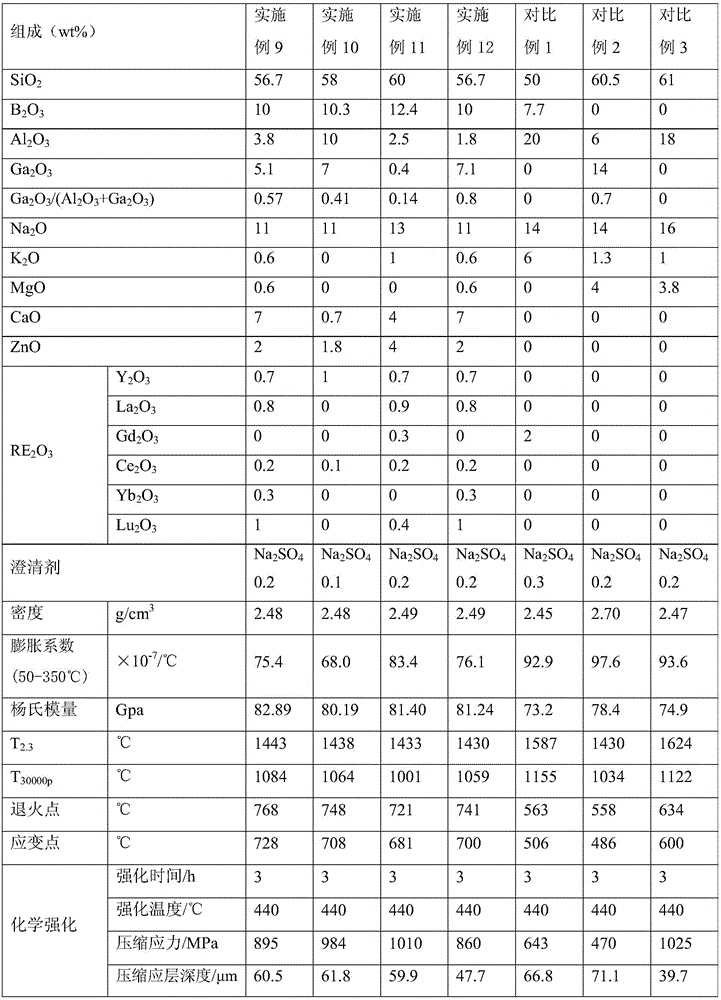

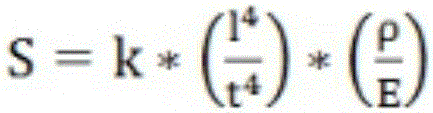

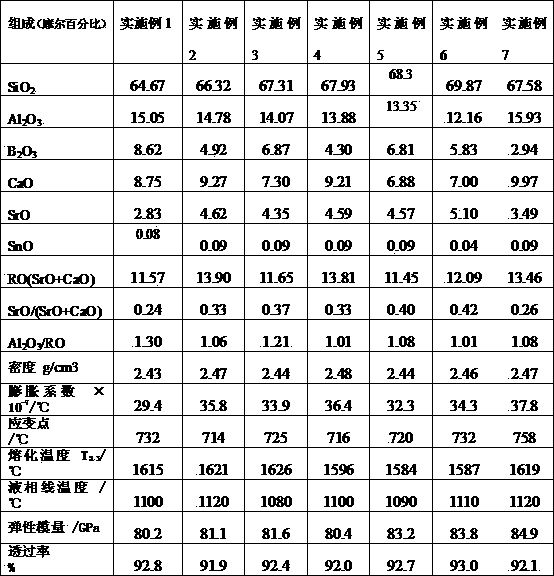

Composition for glass, alumina borosilicate glass, preparation method of alumina borosilicate glass and applications of composition for glass and alumina borosilicate glass

ActiveCN105819684AGood tempering effectHigh strain pointSolid-state devicesSemiconductor/solid-state device manufacturingElastic modulusHigh strain

The invention relates to the field of glass, and discloses a composition for glass, alumina borosilicate glass, a preparation method of the alumina borosilicate glass and applications of the composition for glass and the alumina borosilicate glass. The composition comprises the following components by weight on an oxide basis: 40-60wt% of SiO2, 10-40wt% of B2O3, 3-17wt% of Al2O3+Ga2O3, 11-18wt% of Na2O, 0-5wt% of K2O, 0-8wt% of MgO, 0.1-13wt% of CaO, 0-4wt% of ZnO and 0.1-4wt% of RE2O3. The prepared glass is high in chemical strengthening effect, has a relatively high strain point, a relatively high elasticity modulus, a relatively low melting temperature and favorable impact strength and tenacity, and is suitable for large-scale industrial production.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Method for producing glass for display substrate

ActiveUS20100292068A1Low densityHigh strain pointVehicle body stabilisationGlass furnace apparatusThermal expansionPoise

A method of producing a glass having a SiO2—Al2O3—B2O3—RO based composition, where RO is at least one of MgO, CaO, BaO, SrO and ZnO, a melting temperature corresponding to 102.5 poise of 1570° C. or higher and an alkali content of 0.01 to 0.2% and a ZrO2 content of 0.01 to 0.3%, as expressed in % by mass. And, a method of producing a glass having a SiO2—Al2O3—B2O3—RO based composition, where RO is at least one of MgO, CaO, BaO, SrO and ZnO, a density of 2.5 g / cm3 or less, an average thermal expansion coefficient of 25 to 36×10−7 / ° C. in a temperature range of 30 to 380° C., a strain point of 640° C. or higher and an alkali content of 0.01 to 0.2% and a ZrO2 content of not less than 0.01% and less than 0.4%, as expressed in % by mass.

Owner:NIPPON ELECTRIC GLASS CO LTD

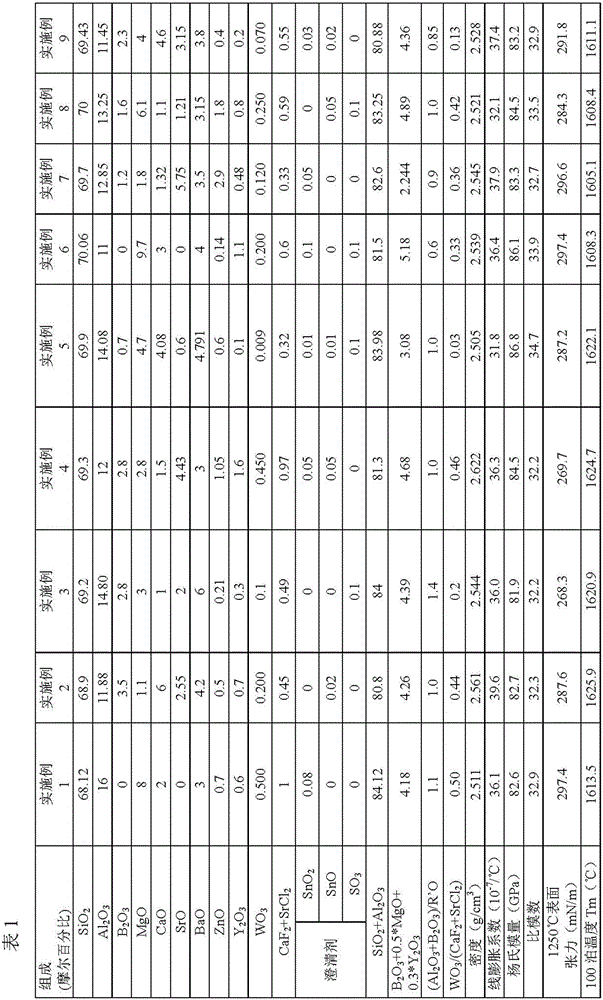

Composition for glass, low-surface-tension alkali-free glass as well as preparation method and application thereof

ActiveCN105859128AHigh strain pointHigh ratio modulusSolid-state devicesNon-linear opticsChemistryGlass manufacturing

The invention relates to the field of glass manufacturing, and discloses a composition for glass. The composition for glass comprises the following components on the basis of the total mole amount of the components of the composition for glass: 68-73.5mol% of SiO2, 11-16mol% of Al2O3, 0.1-4mol% of ZnO, 0.001-0.5mol% of WO3, 0.3-1.5mol% of CaF2 and / or SrCl2, 3-20mol% of alkaline earth metal oxides and 0.1-3mol% of rare earth oxides. The invention further discloses low-surface-tension alkali-free glass as well as a preparation method and application thereof. The low-surface-tension alkali-free glass disclosed by the invention is relatively excellent in comprehensive stability and relatively low in surface tension.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

Tempered glass and method for producing same

ActiveCN103476724ASuitability for etchingHigh ion exchange capacityGlass severing apparatusThin material handlingChemistry

This tempered glass has a compressive stress layer on the surface and is characterized by having a glass composition which contains, in mol%, 45-75% of SiO2, 3-15% of Al2O3, 0-12% of Li2O, 0.3-20% of Na2O, 0-10% of K2O and 1-15% of MgO + CaO, with the molar ratio of (Al2O3 + Na2O + P2O5) / SiO2 being 0.1-1, the molar ratio of (B2O3 + Na2O) / SiO2 being 0.1-1, the molar ratio of P2O5 / SiO2 being 0-1, the molar ratio of Al2O3 / SiO2 being 0.01-1 and the molar ratio of Na2O / Al2O3 being 0.1-5. This tempered glass is also characterized in that the surface or the end faces thereof are etched after the tempering treatment.

Owner:NIPPON ELECTRIC GLASS CO LTD

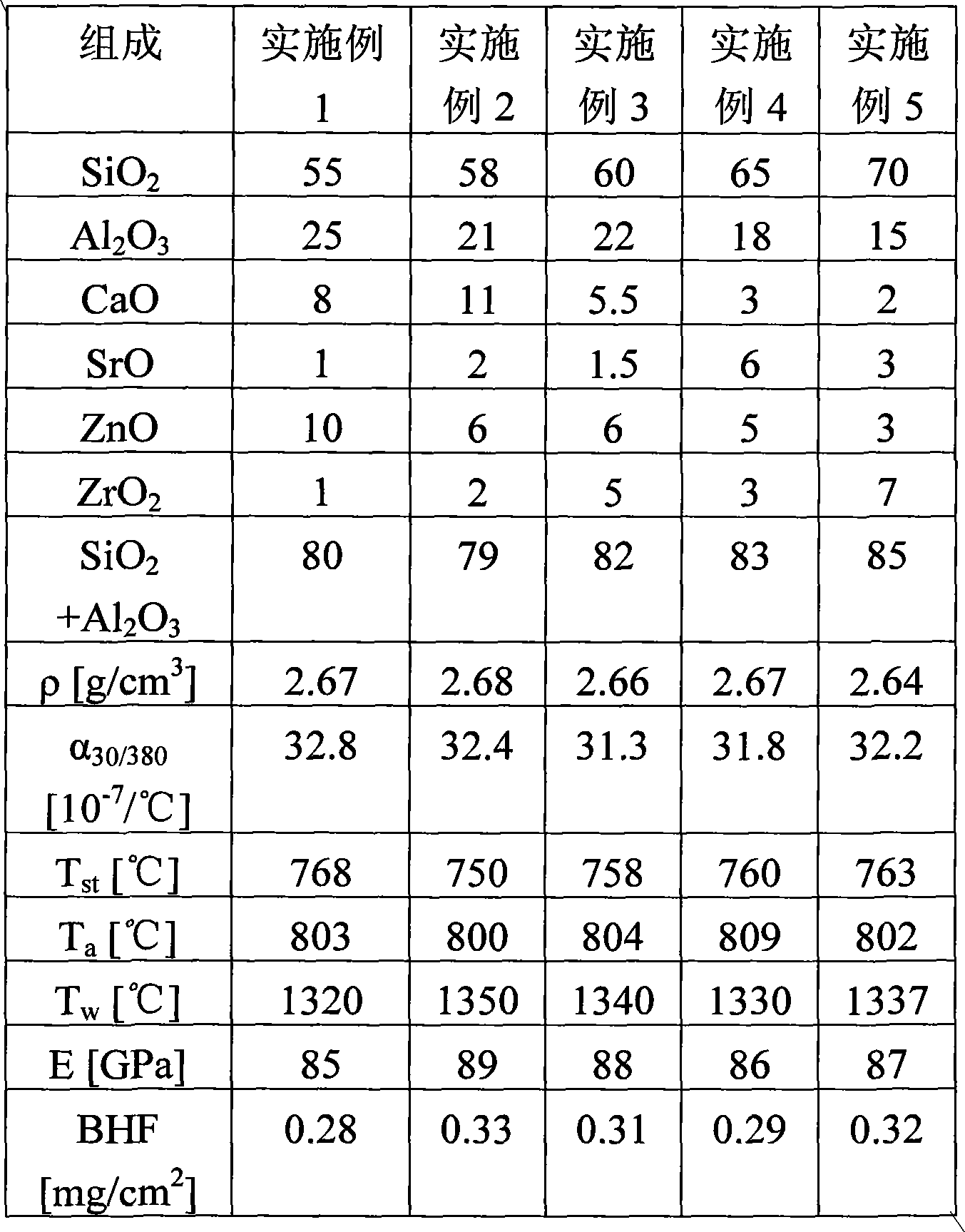

Glass and glass substrate

ActiveUS20150315065A1High strain pointSatisfactory chemical resistanceDevitrificationYoung's modulus

Devised are a glass and glass substrate, which contain an alkaline component at a low content, are low in density and thermal expansion coefficient, are high in strain point and Young's modulus, and are excellent in devitrification resistance, meltability, formability, and the like. That is, the glass of the present invention includes as a glass composition, in terms of mass %, 58 to 70% of SiO2, 16 to 25% of Al2O3, 3 to 8% of B2O3, 0 to 5% of MgO, 3 to 13% of CaO, 0 to 6% of SrO, 0 to 6% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, and 0 to 5% of P2O5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Alumina silicate glass and tempered glass

ActiveCN104556685AHigh strain pointGood chemical stabilityGlass tempering apparatusSilicate glassPotassium

The invention discloses alumina silicate glass. The alumina silicate glass comprises the following components in percentage by mole: 60-75% of silicon dioxide, 5-10% of aluminum oxide, 5-8% of sodium oxide, 0-3% of potassium oxide, 1-5% of calcium oxide, 1-5% of magnesium oxide, 2-5% of diboron trioxide and 0-4% of zirconium dioxide; the free oxygen coefficient delta of the alumina silicate glass is larger than or equal to 0.9 and smaller than or equal to 1.3, wherein delta is (Na2O+K2O+0.7CaO+0.3MgO-Al2O3) / B2O3; in the formula, each component represents the percentage by mole of the component. The alumina silicate glass can be used for improving the tempered strength. The invention also provides tempered glass prepared by tempering the alumina silicate glass.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD

Glass, light guide plate, backlight unit, liquid crystal panel, liquid crystal display terminal and preparation method of glass

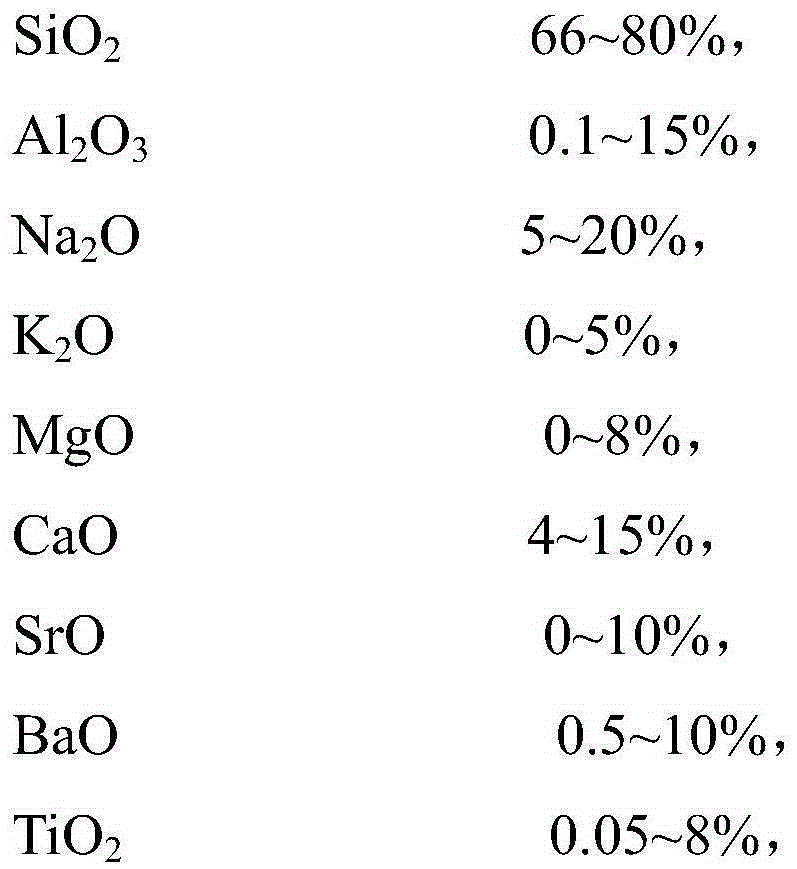

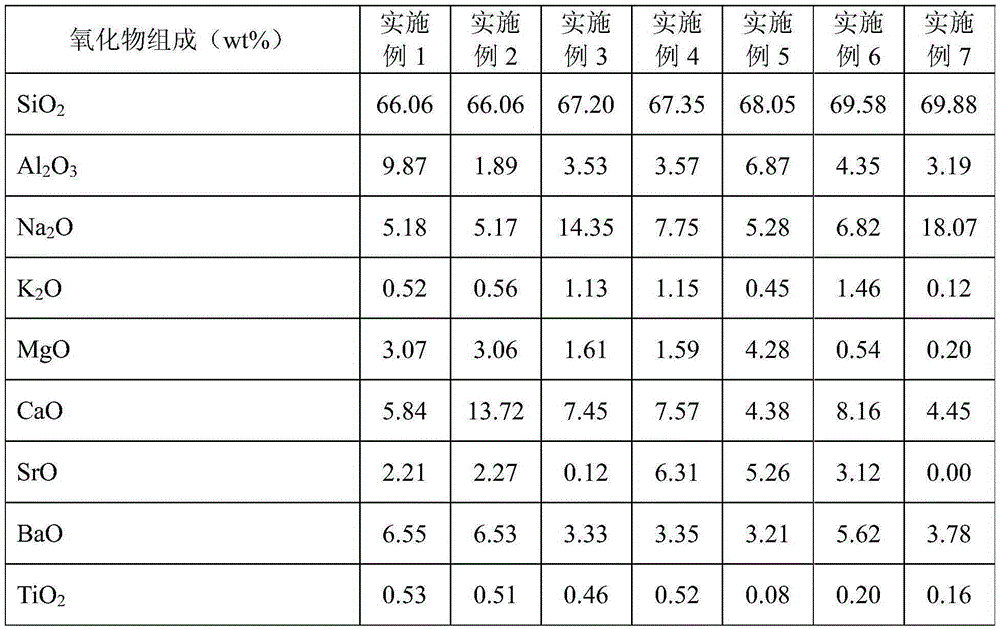

InactiveCN105384337AImprove thermal stabilityHigh strain pointGlass furnace apparatusGlass forming apparatusLiquid-crystal displayLight guide

The invention discloses glass, a light guide plate, a backlight unit, a liquid crystal panel, a liquid crystal display terminal and a preparation method of the glass. The glass is prepared from, by mass, 66%-80% of SiO2, 0.1%-15% of Al2O3, 5%-20% of Na2O, 0-5% of K2O, 0-8% of MgO, 4%-15% of CaO, 0-10% of SrO, 0.5%-10% of BaO, 0.05%-8% of TiO2, 0-8% of ZrO2 and 0.01%-2% of clarifying agent. The glass can serve as the light guide plate.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

TFT-base plate glass

The TFT base plate glass consists of SiO2 55-62 wt%, Al2O3 13-20 wt%, B2O3 8-12 wt%, ZrO2 0.1-4 wt%, CaO 3.5-8 wt%, MgO 0.1-5 wt%, SrO 2-6 wt%, BaO 1-4.0 wt%, ZnO 0.1-1 wt%, GeO2 0.1-2 wt%, V2O5 0-0.8 wt% and La2O3 0.1-2 wt%, as well as Sb2O3 0.1-0.3 wt% or CeO2 0.1-0.3 wt%. It has high performance and is used in producing base plate f TFT-LCD. It has thermal expansion coefficient at 25-400 deg.c of 40x10<-7> / deg.c, strain point higher than 650 deg.c, transition point higher than 710 deg.c, Ritter softening point higher than 900 deg.c, density lower than 2.55 g / cu mm, and visible light transmission rate not lower than 90 %.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Alkali-free glass

InactiveUS9023744B2Increase production capacityHigh strain pointOLED parametersElectroluminescent light sourcesAlkali freeAlkali metal oxide

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for manufacturing alkali-free glass substrate and alkali-free glass substrate

ActiveUS20200199012A1Low heat shrinkagePoint becomes highGlass furnace apparatusTank furnacesAlkali freePhysical chemistry

Provided is an alkali-free glass substrate having a high strain point and excellent bubble count, and a method for manufacturing the alkali-free glass substrate. The method includes: a batch preparing process of preparing a raw material batch so as to obtain alkali-free glass containing, in mass %, 50 to 80% of SiO2, 15 to 30% of Al2O3, 0 to 4.5% of B2O3, 0 to 10% of MgO, 0 to 15% of CaO, 0 to 10% of SrO, 0 to 15% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, 0 to 15% of P2O5 and 0 to 0.5% of SnO2 as a glass composition; a melting process of melting the prepared raw material batch; a fining process of fining the molten glass; and a forming process of forming the fined glass into a sheet shape. The raw material batch is melted such that a bubble enlarging temperature of the obtained glass is lower than a maximum temperature of the fining process.

Owner:NIPPON ELECTRIC GLASS CO LTD

Alkali-free glass

ActiveCN104276756AGood chemical stabilityHigh strain pointAlkali freeThin-film-transistor liquid-crystal display

The invention discloses alkali-free glass. The glass comprises the following chemical components by mole percent: 68.5-72% of SiO2, 12.6-15% of Al2O3, 1-3.7% of B2O3, 0.1-5.5% of MgO, 4-7% of CaO, 0.05-4% of ZnO, 1-3.5% of SrO and 0.05-0.1% of SnO. The alkali-free glass has the advantages of high chemical stability, high strain point, high Young modulus, low coefficient of expansion, low melting temperature, low liquidus temperature, and the like. The high temperature viscosity can be obviously reduced via ZnO and MgO in the formula composition, so that the alkali-free glass has lower melting temperature. The material can be widely suitable for manufacturing the glass substrates of flat panel displays, photovoltaic devices or other photoelectric devices and is especially suitable for manufacturing the glass substrates, and the like of TFT-LCD (thin film transistor-liquid crystal display) using the LTPS (low temperature poly-silicon) technology, and OEL (organic electroluminescence).

Owner:北京远大信达科技有限公司

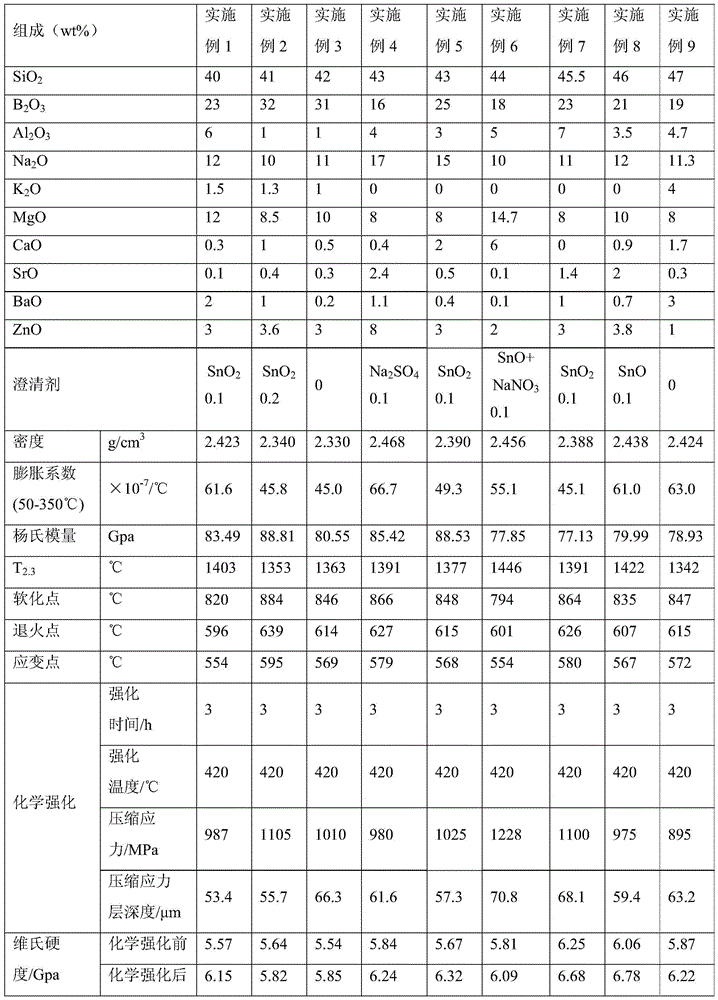

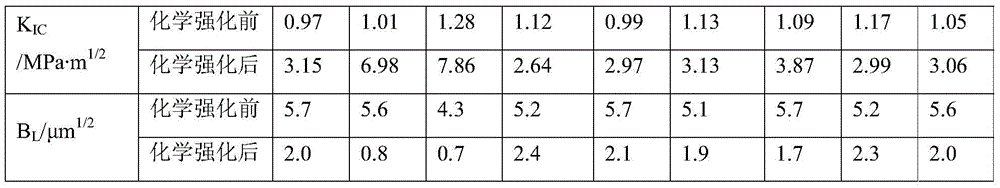

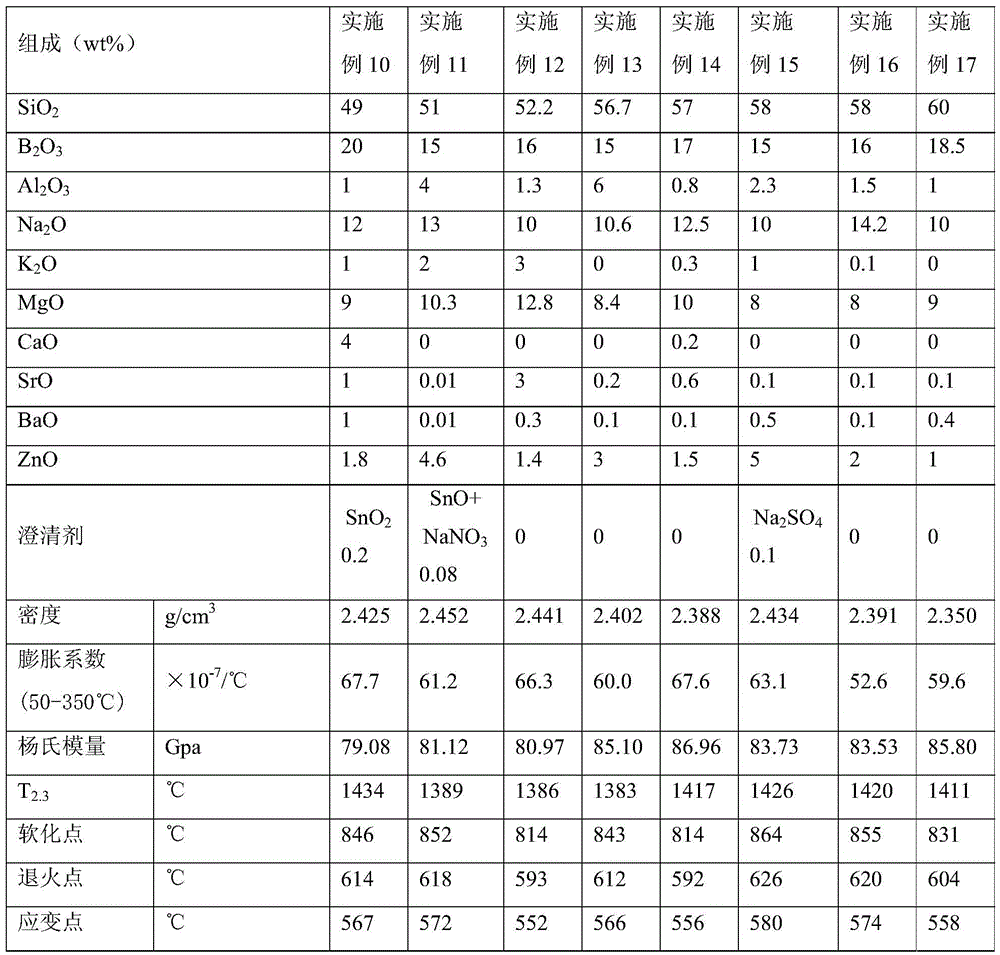

Composition for glass, chemically strengthened glass with low brittleness, and preparation method and application of chemically strengthened glass with low brittleness

The invention relates to the glass field, and discloses a composition for glass, chemically strengthened glass with low brittleness, a preparation method of the chemically strengthened glass with low brittleness and application of the chemically strengthened glass with low brittleness. The composition is prepared from the following components in percent by weight: 40 weight percent to 60 weight percent of SiO2, 15 weight percent to 35 weight percent of B2O3, 1 weight percent to 7 weight percent of Al2O3, 10 weight percent to 17 weight percent of Na2O, 0 to 4 weight percent of K2O, 8 weight percent to 15 weight percent of MgO, 0 to 6 weight percent of CaO, 0.01 weight percent to 3 weight percent of SrO, 0.01 weight percent to 3 weight percent of BaO and 1 weight percent to 8 weight percent of ZnO. The glass prepared according to the preparation method disclosed by the invention has the advantages of good toughening effect, higher strain point, higher modulus of elasticity, lower melting temperature, higher coefficient of thermal expansion, lower brittleness, excellent strength, excellent toughness, suitability for large-scale industrial production, compatibility for PDP (Plasma Display Panel) substrate production and capability of solving the PDP glass waste recycling problem.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

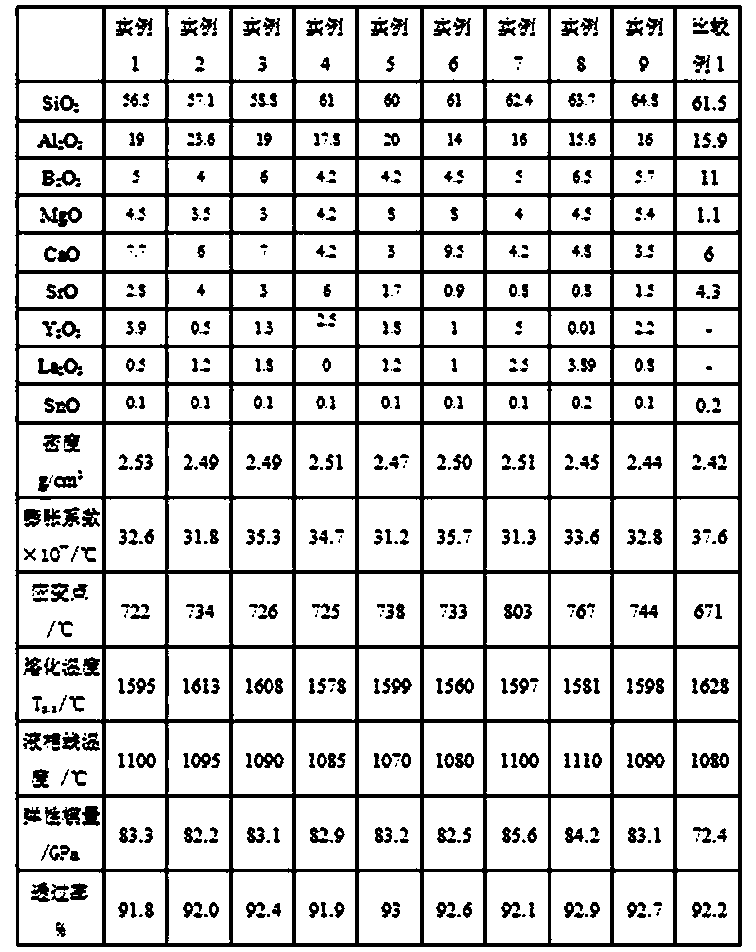

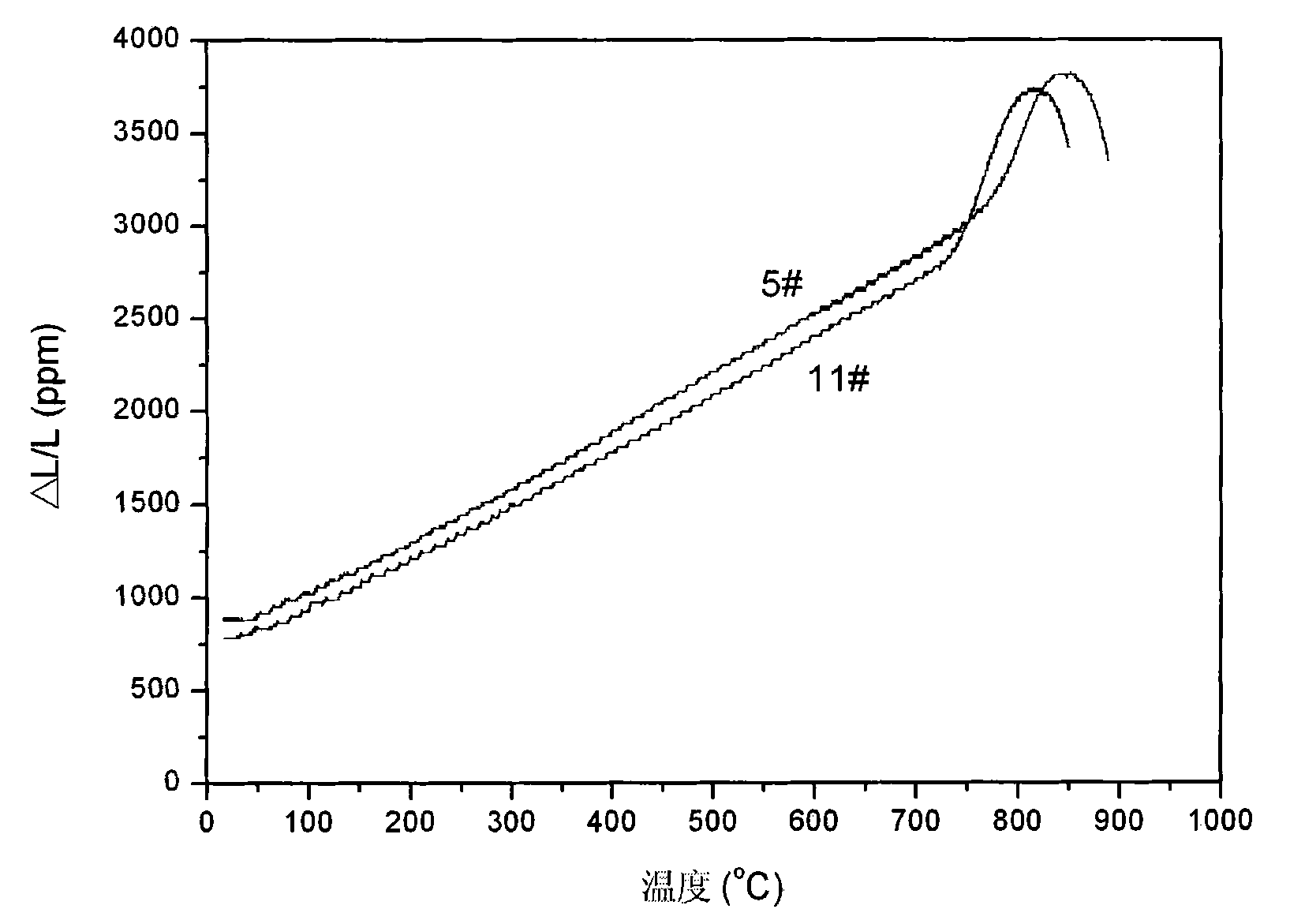

Panel display substrate glass composition

The invention discloses a panel display substrate glass composition which comprises the following components in percentage by weight: 56-65% of SiO2, 15-24% of Al2O3, 4-6.5% of B2O3, 3-8% of MgO, 3-10% of CaO, 0.1-6% of SrO, 0.01-5% of Y2O3 and 0.01-4% of La2O3. By adopting the technical scheme, the composition has the following advantages: the thermal expansion coefficient at 50-380 DEG C is 28-37*10<-7> / DEG C, the strain point is higher than 720 DEG C, the density is less than 2.55 g / cm<3>, and the liquidus temperature is lower than 1150 DEG C. The panel display glass substrate is environment-friendly and stable in performance, and has important functions on enhancing the production yield, reducing the energy consumption and controlling the cost.

Owner:TUNGHSU GRP

Glass Composition

InactiveUS20100273635A1Easy can be thermally toughenedHigh in strain point and softening pointChemistry

Owner:CENT GLASS CO LTD

Environmentally-friendly alkali-free aluminoborosilicate glass for TFT-LCD

The invention relates to alkali-free aluminoborosilicate glass for manufacturing a flat-panel display. The glass comprises the following chemical components in percentage by weight: 55 to 70 percent of SiO2, 7 to 13 percent of B2O3, 14 to 21 percent of Al2O3, 5 to 11 percent of CaO, 0.5 to 10 percent of SrO, 0.1 to 0.2 percent of SnO2, and 0.1 to 4.0 percent of Y2O3, wherein the glass does not contain MgO or BaO. The density of the glass is less than 2.45g / cm<3>, and the glass has the advantages of low glass smelting temperature, strain point of more than 700 DEG C, low thermal expansion coefficient, large elastic modulus, high strength, no alkali metal oxide, liquidus temperature of lower than 1,150 DEG C and the like, and is suitable for manufacturing the flat-panel display, in particular the substrate glass for displaying of a thin film transistor-liquid crystal display (TFT-LCD).

Owner:北京旭辉新锐科技有限公司

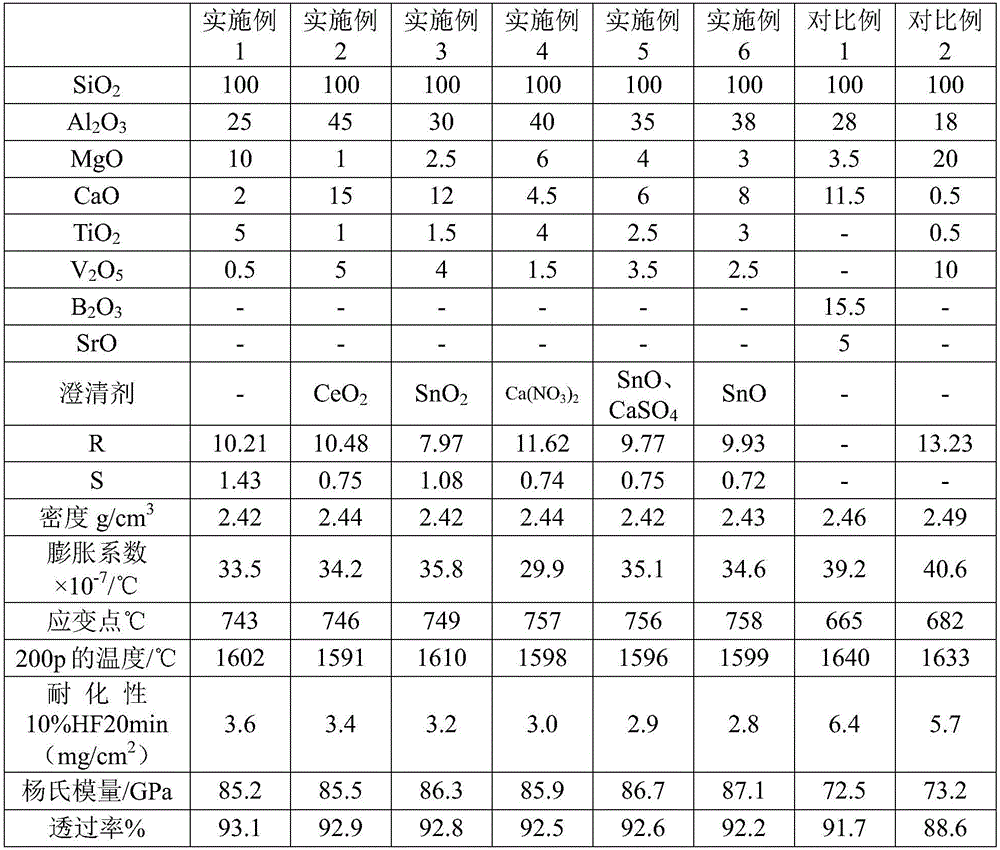

Alkali-free glass and application of alkali-free glass to substrates of flat-panel displays

The invention discloses alkali-free glass. The alkali-free glass comprises, by weight, 100 parts of SiO2, 25-45 parts of Al2O3, 1-10 parts of MgO, 2-15 parts of CaO, 1-5 parts of TiO2 and 0.5-5 parts of V2O5. An R which is computed by the aid of a formula of R=0.206w*(Al2O3)+0.4w*(MgO)-0.007w*(CaO)+0.2w*(TiO2)+0.143w*(V2O5) is 7.5-12. The alkali-free glass has the advantages that the alkali-free glass is high in chemical stability, accordingly, the problem of deterioration of the surface quality of glass of glass substrates due to thinning procedures in the prior art can be solved, glass substrates can have target thicknesses by the aid of thinning treatment on the premise that the quality of the glass substrates is guaranteed, and flat-panel display glass can be lightened and thinned; the alkali-free glass has a high strain point and high Young's modulus and is excellent in performance and wide in application range.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

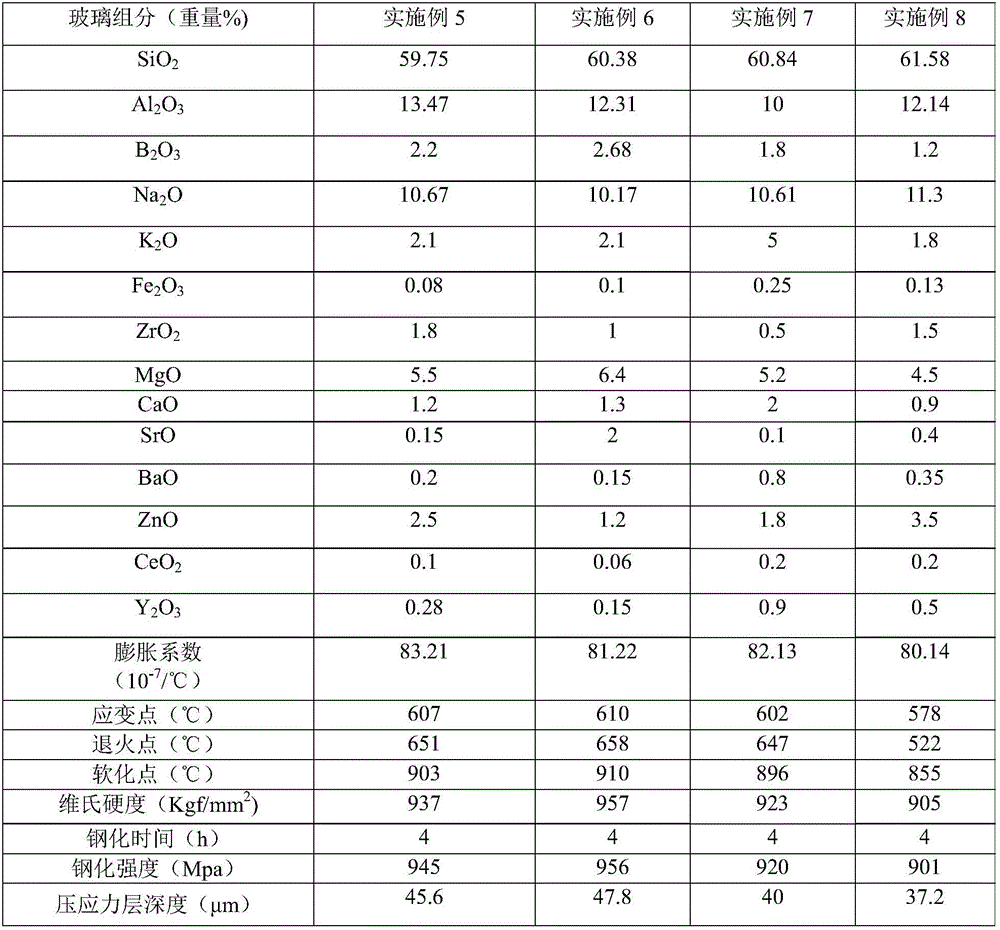

Glass composition and glass and preparation method and application thereof

ActiveCN105859129AHigh light transmittanceHigh strain pointInput/output processes for data processingHigh strainHardness

The invention relates to the field of glass production and particularly relates to a glass composition and glass and a preparation method and application thereof. The glass composition contains SiO2, Al2O3, B2O3, Fe2O3, ZrO2, ZnO, alkali metal oxide, alkaline earth metal oxide and rare-earth metal oxide. The invention also discloses glass and a preparation method and application thereof. In the invention, the prepared glass has excellent mechanical properties such as relatively high strain point, softening point and hardness; and the tempering effect of the prepared glass is relatively good. Therefore, the prepared glass with special properties is relatively applicable to touch screen cover plates of a float process.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

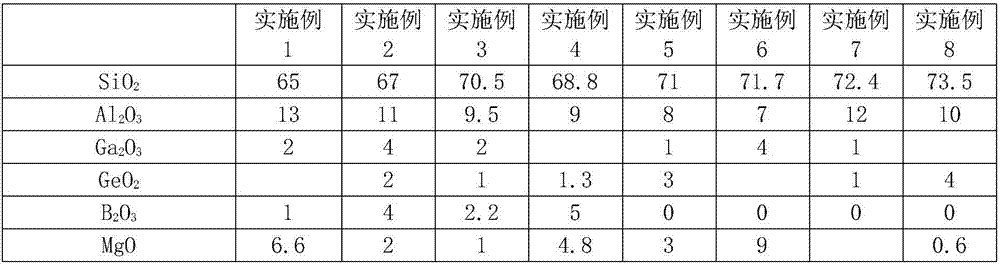

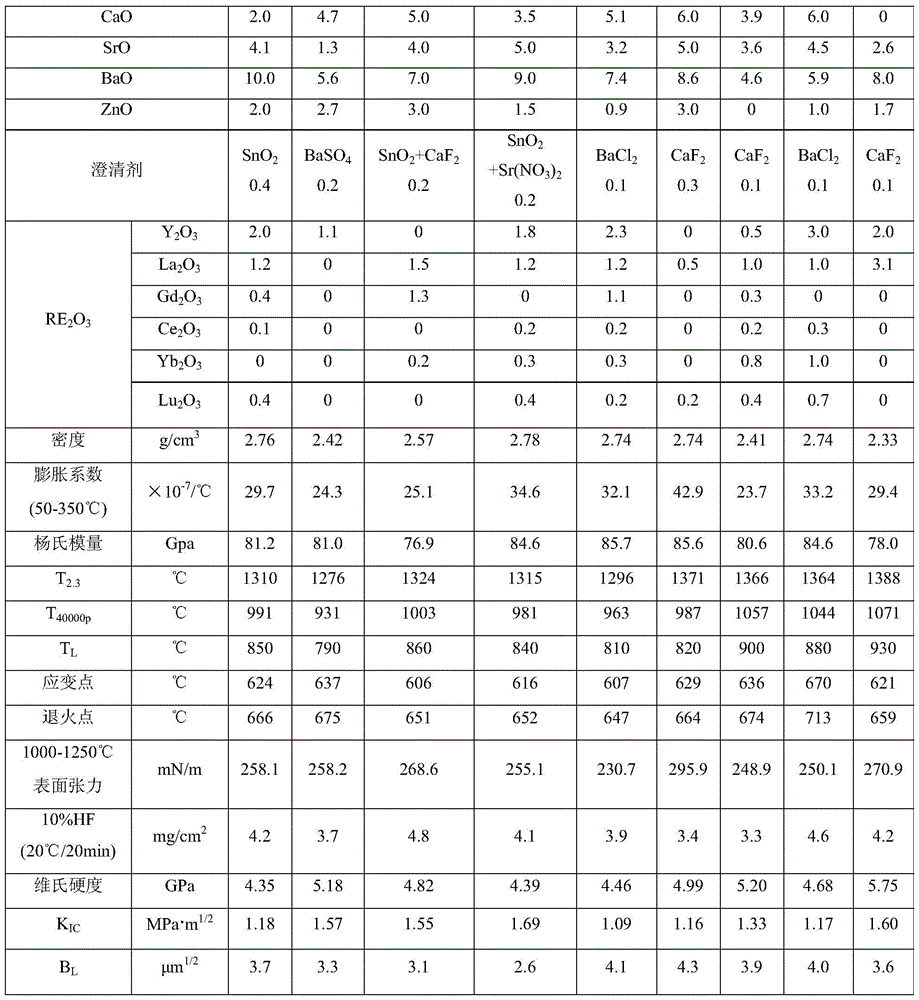

Alkali-free silicate glass and preparation method and application thereof

ActiveCN107382052AHelps to reduce weightHigh expansion coefficientGlass shaping apparatusGlass productionAlkali freeSilicate glass

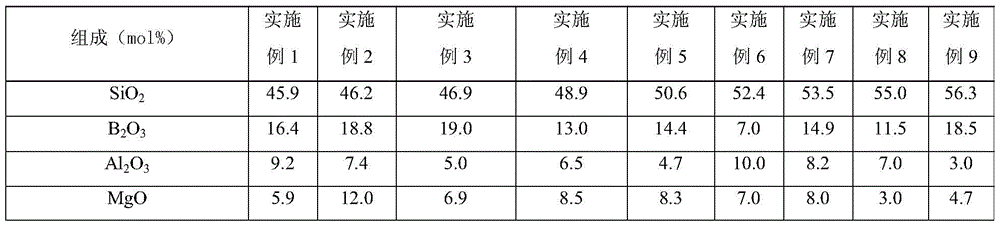

The invention relates to the field of glass and particularly relates to alkali-free silicate glass and a preparation method and application thereof. The alkali-free silicate glass comprises, by mole, 65-75 mol% of SiO2, 11-17 mol% of Al2O3, Ga2O3 and GeO2, 0-8 mol% of B2O3, 0-15 mol% of MgO, 2-10 mol% of CaO, 0.5-14 mol% of SrO and BaO, 0-10 mol% of TiO2, 0.01-2 mol% of Ta2O5 and 0.01-0.5 mol% of Tl2O3. The alkali-free silicate glass has high thermal stability and dimensional stability, a high strain point, a high specific modulus, a low melting temperature, a low liquidus temperature and low density and is suitable for large-scale industrial production.

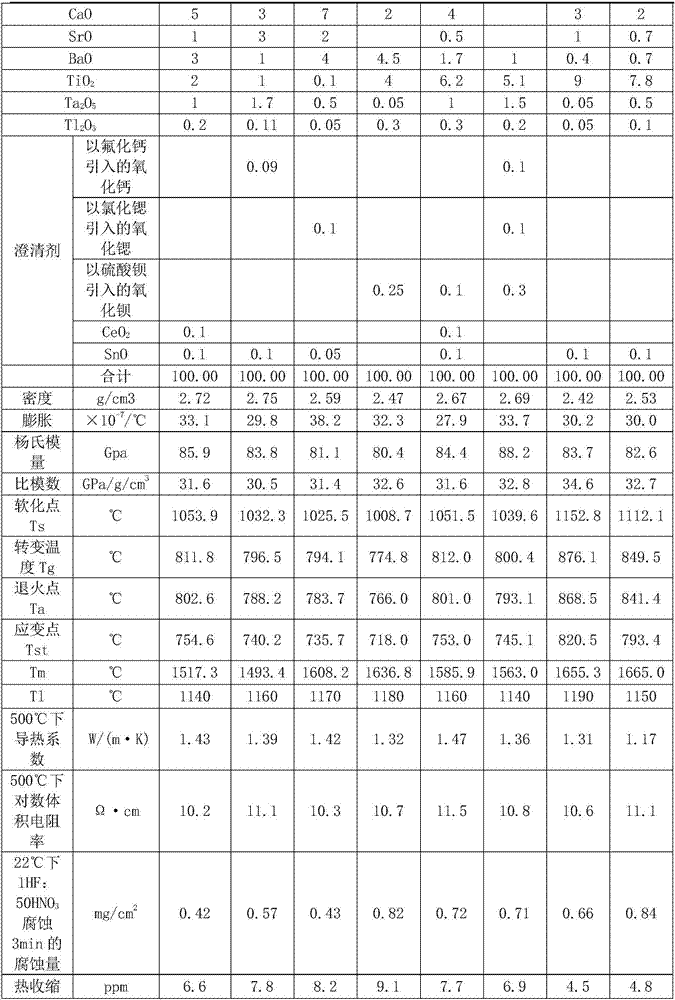

Owner:ZHENGZHOU UNIV

Composition for glass, low-brittleness alkali-free glass and preparation method and application thereof

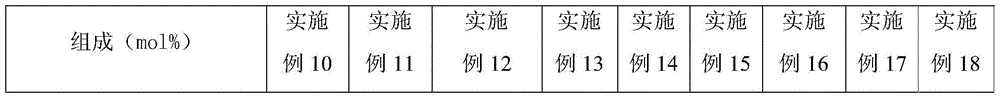

The invention relates to the field of glass and discloses a composition for glass, low-brittleness alkali-free glass and a preparation method and application thereof. The composition comprises 45-66 mol% of SiO2, 3-19 mol% of B2O3, 3-10 mol% of Al2O3, 3-12 mol% of MgO, 0-6 mol% of CaO, 0-5 mol% of SrO, 3-10 mol% of BaO, 0-3 mol% of ZnO and 0.1-6mol% of RE2O3. The glass has the high strain point, high elasticity modulus, high chemical stability, low melting temperature and high-temperature surface tension, low liquidus temperature, low expansion coefficient and low brittleness, and meanwhile has the good strength and toughness.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

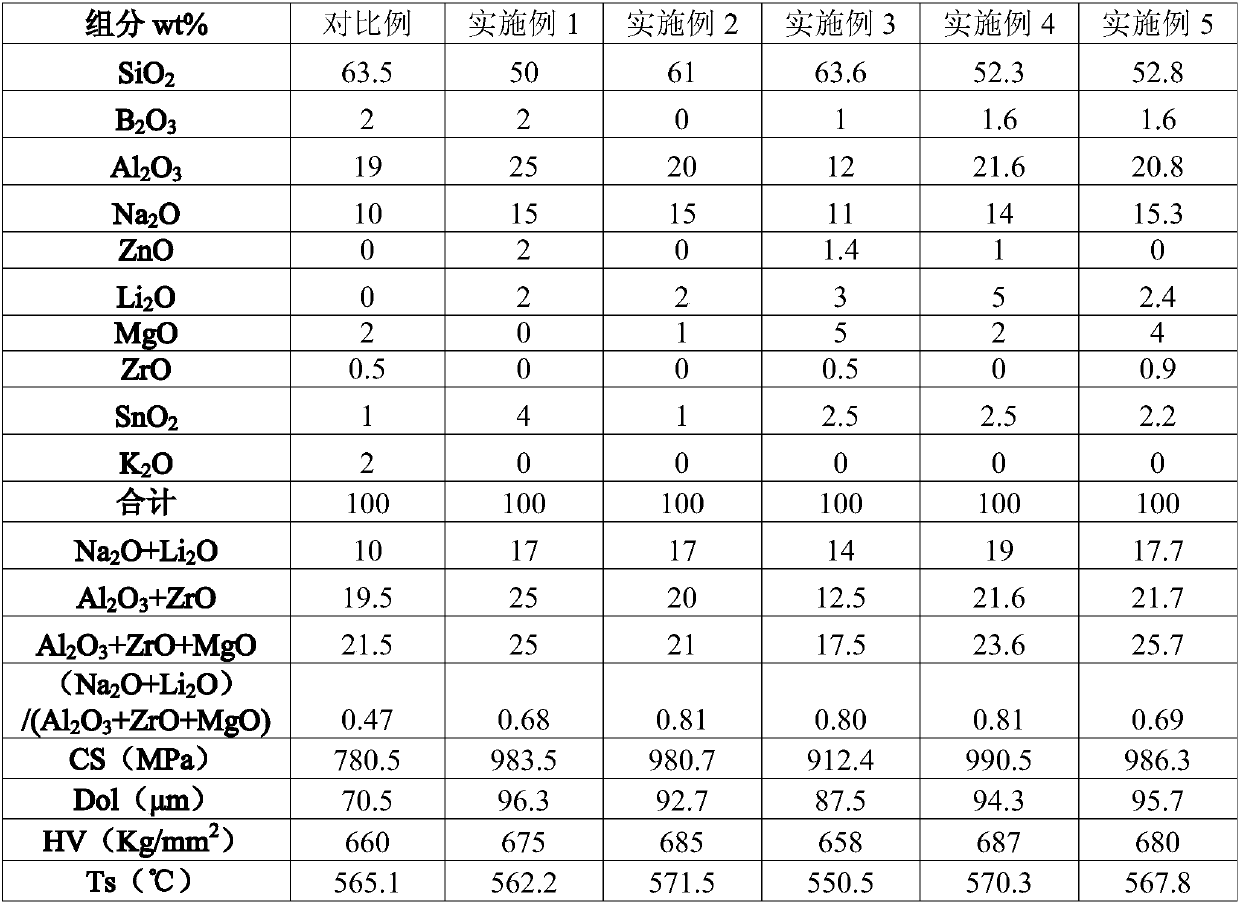

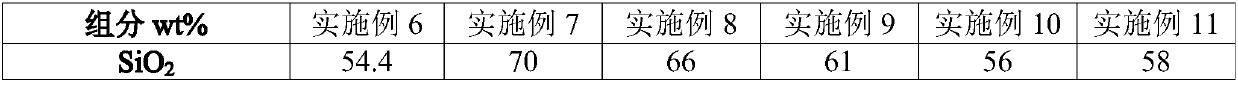

Chemical reinforced glass for electronic device and preparation method thereof

The invention provides chemical reinforced glass for an electronic device and a preparation method thereof. An ideal compression stress layer depth is obtained at relatively low reinforcing temperature and relatively short reinforcing time. The method comprises the following steps: 1) taking raw materials: greater than or equal to 50 percent and less than or equal to 70 percent of SiO2, greater than or equal to 0 percent and less than or equal to 2 percent of B2O3, greater than or equal to 12 percent and less than or equal to 25 percent of Al2O3, greater than or equal to 11 percent and less than or equal to 15 percent of Na2O, greater than or equal to 0 percent and less than or equal to 5 percent of ZnO, greater than or equal to 2 percent and less than or equal to 5 percent of Li2O, greater than or equal to 0 percent and less than or equal to 5 percent of MgO, greater than or equal to 0 percent and less than or equal to 1 percent of ZrO2, greater than or equal to 1 percent and less than or equal to 4 percent of SnO2 and greater than or equal to 0.67 and less than or equal to 0.97 of (Na2O+Li2O) / (Al2O3+ZrO2+MgO); 2) melting and clarifying and carrying out ion change. The surface compressive stress of the reinforced glass is 882.4MPa to 990.5MPa, the surface stress layer depth is 80.5mu m to 96.3mu m, the Vickers hardness is 658kg / mm<2> to 690kg / mm<2> and the strain point temperature is 550.5 DEG C to 572.2 DEG C.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

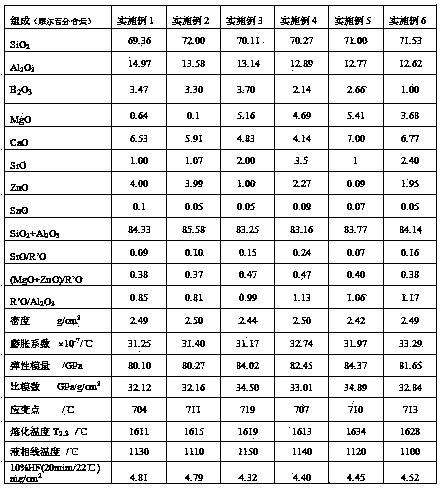

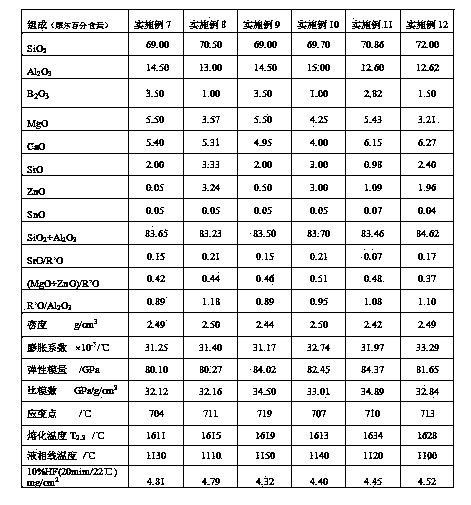

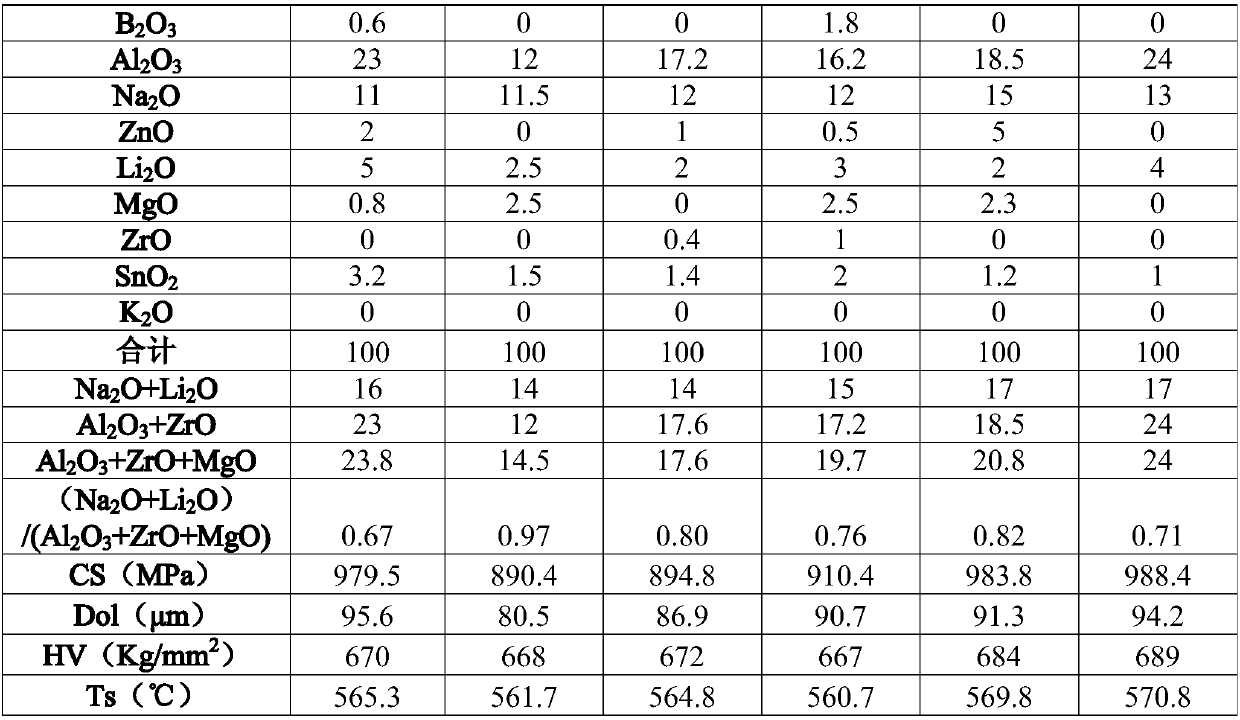

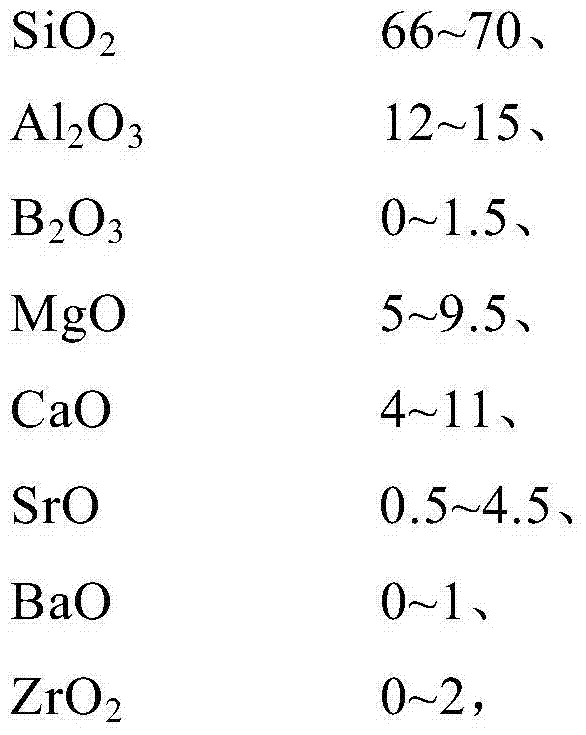

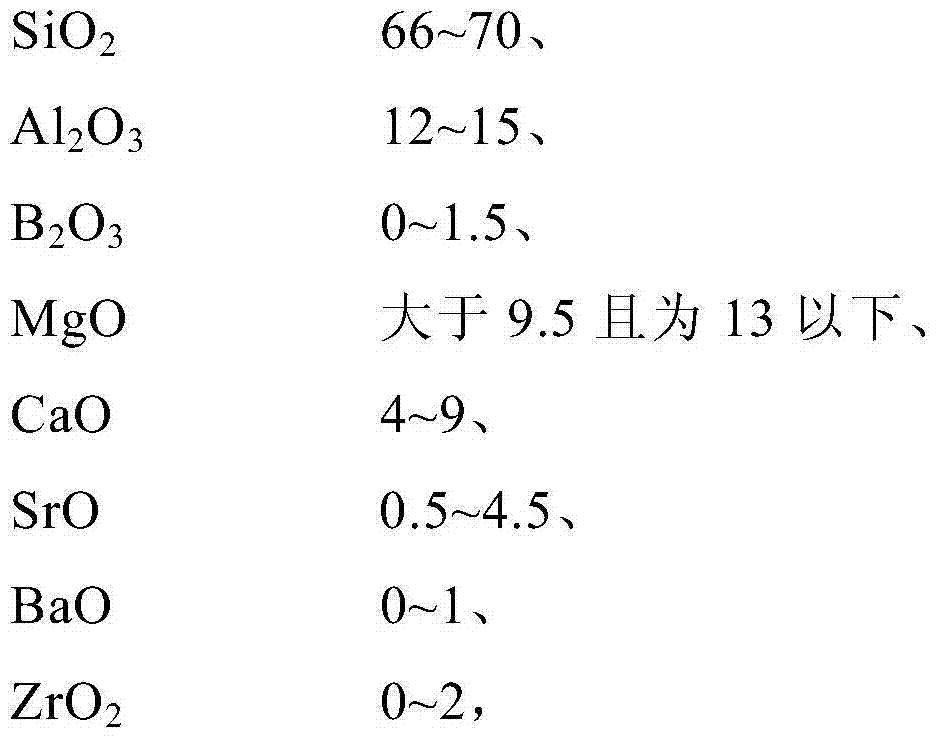

Alkali-free glass substrate and method for reducing thickness of alkali-free glass substrate

The present invention pertains to an alkali-free glass substrate reduced in thickness by at least 5 µm using hydrofluoric acid (HF) etching to yield a plate thickness of no more than 0.4 mm, wherein the alkali-free glass substrate has a relative elastic modulus of at least 32 MNm / kg and a photoelastic constant of no more than 31 nm / MPa / cm; the glass of the substrate has a distortion point of at least 710°C, an average thermal expansion coefficient at 30-350°C of 30×10-7 to 43×10-7 / °C, a temperature T2 where the viscosity is 102 dPa / s of no more than 1710°C, and a temperature T4 at which the viscosity is 104 dPa / s of no more than 1320°C; the composition of the glass expressed as an oxide-basis molar percentage is SiO2: 66 to 70%, Al2O3 : 12 to 15%, B2O3: 0 to 1.5%, MgO: greater than 9.5 to 13%, CaO: 4 to 9%, SrO: 0.5 to 4.5%, BaO: 0 to 1%, and ZrO2: 0 to 2%; MgO+CaO+SrO+BaO is 17 to 21%; MgO / (MgO+CaO+SrO+BaO) is at least 0.40%, MgO / (MgO+CaO) is at least 0.40%; and MgO / (MgO+SrO) is at least 0.60.

Owner:ASAHI GLASS CO LTD

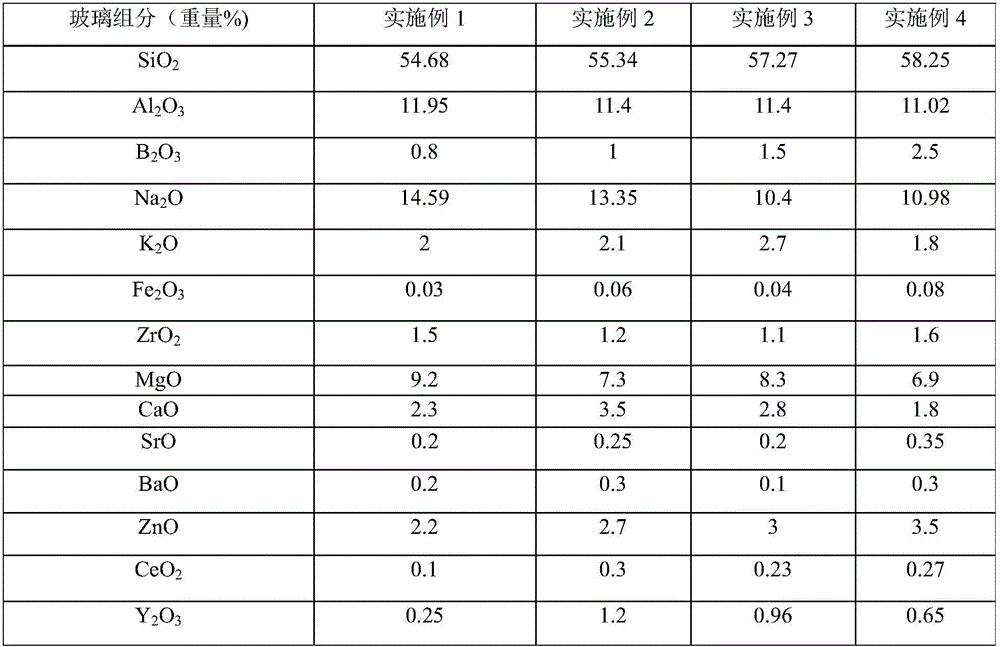

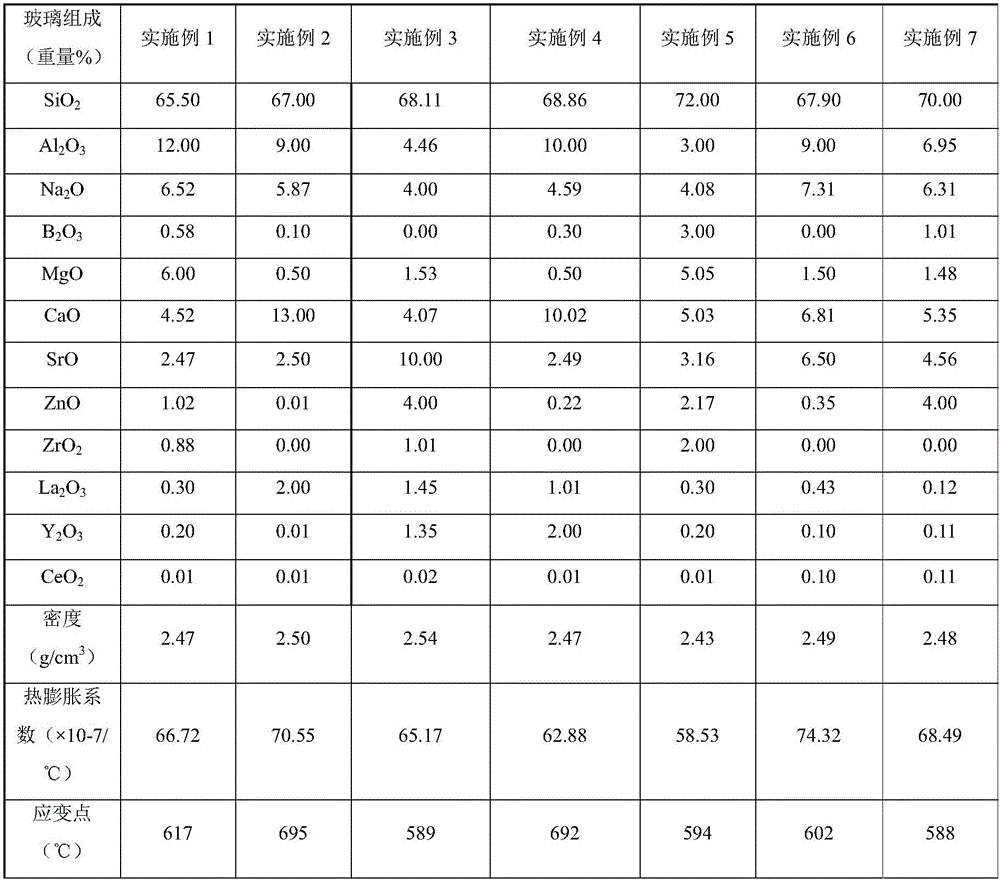

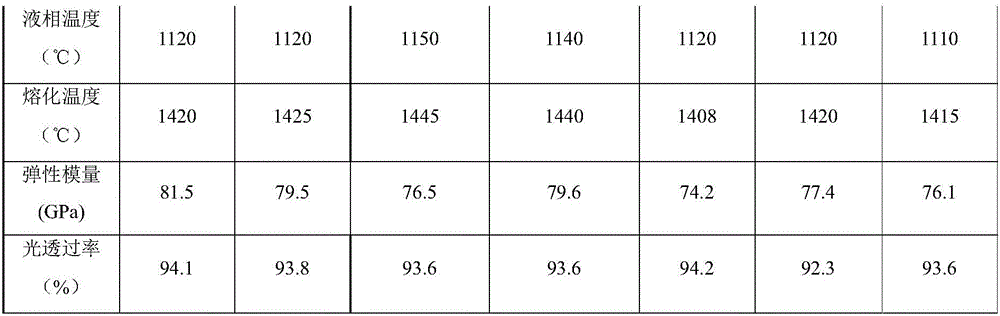

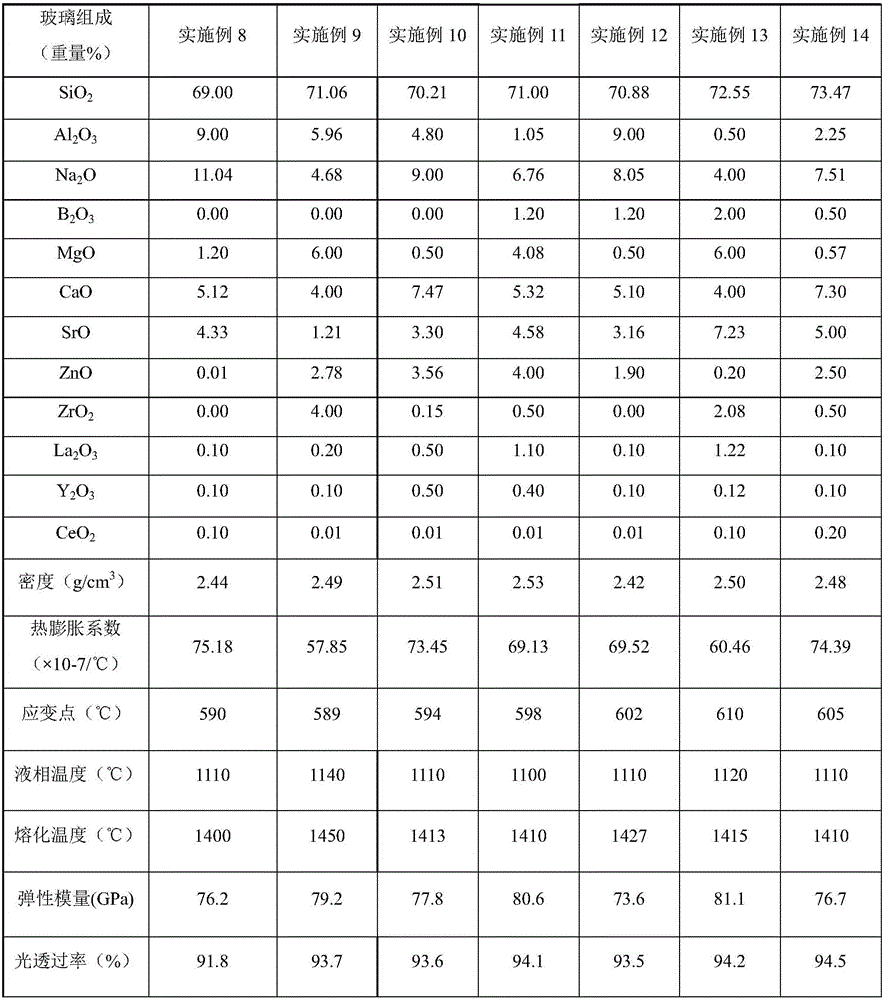

Glass composition, high-transmittance glass, preparation method of high-transmittance glass, and application of glass composition and high-transmittance glass

The invention relates to the field of glassmaking, in particular to a glass composition, high-transmittance glass, a preparation method of the high-transmittance glass, and application of the glass composition and the high-transmittance glass. The glass composition comprises SiO2, Al2O3, Na2O, MgO, CaO, SrO, ZnO, La2O3 and Y2O3. Taking the total weight of the glass composition as the benchmark, the content of SiO2 is 65.5-81%, the content of Al2O3 is 0.5-12%, the content of Na2O is 4-13%, the content of MgO is 0.05-6%, the content of CaO is 4-13%, the content of SrO is 0.5-10%, the content of ZnO is 0.01-4%, the content of La2O3 is 0.01-2%, and the content of Y2O3 is 0.01-2%. The high-transmittance glass, the preparation method of the high-transmittance glass, and the application of the high-transmittance glass are further disclosed. Through the optimization of composition of the glass, a light guide plate is relatively high in heat stability, strain point, light transmissivity and elasticity modulus and relatively low in thermal expansion coefficient, density, melting temperature and liquidus temperature.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

High strain point glass

A family of titania lanthana aluminosilicate glasses, and products such as an electronic device having a poly-silicon coating on such glass as a substrate, are disclosed. The glasses have a strain point in excess of 780 DEG C, a coefficient of thermal expansion of 20-60x10-7 / DEG C, a Young's modulus of greater than 12 Mpsi and are chemically durable.

Owner:CORNING INC

Alkali-free alumina silicate glass with high strain point

The invention relates to alkali-free alumina silicate glass with a high strain point, which comprises the following chemical components: 55-70 wt.% of SiO2, 15-25 wt.% of Al2O3, 2-11 wt.% of CaO, 1-6 wt.% of SrO, 3-10 wt.% of ZnO and 1-7 wt.% of ZrO2. The glass does not contain alkali metal oxides, heavy metal oxides, boron oxide or hazardous elements and has the advantages of high strain point, low expansion coefficient, high modulus of elasticity, low founding temperature and the like, is suitable to substrate glass of an SOC (System on Glass), especially suitable to substrate glass for a panel display.

Owner:TUNGHSU GRP

Silicate glass substrate for flat-panel display

The invention discloses a silicate glass substrate for a flat-panel display. The glass substrate comprises the following components by molar percent: 64-70% of SiO2, 12-16% of Al2O3, 3-8.5% of B2O3, 6.5-9.5% of CaO, 2.5-5% of SrO and 0.02-0.1% of SnO. The glass substrate disclosed by the invention is the silicate glass substrate for the flat-panel display having the advantages of relatively high strain point, relatively low melting temperature, relatively low liquidus temperature and environmental friendliness, and is especially applicable for glass substrates for low-temperature polysilicon thin-film transistor liquid crystal displays (LTPSTFT-LCD) and glass substrates for organic electroluminescence (OEL) displays.

Owner:TUNGHSU GRP

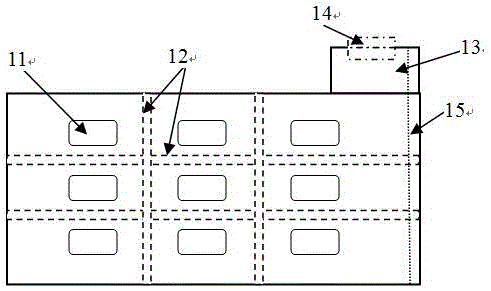

Efficient solar floor tile

ActiveCN106192655ATake advantage ofRealize intelligenceSingle unit pavingsPhotovoltaicsSurface layerPower station

The invention relates to the field of solar energy utilization and glass and mainly relates to an efficient solar floor tile. The floor tile comprises an anode plate, a cathode plate, a cathode and anode plate, a junction box and a control device. Due to the specific arrangement of a longitudinal layered structure, an urban road becomes a solar power plant. An LED part is arranged, so the urban road also becomes an information providing place, any information can be changed freely, and accordingly the overall intelligence level of a city is improved. Tempered glass on the surface layer is subjected to specific limitation, so light transmittance of the tempered glass is improved, strength and thermal properties are also improved, and the tempered glass completely meets the requirement of the specific layered structure.

Owner:泛城设计股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com