Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid cracking tendencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous aluminium oxide base ceramic fibre preparation method

ActiveCN101381225AAvoid instabilityAvoid cracking tendenciesInorganic material artificial filamentsFiberSilicon dioxide

The invention provides a method for preparing a continuous alumina-based ceramic fiber, which relates to an alumina-based ceramic fiber, in particular to a method for preparing a continuous alumina-based ceramic fiber which takes alumina as a main component and adds a second component as a crystalling phase inhibitor. The invention provides a method for preparing the continuous alumina-based ceramic fiber, which is simple in technique and low in cost. The method comprises the steps: preparing alumina sol; preparing silicon dioxide sol; mixing the alumina sol and the silicon dioxide sol to obtain biphase sol, and adding a spinning addition agent into the biphase sol; condensing the biphase sol added with the addition agent and spinning by a dry method to obtain the gel fiber; pyrolyzing the gel fiber to obtain the ceramic fiber; and sintering the ceramic fiber to obtain the continuous alumina-based ceramic fiber.

Owner:FUJIAN ESTABLISHED YATE TAO CO LTD

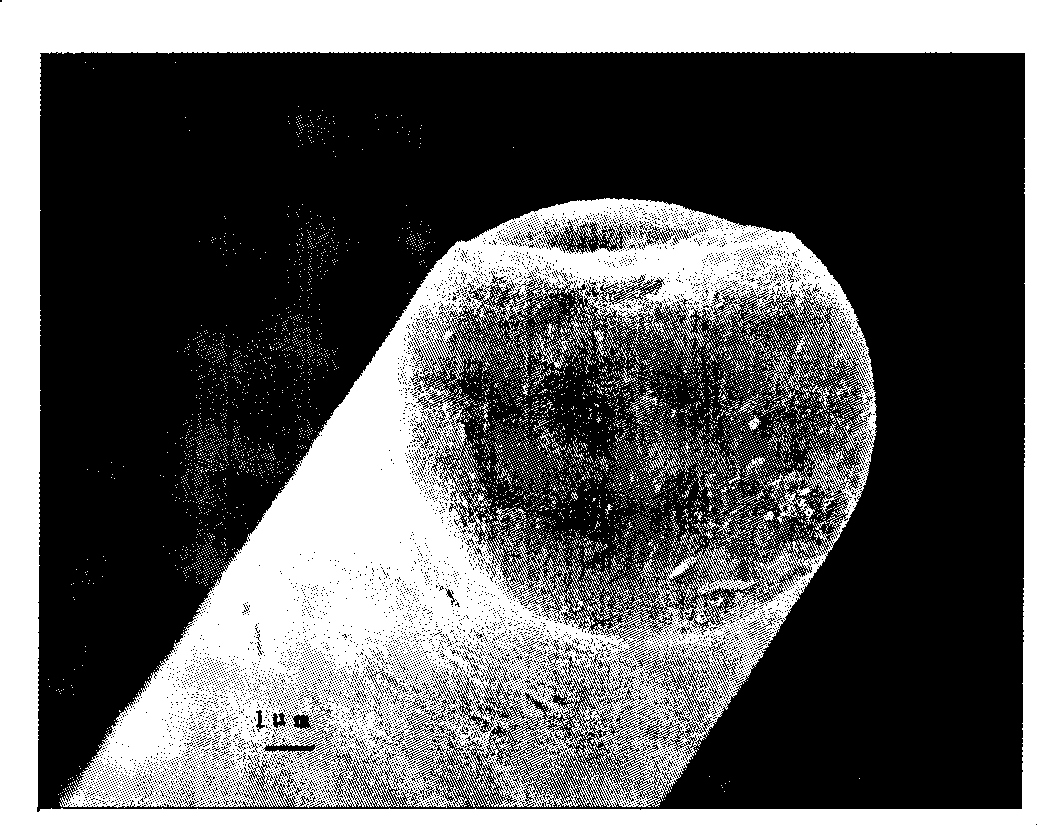

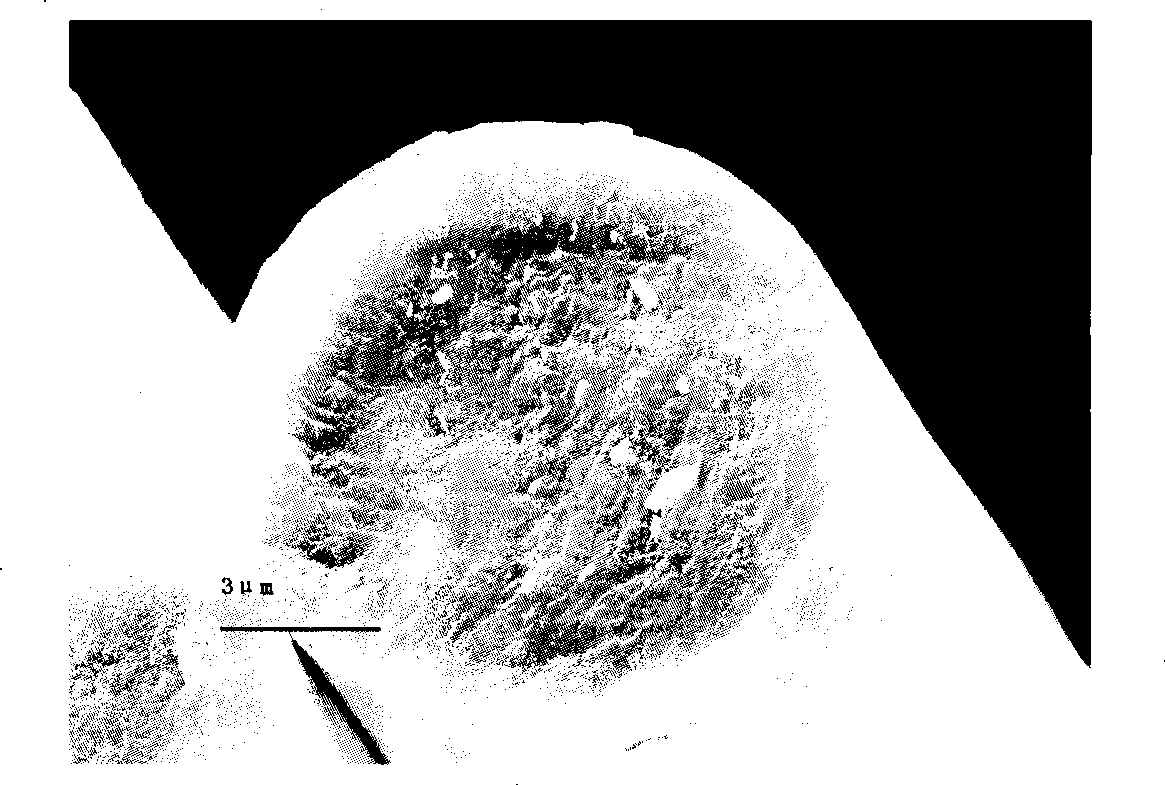

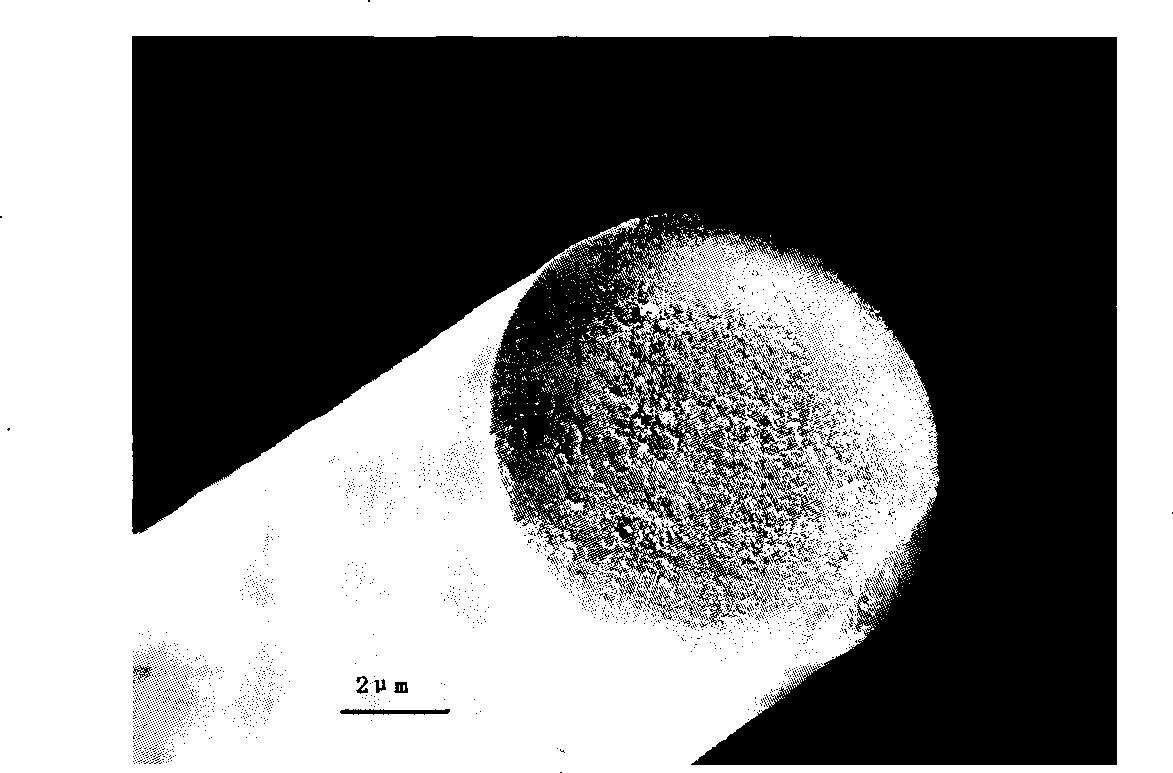

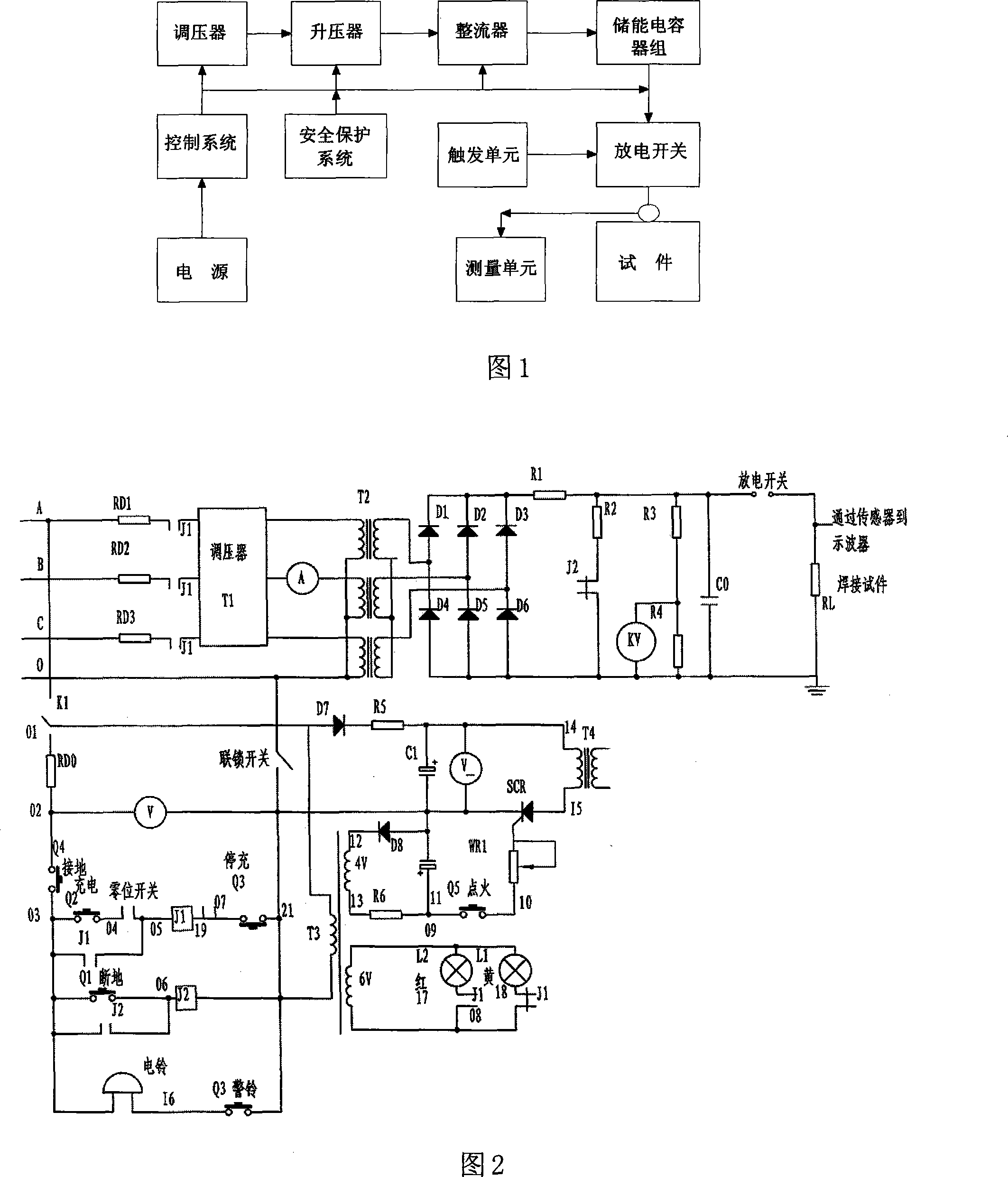

Electromagnetic thermal effect welding seam crack arresting and soldering structure strengthening device

InactiveCN101215630AInhibition of cracking tendencyImprove the extension functionHigh pressure pulseVoltage

The invention discloses an electromagnetic thermal effect weld metal crack arrest and welded structure strengthening device, which comprises a boost pressure rectification unit, a high pressure energy storage unit and a pulse discharge unit, wherein two outputted terminals of pulse discharge unit are connected with components of the welded structure through fasteners. The welded structure weld metal cracking and structure strengthening are realized through adopting the method of instant high pressure pulse discharge, the surface of an electrode is tightly applied with the surface of welded structure and a crossing type positive electrode and negative electrode is formed towards a weld seam when the electrode is fixed on the components of the welded structure through a fastener, and basic parameters such as discharge voltage and discharge time and the like are analyzed and determined through applying numerical modeling or theoretical analysis. The electromagnetic thermal effect weld metal micro-crack arrest and strengthening prevents the development of the micro-crack, realizes the ultra-fining of structures around the weld seam, removes residual stress in the weld seam, thereby achieving the purpose of strengthening and toughening of the welded structure. The invention simultaneously does not change the structure and property of a body without crack welded structure, and has the advantages of simple application method, instant finish, low cost and on-line strengthening repair and the like.

Owner:YANSHAN UNIV

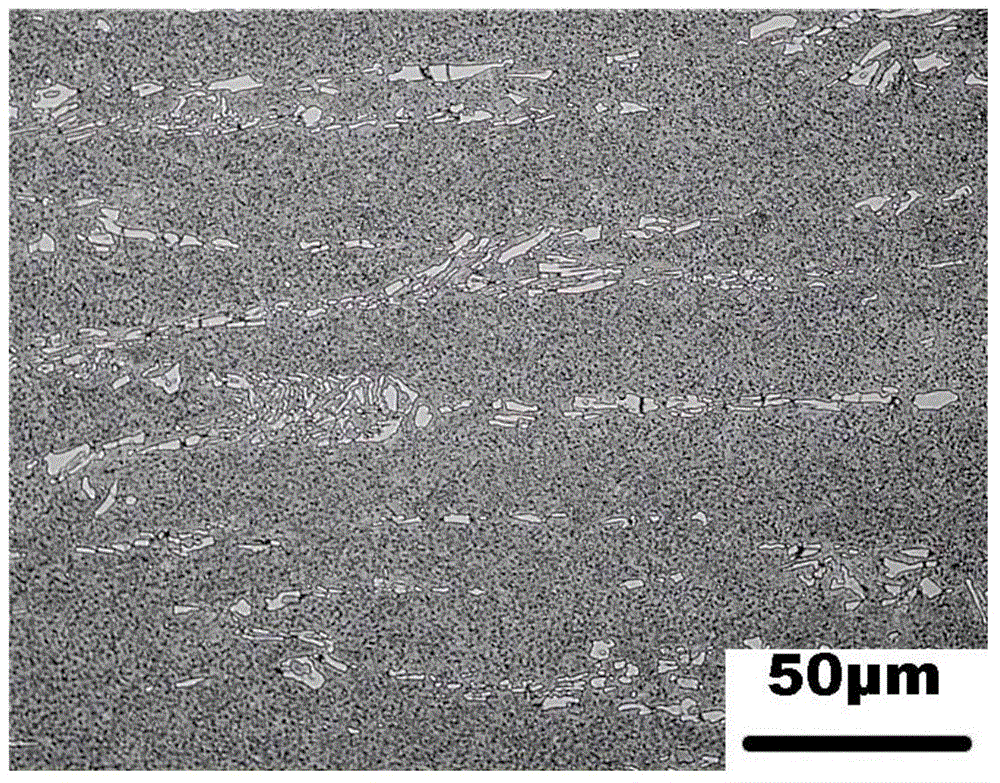

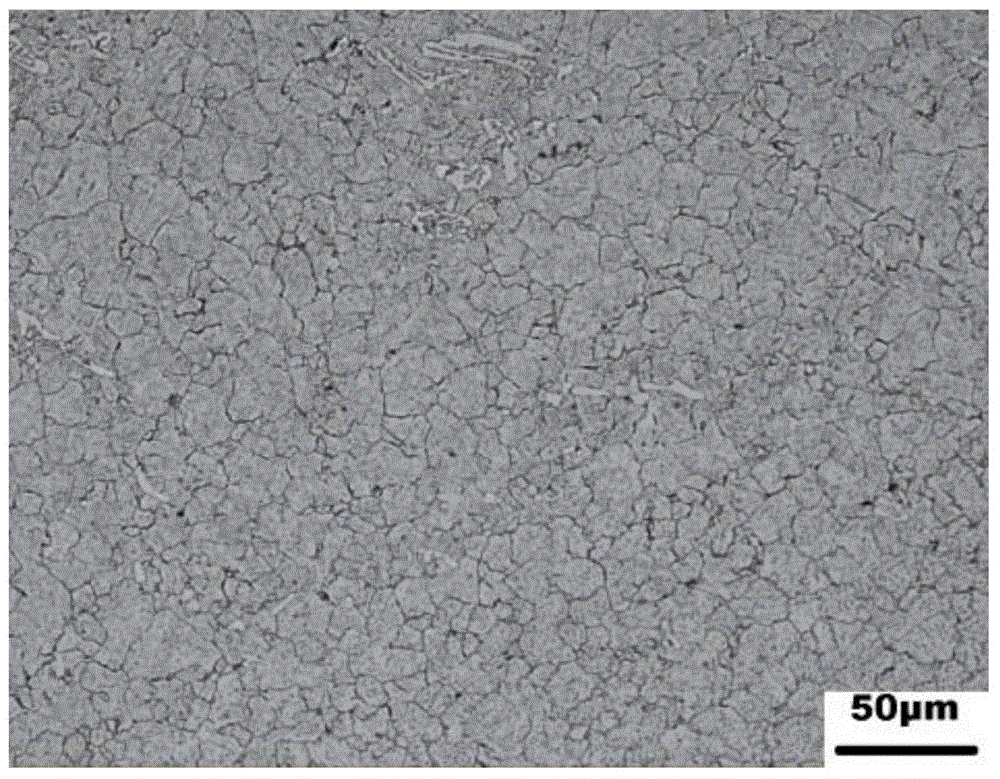

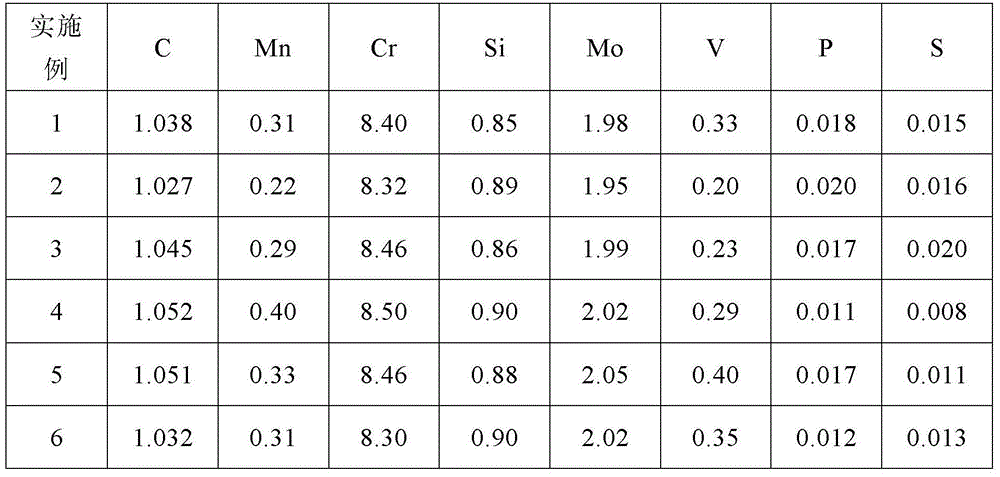

High-hardness high-toughness cold work die steel as well as preparation method thereof

The invention relates to high-hardness high-toughness cold work die steel as well as a preparation method thereof. The high-hardness high-toughness cold work die steel comprises the following chemical components in percentage by weight: 1.025-1.055% of C, 0.85-0.90% of Si, 0.20-0.40% of Mn, less than 0.02% of P, less than 0.02% of S, 8.30-8.50% of Cr, 1.95-2.05% of Mo, 0.20-0.40% of V and the balance of Fe and inevitable impurities, wherein the elements satisfy the following relationship: C=0.1(Cr+Mo). The preparation method comprises the following steps: smelting and pouring to obtain a steel ingot which serves as a consumable electrode and is placed in an electroslag remelting device for electroslag remelting and then re-solidifying to form the steel ingot; and heating the re-solidified steel ingot to 1200-1220 DEG C and then forging, quenching and tempering to obtain the cold work die steel. The impact energy of the steel is greater than or equal to 76J and the hardness of the steel is greater than or equal to 63HRC, and the steel has relatively good hardness and toughness match.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

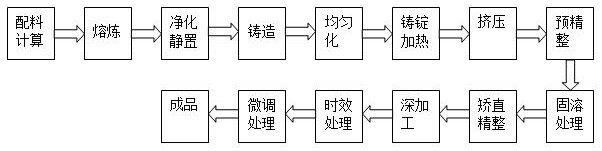

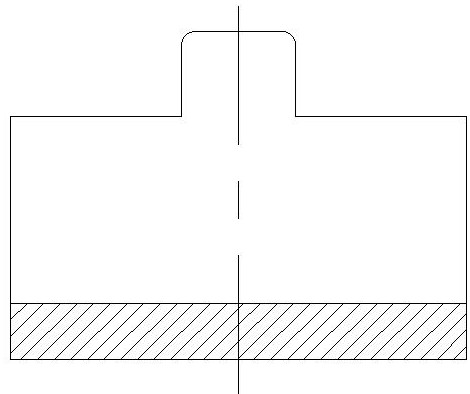

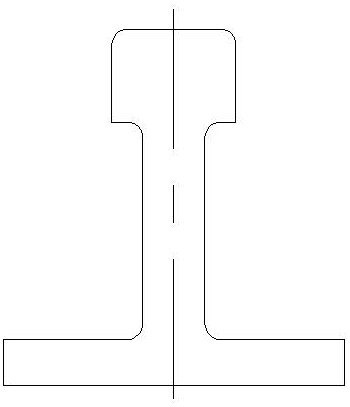

Aluminum alloy variable section extruded profile for spaceflight and preparation method of aluminum alloy variable section extruded profile

The invention discloses an aluminum alloy variable section extruded profile for spaceflight and a preparation method of the aluminum alloy variable section extruded profile. The profile consists of the following elements of, in percentage by weight, 5.0%-6.0% of Zn, 1.0%-2.0% of Cu, 0.04%-0.1% of Mn, 2.0%-3.0% of Mg, 0.15%-0.25% of Cr, 0.35%-0.42% of Fe, less than or equal to 0.25% of Si, and thebalance Al. During preparation, a finished product is obtained after being subjected to smelting, purifying, standing, casting, homogenizing treatment, ingot heating, extrusion, pre-finishing, solution treatment, straightening finishing, deep machining, aging treatment and fine adjustment treatment. According to the method, by setting specific alloy composition and the preparation process, the aluminum alloy variable section extruded profile formed by once is obtained, the strength, fatigue resistance, corrosion resistance and stress corrosion resistance of the aluminum alloy profile are greatly improved, comprehensive performance requirements of a carrier rocket launcher on the variable section aluminum alloy profile can be met, the bottleneck of extrusion forming of the variable sectionprofile at present is broken, various indexes of the aluminum alloy profile are ensured to meet standards and use requirements, and material guarantee is provided for research of new carrier rockets in China.

Owner:西北铝业有限责任公司

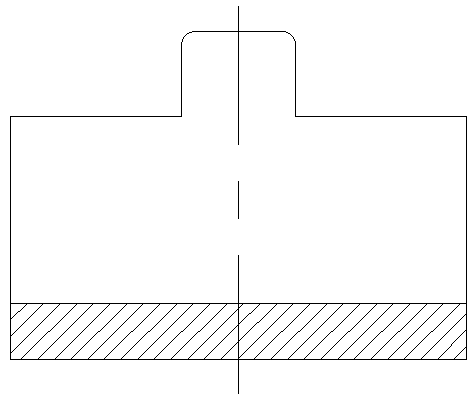

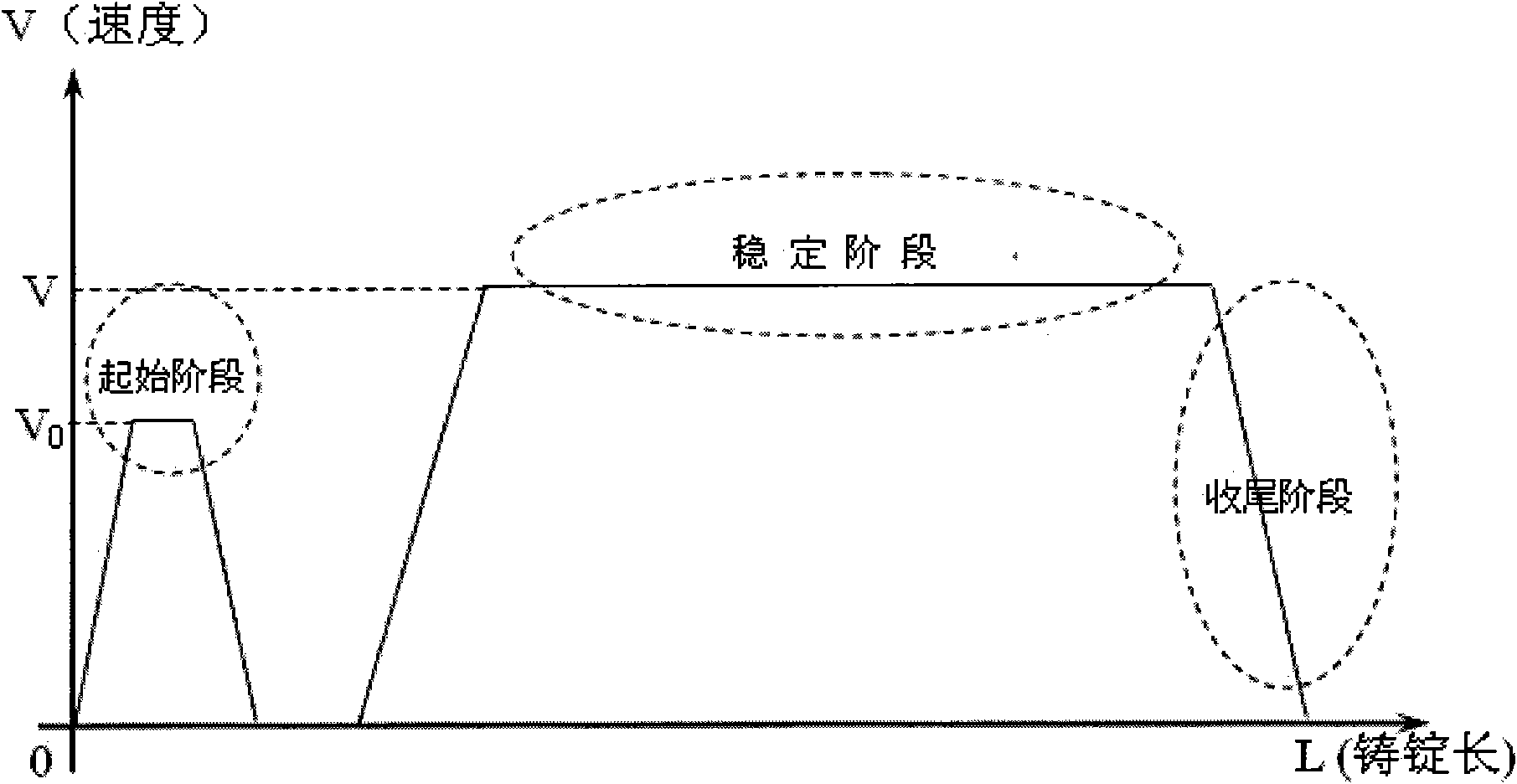

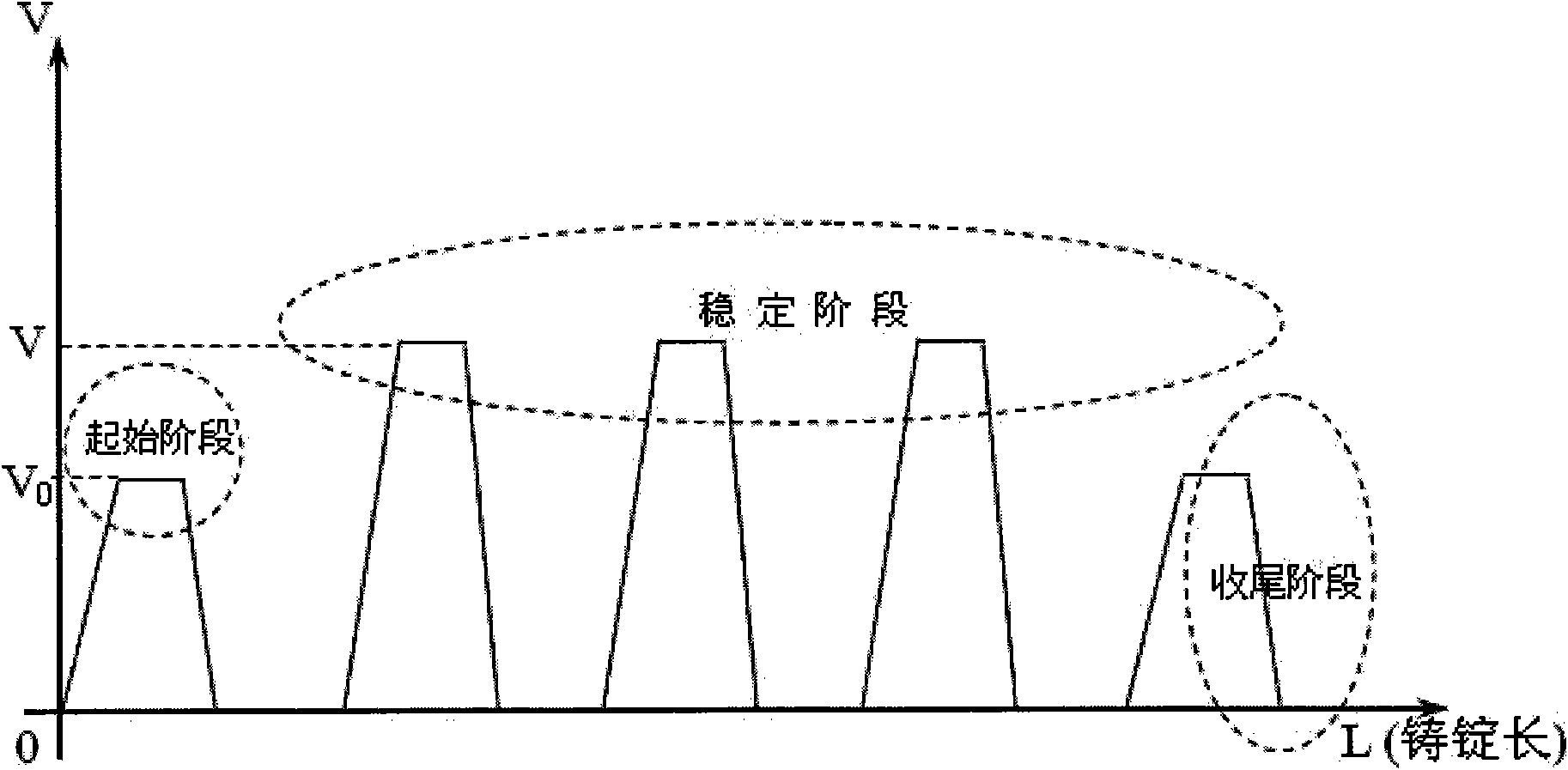

Casting method for inhibiting bottom crack of ingot

The invention relates to a casting method for inhibiting bottom crack of an ingot. The numerical values of casting speed and cooling water flow in the initial stage of casting are both 1 / 2-2 / 3 of those of casting speed and cooling water flow in the stable stage, when the length of the ingot achieves 20-100mm, the cooling water flow is kept still, the casting speed gradually reduces to zero within1-10s, after the casting machine stops running for 1-60s, the casting process is restarted, the numerical values of casting speed and cooling water flow are gradually restored to the initial preset values, the casting speed gradually reduces to zero after the initial stage, the stable stage and the ending stage of the casting process, and the casting machine suspends once in the midway during thewhole casting process. The technical scheme can effectively reduce overall inner-stress value of the ingot, achieve the aim of inhibiting crack and improve casting success ratio.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

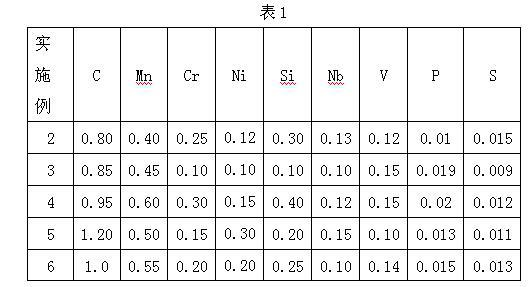

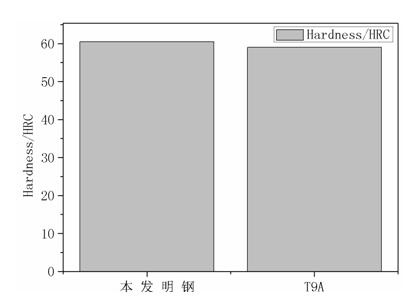

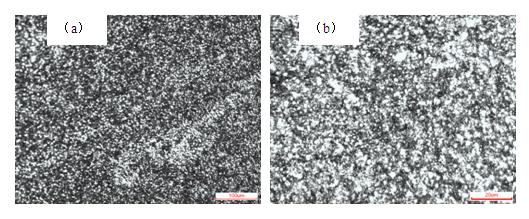

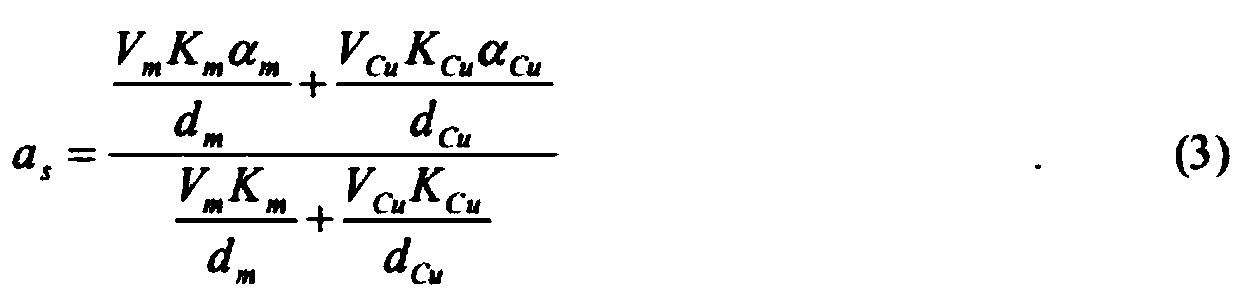

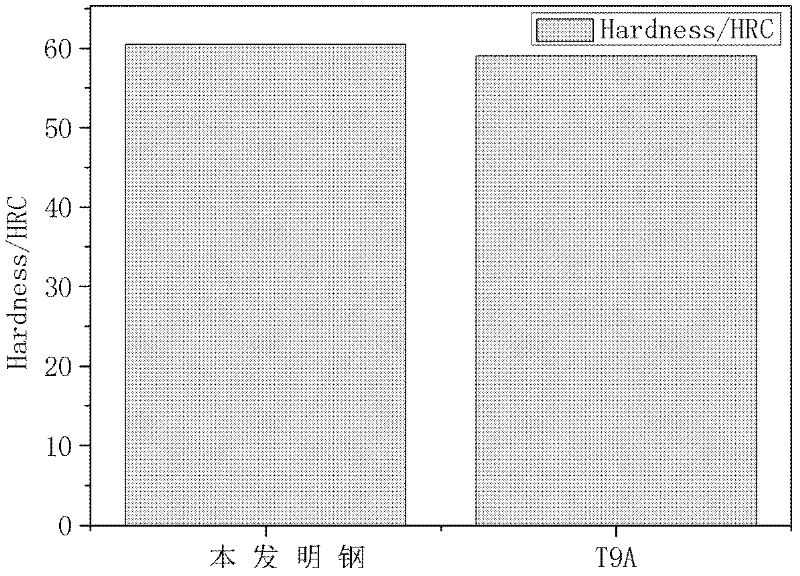

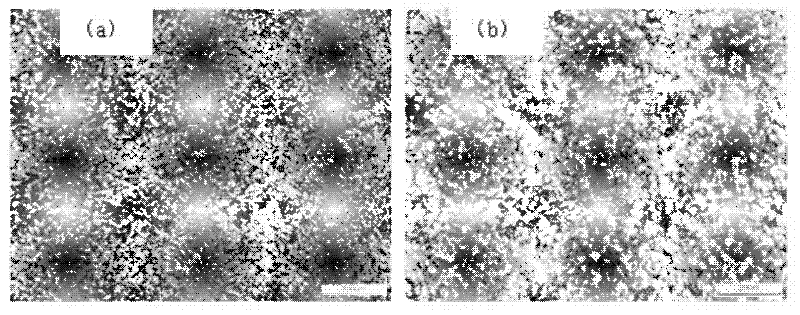

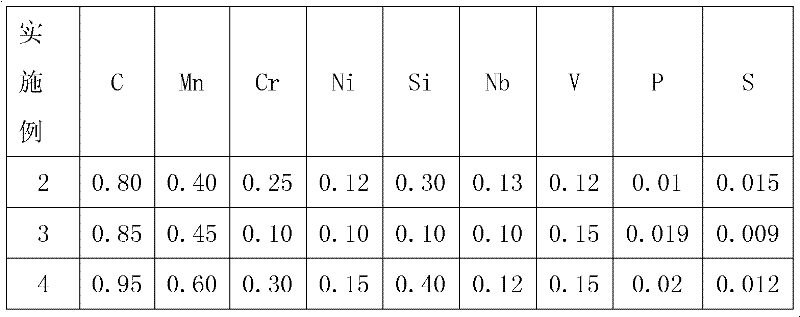

High-wear-resistant steel for knitting needle and manufacturing method thereof

The invention relates to the field of steel for knitting machinery, in particular to high-wear-resistant steel for a knitting needle and a manufacturing method of the high-wear-resistant steel for the knitting needle. The high-wear-resistant steel comprises the following ingredients (weight percentage): C 0.8-1.2%, Si 0.1-0.4%, Mn 0.4-0.6%, Nb 0.1-0.15%, V 0.1-0.15%, Ni 0.1-0.3%, Cr 0.1-0.3%, and Fe and other unavoidable impurities in balance. A steel ingot casted after being subjected to smelting in an induction furnace is arranged in an electroslag remelting device as a consumable electrode for electroslag remelting, and then liquid metal drops in a water-cooling crystallizer at the bottom through a slag layer of a slag pool so as to be re-solidified to a steel ingot. After being heated a temperature range of 1000-1030 DEG C and kept for 3-5 hours, the re-solidified steel ingot is sequentially forged, bent, flattened, milled and subjected to thermal treatment to obtain cold working die steel with high combination of strength and toughness , high hardness, high wear resistance and the like.

Owner:LANGSHA KNITTING

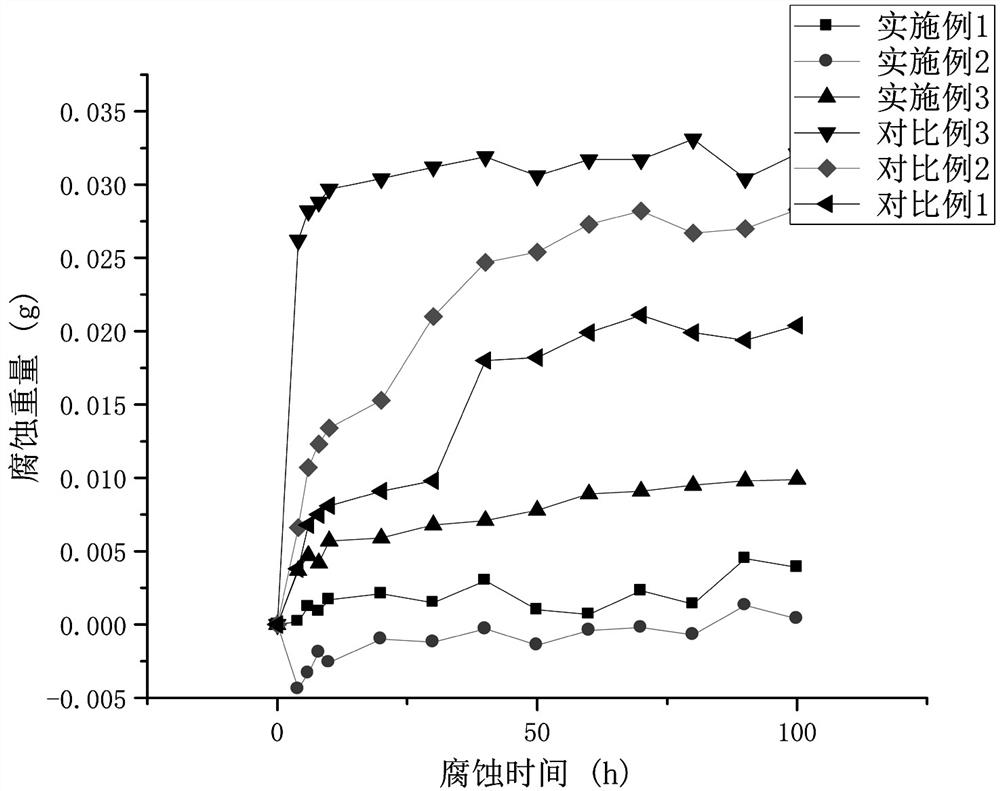

Amorphous composite brazing filler metal for brazing ceramic and alloy

PendingCN110153591AImprove mechanical propertiesImprove shear resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesUltimate tensile strengthFiller metal

The invention relates to a composite brazing filler metal layer for brazing ceramic and alloy, and belongs to the field of brazing filler metal. The brazing filler metal comprises a double-layer CuTiZrNi amorphous brazing filler metal and a foam Cu intermediate layer, and the foam Cu intermediate layer is filled between the double-layer CuTiZrNi amorphous brazing filler metal, and the atomic percentage of the CuTiZrNi brazing filler metal is Cu: 41.83, Ti: 30.21, Zr:19.76 and Ni:8.19. A foam Cu intermediate layer is added into the CuTiZrNi amorphous brazing filler metal, the brazing temperature is kept at 910 DEG c for 20 minutes, plastic deformation is generated between the brazing filler metal and the foam Cu intermediate layer,and the brazing filler metal and the foam cu intermediate layer are in close contact with each other, the surface of the base material is wetted, so that part of the base material is also dissolved in the molten brazing filler metal, a staggered structure isgenerated, so that the mechanical property of the ceramic and alloy connectivity is improved, the bonding strength of the interface is improved, the stress is effectively released, the cracking tendency is inhibited, so that the weld joint has good joint performance, and the negative influence of the hardening and the ductility of the braze welding head on the bonding strength is avoided;

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

High wear resistance steel for knitting needle and manufacture method thereof

ActiveCN102383052AGood effectPrevent thermal stress cracksIncreasing energy efficiencySlagLiquid metal

The invention relates to the field of steel for knitting machinery and specifically relates to a high wear resistance steel for knitting needle and a manufacture method thereof. The high wear resistance steel for knitting needle comprises, by weight, 0.8-1.2% of C, 0.1-0.4% of Si, 0.4-0.6% of Mn, 0.1-0.15% of Nb, 0.1-0.15% of V, 0.1-0.3% of Ni, 0.1-0.3% of Cr and the balance of Fe and inevitable impurities. A steel ingot casted after melting in an induction furnace is employed as a consumable electrode and placed in an electroslag remelting apparatus for electroslag remelting; liquid metal passes through a slag layer of a slag bath, falls to a water cooling crystallizer below and solidifies into a steel ingot again; the steel ingot is heated to 1000-1030 DEG C, insulated for 3-5 h and treated with forging, turning, flattening and milling and heat treatment, so as to obtain a cold working die steel with characteristics of high strength and toughness cooperation, high hardness and high wear resistance, etc.

Owner:LANGSHA KNITTING

Oil removal and heavy metal removal modified walnut shell filter material and preparation method thereof

InactiveCN105498358ALarge specific surface areaIncrease distanceWater contaminantsWater/sewage treatmentCross-linkOil and grease

The invention discloses an oil removal and heavy metal removal modified walnut shell filter material and a preparation method thereof; the surface of the oil removal and heavy metal removal modified walnut shell filter material is provided with an oxidized graphene coating. The preparation method of the filter material includes the steps that walnut shell powder and oxidized graphene powder are added into a V-shaped mixer simultaneously to be stirred and mixed uniformly, then a cross-linking agent and deionized water are added, cross linking is conducted at the temperature of 50-80 DEG C for 3-3.5 hours, after the liquid phase is filtered out, absolute ethyl alcohol is washed to be neutral, drying is conducted for 1-3 hours at the temperature of 100-140 DEG C, finally a vibration screen is utilized to screen out the filter material with the particle size meeting the requirement, and a finished product is obtained. By means of the filter material, grease and heavy metal in sewage water can be removed simultaneously, the sewage treatment process is greatly simplified, sewage treatment cost is lowered, sewage treatment efficiency is high, the filter material is high in hardness, resistant to wear, good in pressing resistance, not prone to caking, large in toughness, easy to regenerate, long in replacement cycle and low in cost.

Owner:MAANSHAN JILI MACHINERY EQUIP

Continuous aluminium oxide base ceramic fibre preparation method

ActiveCN101381225BAvoid instabilityAvoid cracking tendenciesInorganic material artificial filamentsFiberSilicon dioxide

The invention provides a method for preparing a continuous alumina-based ceramic fiber, which relates to an alumina-based ceramic fiber, in particular to a method for preparing a continuous alumina-based ceramic fiber which takes alumina as a main component and adds a second component as a crystalling phase inhibitor. The invention provides a method for preparing the continuous alumina-based ceramic fiber, which is simple in technique and low in cost. The method comprises the steps: preparing alumina sol; preparing silicon dioxide sol; mixing the alumina sol and the silicon dioxide sol to obtain biphase sol, and adding a spinning addition agent into the biphase sol; condensing the biphase sol added with the addition agent and spinning by a dry method to obtain the gel fiber; pyrolyzing the gel fiber to obtain the ceramic fiber; and sintering the ceramic fiber to obtain the continuous alumina-based ceramic fiber.

Owner:FUJIAN ESTABLISHED YATE TAO CO LTD

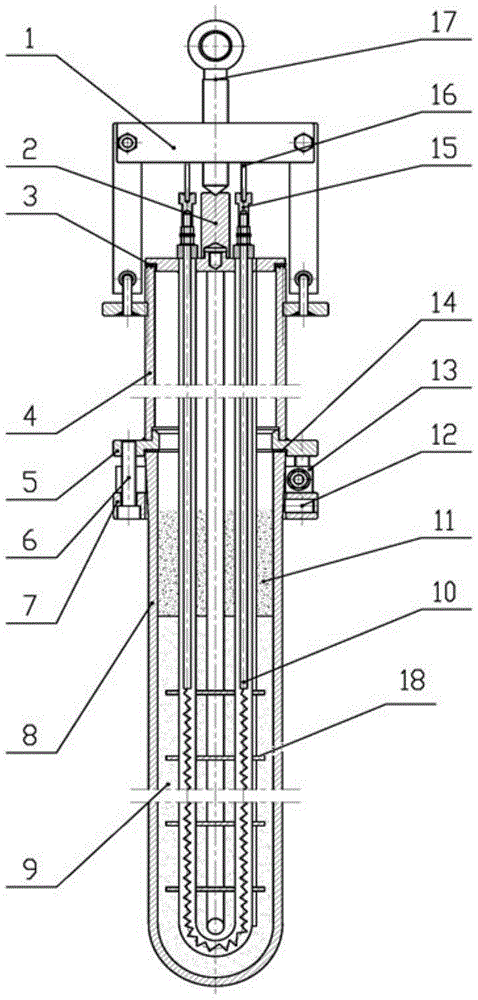

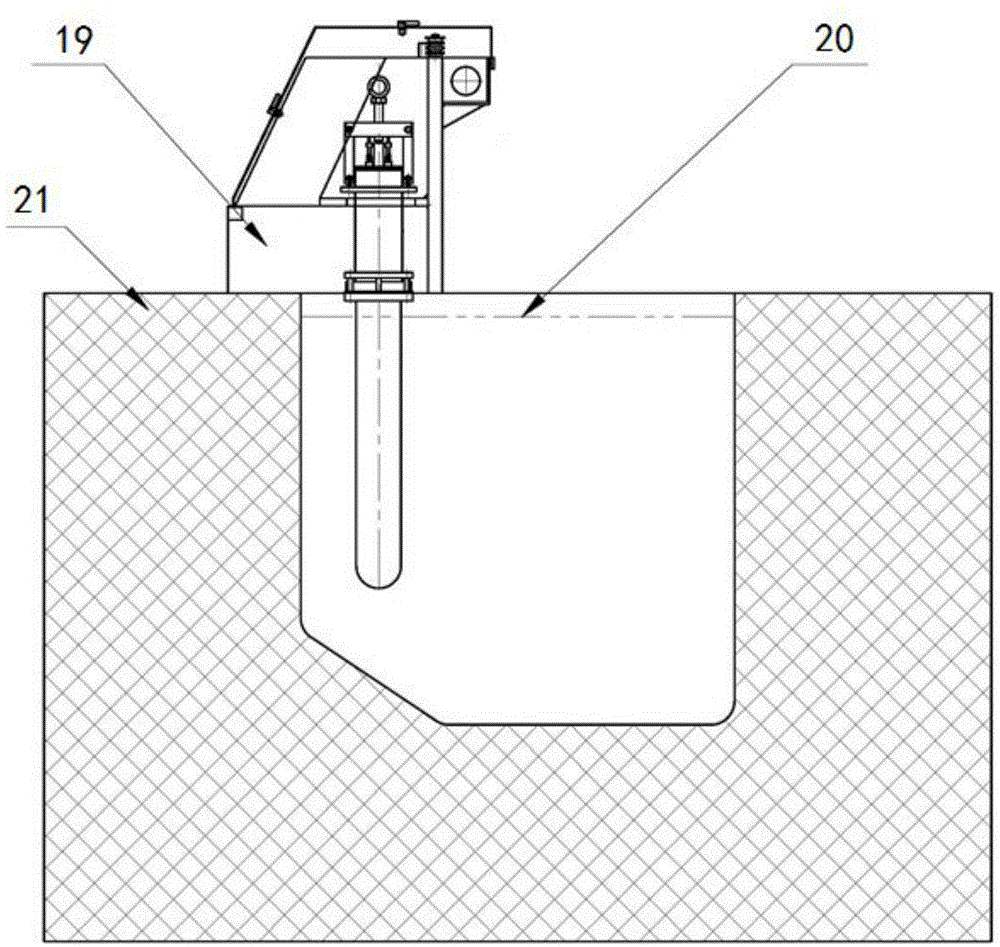

Inner heater of liquid zinc corrosion resistance alloy

ActiveCN104363671ALongitudinal temperature uniformityReduce heat lossHot-dipping/immersion processesHeating element shapesCircular discAlloy

The invention relates to an inner heater of liquid zinc corrosion resistance alloy. The inner heater of the liquid zinc corrosion resistance alloy is characterized by comprising a compression seal device, an additional pipe, a first connecting flange, a second connecting flange, an outer sleeve, a heat conductor, an electrical heating core, a top pillar, an antioxidant and two extraction electrodes, wherein the electrical heating core is a U-shaped electrical heating pipe, and comprises a heating area and a connection electrode area, a designed number of metal plates are evenly distributed along the length direction of the heating area of the electrical heating core, a disk is welded at the top of the connection electrode area of the electrical heating core, the top of the U-shaped electrical heating pipe and the disk are welded into a whole, the two extraction electrodes are respectively extracted from two ends of the U-shaped electrical heating pipe, the two extraction electrodes are connected with a power source through lead wires, a connection blind hole is formed in the disk, the lower end of the top pillar is connected with the connection blind hole, the upper end of the top pillar is connected with a compression bolt, the additional pipe is a cylinder with two ends open, and the upper end of the additional pipe is connected with the disk.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

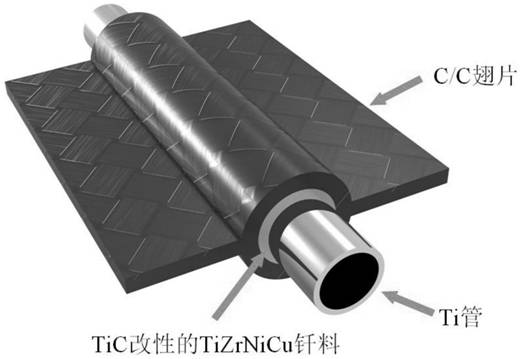

Vacuum brazing connection method for C/C radiating fins and Ti tubes

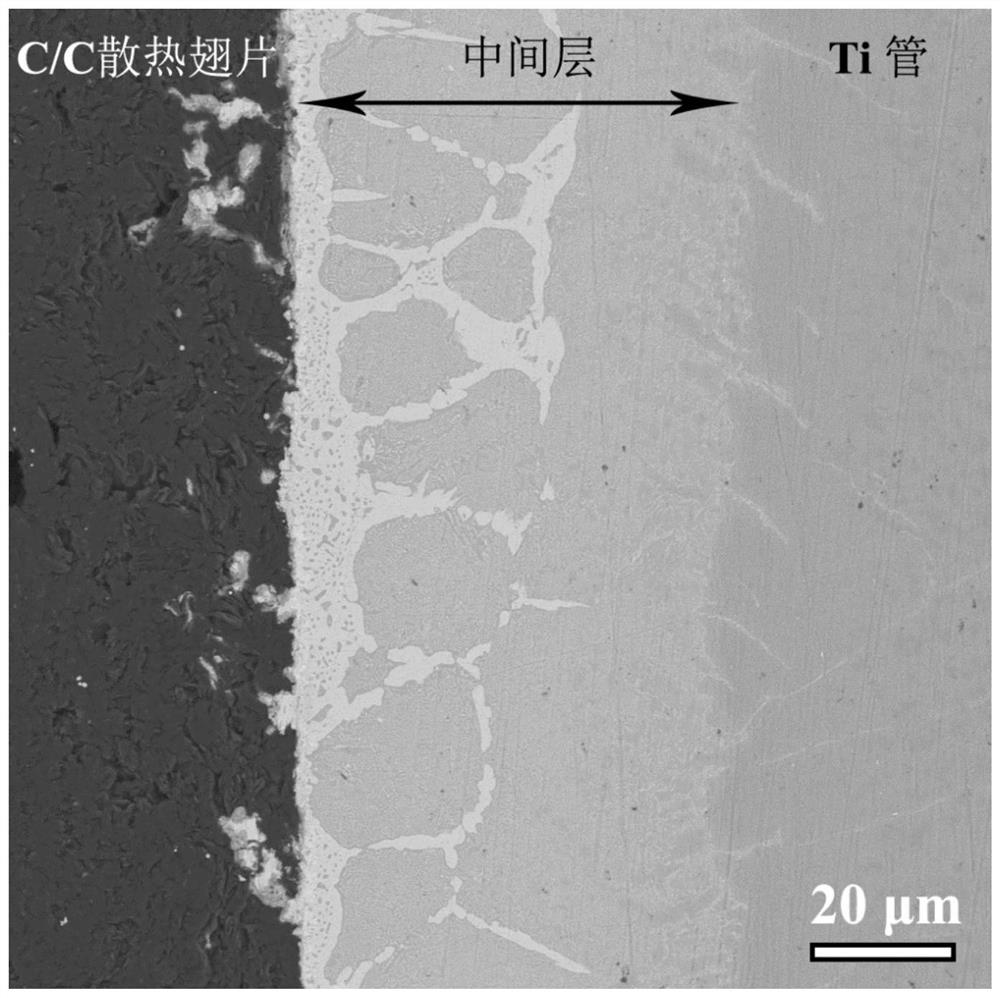

ActiveCN114247947AMeet the structureMeet compactnessWelding/soldering/cutting articlesHeat exchange apparatusGraphiteAlloy

The invention discloses a vacuum brazing connection method for C / C radiating fins and Ti tubes. The method comprises the following specific process steps: grinding and polishing a Ti pipe to remove an oxide film, and performing vacuum drying for later use after ultrasonic cleaning; tiZrNiCu alloy powder and TiC powder with the mass percent being 3%-5% are mixed, then alcohol is added for ball milling for 15-18 h, the powder is dried and sieved after ball milling, then an oily binder with the mass percent being 8%-10% is added into sieved powder, the mixture is stirred into paste brazing filler metal, then the portion between the connecting surfaces of the C / C cooling fins and the Ti pipe is filled with the paste brazing filler metal, assembling is conducted, and the C / C cooling fins and the Ti pipe are assembled. And the assembly part is clamped by a graphite clamp and then placed in a vacuum furnace, the temperature is increased to 920 DEG C at the speed of 4-7 DEG C / min under the vacuum degree not lower than 1 * 10 <-3 > Pa, heat preservation is conducted for 10-20 min, and finally connection is completed after the furnace is cooled to the room temperature. The connecting method is simple in process, safe, free of pollution, low in cost and high in reliability, and the problems that in the welding process, due to large residual stress, a connecting piece cracks, and wettability between base metal is insufficient are effectively solved.

Owner:XIANGTAN UNIV +1

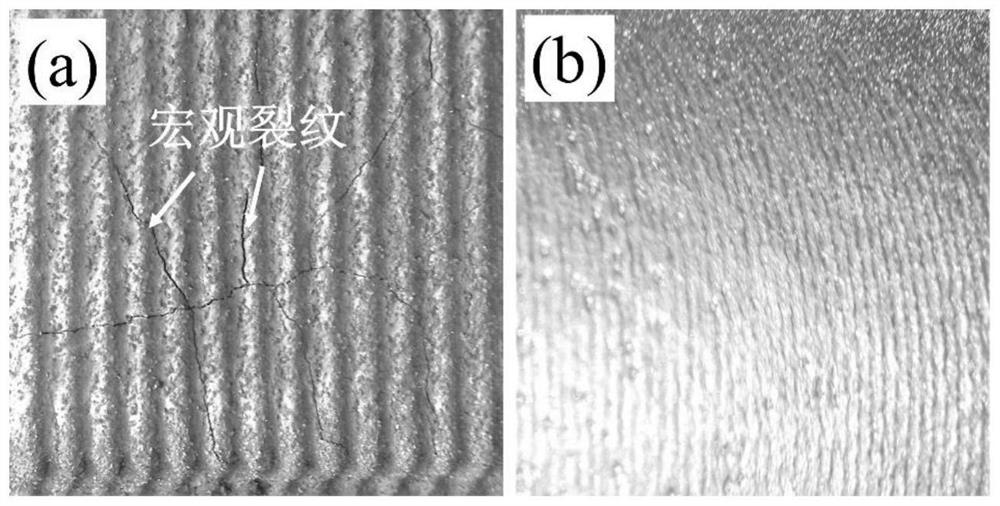

Method for reducing cracks of cladding coating on surface of stainless steel under high-temperature service

PendingCN114411145AAvoid cracking tendenciesHigh hardnessMetallic material coating processesTemperingCrazing

The invention discloses a method for reducing cracks of a cladding coating on the surface of stainless steel under high-temperature service, which comprises the following steps: performing laser cladding on Ni625 alloy powder on the surface of a preheated stainless steel matrix to form a transition coating, preheating again, performing laser cladding on NiCoCrAlY alloy powder to form a protective coating, cooling, heating to 150-250 DEG C in a vacuum environment, and performing vacuum low-temperature tempering treatment. By adding the transition coating and carrying out heat treatment on the formed cladding coating, on one hand, the internal stress of the coating can be released and relieved, and crack formation is inhibited; on the other hand, the cracking tendency of the coating can be solved by reducing the temperature gradient, and meanwhile, the hardness and the wear resistance of the coating can be improved, so that the high-temperature oxidation resistance and the corrosion resistance of the stainless steel are improved, and the service life of the stainless steel is prolonged.

Owner:ZHONGBEI UNIV

Heat-resistant sphere and production process thereof

The invention relates to a heat-resistant sphere which is prepared from the following components in percentage by weight: 3.00-4.20% of C, 1.8-3.0% of Si, 0.2-1.2 of Mn, 2.0-4.0% of Ni, 0.3-1.0% of Mo, less than or equal to 0.07% of P, less than or equal to 0.02% of S and the balance of Fe. According to the heat-resistant sphere provided by the invention, the fatigue resistance of the material is guaranteed by adding Ni and Mo elements; and moreover, the cold cracking tendency is reduced, the safety coefficient is improved, and the service life is prolonged. The preparation process is further improved, for example, the content of S is strictly controlled, and S is removed in a ladle by using industrial sodium carbonate; a metal-stream inoculation treatment method is adopted; a unique high-medium annealing treatment process and the like are adopted, and the tensile strength, yield strength, ductility and hardness HS of the prepared heat-resistant sphere are greatly improved.

Owner:TOYO GRINDING BALL MAANSHAN

7B04-T7451 aluminum alloy plate and preparation method thereof

The invention discloses a 7B04-T7451 aluminum alloy plate and a preparation method thereof, and relates to the technical field of plate manufacturing. The invention aims to solve the problem that the 7B04 alloy T7451 state plate production technology is blank in China at present. The method comprises the following steps that surface treatment is performed on an aluminum alloy ingot, the aluminum alloy ingot is sawn and then placed into a heating device, is heated and is subjected to heat preservation, and a heat-preserved aluminum alloy long plate is obtained; the aluminum alloy cast ingot obtained after heat preservation is rolled, and a rolled aluminum alloy long plate is obtained; and the rolled aluminum alloy long plate is subjected to length fixed-length shearing, then solid solution quenching is carried out, straightening and stretching are carried out after solid solution quenching, then aging treatment is carried out, and finally saw cutting is carried out, so that the 7B04-T7451 aluminum alloy plate is obtained. The 7B04-T7451 aluminum alloy plate and the preparation method thereof can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Nickel-free grate material for sintering machine and manufacturing method thereof

InactiveCN101748335BHigh hardnessImprove wear resistanceProcess efficiency improvementElectric furnaceChemical compositionOperability

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

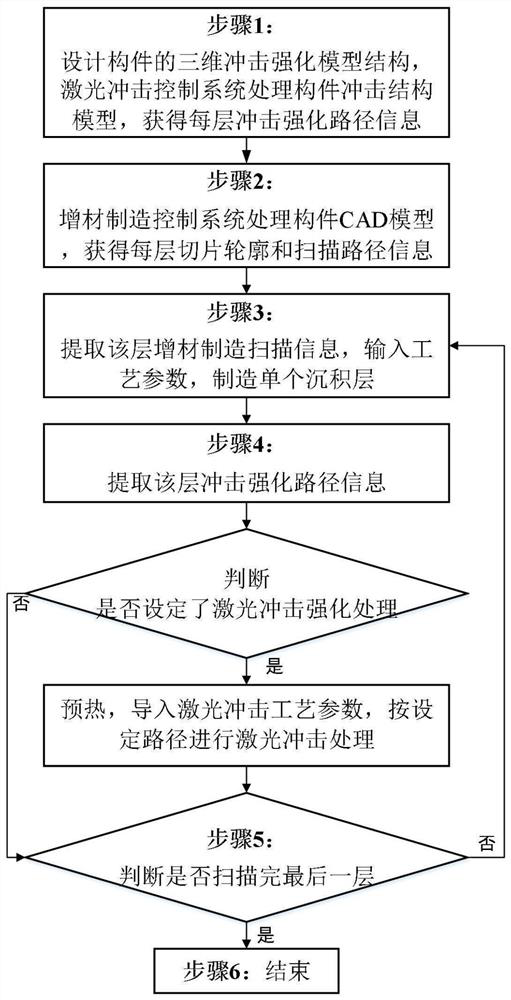

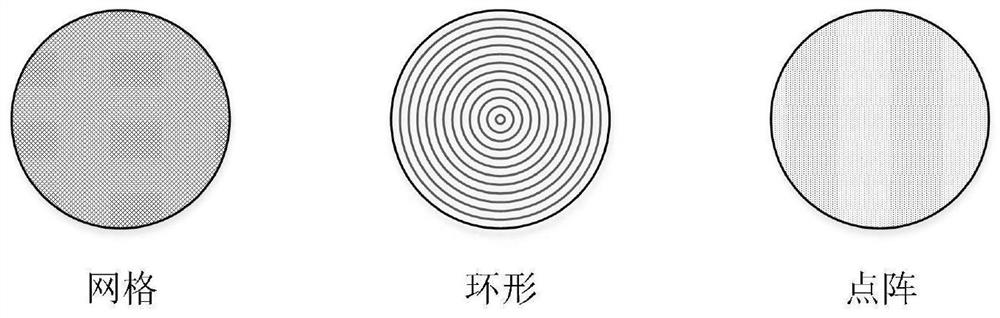

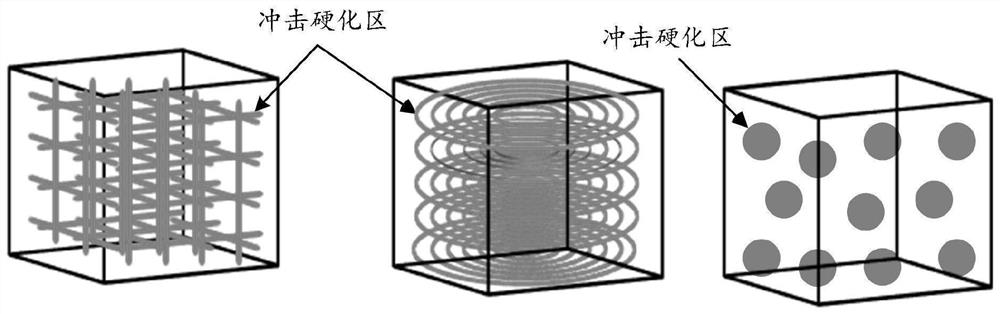

Laser Selective Shock-Additive Composite Manufacturing Method for Three-dimensionally Reinforced Shape Memory Alloys

ActiveCN113414408BIncrease the hardness valueRealize three-dimensional composite enhancementAdditive manufacturing apparatusIncreasing energy efficiencyGraphicsControl system

The invention discloses a laser selective area impact-additive composite manufacturing method for a three-dimensionally reinforced shape memory alloy, which comprises the following steps: designing a three-dimensional laser shock-strengthened structural model of a component, generating impact-strengthened path information for each layer; the additive manufacturing control system based on The alloy component model and process parameters are used to manufacture a single deposition layer; the laser shock strengthening control system extracts the impact strengthening path information of this layer, applies preheating to the deposited component as required, and performs laser shock treatment; and so on until the entire component forming and manufacture. By controlling the graphic structure and process parameters of the laser shock, the invention can accurately control the deformation state of austenite and martensite in the three-dimensional direction and the forward and reverse phase transformation of martensite in the shape memory alloy in situ, and realize the solid phase transformation of the alloy. , high-efficiency, high-quality integrated control and optimization of superelasticity and shape memory effects, providing new manufacturing methods and means for complex structures and high-performance shape memory alloys.

Owner:WUHAN UNIV

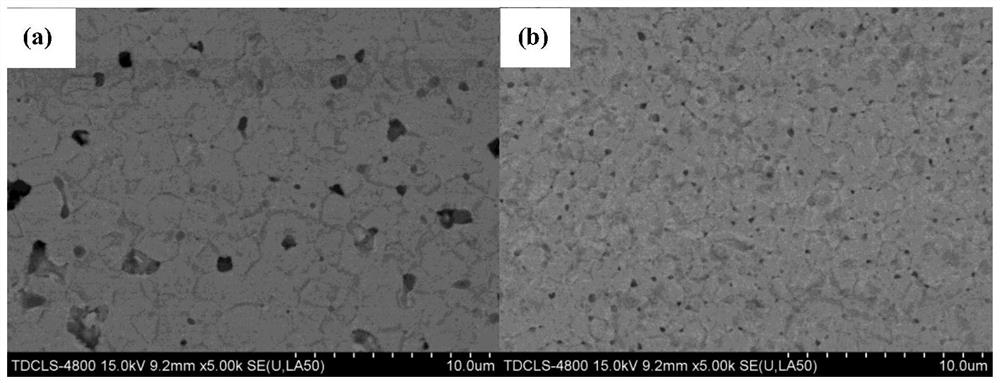

A kind of plasma surfacing iron-based cr with micron ti added 3 c 2 Hypereutectic wear-resistant coating and preparation method thereof

ActiveCN109234727BSpeed up meltingImprove cladding qualityMetallic material coating processesCrazingAlloy

The invention discloses a plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer added with micrometer Ti and a preparation method thereof and belongs to the technical field of wear-resistant coating layers on the surfaces. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer is prepared from the following components in percent by mass after plasmasurfacing: 49%-69.5% of iron-based self-fluxed alloy powder, 30%-50% of micrometer Cr3C2 powder and 0.5%-1% of micrometer Ti powder. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistantcoating layer is prepared by the following steps: pretreatment of base materials, preparation and drying of composite powder, preparation of the coating layer and post heat treatment. By use of the technical scheme disclosed by the invention, on the basis of improving the hardness and wear resistance of the plasma-surfacing iron-based hypereutectic wear-resistant coating layer enhanced by multiscale particles, the process characteristics of the coating layer can be obviously improved, and the generation of cracks of the coating layer can be effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of extrusion profile of aluminum alloy with multiple variable cross-sections for aerospace and its preparation method

The invention discloses an aluminum alloy multi-variable cross-section extrusion profile for aerospace and a preparation method thereof. The profile is composed of the following elements in weight percent: Zn 5.0-6.0%, Cu1.0-2.0%, Mn 0.04-0.1% , Mg2.0‑3.0%, Cr0.15‑0.25%, Fe0.35‑0.42%, Si≤0.25%, and the balance is Al. The finished product is obtained after smelting, purification and standing, casting, homogenization treatment, ingot heating, extrusion, pre-finishing, solution treatment, straightening and finishing, deep processing, aging treatment and fine-tuning treatment during preparation. In the present invention, by setting a specific alloy composition and its preparation process, a one-time formed aluminum alloy multi-section extruded profile is obtained, which greatly improves the strength, fatigue resistance toughness, corrosion resistance and stress corrosion resistance of the aluminum alloy profile. It can meet the comprehensive performance requirements of the carrier rocket launcher for multi-section aluminum alloy profiles, break through the current bottleneck of extrusion molding of multi-section profiles, and ensure that its various indicators meet the standards and use requirements. Material guarantee is provided.

Owner:西北铝业有限责任公司

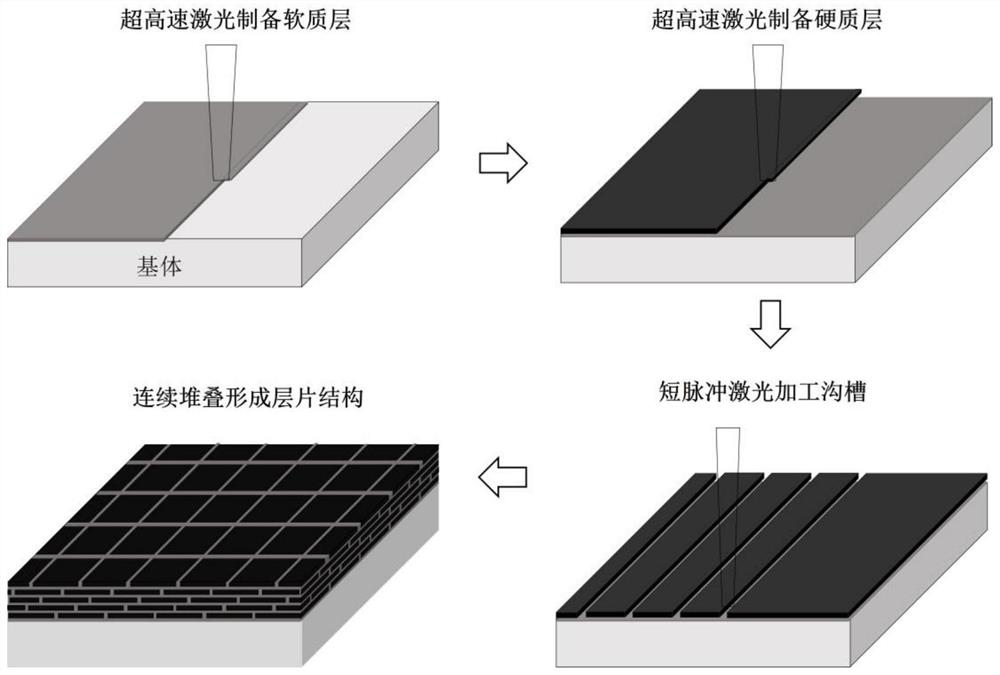

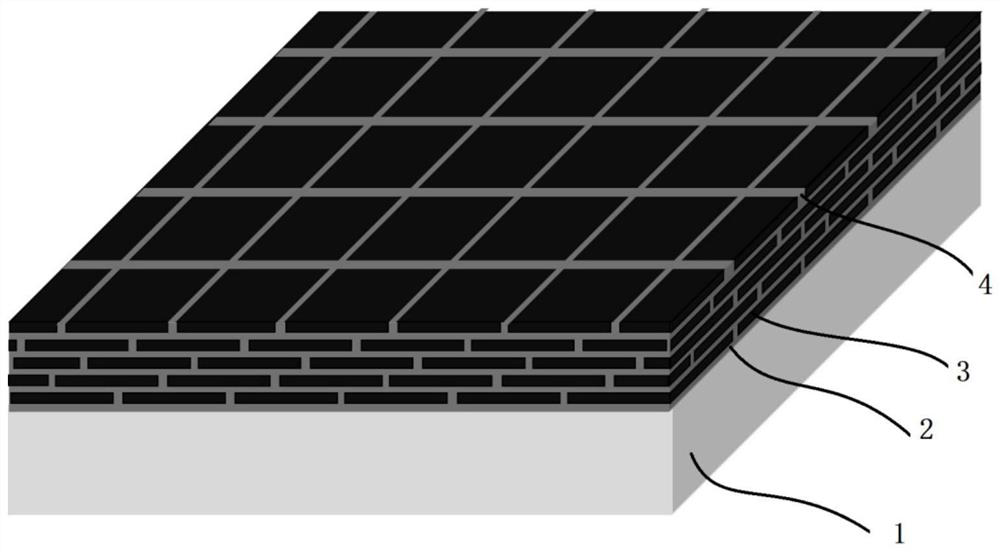

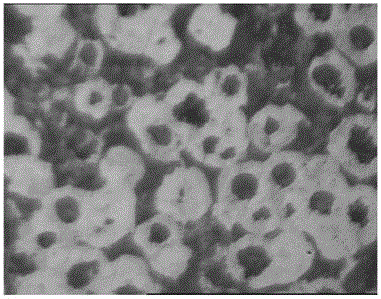

Laser-induced formed mother-of-pearl layered steel bond hard alloy and preparation method thereof

PendingCN114351137AEffective control extensionControl extensionMetallic material coating processesLaser beam welding apparatusLaser technologyUltra high speed

The preparation method mainly comprises the following steps: preparing each hard ceramic material layer and each soft material layer of the layered steel bond hard alloy by utilizing an ultra-high-speed laser cladding technology, and after each layer of material is prepared, preparing the hard ceramic material layer and the soft material layer of the layered steel bond hard alloy by utilizing an ultra-high-speed laser cladding technology; a grid structure in a'mud brick '-shaped structure is prepared by using an ultrafast laser processing technology, and finally, the steel bond hard alloy with the imitated mother-of-pearl layered structure is formed through continuous stacking forming. The obtained layered steel bond hard alloy structure is of a mud brick-shaped structure which is formed by alternately arranging hard ceramic material layers and soft material layers and is similar to nacre in the nature. According to the method, the technical characteristics of an ultra-high-speed laser cladding technology and an ultra-fast laser technology can be effectively coupled, a'mud brick '-shaped steel bond hard alloy structure similar to a mother-of-pearl is prepared, a good strengthening effect is achieved, and the problems of cracking and the like caused by a conventional laser steel bond hard alloy layer in the laser cladding preparation process are effectively controlled.

Owner:JIANGSU UNIV

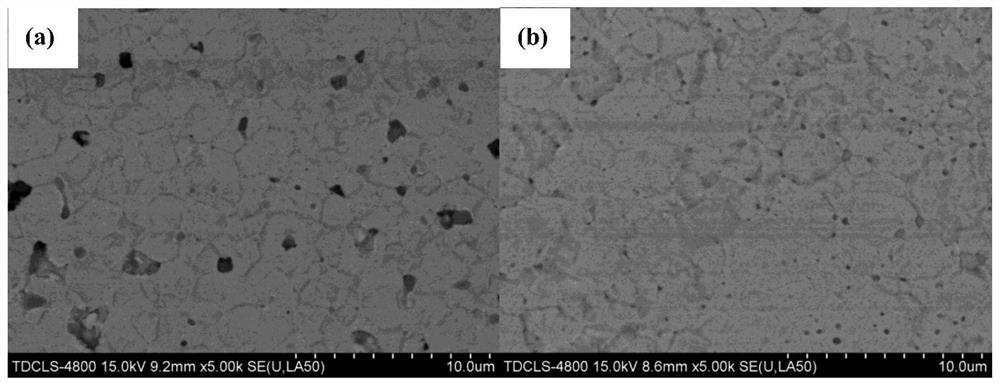

A method for refining the size of yttrium oxide at grain boundaries in yttrium oxide dispersion-strengthened tungsten-based alloys

The invention relates to a method for refining the size of yttrium oxide at the grain boundary in yttrium oxide dispersion-strengthened tungsten alloy. Dissolving yttrium nitrate hexahydrate, lanthanum nitrate hexahydrate or hafnium oxychloride in deionized water, stirring them mechanically to make them fully dispersed, Dissolve, and then add ammonium paratungstate; HNO 3 Add it into the above solution under mechanical stirring to make the chemical precipitation reaction uniformly form a white suspension; add absolute ethanol to the suspension to continue the reaction, filter the reacted suspension and wash the obtained precipitate with absolute ethanol; The precipitate is dried, ground to obtain a composite powder, and then calcined; the obtained composite is oxidized to a powder and subjected to two-step reduction with pure hydrogen in a tube furnace to obtain W‑Y 2 o 3 Composite precursor powder; then sintered under a hydrogen atmosphere to obtain W‑Y with significantly refined yttrium oxide at grain boundaries 2 o 3 alloy. The size of yttrium oxide at the grain boundary of yttrium oxide dispersion strengthened tungsten alloy is obviously refined, and the distribution uniformity is improved.

Owner:TIANJIN UNIV

A kind of preparation method of modified walnut shell filter material for oil removal and heavy metal removal

InactiveCN105498358BLarge specific surface areaIncrease distanceWater contaminantsWater/sewage treatmentCross-linkOil and grease

The invention discloses an oil removal and heavy metal removal modified walnut shell filter material and a preparation method thereof; the surface of the oil removal and heavy metal removal modified walnut shell filter material is provided with an oxidized graphene coating. The preparation method of the filter material includes the steps that walnut shell powder and oxidized graphene powder are added into a V-shaped mixer simultaneously to be stirred and mixed uniformly, then a cross-linking agent and deionized water are added, cross linking is conducted at the temperature of 50-80 DEG C for 3-3.5 hours, after the liquid phase is filtered out, absolute ethyl alcohol is washed to be neutral, drying is conducted for 1-3 hours at the temperature of 100-140 DEG C, finally a vibration screen is utilized to screen out the filter material with the particle size meeting the requirement, and a finished product is obtained. By means of the filter material, grease and heavy metal in sewage water can be removed simultaneously, the sewage treatment process is greatly simplified, sewage treatment cost is lowered, sewage treatment efficiency is high, the filter material is high in hardness, resistant to wear, good in pressing resistance, not prone to caking, large in toughness, easy to regenerate, long in replacement cycle and low in cost.

Owner:MAANSHAN JILI MACHINERY EQUIP

A heat-resistant sphere and its production process

Owner:TOYO GRINDING BALL MAANSHAN

Production method for abrasion-resistant anti-fouling knitting needle

InactiveCN110629101AImprove wear resistanceAvoid cracking tendenciesIncreasing energy efficiencyFurnace temperatureIngot casting

The invention relates to the technical field of knitting needle manufacturing, in particular to a production method for an abrasion-resistant anti-fouling knitting needle. A knitting needle steel material is produced through the following steps of steel ingot casting, furnace annealing, steel material quenching and steel material tempering. By controlling the furnace temperature and the temperature rise speed of a steel ingot, the steel ingot can be prevented from generating thermal stress cracks in the heating process, and the temperature of the whole surface of the steel ingot to the core part can be kept uniform through heating and heat preservation, so that the forging shape of the steel ingot can be improved, the cracking tendency of the steel in the forging process is prevented, thestrength and toughness of the steel are improved, and meanwhile, the wear resistance of the knitting needle is improved.

Owner:福建省精新科技制针有限公司

A kind of high temperature titanium alloy and preparation method thereof

InactiveCN104532056BGood castabilityGood welding performanceIncreasing energy efficiencySolid solutionTitanium alloy

The invention relates to a high temperature titanium alloy and a preparation method thereof. Sn element is not added into the alloy provided by the invention, and the tearing tendency in a casting process and the cracking tendency in a welding process that likely to be caused by the brittle phase Ti3Sn can be eliminated, so that the high temperature titanium alloy involved in the invention can have better casting performance, welding performance and product reliability. Nb and Si elements are added at the same time to form Nb-Si high-melting-point compound particles, thus enhancing the high temperature endurance and creep properties of the material. In addition, a certain amount of C element is almost dissolved in the material matrix in the form of solid solution after adding, thus improving the high temperature endurance, creep properties and the like of the material.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

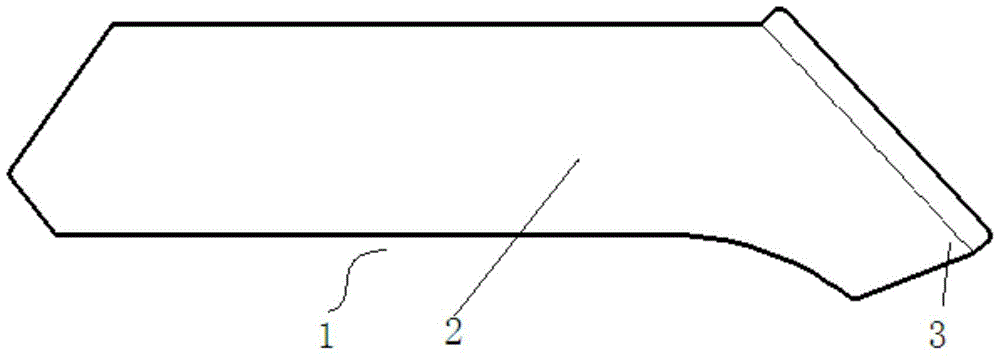

Method for making plow blade stiffeners for agricultural plow tools

ActiveCN105033133BSimple structureStable functionForging/hammering/pressing machinesAgricultural engineeringUltimate tensile strength

The invention discloses a method used for manufacturing ploughing blade reinforcing ribs of agricultural ploughs. The method comprises the steps of carrying out blanking on steel sheets to form ploughing blade blanks with to-be-upset parts on the edges; heating the to-be-upset parts, on the edges, of the ploughing blade blanks; placing the ploughing blade blanks partially heated into upsetting dies; carrying out upsetting on the heated to-be-upset parts, placed into the upsetting dies, of the ploughing blade blanks through a forging machine so as to thicken the to-be-upset parts; forging and pressing the thickened to-be-upset parts of the ploughing blade blanks so as to form the reinforcing ribs on the ploughing blade blanks. According to the invention, the upsetting dies are simple in structure and convenient to use, blade bodies and the reinforcing ribs of ploughing blade products machined through the upsetting dies can be formed through one steel sheet, machined ploughing blades are high in strength and good in durability, the reinforcing ribs of the ploughing blades are prevented from being separated from the blade bodies, and the production efficiency is improved.

Owner:ZUNHUA SHUANGJIAN AGRI MACHINERY MFG CO LTD

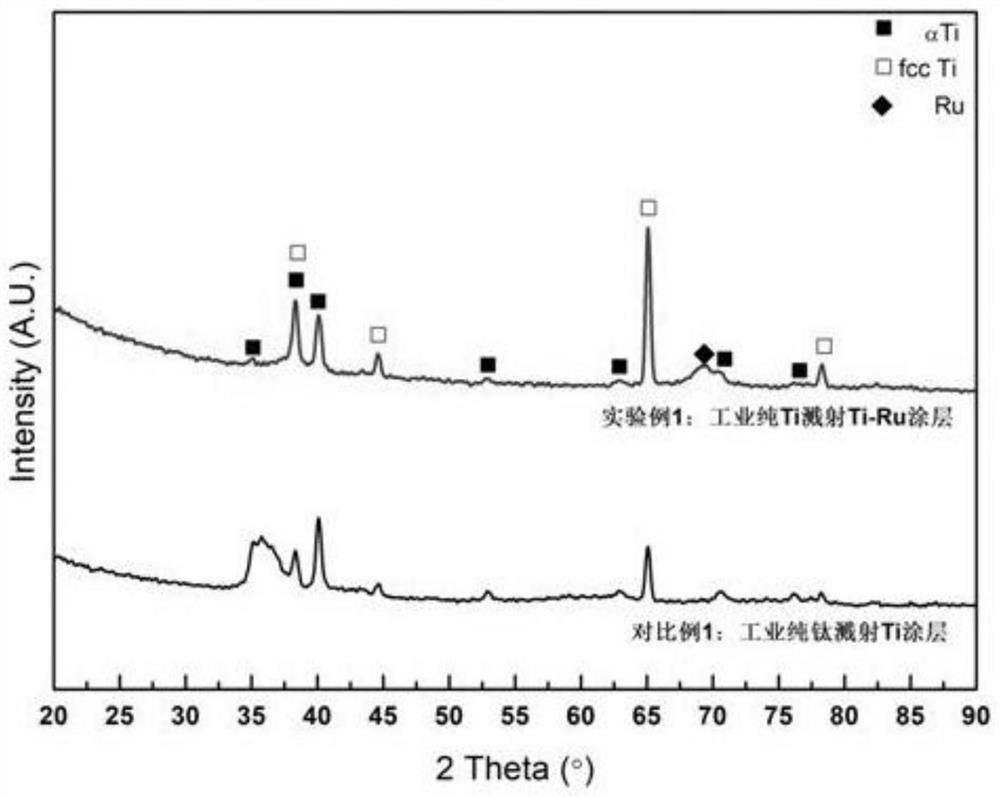

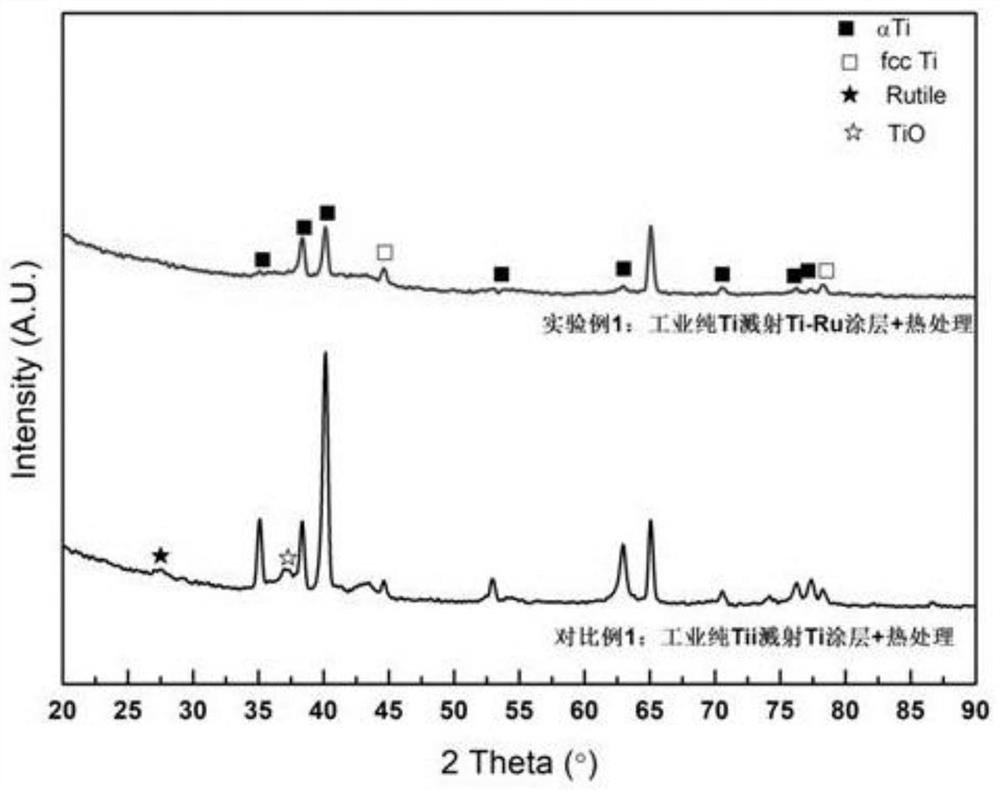

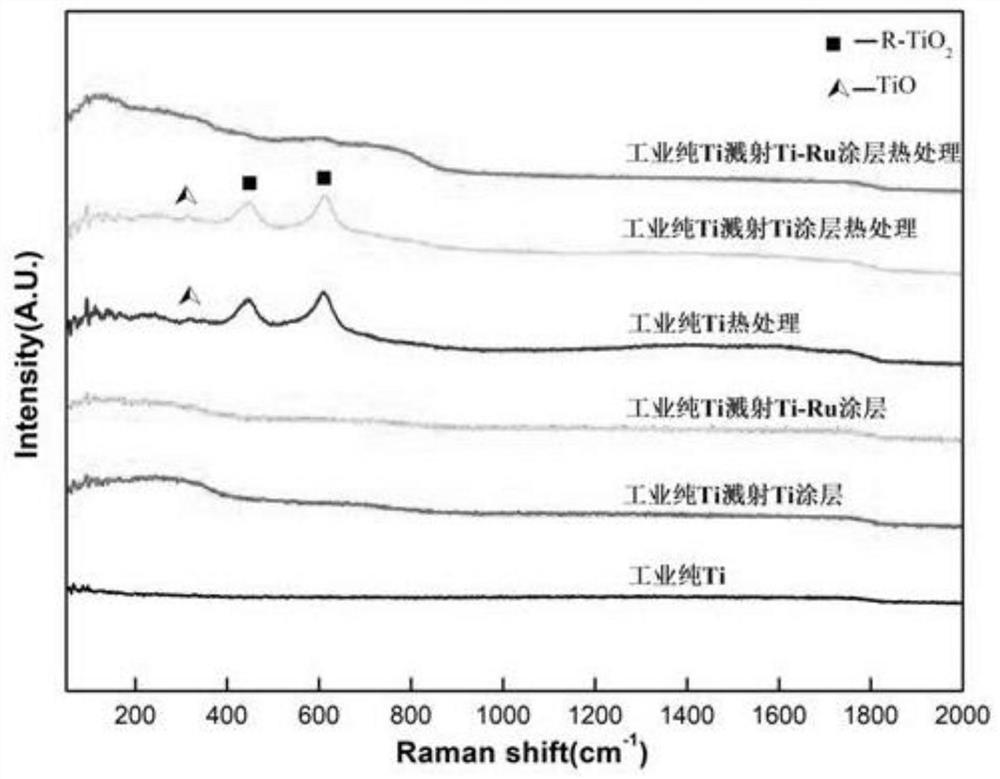

A kind of ti material with good bonding anti-oxidation coating and preparation method thereof

ActiveCN111519133BImprove antioxidant capacitySurface performance is stableVacuum evaporation coatingSputtering coatingMetallic materialsOxidation resistant

The invention discloses a Ti material with a good bonding anti-oxidation coating, which is characterized in that the Ti material substrate is covered with a layer of anti-oxidation Ti-Ru alloy coating with good bonding with the substrate. The content of Ru in the Ti-Ru alloy coating is 5-40wt%, and the thickness of the coating is 1-20 μm; the preparation method includes substrate pretreatment, substrate cleaning, target cleaning, coating sputtering forming process, Obtain the required Ti material with Ti-Ru alloy coating. The Ti material with the Ti-Ru alloy coating of the present invention has good metallurgical bonding and less interfacial stress because the coating resists oxidation and does not generate oxides during the heating process, which enhances the overall oxidation resistance of the Ti material performance. The method of the invention can be widely used in the preparation of functional coatings on the surface of metal materials to obtain metal materials with excellent surface performance.

Owner:KUNMING INST OF PRECIOUS METALS

A preparation process of solder suitable for rapid repair of cold stamping dies and inserts

ActiveCN104722948BNo heat treatment requiredShort repair timeWelding/cutting media/materialsSoldering mediaPunchingManganese

The invention provides soldering flux applicable to quick restoration of cold-punching dies and inserts and a preparation process of the soldering flux. The soldering flux comprises, by weight, 15-20% of aluminum, 1-5% of chromium, 1-5% of manganese, 1-3% of iron and the balance of copper and inevitable impurity. The preparation process of the soldering flux includes steps of continuously casting blank metal bar in the diameter of 3-6 mm in a horizontal or vertical continuous casting manner, and grinding and polishing the blank metal bar so as to be directly used as soldering flux for quickly restoring the cold-punching dies and the inserts. The soldering flux used for quickly restoring the cold-punching dies and the inserts has the advantages of short restoration time, less post-welding defects, good mobility during welding, less deformation and cracking and capability of preventing scratch or drag damage and the like. The cold-punching dies and the inserts after restoration can be further used more than 30,000 times.

Owner:有研金属复材技术有限公司

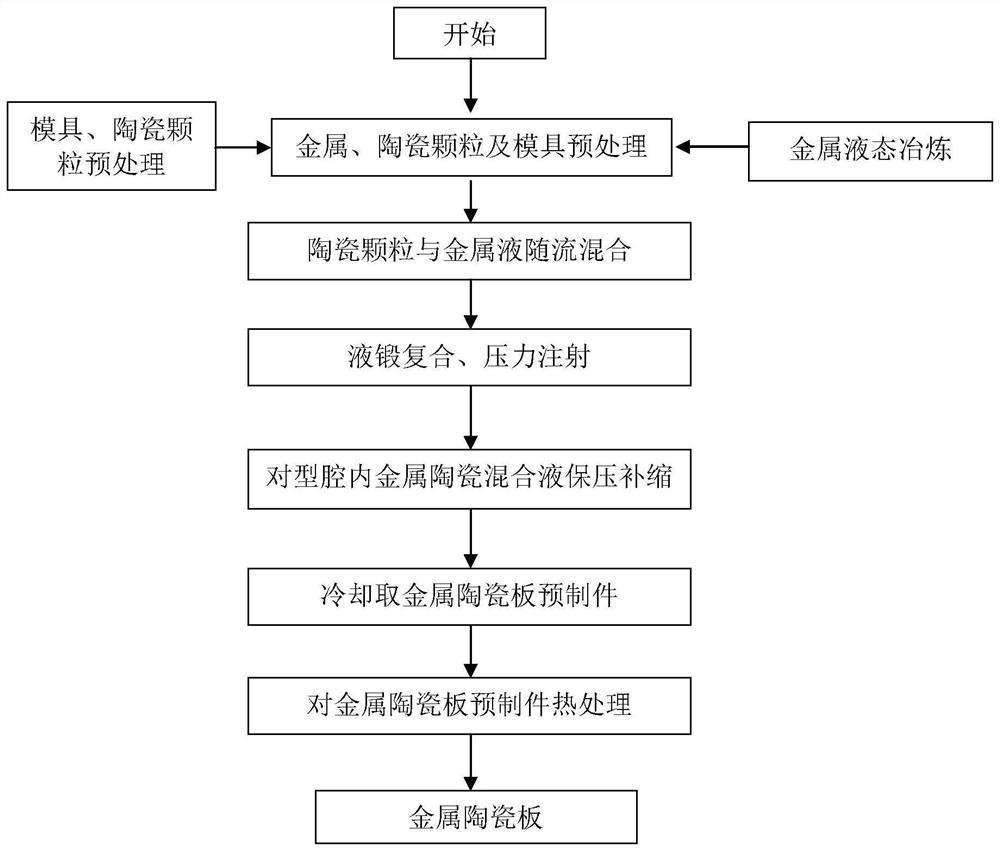

A kind of preparation technology of metal-ceramic plate and metal-ceramic plate

ActiveCN110695331BHigh strengthImprove impact toughnessFurnace typesHeat treatment furnacesComposite ceramicMolten metal

The preparation process of the cermet plate and the cermet plate provided by the present invention relate to the technical field of preparation of wear-resistant materials. The cermet plate is made by preheating the ceramic particles and the molten metal and then liquid forging and compounding. The injection into the metal liquid realizes the primary mixing of ceramic particles and metal liquid, and the pressure device pushes and squeezes the metal-ceramic mixed liquid to realize the secondary mixing of ceramic particles and metal liquid, and the two-time mixing improves the wettability of ceramic particles and metal liquid. Under the action of pressure, the encapsulation strength of the metal liquid on the ceramic particles is improved, and the ceramic particles are evenly dispersed in the metal liquid to avoid agglomeration. The combination of ceramic particles and metal is tighter than that of traditional cast metal composite ceramics. In addition, during liquid forging and compounding, through the extrusion of the metal-ceramic mixture and constant pressure feeding, the filling of the metal-ceramic mixture in the cavity is more in place and dense, and the strength and impact toughness of the metal-ceramic plate are further improved.

Owner:ANHUI CHENGUANG HIGH WEAR RESISTANCE TECH CO LTD

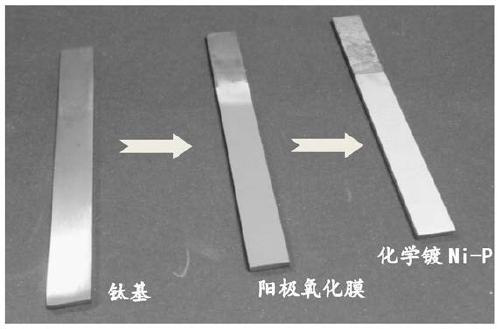

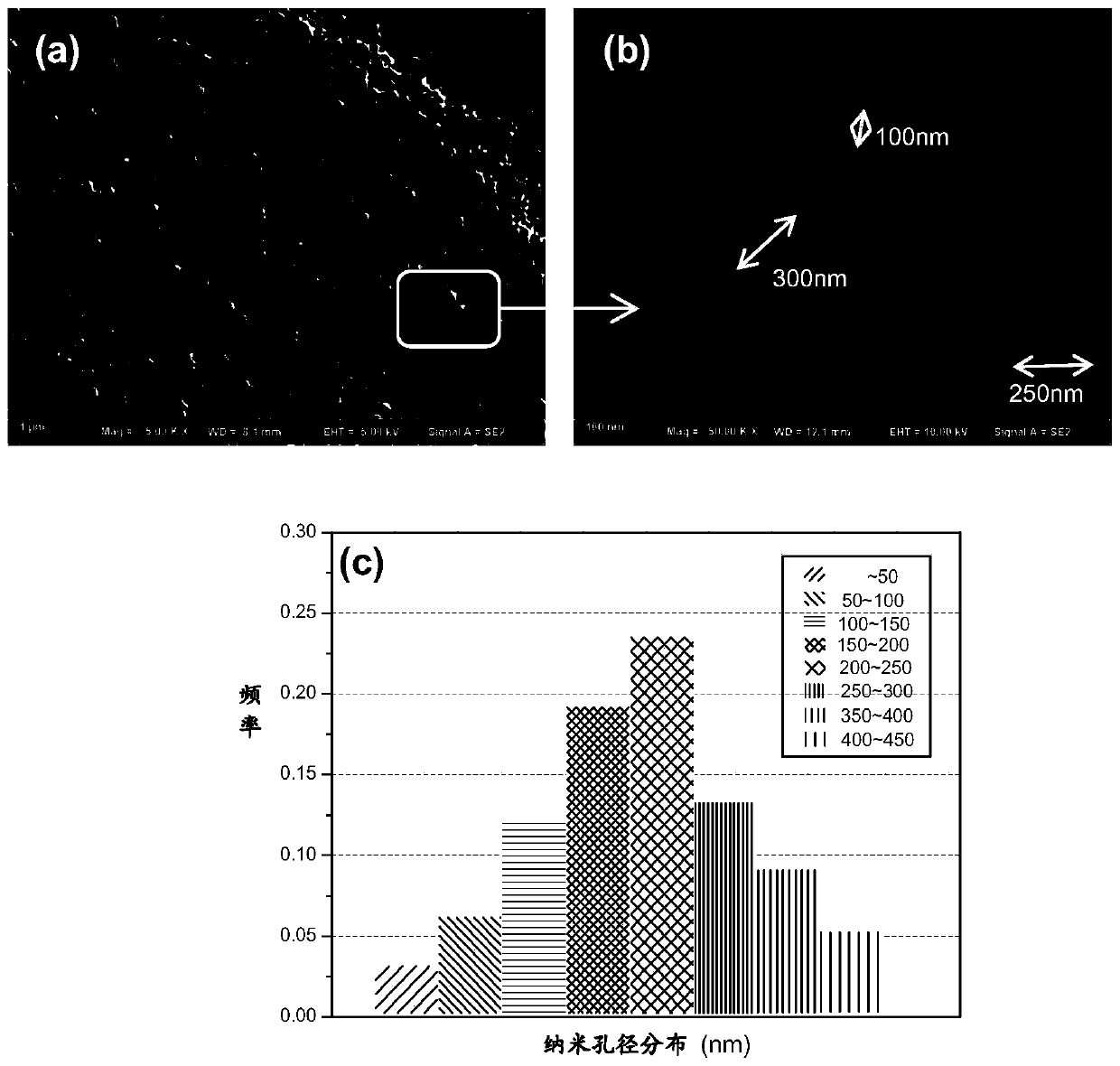

A method for electrodepositing nanocrystalline functional coatings on the surface of anodized porous metal substrates

ActiveCN107313088BPromote continuous growthRelieve growth stressAnodisationLiquid/solution decomposition chemical coatingThin membraneTitanium

Owner:江苏柏瑞鑫铝业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com