Polyurethane urea elastic fibre and its preparation method

一种弹性纤维、聚氨酯脲的技术,应用在聚氨酯脲弹性纤维及其制备领域,能够解决没有描述耐光、耐废气、耐氯、抗氧化总耐候性、聚氨酯类弹性纤维性能和颜色易被日光改变、不能防止弹性体性能的等问题,达到优异耐热性和防紫外性、原有性能不会劣化、提高耐光性和加工性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A mixture of 4,4'-diphenylmethane diisocyanate and polytetramethylene ether glycol with a molar ratio of 2.0 was reacted at 90° C. for 90 minutes to prepare isocyanate-terminated polyurethane urea (prepolymer).

[0054] After cooling the prepolymer to 40°C, N,N'-dimethylacetamide was added to prepare a 45% solution containing the prepolymer. Cool the prepolymer solution to 5°C, then, to prepare the polyurethaneurea solution, add N,N'-dimethylacetamide solution containing 96% equivalent of ethylenediamine and 6% equivalent of diethylamine slowly under vigorous stirring , to grow and / or terminate its chain.

[0055] In the obtained polyurethaneurea solution, add 1.2% (weight) of 1,3,5-tri(4-tert-butyl-3-hydroxyl-2,6-xylene)-1 which accounts for the solids of the polyurethaneurea solution , 3,5-triazine-2,4,6-(1H,3H,5H)trione, 1.0% by weight of 1,1,1',1'-tetramethyl-4,4'-( Methylene-two-p-phenylene) diamino acid exhaust gas stabilizer, 1.2% (weight) of zinc oxide chlorin...

Embodiment 2

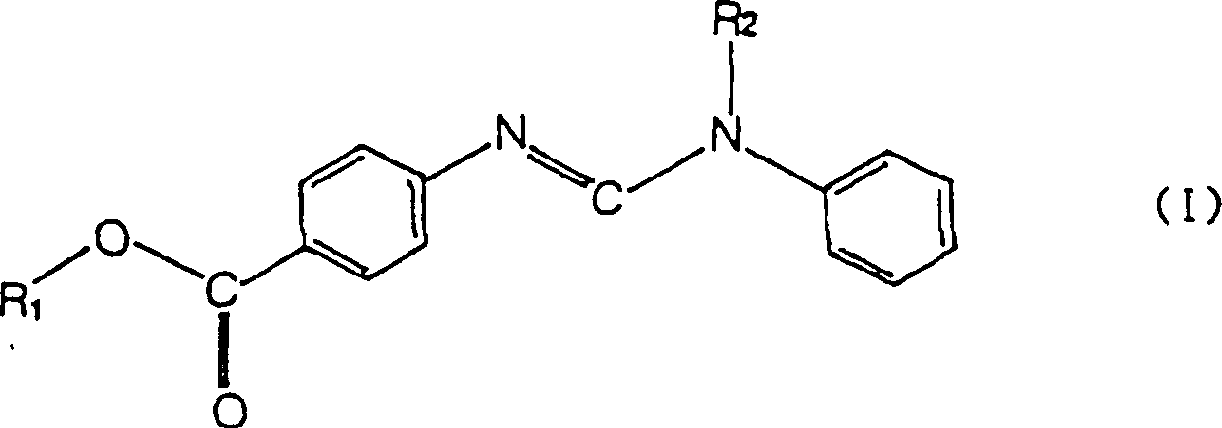

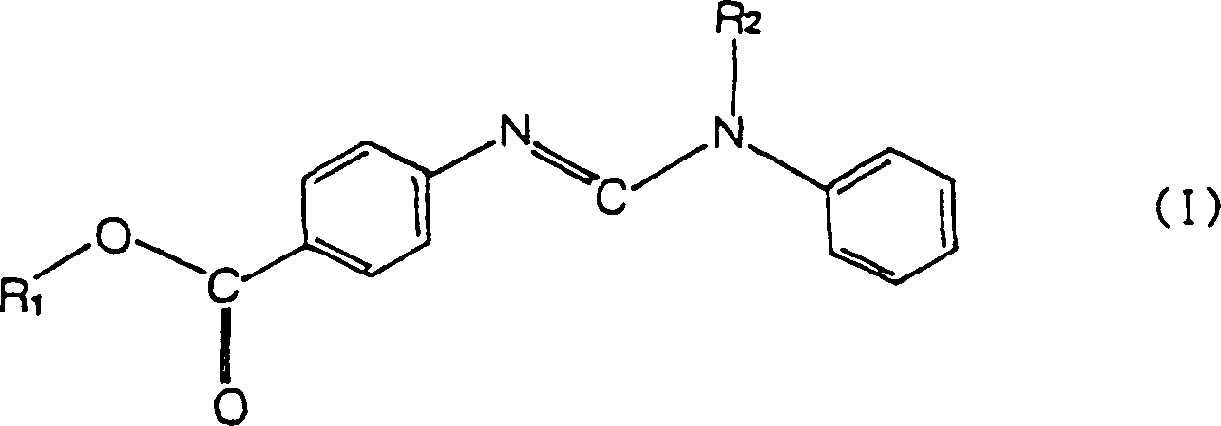

[0057] Use the method identical with embodiment 1, make polyurethane urea elastic fiber, difference is to use the additive N of 1.5% (weight). 2 -(4-carboethoxyphenyl)-N 1 -Methyl-N 1 - phenylformamidine UV absorber. Then, the light resistance, oxidation resistance (heat resistance), chlorine resistance and exhaust gas resistance of the fibers were evaluated, and the results are shown in Table 1 below.

Embodiment 3

[0059] Use the method identical with embodiment 1, make polyurethane urea elastic fiber, difference is to use the additive N of 1.0% (weight). 2 -(4-carboethoxyphenyl)-N 1 -Methyl-N 1 - phenylformamidine UV absorber. Then, the light resistance, oxidation resistance (heat resistance), chlorine resistance and exhaust gas resistance of the fibers were evaluated, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength retention rate | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com