Composition for glass, low-brittleness alkali-free glass and preparation method and application thereof

An alkali-free glass and composition technology, applied in the field of glass, to achieve the effects of high elastic modulus, low melting temperature, high temperature surface tension, and low liquidus temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

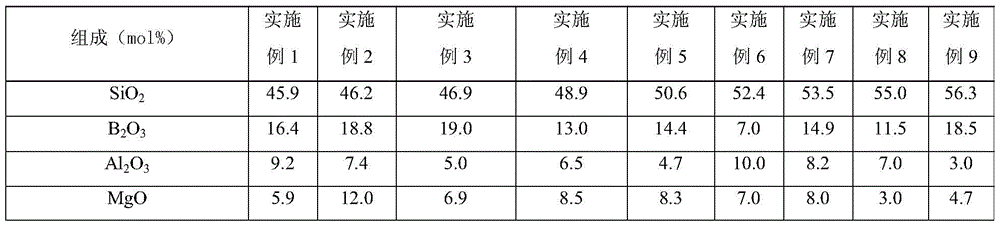

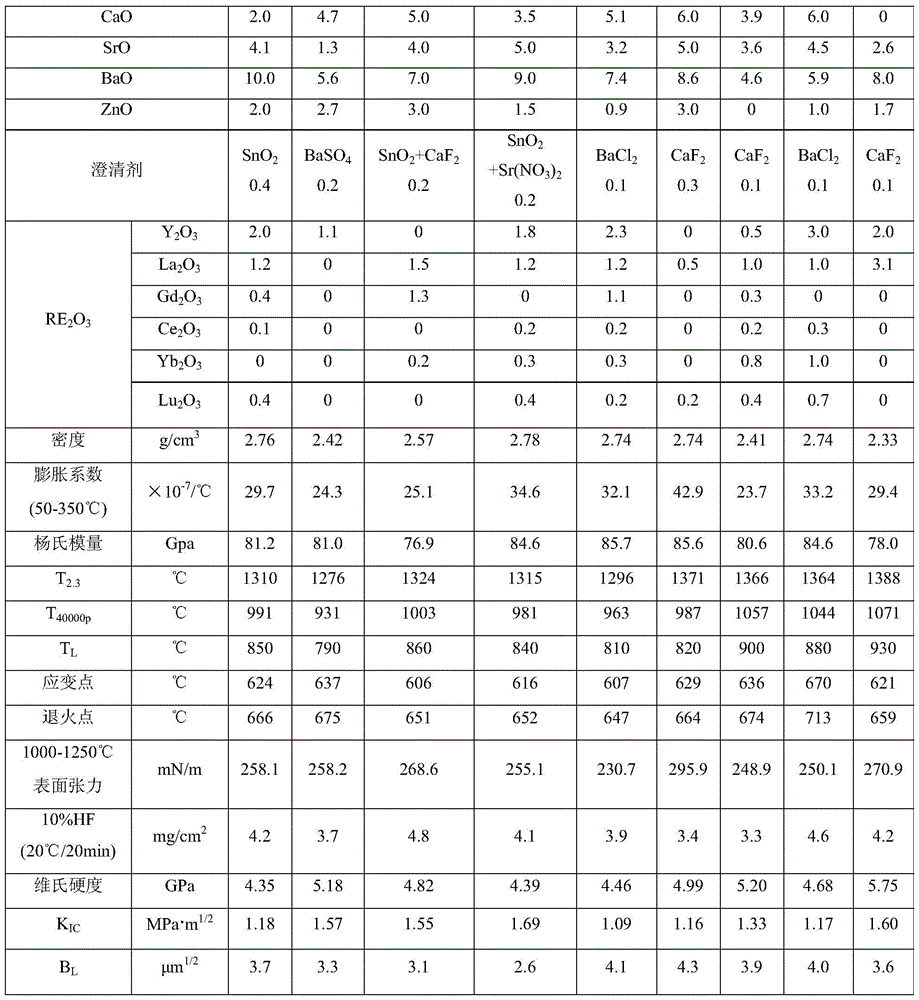

Embodiment 1-9

[0059] Weigh each component as shown in Table 1, mix well, pour the mixture into a platinum crucible, then heat in a resistance furnace at 1430°C for 4 hours, and stir with a platinum rod to remove air bubbles. Pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product. Various properties of each glass product were measured respectively, and the results are shown in Table 1.

[0060] Table 1

[0061]

[0062]

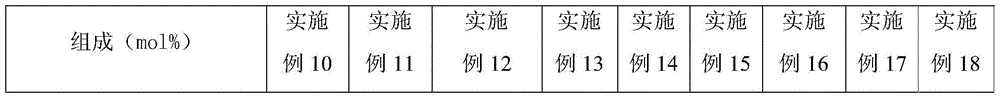

Embodiment 10-18

[0064] According to the method of Example 4, the difference is that the performance measurement results of the mixture components and the obtained product are shown in Table 2.

[0065] Table 2

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com