Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

A radio frequency plasma and atomization powder making technology, applied in the field of powder metallurgy, can solve the problem of difficulty in obtaining high-quality spherical powder, and achieve the effect of avoiding raw material purity and particle size restrictions, improving output and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

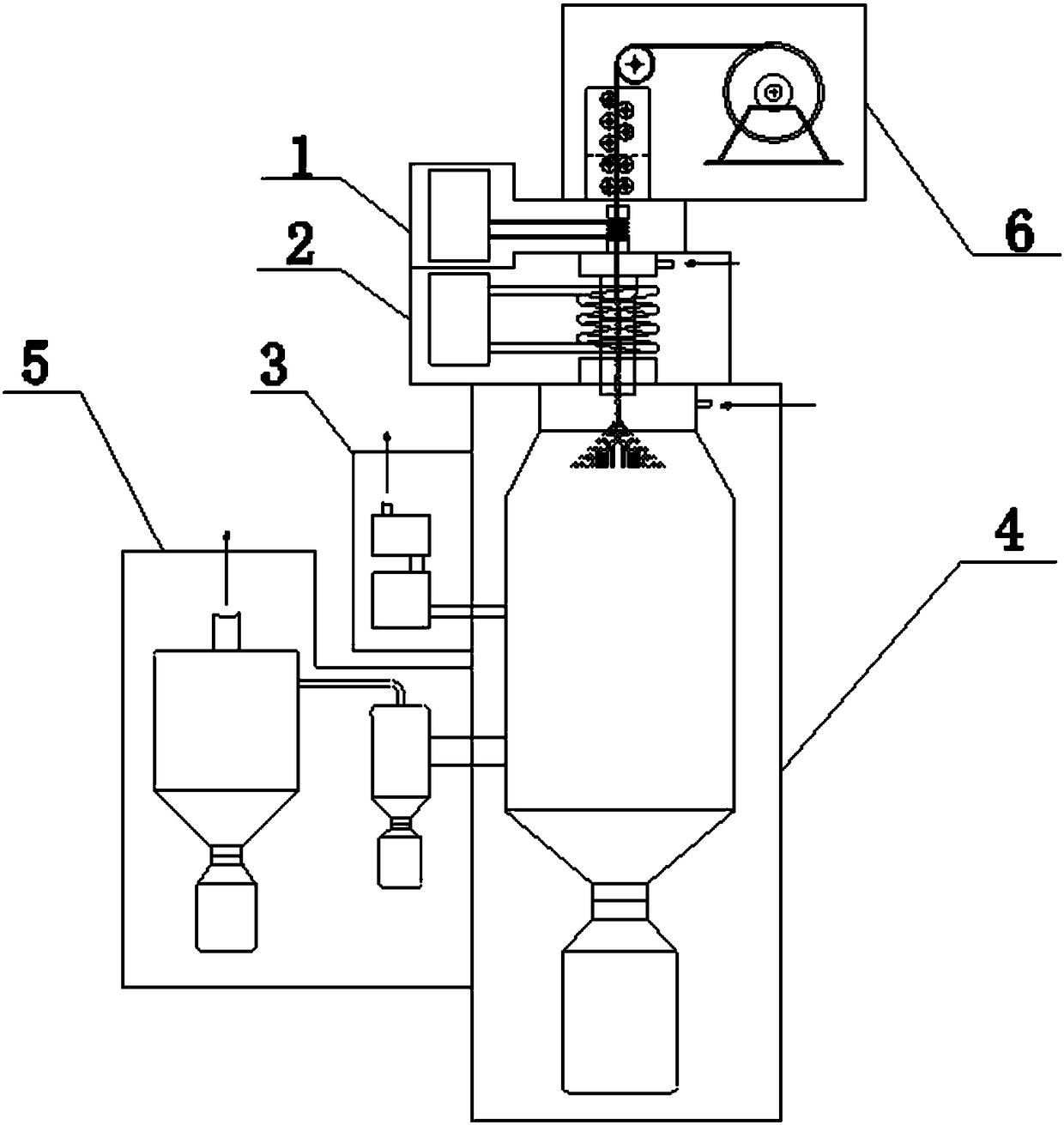

[0037] Such as figure 1As shown, a pulverizing method of an induction heating and radio frequency plasma combined atomization pulverization system, the induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum pumping Device 3, atomization collection device 4, separation dedusting device 5 and wire material conveying device 6, described powder making method is used for preparing titanium alloy TC4 spherical powder, comprises the following steps:

[0038] A. Raw material preparation and processing: the titanium alloy TC4 ingot-shaped billet is drawn into a φ3mm wire through a φ3mm die, and rolled into a disc shape, in HF: HNO 3 = 1:5 solution, ultrasonic cleaning at 50°C for 20 minutes, drying and use immediately;

[0039] B. Pre-vacuumize the system and establish a protective atmosphere: before atomization and pulverization, the entire syste...

Embodiment 2

[0047] Such as figure 1 As shown, a pulverizing method of an induction heating and radio frequency plasma combined atomization pulverization system, the induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum pumping Device 3, atomization collection device 4, separation and dust removal device 5 and wire material conveying device 6, the powder making method is used to prepare spherical powder of metal tungsten, comprising the following steps:

[0048] A. Raw material preparation and processing: use φ2mm finished tungsten wire;

[0049] B. Pre-vacuumize the system and establish a protective atmosphere: before atomization and pulverization, the entire system is vacuumed to 10 -1 Pa, system air leakage rate < 0.005Pa L / s, and then filled with helium to establish a protective atmosphere, the system pressure is controlled at -20KPa ~ +20KPa;

...

Embodiment 3

[0057] Such as figure 1 As shown, a pulverizing method of an induction heating and radio frequency plasma combined atomization pulverization system, the induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum pumping Device 3, atomization collection device 4, separation and dust removal device 5 and wire material conveying device 6, the powder making method is used to prepare spherical powder of metal tantalum, comprising the following steps:

[0058] A. Raw material preparation and processing: use φ4mm finished tantalum wire;

[0059] B. Pre-vacuumize the system and establish a protective atmosphere: before atomization and pulverization, the entire system is vacuumed to 10 -2 Pa, system air leakage rate < 0.005Pa L / s, and then filled with argon to establish a protective atmosphere, the system pressure is controlled at -40KPa ~ +40KPa;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com