Chemical reinforced glass for electronic device and preparation method thereof

A technology for strengthening glass and electronic devices, which is applied in the field of chemical strengthening glass and its preparation, can solve problems such as gaps, and achieve the effect of high scratch resistance and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

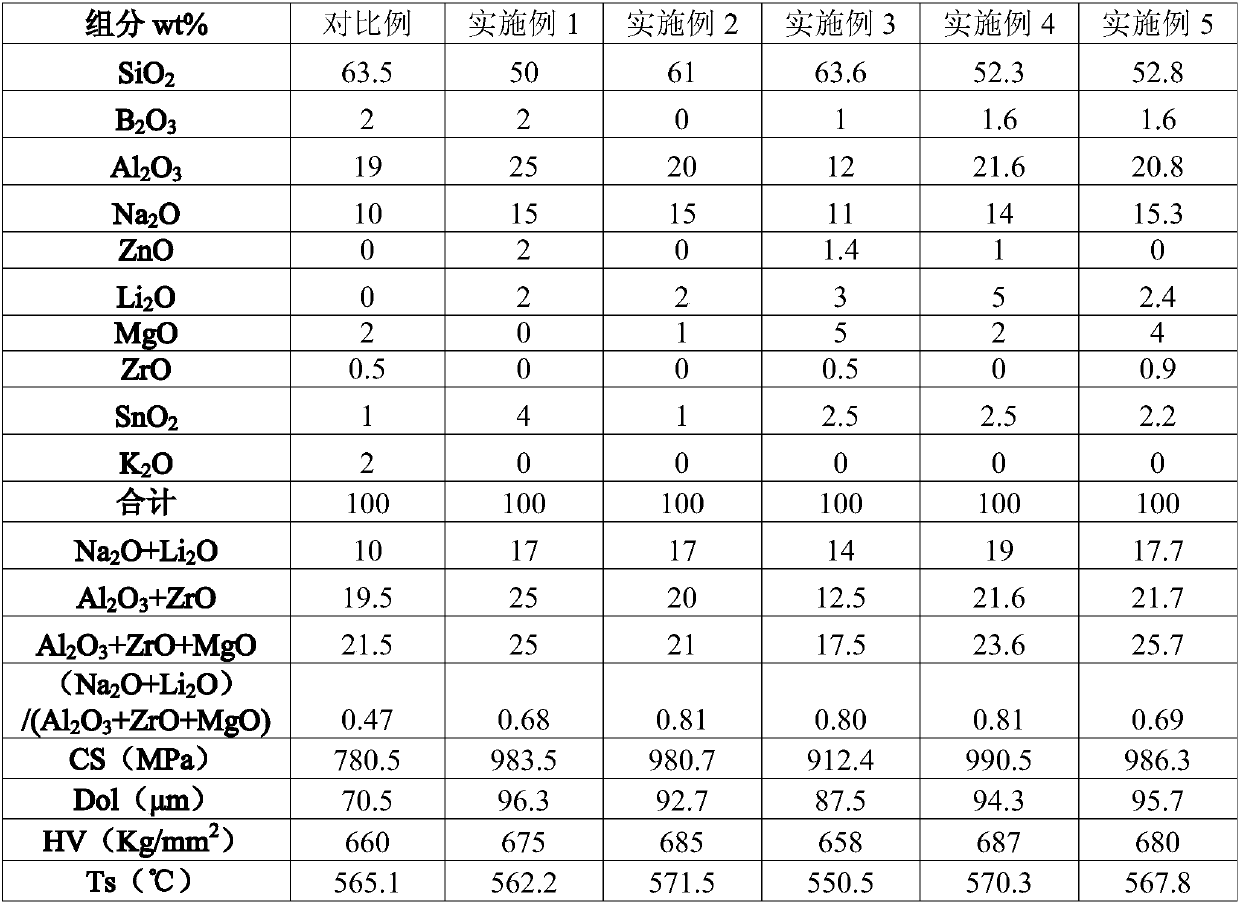

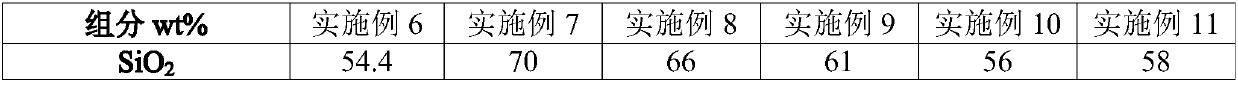

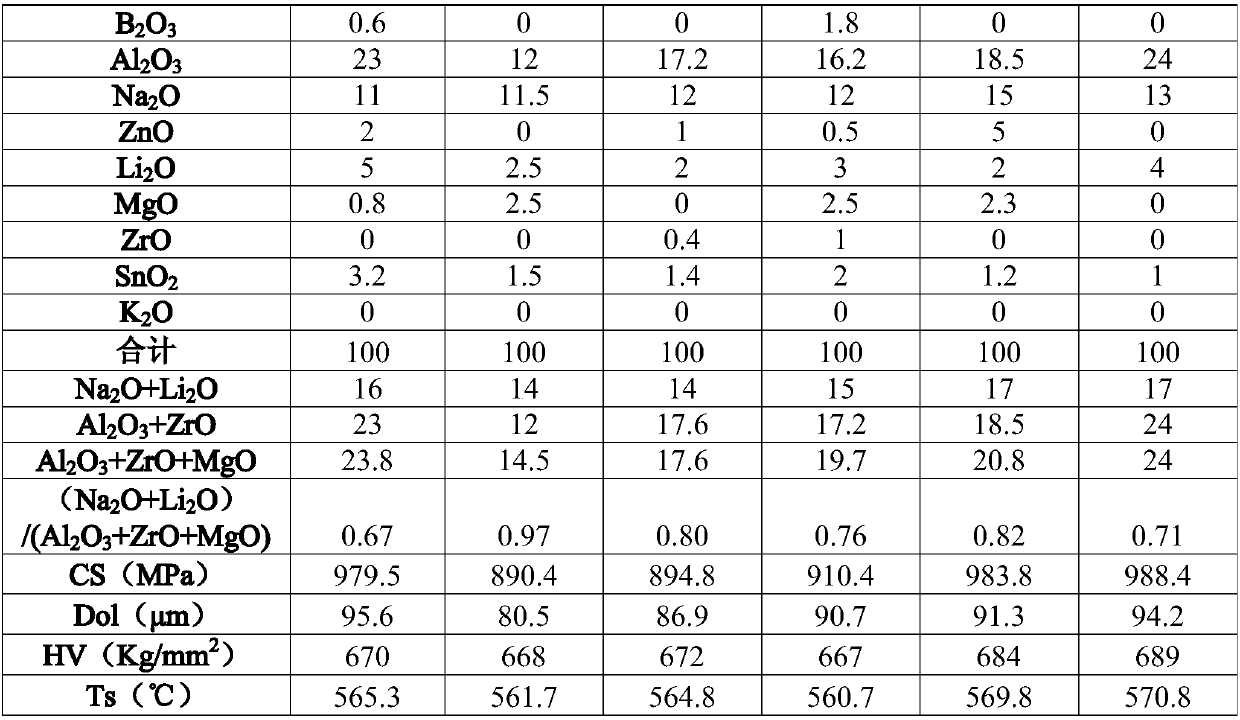

Examples

Embodiment 1

[0034] A chemically strengthened glass for electronic devices, the composition of which consists of: 50% SiO in terms of overall mass percentage 2 , 25% Al 2 o 3 , 2% B 2 o 3 , 15% Na 2 O, 2% Li 2 O, 2% ZnO and 4% SnO 2 .

[0035] The specific production process is as follows:

[0036] Step 1: Select glass raw materials according to the mass percentage of the above components, mix them thoroughly, add them into a platinum crucible, melt and clarify them in a glass melting furnace, and melt them at 1500°C to form molten glass;

[0037] Step 2: pour the molten glass into the preheated metal mold, put the metal mold into the annealing furnace for annealing, and obtain a glass block, then cut and polish the glass block into glass pieces of 110*50*0.7mm.

[0038] Step 3: Clean the glass sheet surface prepared in step 2 with deionized water for 3 times and place it in a mixed melt of molten sodium nitrate and potassium nitrate at 390°C for ion exchange treatment for 5 hours,...

Embodiment 2

[0042] A chemically strengthened glass for electronic devices, the composition of which includes: 61% SiO in terms of overall mass percentage 2 , 20% Al 2 o 3 , 15% Na 2 O, 2% Li 2 O, 1% MgO and 1% SnO 2 .

[0043] The specific production process is as follows:

[0044] Step 1: Select glass raw materials according to the mass percentage of the above components, mix them thoroughly, add them into a platinum crucible, melt and clarify them in a glass melting furnace, and melt them at 1600°C to form molten glass;

[0045] Step 2: pour the molten glass into the preheated metal mold, put the metal mold into the annealing furnace for annealing, and obtain a glass block, then cut and polish the glass block into glass pieces of 110*50*0.7mm.

[0046] Step 3: Clean the glass sheet surface prepared in step 2 with deionized water for 3 times and place it in a mixed melt of molten sodium nitrate and potassium nitrate at 400°C for ion exchange treatment for 3.5 hours, wherein sodium ...

Embodiment 3

[0050] A chemically strengthened glass for electronic devices, the composition of which includes: 63.6% SiO in terms of overall mass percentage 2 , 1% B 2 o 3 , 12% Al 2 o 3 , 11% Na 2 O, 3% Li 2 O, 0.5% ZrO, 1.4% ZnO, 5% MgO and 2.5% SnO 2 .

[0051] The specific production process is as follows:

[0052] Step 1: Select glass raw materials according to the mass percentage of the above components, mix them thoroughly, add them into a platinum crucible, melt and clarify them in a glass melting furnace, and melt them at 1650°C to form molten glass;

[0053] Step 2: pour the molten glass into the preheated metal mold, put the metal mold into the annealing furnace for annealing, and obtain a glass block, then cut and polish the glass block into glass pieces of 110*50*0.7mm.

[0054] Step 3: Clean the glass sheet surface prepared in step 2 with deionized water for 4 times and then place it in a mixed melt of molten sodium nitrate and potassium nitrate at 420°C for ion excha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com