High-strength, high-conductivity and heat-resistant aluminum alloy conductor material and preparation method thereof

A technology of aluminum alloy conductor and high conductivity, applied in the direction of metal/alloy conductor, etc., can solve the problem of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

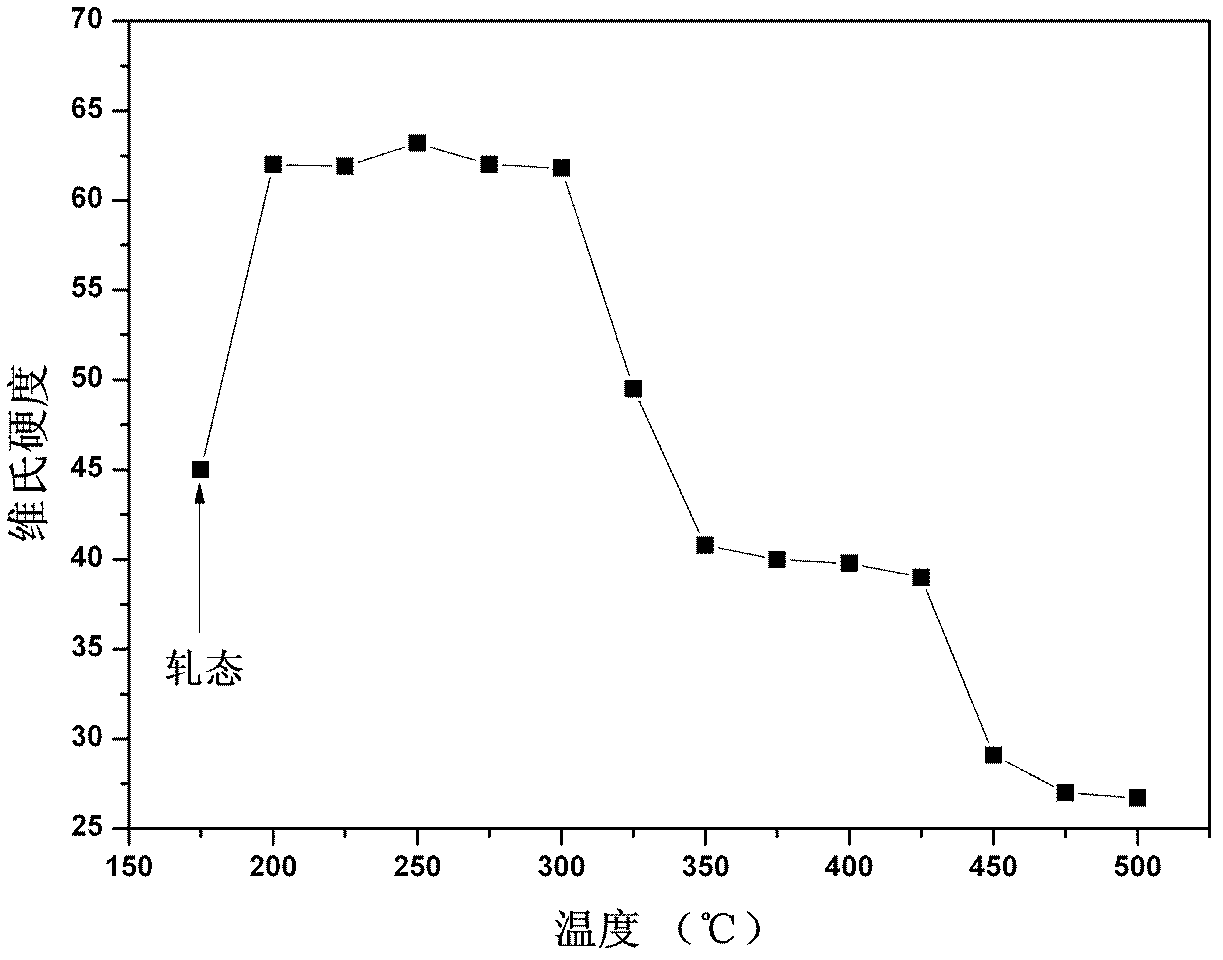

[0017] Example 1: An alloy ingot was prepared by melting in a graphite crucible and casting in an iron mold. The raw materials used were pure aluminum and Al-6Er and Al-4Zr master alloys, and the melting temperature was 780±10°C. After reaching the melting temperature, keep it warm for 30 minutes, and then cast it with an iron mold. The mass percentage of each element is: 0.20% Zr, 0.25% Er, the content of Fe, Si and other impurities figure 1 The hardness curves of heat treatment at different temperatures are given, indicating that heat treatment at 200-300°C for 3 hours after rolling can reach the highest hardness, and treatment at higher temperatures will reduce the strength of the alloy. The electrical conductivity of the alloy after heat treatment is above 60% IACS, and has high electrical conductivity.

example 2

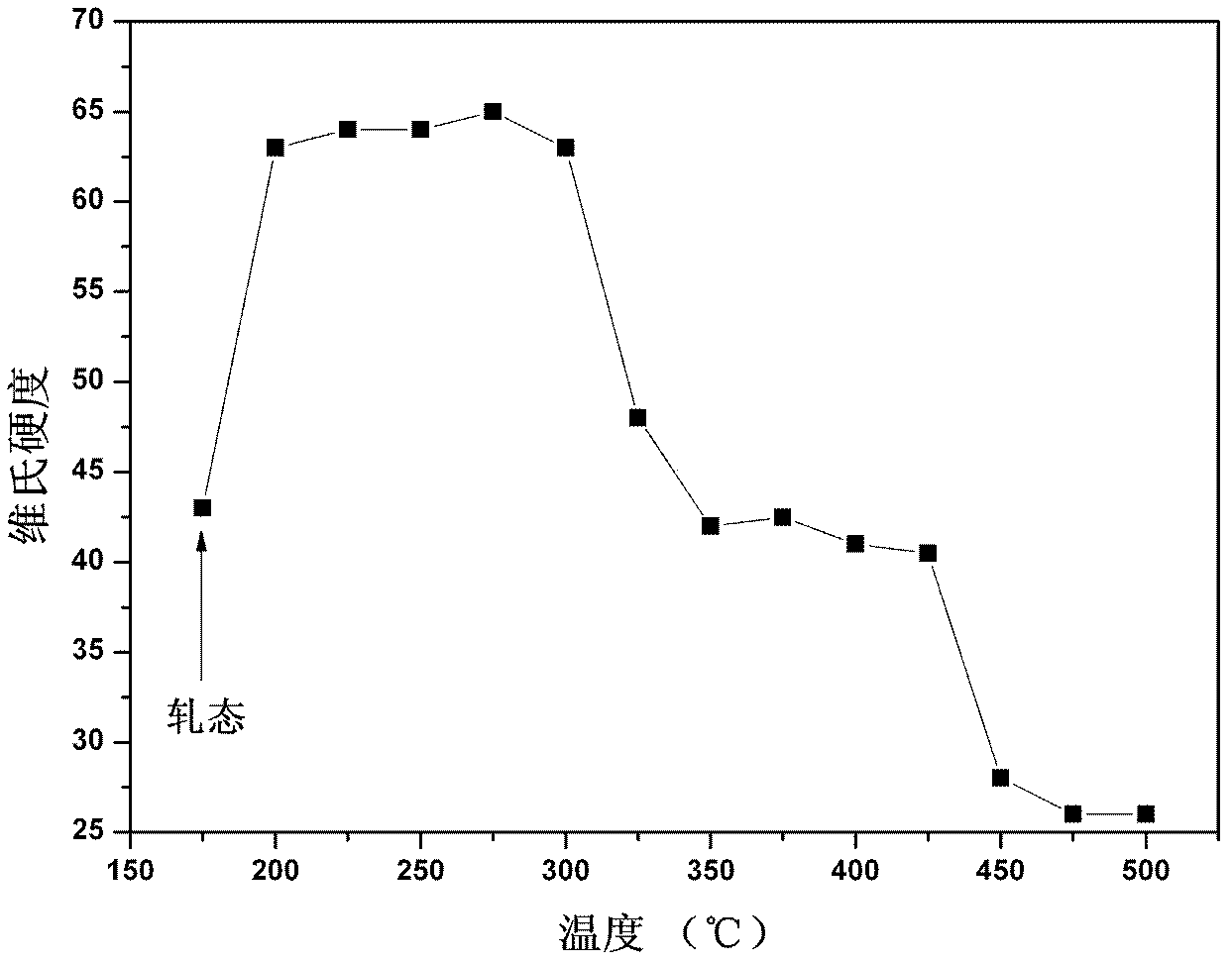

[0018] Example 2: An alloy ingot was prepared by melting in a graphite crucible and casting in an iron mold. The raw materials used were pure aluminum and Al-6Er and Al-4Zr master alloys, and the melting temperature was 780±10°C. After reaching the melting temperature, keep it warm for 30 minutes, and then cast it with an iron mold. The mass percentage of each element is: 0.30% Zr, 0.25% Er, Fe, Si and other impurity content figure 2 The hardness curves of heat treatment at different temperatures are given. It shows that heat treatment at 200~300℃ for 3 hours after rolling can reach the highest hardness, and the treatment at higher temperature will make the strength of the alloy decrease. The electrical conductivity of the alloy after heat treatment is above 59.5% IACS, and has high electrical conductivity.

example 3

[0019] Example 3: Alloy ingots were prepared by graphite crucible melting and iron mold casting. The raw materials used were pure aluminum and Al-6Er and Al-4Zr master alloys, and the melting temperature was 780±10°C. After reaching the melting temperature, keep it warm for 30 minutes, and then cast it with an iron mold. The mass percentage of each element is: 0.28% Zr, 0.15% Er, the content of Fe, Si and other impurities image 3 The hardness curves of heat treatment at different temperatures are given, indicating that heat treatment at 200-300°C for 3 hours after rolling can reach the highest hardness, and treatment at higher temperatures will reduce the strength of the alloy. The electrical conductivity of the alloy after heat treatment is above 59.8% IACS, and has high electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com