Bearing seat inner hole abrasion remanufacturing spray repair method

A repair method and bearing seat technology, which are applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of large shrinkage rate of spray coating and high repair cost, and improve mechanical matching and physical compatibility. , strong versatility, solve the effect of easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

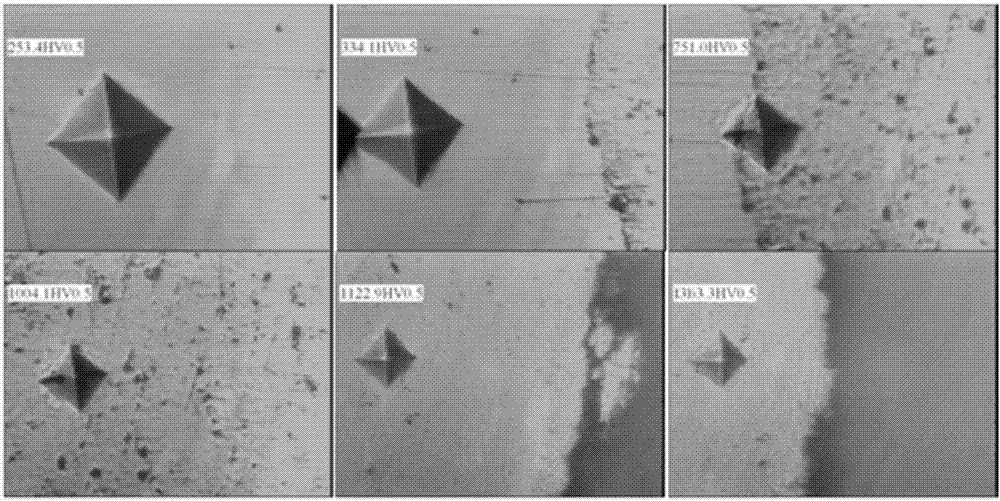

Image

Examples

Embodiment 1

[0063] The wear remanufacturing and spraying repair method of the inner hole of the bearing seat in this embodiment is applied to the repair of the inner hole of the large and medium-sized bearing seat, and the steps are as follows:

[0064] Step 1. Surface pretreatment of the inner hole of the bearing seat:

[0065] A. Remove oil stains and oil stains on the surface of the inner hole of the bearing seat;

[0066] B. Grinding the fatigue layer of the inner hole of the bearing seat;

[0067] C. Clean the surface to be sprayed with detergent;

[0068] D. The inner hole of the bearing seat is roughened before spraying to improve the adhesion of the coating;

[0069] Step 2. Preheating before spraying: place the bearing seat in the preheating device for preheating treatment to eliminate moisture and humidity on the surface to be sprayed, increase the interface temperature between the sprayed particles and the workpiece, and reduce the thermal expansion caused by the workpiece. ...

Embodiment 2

[0079] The basic steps of the method for remanufacturing and spraying the wear of the inner hole of the bearing housing in this embodiment are the same as those in Embodiment 1. The difference and improvement are that in step D of the first step, 24# special emery for thermal spraying is used for roughening treatment. The final surface roughness is Ra6~8; in step 2, the preheating temperature is controlled at 80°C; in step 3, use NiA1 material as the base, and its thickness is 0.08mm, which can eliminate the wear-resistant working layer and the inner hole of the bearing seat. The problem of thermal expansion coefficient mismatch between the base layer is to reduce the thermal stress caused by the mismatch between the expansion coefficient of the working layer and the base layer of the inner hole of the bearing seat, and improve the mechanical matching and physical compatibility between the working layer and the base layer of the inner hole of the bearing seat The working layer ...

Embodiment 3

[0085] The basic steps of the bearing seat inner hole wear remanufacturing and spraying repair method in this embodiment are the same as those in Embodiment 2, the difference and improvement are: in step D of the first step, the roughening treatment is carried out with 24# special emery for thermal spraying, and the coarsening The final surface roughness is Ra8; in step 2, the preheating temperature is controlled at 90°C; in step 3, use NiA1 material as the primer, and its thickness is 0.1mm; the working layer uses NiCr-Cr 3 C 2 Composite coating with a thickness of 0.50mm. NiCr alloy has excellent heat resistance, corrosion resistance, high temperature oxidation resistance and other properties, and also plays the role of bonding phase. Cr 3 C 2 It has good high-temperature hardness and high-temperature oxidation resistance, and acts as a hard phase. In the coating, it also mainly plays the role of dispersion strengthening of the second phase particles, which can solve the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com