Milk containing jelly and method for its manufacture

A milk fruit and fruit granule technology, which is applied in the field of milk-containing jelly and its production, can solve the problems of children's health damage, low nutritional content and low content, and achieve the effects of expanding the sales range, reducing the gel strength, and making the tissue soft and moderate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Formula (according to 1 ton):

[0029] Milk 300.0 kg white sugar 30.0 kg fructose syrup 60.0 kg sucrose fatty acid ester 1.0 kg gelatin 0.3 kg locust bean gum 0.1 kg carrageenan 0.2 kg grape juice 66.0 kg lactic acid 1.3 kg citric acid 2.5 kg essence 1.82 kg purified water 536.78 kg.

[0030] Raw material standard:

[0031] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0032] White granulated sugar: in line with the national first-class standard.

[0033] High fructose syrup: F≥42.0%.

[0034] Grape Juice:

[0035] grape puree;

[0036] Pulp system pH3.7;

[0037] Brix 35BX.

[0038] Purified water, lactic acid, citric acid: in line with national standards.

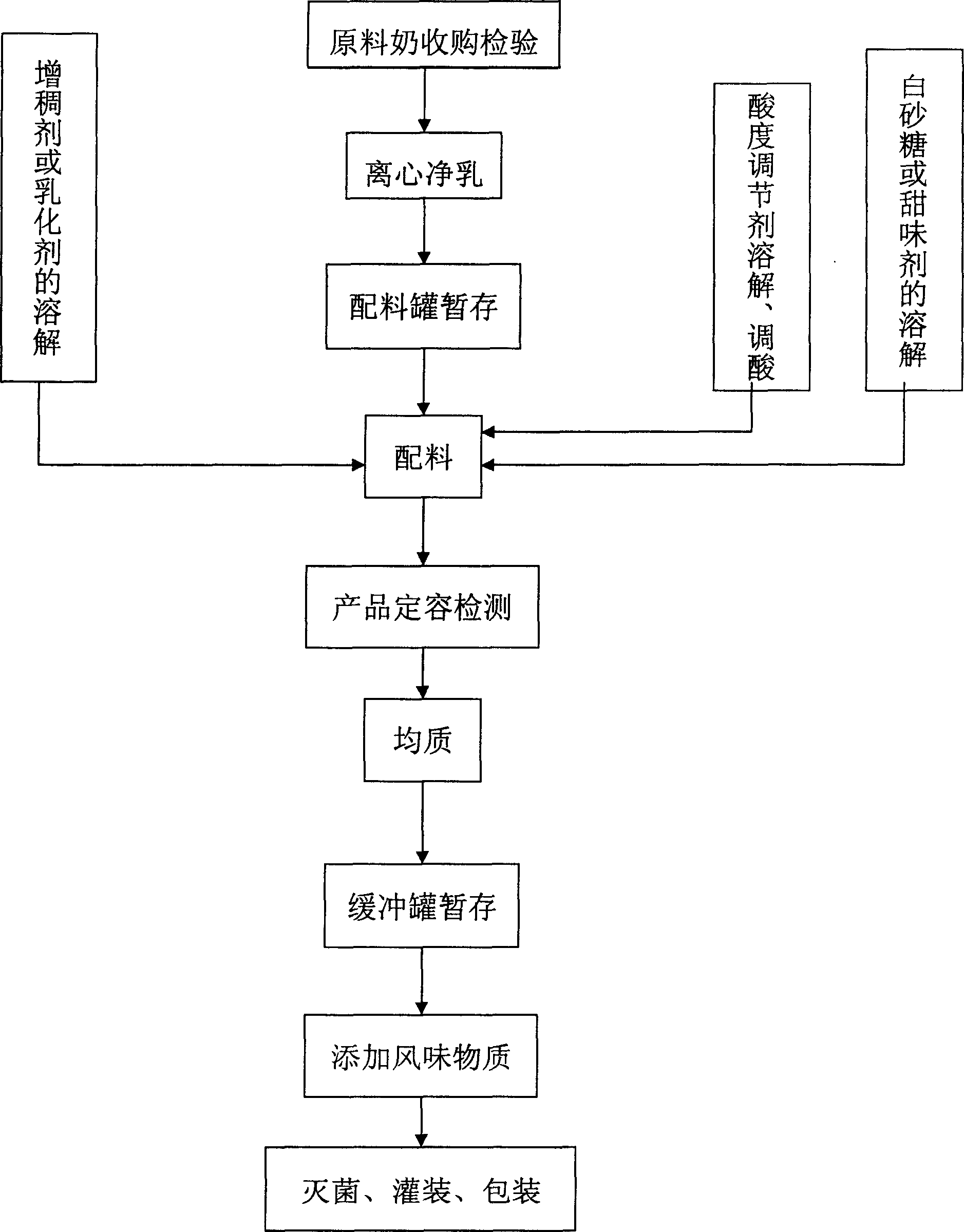

[0039] Milk-containing jelly of the present invention presses figure 1 The shown process route is produced, and the preparation process is as follows:

[0040] 1) Pour cold milk at 4°C into the chemical tank, and slowly raise the temperature to 55°C. Pour into the ingredients jar.

[00...

Embodiment 2

[0052] Formula (according to 1 ton):

[0053] Milk 460.0 kg white sugar 30.0 kg fructose syrup 55.0 kg pectin 0.8 kg konjac gum 0.2 kg polyglyceride 0.3 kg vitamin A, vitamin D, calcium lactate 2.3 kg malic acid 1.1 kg citric acid 1.3 kg essence 1.64 kg purified water 497.36 kg .

[0054] Raw material standard:

[0055] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0056] White granulated sugar: in line with the national first-class standard.

[0057] High fructose syrup: F≥42.0%.

[0058] Vitamin A, D, calcium: in line with national standards.

[0059] Purified water, lactic acid, citric acid: in line with national standards.

[0060] Preparation Process:

[0061] 1) Pour cold milk at 6°C into the chemical tank, and slowly raise the temperature to 45°C. Pour into the ingredients jar.

[0062]2) Dissolution of the stabilizer: mix the stabilizer, vitamins A, D, calcium and white sugar evenly, take an appropriate amount of pure water and heat it to 80°C...

Embodiment 3

[0073] Formula (according to 1 ton):

[0074] Milk 500.0 kg white sugar 55.0 kg fructose syrup 53.0 kg glycerin fatty acid ester 0.3 kg gellan gum 0.7 kg pectin 0.4 kg lactic acid 1.7 kg citric acid 2.0 kg essence 0.67 kg purified water 386.23 kg.

[0075] Raw material standard:

[0076] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0077] White granulated sugar: in line with the national first-class standard.

[0078] High fructose syrup: F≥42.0%.

[0079] Purified water, lactic acid, citric acid: in line with national standards.

[0080] Preparation Process:

[0081] 1) Pour 8°C cold milk into the chemical tank and slowly raise the temperature to 50°C. Pour into the ingredients jar.

[0082] 2) Dissolution of the stabilizer: Mix the stabilizer and white sugar evenly, take an appropriate amount of pure water and heat it to 76°C, add the mixture of the stabilizer into the hot water, dissolve for 12 minutes, and pour the mixture into the Ingredient jar,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com