Silicon manganese slag rock/mineral wool product and preparation method thereof

A technology for silico-manganese slag and cotton products, which is applied in the field of silico-manganese slag/mineral wool products and their preparation, can solve the problems that high-quality mineral wool is difficult to succeed, etc., and achieve the effect of obvious quenching and tempering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

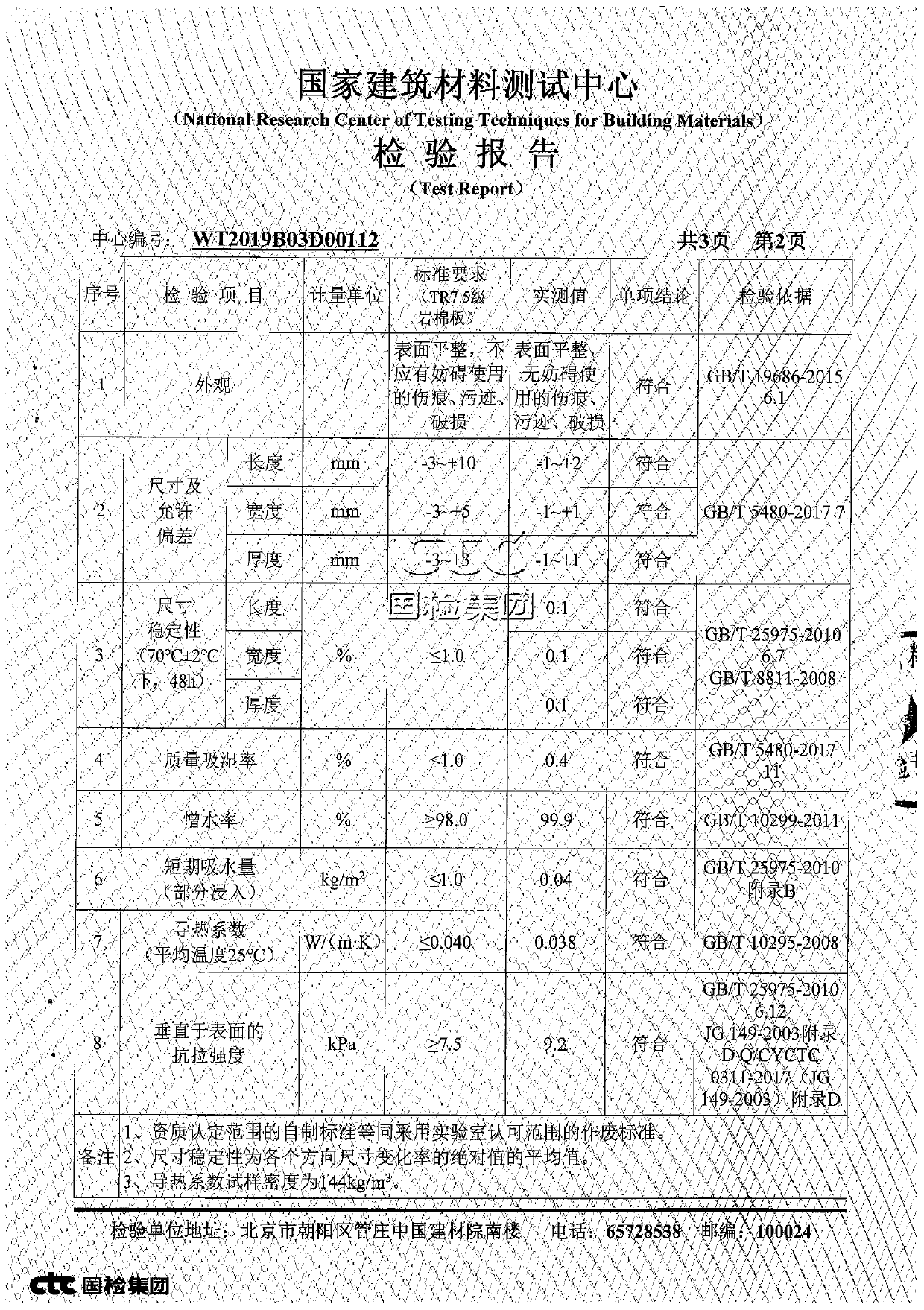

[0016] A kind of silico-manganese slag rock / mineral wool product of the present embodiment mainly consists of the following components in parts by mass: SiO 2 30-35 parts, Al 2 o 3 5-10 parts, CaO 20-25 parts, MgO 3-8 parts, MnO 10-15 parts, TFe 1-5 parts, K 2 O 3-6 parts, the corrected acidity coefficient Mk of the described silicomanganese slag rock / mineral wool products * 1.3, when the viscosity is 11-7Pa·S, the corresponding temperature is 1290-1350℃, showing short slag properties;

[0017] Corrected acidity coefficient Mk * Calculated as follows:

[0018]

[0019] for SiO 2 the weight of; for Al 2 o 3 weight; W CaO is the weight of CaO; W MgO is the weight of MgO; W MnO is the weight of MnO; W TFe is the weight of TFe; for K 2 O's weight.

[0020] A method for preparing the above-mentioned silicomanganese slag rock / mineral wool products. The silicon-manganese alloy hot slag flows into the tempering electric furnace through the ladle, adds the loess...

Embodiment 2

[0023] A kind of silico-manganese slag rock / mineral wool product of the present embodiment mainly consists of the following components in parts by mass: SiO 2 32-37 copies, Al 2 o 3 7-12 parts, 20-25 parts of CaO, 2-6 parts of MgO, 9-14 parts of MnO, 1-5 parts of TFe, K 2 O 3-6 parts, the corrected acidity coefficient Mk of the described silicomanganese slag rock / mineral wool products * 1.4, when the viscosity is 11-7Pa·S, the corresponding temperature is 1320-1380℃, showing short slag properties;

[0024] Corrected acidity coefficient Mk * Calculated as follows:

[0025]

[0026] for SiO 2 the weight of; for Al 2 o 3 weight; W CaO is the weight of CaO; W MgO is the weight of MgO; W MnO is the weight of MnO; W TFe is the weight of TFe; for K 2 O's weight.

Embodiment 3

[0028] A kind of silico-manganese slag rock / mineral wool product of the present embodiment mainly consists of the following components in parts by mass: SiO 2 35-40 parts, Al 2 o 3 7-12 parts, 20-25 parts of CaO, 2-7 parts of MgO, 8-13 parts of MnO, 1-5 parts of TFe, K 2 O 2-5 parts, the corrected acidity coefficient Mk of the described silicomanganese slag rock / mineral wool product * When the viscosity is 1.5 and the viscosity is 11-7Pa·S, the corresponding temperature is 1340-1410℃, showing the property of long slag;

[0029] Corrected acidity coefficient Mk * Calculated as follows:

[0030]

[0031] for SiO 2 the weight of; for Al 2 o 3 weight; W CaO is the weight of CaO; W MgO is the weight of MgO; WMnO is the weight of MnO; W TFe is the weight of TFe; for K 2 O's weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com