A kind of ti material with good bonding anti-oxidation coating and preparation method thereof

An anti-oxidation coating and bonding technology, which is applied in the field of metal surface coating and metal surface modification, can solve the problems of complex preparation process, complex coating composition, and long time consumption, and achieve good biocompatibility and excellent anti-corrosion. Corrosiveness, effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

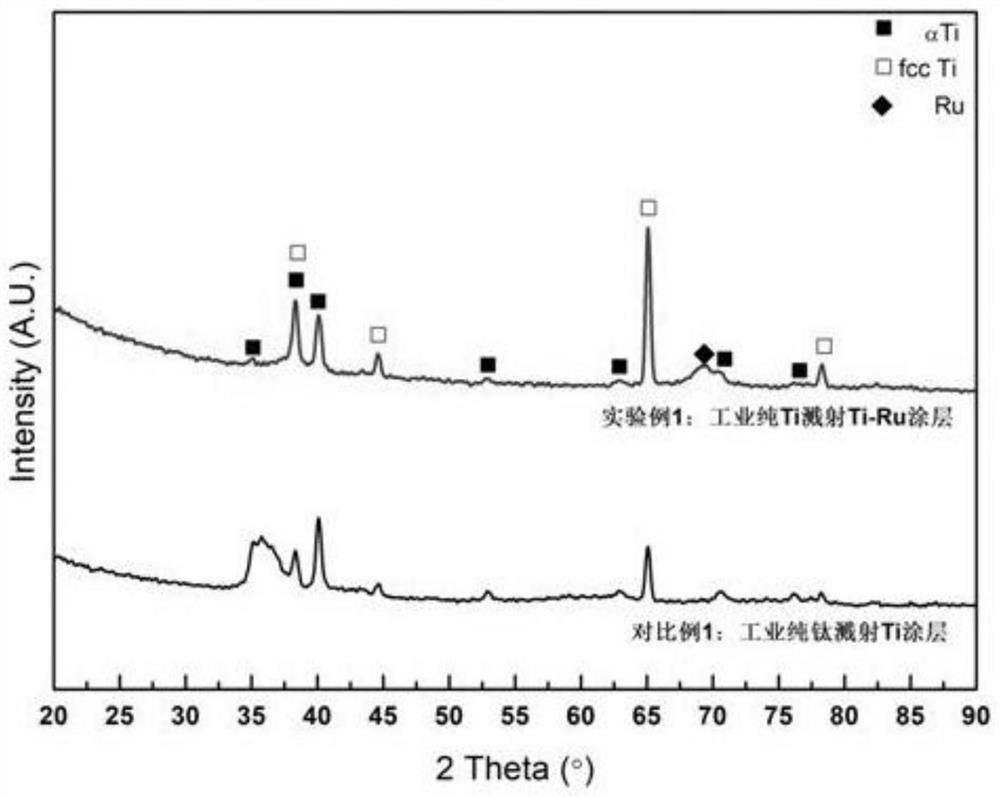

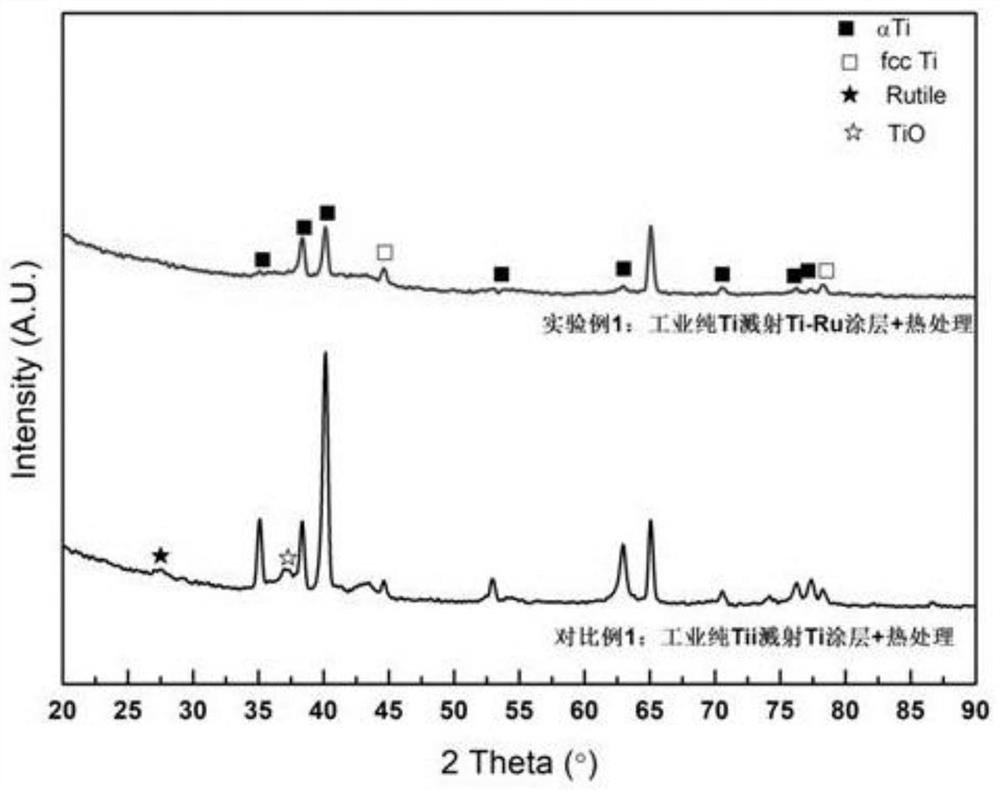

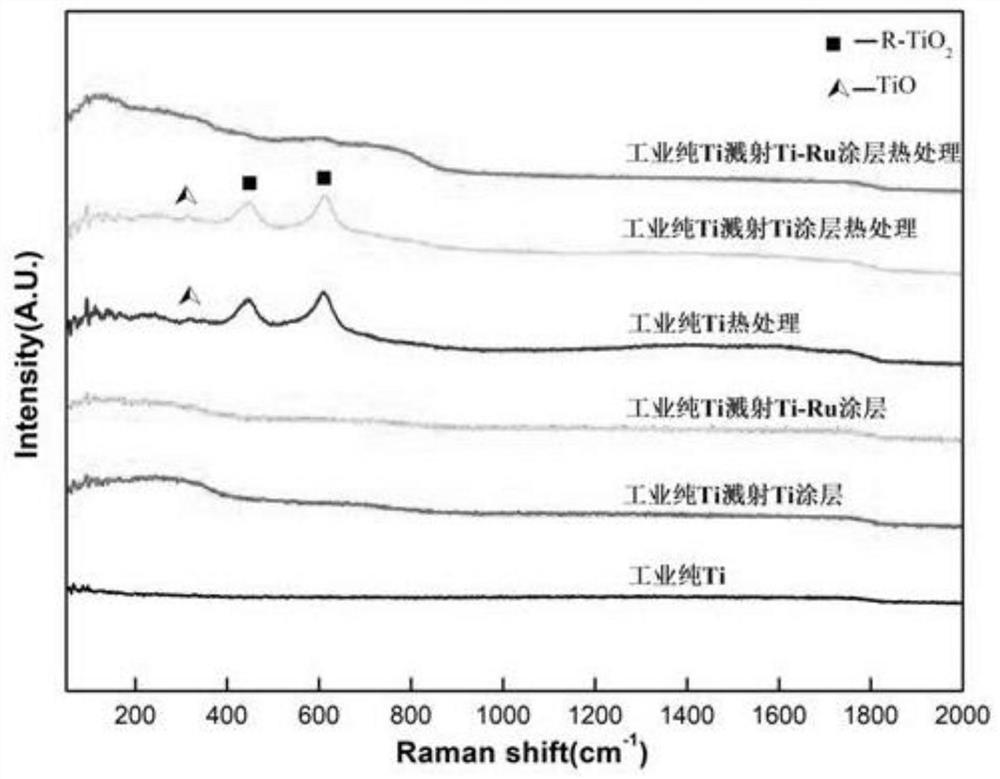

experiment example 1

[0035] (1) Mechanically polish the commercially pure Ti (TA2) and ultrasonically clean it with acetone for 3 minutes, then recrystallize and anneal the commercially pure Ti under vacuum conditions to obtain commercially pure Ti with a uniform microstructure. The annealing temperature is 700℃, treatment time is 1h, vacuum degree is 1x10 -3 Pa;

[0036] (2) The industrially pure Ti treated in step (1) was ultrasonically cleaned with 3wt% dilute hydrochloric acid for 3 minutes and dried;

[0037] (3) Fix the dried Ti material substrate on the sample stage of the dual magnetron sputtering source system. Controlled sputtering source system, Ti target adopts DC sputtering source system, Ru target adopts RF sputtering source system; vacuumize to 1x10 -3 Pa, then start to heat the industrial pure Ti substrate, after heating to 100°C, introduce Ar gas, adjust the air pressure to 0.5Pa, separate the substrate with a baffle, and adjust the power of the DC sputtering source used for the...

Embodiment 1

[0050] The substrate is industrially pure Ti (TA0), and the Ti material with a good bonding anti-oxidation coating Ti-Ru alloy coating is prepared. First, the industrial pure Ti is mechanically polished, and ultrasonically cleaned with anhydrous alcohol for 3 minutes, and then Under the condition of vacuum degree of 1×10-3Pa, recrystallization annealing was carried out on commercially pure Ti, the annealing temperature was controlled at 700°C, and the treatment was performed for 4 hours to obtain commercially pure Ti substrate with uniform microstructure; then, commercially pure Ti was treated with concentration Ultrasonic cleaning with 3wt% dilute sulfuric acid for 10 minutes and drying; then the dried industrial pure Ti substrate was fixed on the sample stage of the dual magnetron sputtering source system, and the center of the surface of the industrial pure Ti substrate and the Ti target (purity 99.99wt%) and Ru target (purity 99.99wt%) have the same surface center distance ...

Embodiment 2

[0052] The substrate is Ti6Al4V alloy, and the Ti6Al4V alloy coated with anti-oxidation coating Ti-Ru alloy with good adhesion is prepared. Firstly, the Ti6Al4V alloy is mechanically polished, and ultrasonically cleaned with acetone for 10 minutes, and then vacuumed at a degree of 1×10 -4 Under the condition of Pa, the Ti6Al4V alloy was recrystallized and annealed, the annealing temperature was controlled at 900 ° C, and the treatment was performed for 1 h to obtain a Ti6Al4V alloy with a uniform microstructure; then, the Ti6Al4V alloy was ultrasonically cleaned with 10 wt% dilute nitric acid for 3 min and dried; Then the dried Ti6Al4V alloy substrate was fixed on the sample stage of the dual magnetron sputtering source system, and the surface center of the Ti6Al4V alloy substrate was connected with the Ti target (purity 99.995wt%) and Ru target (purity 99.995wt%) The center distance of the surface is equal, the distance is 60mm; the dual magnetron sputtering source system is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com