Composition for glass, chemically strengthened glass with low brittleness, and preparation method and application of chemically strengthened glass with low brittleness

A technology for strengthening glass and composition, which is applied in the fields of low brittle chemically strengthened glass and its preparation, and glass composition. Effect of melting temperature, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

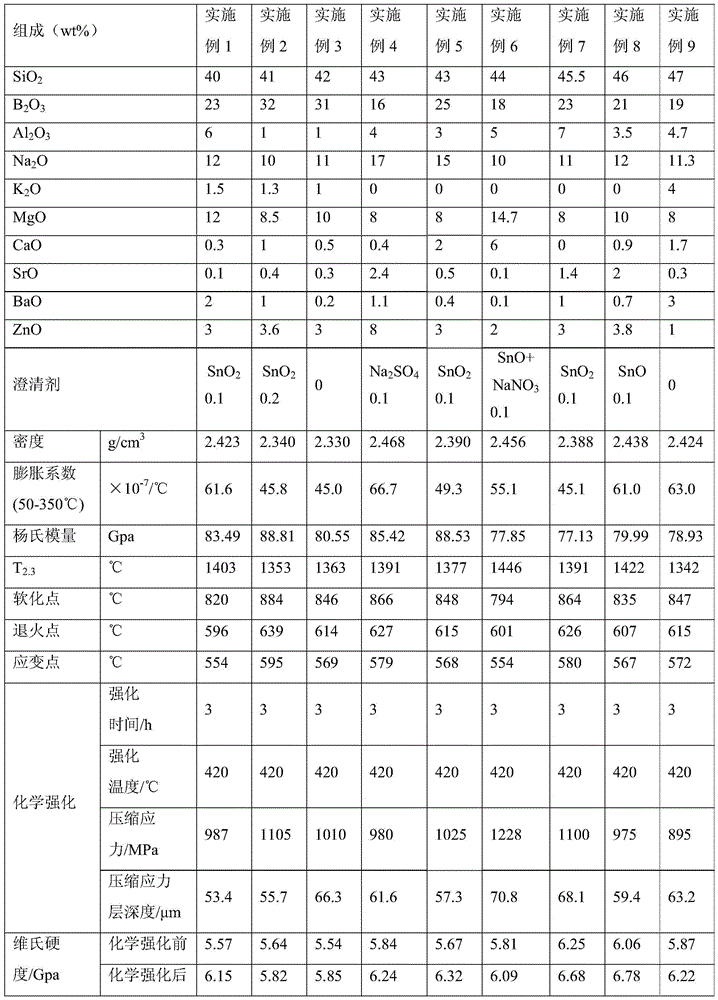

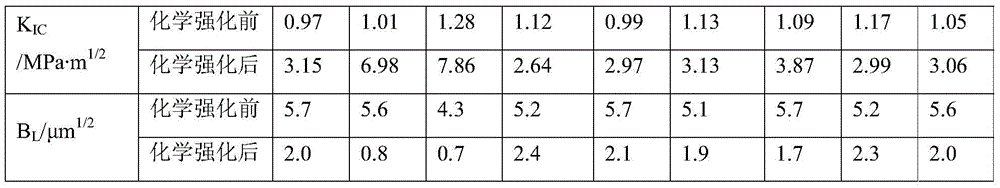

[0056] Weigh the components as shown in Table 1, mix them well, pour the mixture into a platinum crucible, and then heat it in a resistance furnace at 1430°C for 4 hours, and stir with a platinum rod to expel bubbles. Pour the molten glass into a stainless steel cast iron grinding tool and shape it into a specified block glass product. Then, the glass product is annealed in an annealing furnace for 2 hours. The power is turned off and the furnace is cooled to 25°C. Cut, grind, and polish the glass product, and clean the surface of the polished 50*50*1mm glass product with deionized water and put it into 420℃ molten KNO 3 It is treated for 3 hours, then taken out and cooled to 25°C, cleaned with deionized water and dried to obtain a glass product. The various properties of each glass product were measured, and the results are shown in Table 1.

[0057] Table 1

[0058]

[0059]

Embodiment 10-17

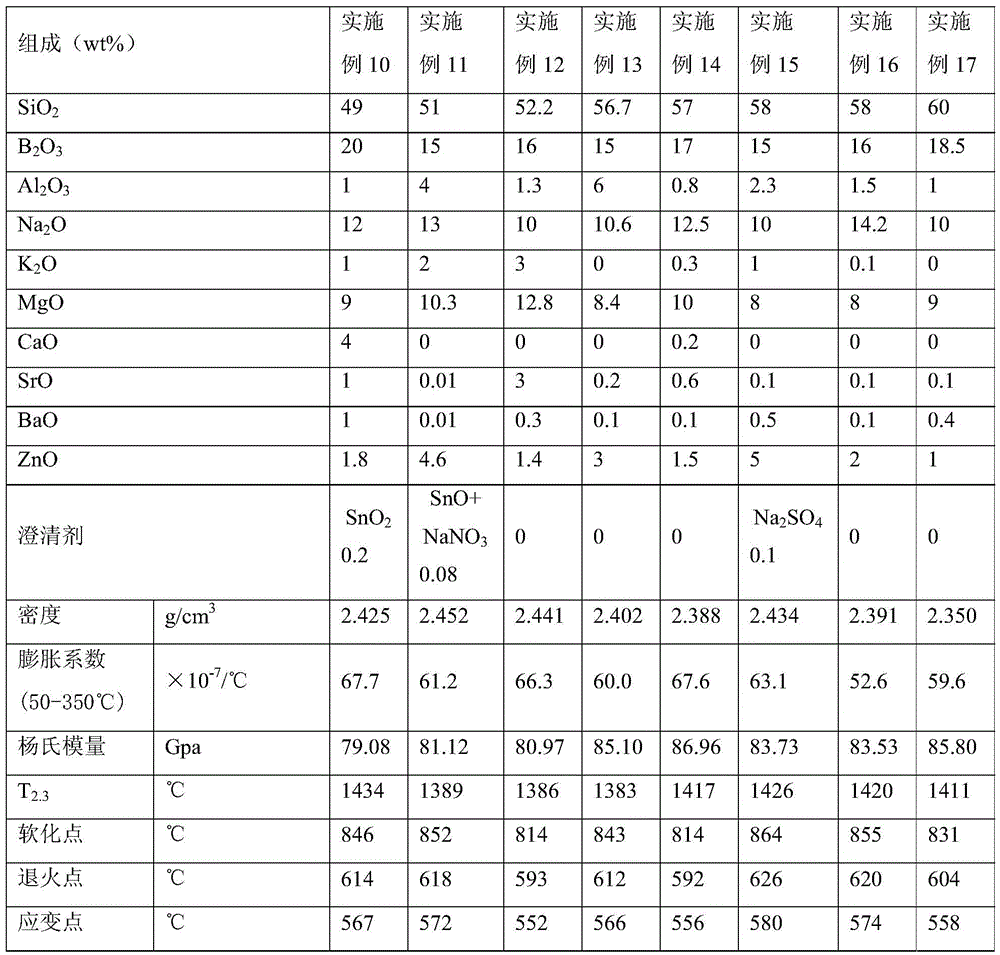

[0061] According to the method of Example 1, the difference is that the composition of the mixture and the performance measurement results of the obtained product are shown in Table 2.

[0062] Table 2

[0063]

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com