Coarse cereal instant rice and preparation method thereof

A technology for instant rice and miscellaneous grains, applied in the field of food processing, can solve the problems of poor rehydration of products, and achieve the effects of low loss of nutrients, bulky tissue state, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 89 parts of corn flour, 10 parts of starch, and 1 part of solid vegetable oil are fully mixed, and 25 kg of mixed raw materials are sent to the solid feeder at a speed of 100 kg / h. Then it is sent to the twin-screw extruder, and the temperature in each temperature zone is adjusted to 60°C for zone II, 100°C for zone III, 110°C for zone IV, 70°C for zone V, and 50°C for zone VI, with the screw speed It is 220r / min, and the amount of water added is 30%. The temperature of the die head is 80°C. The mature material is cut and transported to a fluidized bed at 80°C for drying, so that the moisture reaches 8%. Finally, it is sieved and packaged after cooling.

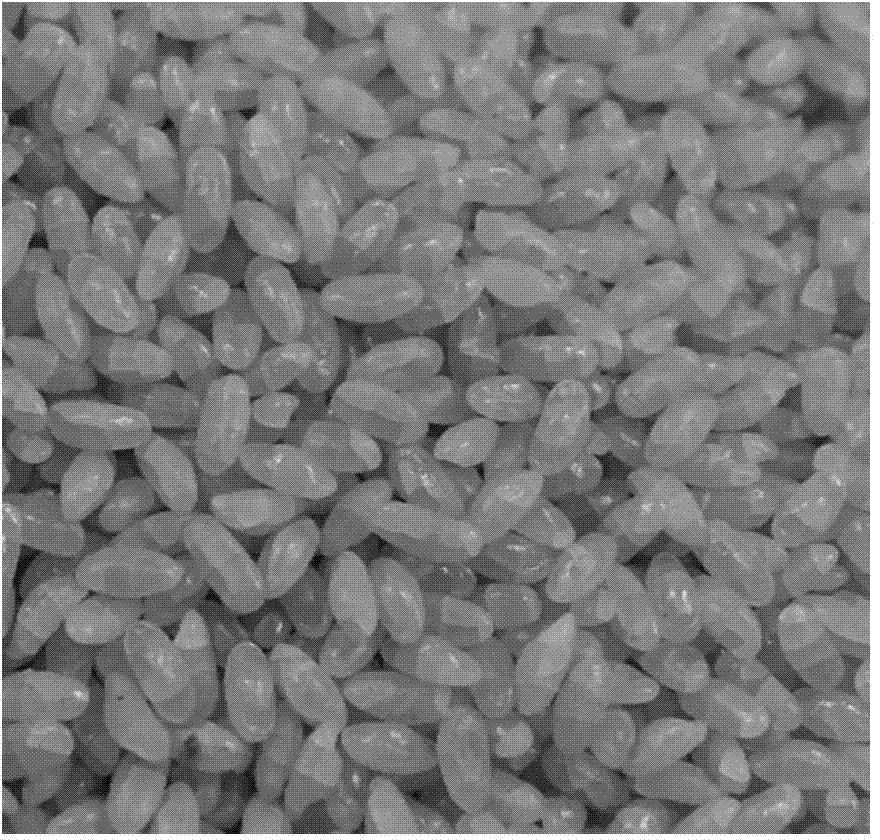

[0035] Conclusion: The grains of instant rice with miscellaneous grains obtained from the above tests are compact and have no puffing phenomenon inside (see figure 1 ), the rehydration property was very poor, and the rehydration time was as long as 30 minutes.

Embodiment 2

[0037] 89 parts of corn flour, 10 parts of starch, and 1 part of solid vegetable oil are fully mixed, and 25 kg of mixed raw materials are sent to the solid feeder at a speed of 100 kg / h. Then it is sent to the twin-screw extruder, and the temperature in each temperature zone is adjusted to 60°C for zone II, 100°C for zone III, 110°C for zone IV, 70°C for zone V, and 50°C for zone VI, with the screw speed It is 220r / min, and the amount of water added is 30%. The temperature of the die head is 80°C, the cured material is cut, transported to a fluidized bed at 80°C for drying, so that the moisture reaches 15%, and then baked at a high temperature of 150°C for 1-2 minutes, so that the moisture reaches 8%. Finally, carry out sub-sieving treatment, and pack after cooling.

[0038] Conclusion: The rice grains of instant rice with miscellaneous grains obtained from the above experiments are dense in texture, with only a few small air bubbles inside, which are not uniform, and the re...

Embodiment 3

[0040] 89 parts of corn flour, 10 parts of starch, and 1 part of solid vegetable oil are fully mixed, and 25 kg of mixed raw materials are sent to the solid feeder at a speed of 100 kg / h. Then it is sent to the twin-screw extruder, and the temperature in each temperature zone is adjusted to 60°C for zone II, 100°C for zone III, 110°C for zone IV, 70°C for zone V, and 50°C for zone VI, with the screw speed It is 220r / min, and the amount of water added is 30%. The temperature of the die head is 80°C, the cured material is cut, transported to a fluidized bed at 80°C for drying, so that the moisture content reaches 12%, and then baked at a high temperature of 190°C for 1-2 minutes, so that the moisture content reaches 8%. Finally, carry out sub-sieving treatment, and pack after cooling.

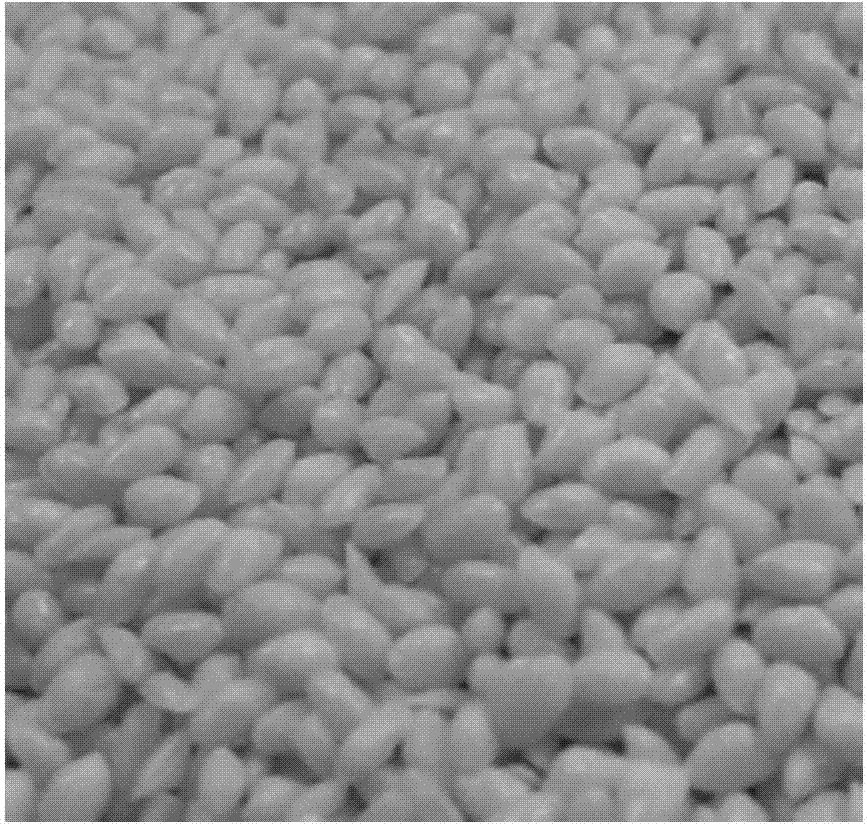

[0041] Conclusion: the texture state of rice grains of instant rice obtained from the above tests is more bulky and the surface is smooth (see figure 2 ), there are uniform air bubbles inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com