Tempered glass and method for producing same

A technology for strengthening glass and a manufacturing method, which can be applied to glass manufacturing equipment, manufacturing tools, glass cutting devices, etc., and can solve the problem of increasing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Hereinafter, examples of the present invention will be described. It should be noted that the following examples are merely examples. The present invention is not limited by the following examples.

[0110] Tables 1 to 3 show examples (sample Nos. 1 to 21) of the present invention. In addition, "not" in the table means not measured.

[0111] 【Table 1】

[0112] [Table 1]

[0113]

[0114] 【Table 2】

[0115] [Table 2]

[0116]

[0117] 【table 3】

[0118] [table 3]

[0119]

[0120] Each sample in the table was prepared as follows. First, glass raw materials were prepared according to the glass composition in the table, and melted at 1580° C. for 8 hours using a platinum boat. Then, the resulting molten glass was flowed onto a carbon plate to be formed into a plate shape. Various characteristics were evaluated about the obtained glass plate. In addition, as the measurement sample of strengthening characteristic, the glass plate processed to the plate th...

Embodiment 2

[0135] The glass raw materials prepared according to the glass composition described in sample No. 21 were put into a continuous melting furnace, heated, melted and clarified, and formed by a float method so that the plate thickness was 0.8 mm. Next, after processing the obtained glass into 1m×1.2m, the KNO at 420°C 3 Ion exchange treatment was performed by immersing in molten salt for 2 hours.

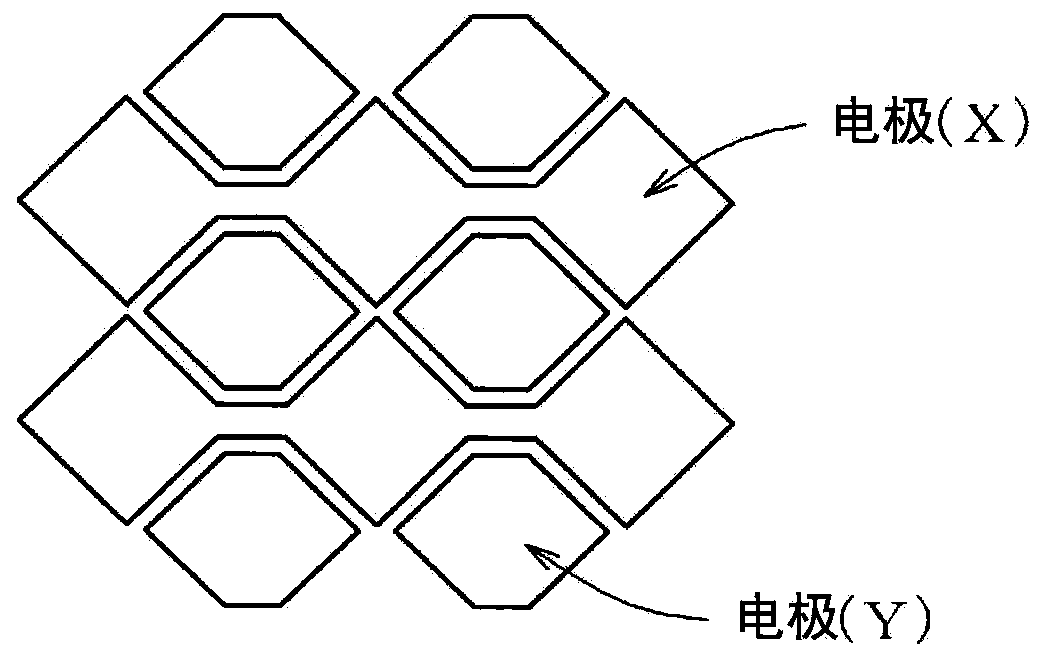

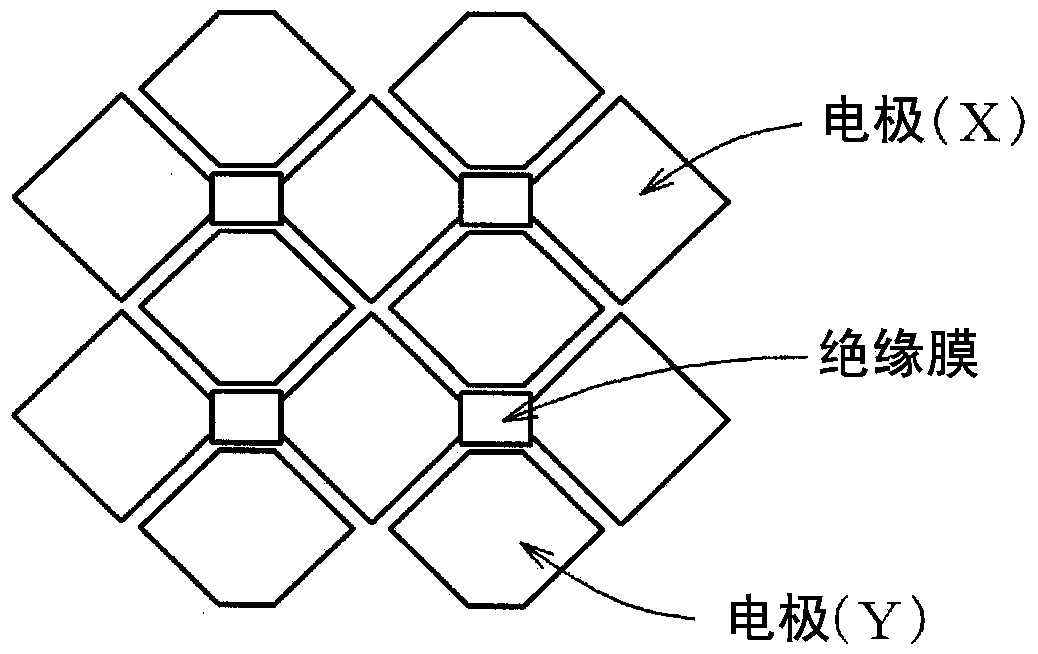

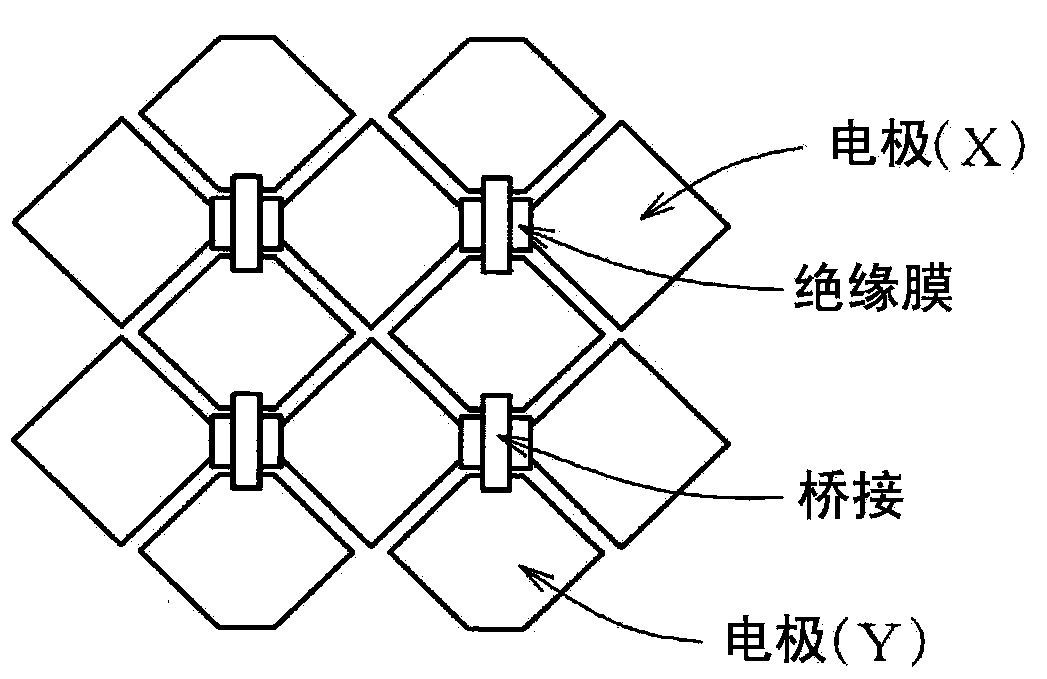

[0136] For the resulting strengthened glass, according to Figure 1A After patterning the ITO on the rectangle (for the XY direction) in this way, as Figure 1B In this way, patterning of the insulating film is performed. Furthermore, if Figure 1C In this way, the metal film bridge patterning (Y direction) was performed, and the touch panel sensor was formed on the tempered glass.

[0137] Next, masking was performed with Au in a size of 170 mm×100 mm (R=7 mm at the corner). Next, the touch panel sensor and the strengthened glass with an Au mask were immersed in 48% by mass of HF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com