Composition for glass, low-surface-tension alkali-free glass as well as preparation method and application thereof

A low surface tension, alkali-free glass technology, used in optics, instruments, electrical components, etc., can solve the problems of low thermal stability and low formation stability of alkali-free glass plates, and achieve high specific modulus, high strain point, Effects of high liquidus temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17

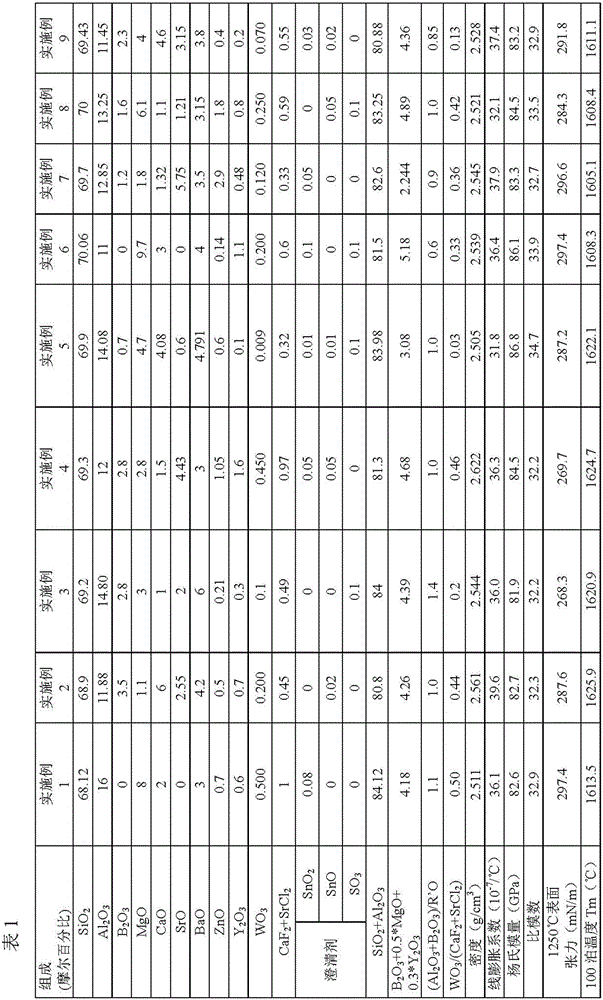

[0076] Weigh each component as shown in Tables 1 and 2, mix well, pour the mixture into a platinum crucible, then heat in a 1530°C resistance furnace for 4 hours, and stir with a platinum rod to remove air bubbles. The molten glass is poured into a stainless steel cast iron mold to form a specified block glass product, and then the glass product is annealed at 830°C for 2 hours in the annealing furnace, and then the power is turned off and the furnace is cooled to 25°C. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product. Various properties of each glass product were measured respectively, and the results are shown in Tables 1 and 2.

Embodiment 18-20 and comparative example 1-4

[0078] According to the method of Example 3, the difference is that the performance measurement results of the mixture components and the obtained product are shown in Table 3.

[0079] Comparing the data in Tables 1-2 and Table 3 shows that the glass prepared by the present invention has lower surface tension and higher comprehensive stability. The composition for glass or the alkali-free glass with low surface tension of the present invention can be used to prepare display devices and / or solar cells, especially can be used to prepare base glass substrate materials for flat panel display products.

[0080] Comparing Example 1 and Example 18, B 2 o 3 +0.5*MgO+0.3*Y 2 o 3 <8mol%, so that the thermal stability and glass formation stability of the prepared glass can be significantly improved.

[0081] Comparing Example 1 and Example 19, it can be seen that when the composition for glass contains B 2 o 3 , based on the total moles of each component of the composition for gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain point | aaaaa | aaaaa |

| Liquidus viscosity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com