Turbine rotor of micro gas turbine and casting method thereof

A technology of micro gas turbine and turbine rotor, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as inability to work stably, and achieve the effects of eliminating under-casting, reliable work, good casting process performance and forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The maximum working speed of the turbine rotor of the micro gas turbine is 90,000 RPM, the working temperature is as high as 1000°C, and the blade bears a maximum stress of about 900MPA. In order to ensure the stable operation of the turbine rotor, the present invention uses high-strength nickel-based cast superalloy K4002 as the material of the turbine rotor. The chemical composition (by mass percentage) of K4002 is as shown in table 1:

[0033] Table 1

[0034] C

Cr

Ni

co

W

Mo

AL

0.13~0.17

8.0~10.0

Remain

9.0~11.0

9.0~11.0

≦0.5

5.25~5.75

Ti

Fe

Ta

f

V

B

Zr

1.25~1.75

≦0.5

2.25~2.75

1.3~1.7

≦0.10

0.01~0.02

0.03~0.08

mn

Si

S

P

Cu

Mg

Ag

≦0.20

≦0.20

≦0.010

≦0.10

≦0.10

≦0.003

≦0.0005

Pb

Bi

≦0.0005

≦0.00005

[0035] It can be seen from Table 1 that there ...

Embodiment 2

[0058] Step 1. Design a spherical casting system according to the structure and parameters of the turbine rotor to be cast;

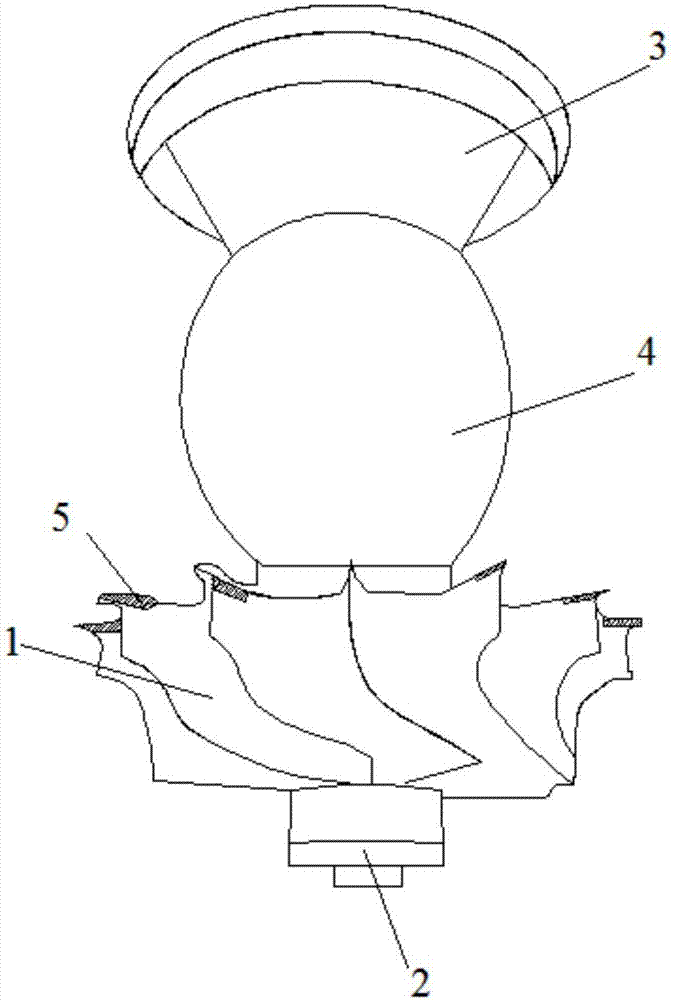

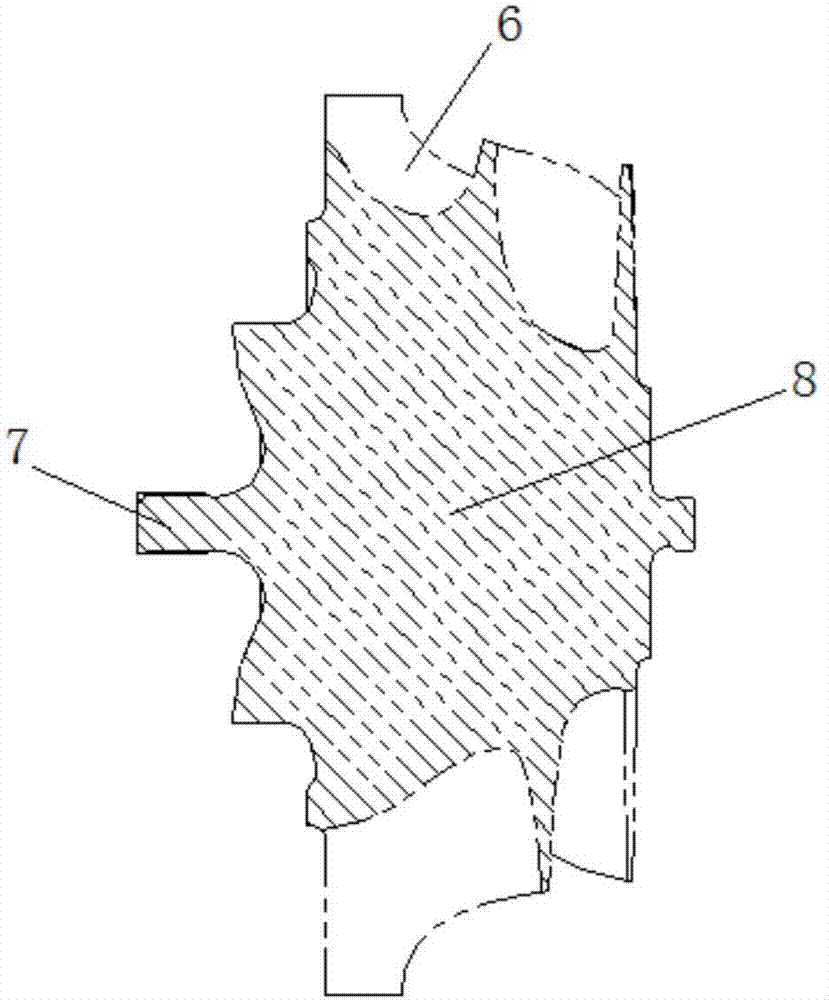

[0059] Step 2, manufacture turbine rotor wax film 2, spherical wax film 4 and runner wax film 3, wherein the blade tip of the turbine blade 1 of turbine rotor wax film 2 offers runner 5; Its structure is as follows figure 1 shown.

[0060] The shape and structural parameters of the turbine blade 1 of the wax film of the turbine rotor and the parameters of the spherical wax film 4 and the runner wax film 3 are all set by the spherical casting system in step 1. After setting, use the wax film machine to make the turbine rotor wax film 2, spherical wax film 4 and flow channel wax film 3 at 55°C and 4 bar pressure. In order to prevent under-casting during the casting process, a flow channel 5 is opened at the tip of the turbine blade 1 of the wax film 2 of the turbine rotor.

[0061] Step 3, combine the turbine rotor wax film 2, the spherical wax film 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com