Weather resistant polypropylene composite material and its preparation method and uses

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of poor mechanical properties and UV aging resistance, and achieve the effects of improving UV aging resistance, reducing damage, and promoting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

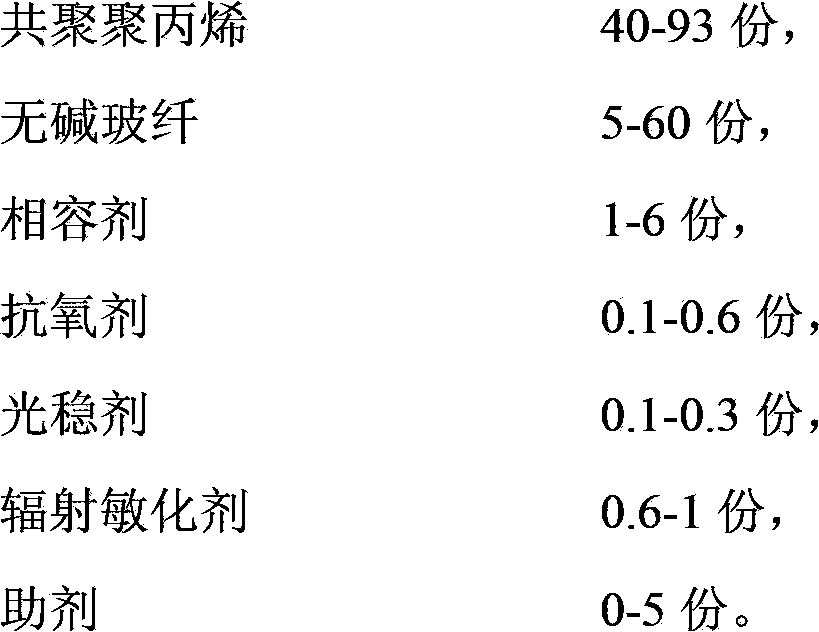

Method used

Image

Examples

Embodiment 1

[0048] (1) Weigh 93.0 parts of dry polypropylene copolymer with a melting index of 29g / 10min, 5.0 parts of continuous glass fiber, 1 part of PP-g-GMA compatibilizer, and 0.2 parts of antioxidant 1010 according to the weight ratio. Antioxidant 168 is 0.1 part, radiation sensitizer pentaerythritol acrylate is 0.6 part, and light stabilizer 5589 of Cytec Surface Technology Company is 0.1 part;

[0049] (2) Add the mixed materials into a twin-screw extruder, and melt and extrude to prepare a glass fiber reinforced composite material. Among them, the processing temperature is 180, 195, 210, 210, 220°C from the feeding port to the die port, the main engine speed is 60-80rpm, and the vacuum degree is 0.3MPa. The performance test results are shown in Table 1.

Embodiment 2

[0051] (1) Weigh 82.0 parts of dry copolymerized polypropylene with a tensile strength of 26 MPa, 10.0 parts of continuous glass fiber, 2 parts of PP-g-GMA compatibilizer, 0.2 parts of antioxidant 1010, and 0.2 parts of antioxidant 1010. Oxygen agent 168 is 0.1 part, radiation sensitizer pentaerythritol acrylate is 0.6 part, light stabilizer 5589 is 0.1 part, black masterbatch (PE2772) is 5.0 part;

[0052] (2) Add the mixed materials into a twin-screw extruder, and melt and extrude to prepare a glass fiber reinforced composite material. Among them, the processing temperature is 180, 195, 210, 210, 220°C from the feeding port to the die port, the main engine speed is 60-80rpm, and the vacuum degree is 0.3MPa. The performance test results are shown in Table 1.

Embodiment 3

[0054] (1) Weigh 76.0 parts of dry polypropylene copolymer with a melting index of 45g / 10min, 15.0 parts of chopped glass fiber, 2.4 parts of PP-g-GMA compatibilizer, and 0.2 parts of antioxidant 1010 according to the weight ratio , 0.2 parts of antioxidant 168, 0.2 parts of antioxidant DSTDP, 0.8 parts of radiation sensitizer pentaerythritol acrylate, 0.2 parts of light stabilizer 3808pp5, and 5.0 parts of black masterbatch PE2772;

[0055] (2) Add the mixed materials into a twin-screw extruder, and melt and extrude to prepare a glass fiber reinforced composite material. Among them, the processing temperature is 180, 195, 210, 210, 220°C from the feeding port to the die port, the main engine speed is 60-80rpm, and the vacuum degree is 0.3MPa. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com