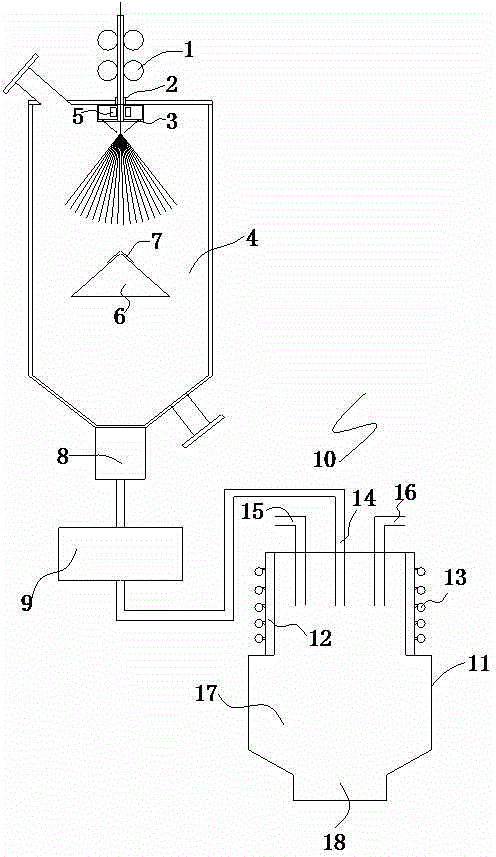

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

A spherical titanium powder, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of difficulty in controlling the shape of titanium or titanium alloy powder, high cost of electrochemical and reduction methods, and inability to control the shape of powder particles. The effect of fast processing speed, moderate equipment cost and few defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

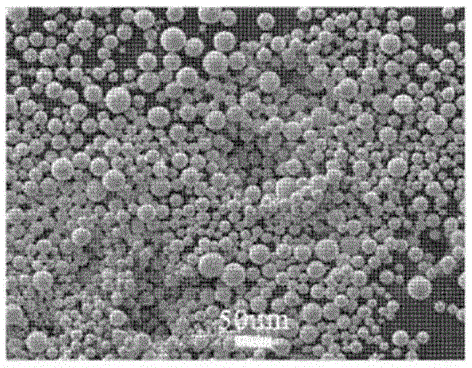

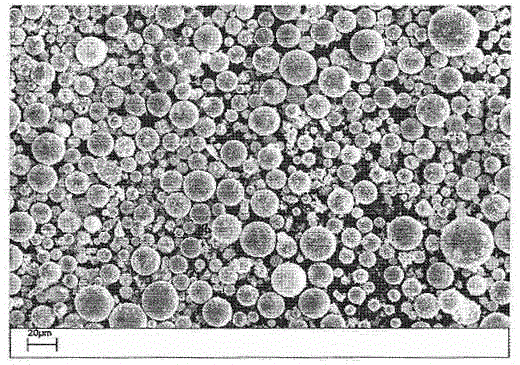

[0046] First select the titanium rod with a specification of φ50mm×500mm, send the titanium rod to the inside of the arc cathode smelting well through the automatic feeding system, and then evacuate the whole device to a vacuum degree of 1×10 -5 Pa, then fill the whole device with the inert gas argon; then use the high-purity titanium block as the anode, and use the smelting well as the cathode, in the environment of the inert gas argon, a high-intensity arc is formed by discharge, and the arc starting current is 1000A, the arc voltage is 50V; under the action of high-intensity arc, the titanium rod undergoes primary melting to form a continuous metal flow or droplet; the obtained metal flow or droplet falls freely under the action of gravity, leaving the high-intensity After the arc heating zone, it is crushed into fine metal droplets by the inert airflow generated by the annular gas atomization nozzle. The pressure of the atomizing gas is 5MPa, and the flow rate of the atomiz...

Embodiment 2

[0049] First select the titanium rod with a specification of φ50mm×500mm, send the titanium rod to the inside of the arc cathode smelting well through the automatic feeding system, and then evacuate the whole device to a vacuum degree of 1×10 -5 Pa, then fill the whole device with the inert gas argon; then use the high-purity titanium block as the anode, and use the smelting well as the cathode, in the environment of the inert gas argon, a high-intensity arc is formed by discharge, and the arc starting current is 1000A, the arc voltage is 50V; under the action of high-intensity arc, the titanium rod undergoes primary melting to form a continuous metal flow or droplet; the obtained metal flow or droplet falls freely under the action of gravity, leaving the high-intensity After the arc heating zone, it is crushed into fine metal droplets by the inert airflow generated by the annular gas atomization nozzle. The pressure of the atomizing gas is 10MPa, and the flow rate of the atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com