Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Improve cladding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibrating cladding repair technology for damaged last-stage blades of steam turbine

ActiveCN108505035AAvoid deformationAvoid crackingMetallic material coating processesSurface stressEngineering

The invention relates to the technical field of repair of blades of a steam turbine, in particular to a vibrating cladding repair technology for damaged last-stage blades of the steam turbine. Firstly, the last-stage blades of the steam turbine are heated at the low temperature, surface defect parts or damaged parts are pre-cleaned and subjected to surface detection and analysis, then, proper technological parameters are selected according to detection results, and the surface defect parts or the damaged parts are subjected to laser cladding under assistance of vibrating stress relief treatment. After cladding, samples are subjected to vibrating stress relief treatment for 20-30 min, and the residual stress of components is further eliminated. By means of the method, the surface defect orthe damaged parts of the last-stage blades of the steam turbine can be effectively repaired, and meanwhile, defects of non-uniform structure and performance distribution and the like caused by non-uniform surface stress of clad layers are overcome.

Owner:JIANGSU UNIV

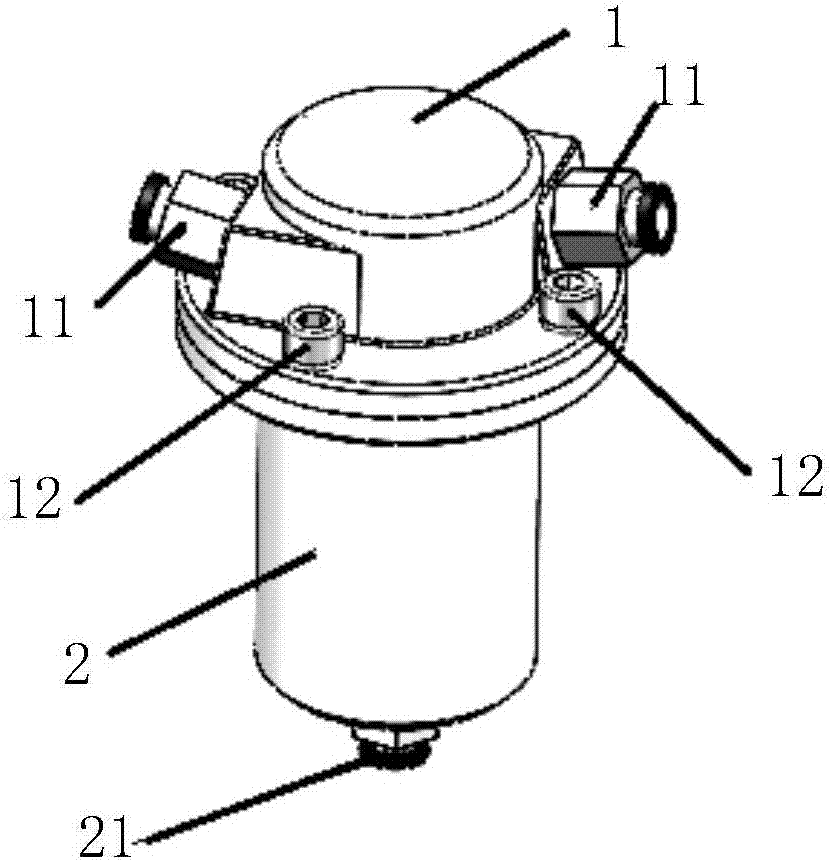

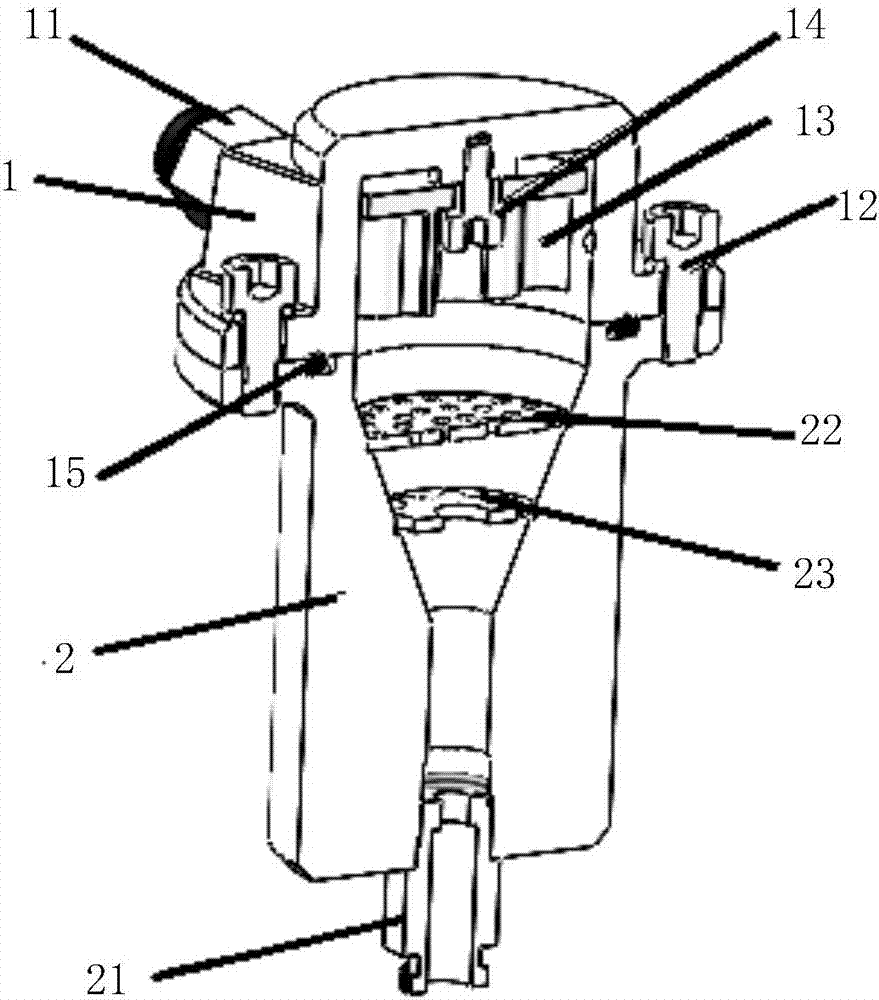

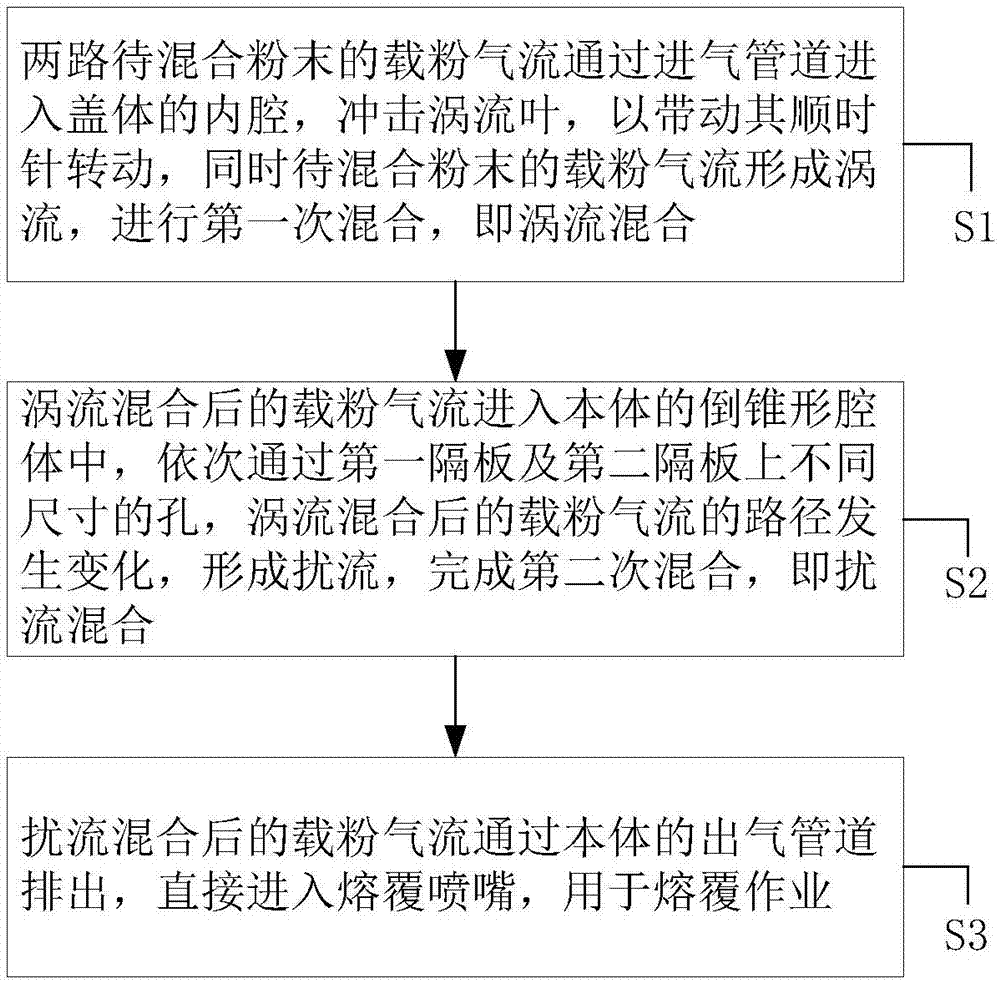

Powder mixing device and powder mixing method

ActiveCN106925175AAvoid uniformityReduce turbulenceFlow mixersTransportation and packagingEngineeringLaser

The invention provides a powder mixing device and a powder mixing method. Multiple paths of to-be-mixed powder carrying airflows respectively enter into an inner chamber of a cover through a plurality of air inlet pipes arranged on the cover, and meanwhile, a vortex blade in the inner chamber of the cover is driven to rotate, namely, a powder-carrying airflow direct mixing manner is adopted for mixing the to-be-mixed powder. Specifically, the vortex blade is used for mixing, the use of multiple connectors is avoided and the possibility of turbulence in the gathering process of multiple paths of airflows is reduced, so that the mixing quality is promoted; the powder-carrying airflows respectively enter into the air inlet pipes so as to complete the mixing of the powder in the powder mixing device, so that the time and labor for manually mixing can be saved, the resource can be saved and the cost can be lowered; the powder mixing device can be mounted at a fusion covering end, the uniformly mixed powder can be directly connected with a fusion covering nozzle through an air outlet pipeline and the laser fusion covering is performed, so that the worse uniformity caused by various unstable factors in the process of conveying after mixing can be avoided and the fusion covering quality is promoted.

Owner:NANJING HUIRUI PHOTOELECTRIC TECH CO LTD

Repairing method of cracks on roll surface of back-up roll of rolling mill

ActiveCN103898518ASmall amount of grindingNo metallurgical cracksMetallic material coating processesAlloyHardness

The invention provides a repairing method of cracks on a roll surface of a back-up roll of a rolling mill. The repairing method comprises the following steps: (a) pre-treatment of cracks; (b) repairing, namely carrying out fusion covering on a to-be-repaired part through a laser by means of nickel base alloy powder; carrying out a vibration aging treatment, wherein the nickel base alloy powder comprises the following chemical components in percentage by mass: 0.5% of C, 18-20% of Cr, 2-3% of Mo, 0.5-1% of Mn, 2-3% of Si, 3.5-4.5% of Fe, 1.5-3% of W, 1.5-2% of Co, 2-3% of CeO and the balance of Ni; and carrying out fusion covering on rectangular spots in a laminated manner; and (c) post-treatment. The repairing method provided by the invention is used for repairing the cracks on the roll surface by adopting the laser cladding technology without pre-heating. Furthermore, subsequent grinding amount is small without metallurgical cracks, and the hardness can reach the operating requirement of a new roll [HRC (Rockwell Hardness) is over 60].

Owner:HANGZHOU DAYE LASER TECH

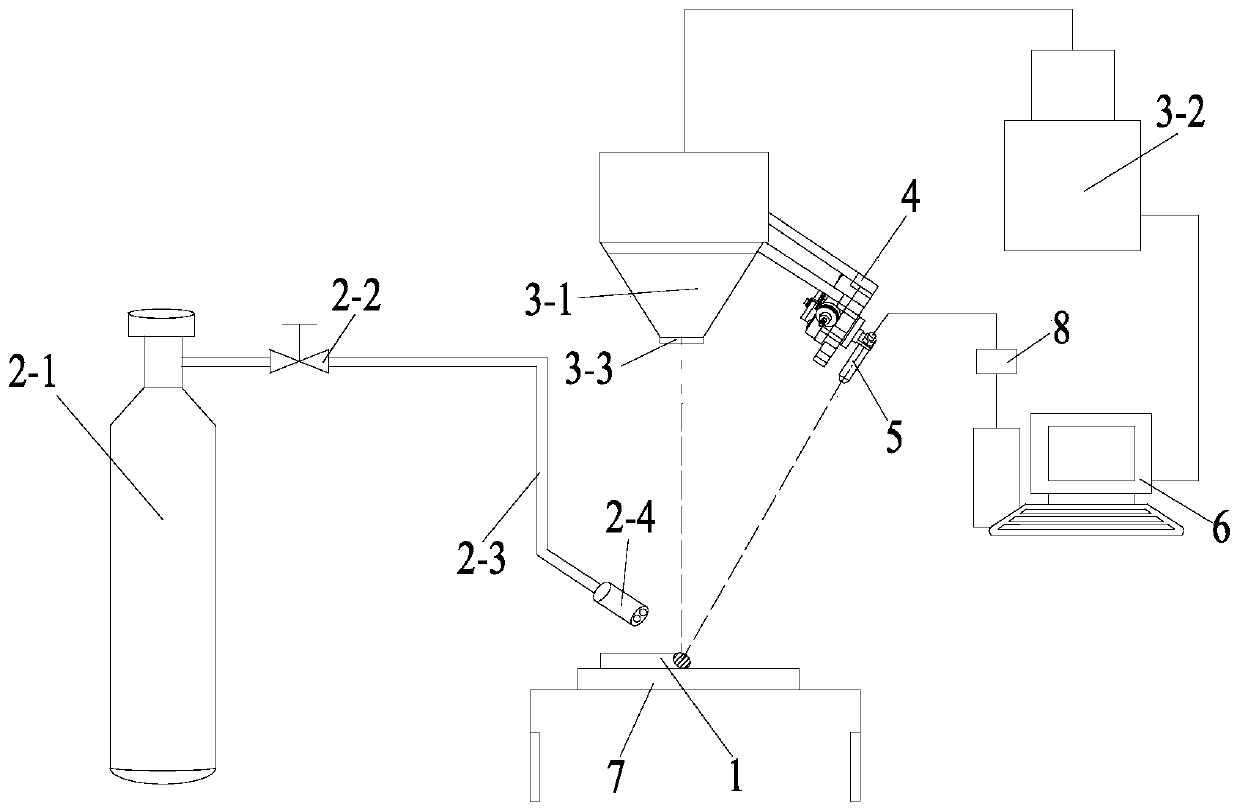

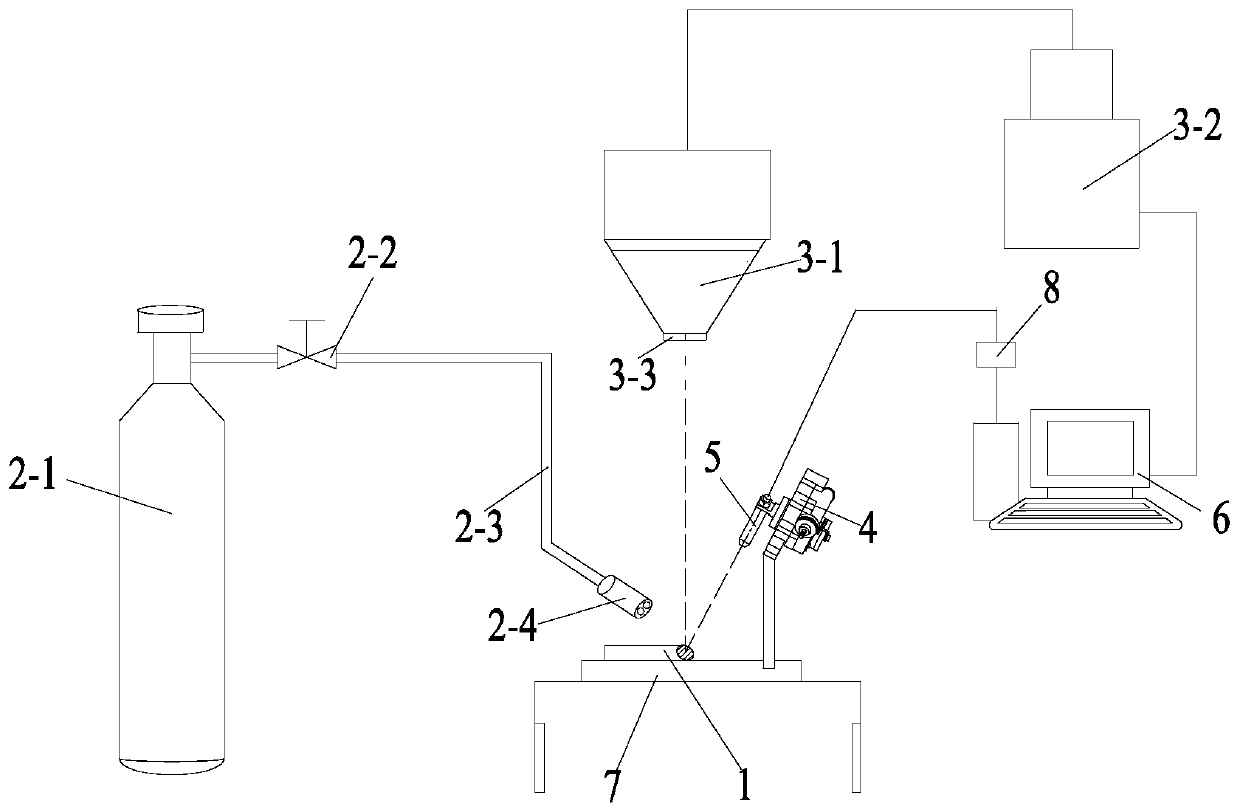

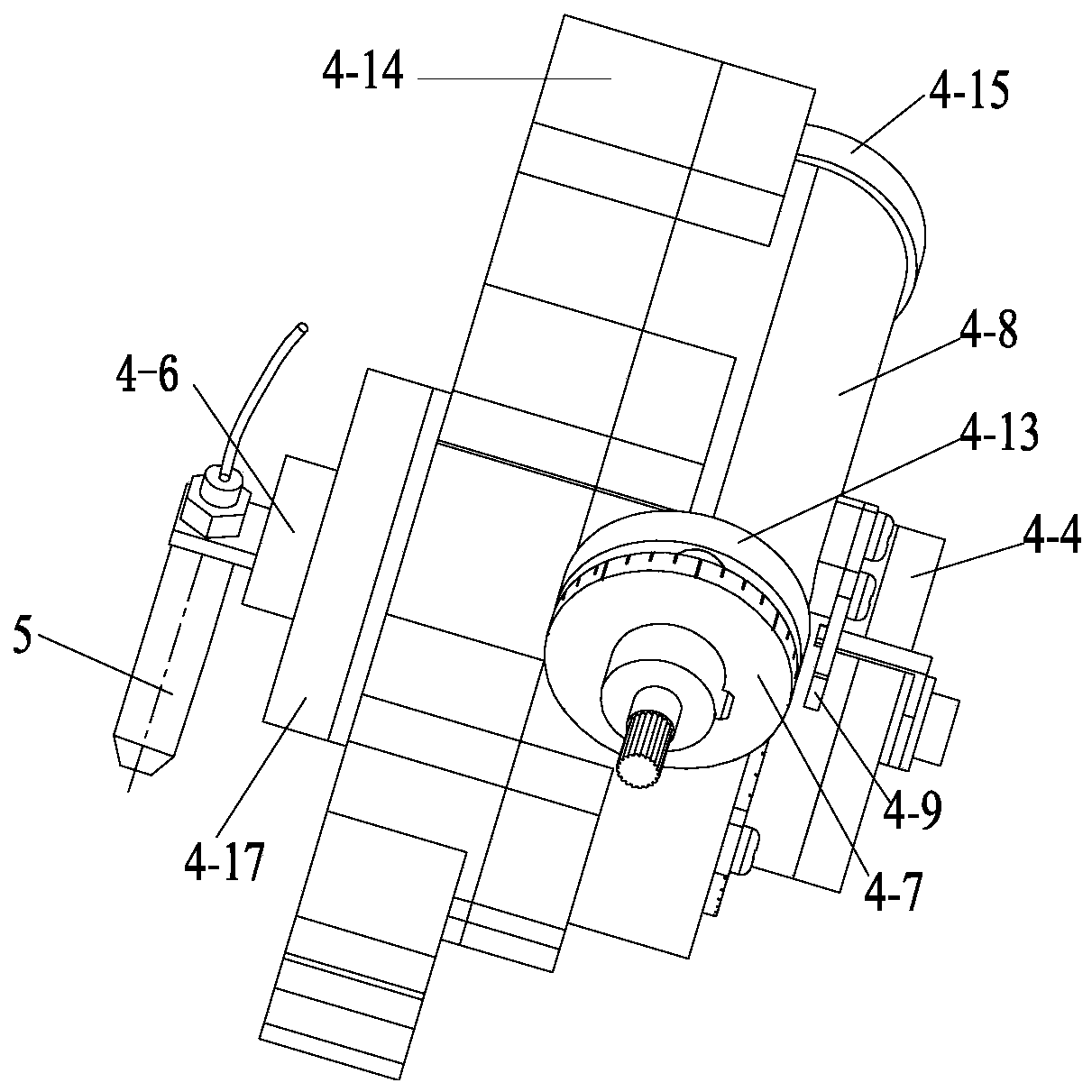

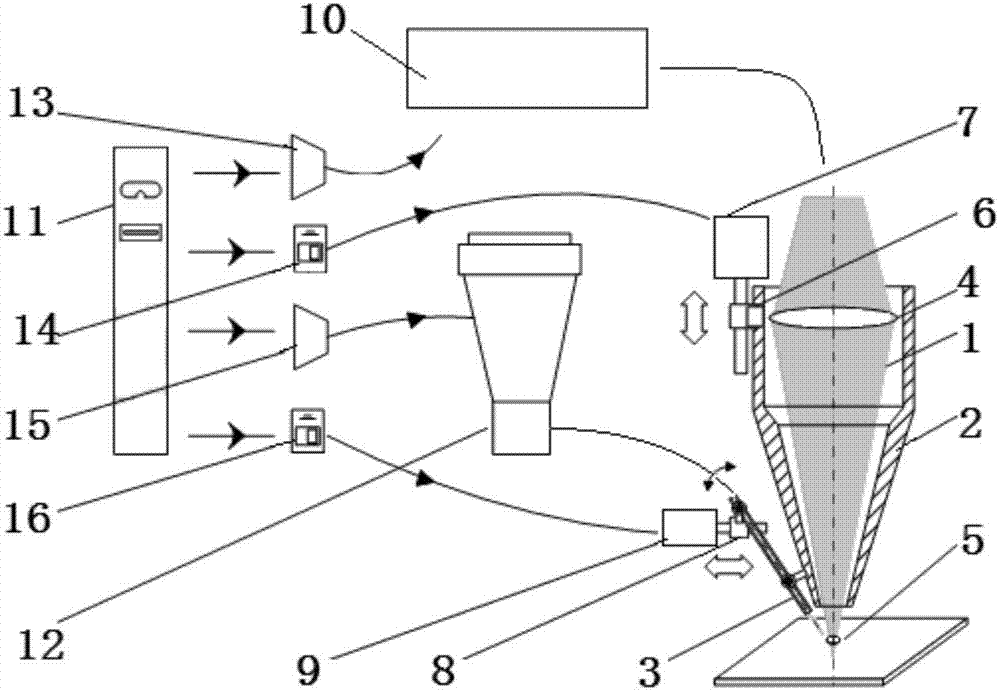

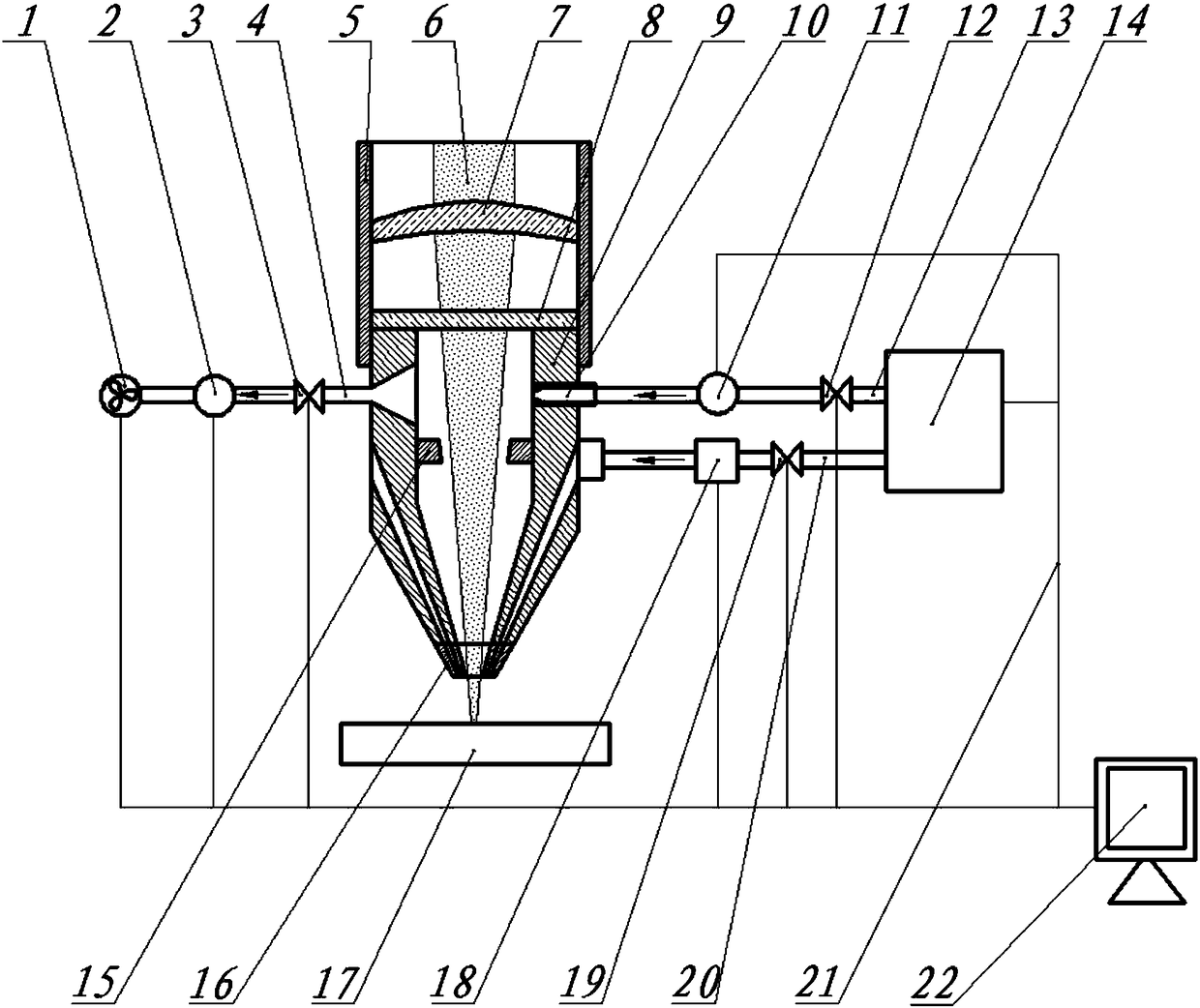

Laser cladding process molten bath temperature online monitoring device and method

InactiveCN110144587ARapid positioningAccurate temperature measurement resultsSensing heat from liquidsMetallic material coating processesControl systemData acquisition

The invention discloses a laser cladding process molten bath temperature online monitoring device and method. The laser cladding process molten bath temperature online monitoring device comprises an inert gas shielding device, a laser control system, an infrared thermometer clamp, an infrared thermometer and a servo working platform, and further comprises a data acquisition unit connected with theinfrared thermometer and a computer connected with the data acquisition unit. The method comprises the two modes of tracking monitoring and fixed-point monitoring. Through the method, tracking monitoring and online real-time display can be effectively conducted on the molten bath temperature in the laser cladding process, and the temperatures of the quick heating and quick cooling process of a certain fixed-point position can be monitored and displayed on line in real time. In the using process, different methods can be selected according to requirements. The laser cladding process molten bath temperature online monitoring device and method are novel and reasonable in design, convenient to implement and low in cost and lays the foundation for optimizing the laser cladding process and improving the laser cladding quality.

Owner:XIAN UNIV OF SCI & TECH

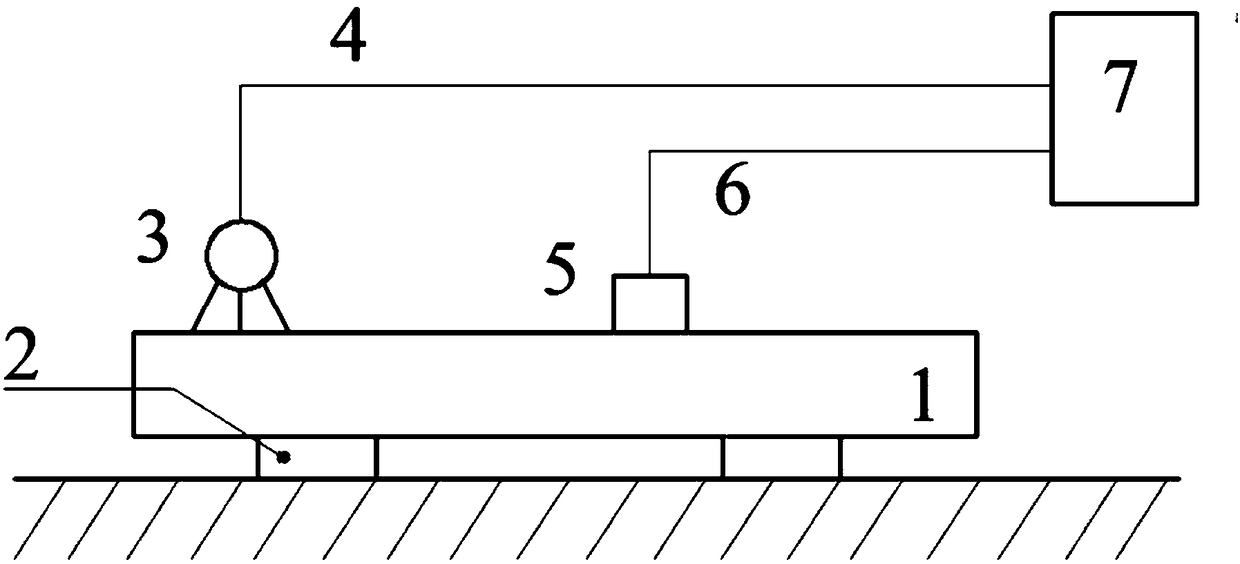

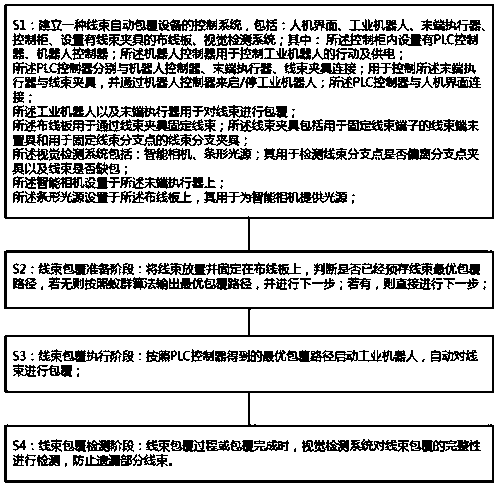

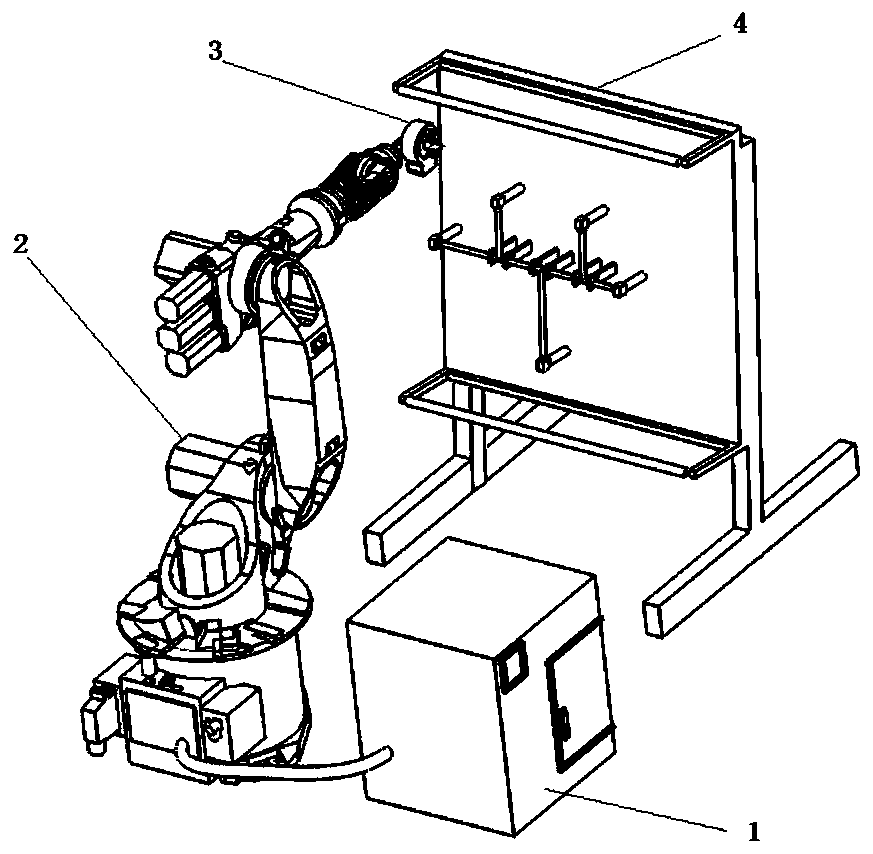

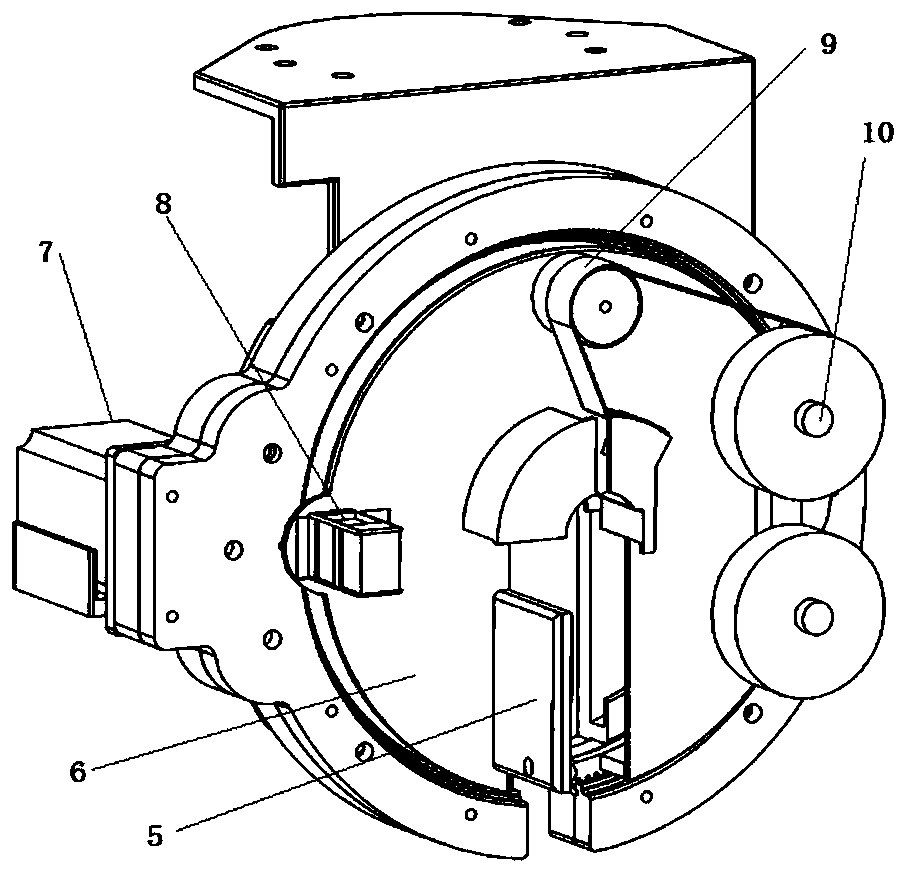

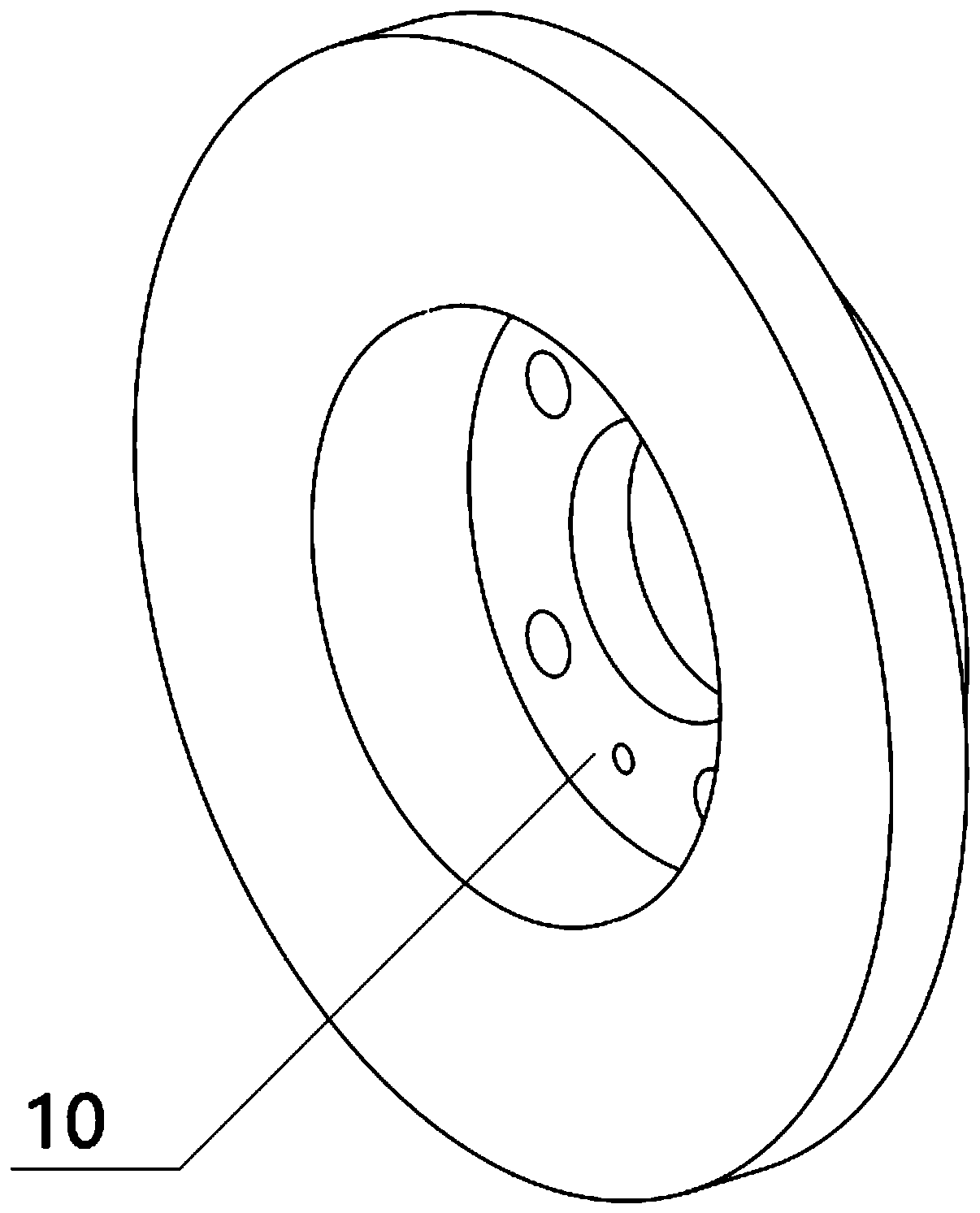

Control method of automatic wire harness cladding equipment

ActiveCN110767381AImprove coating efficiencyFriendly man-machine interfaceProgramme-controlled manipulatorManufacturing wire harnessesHuman–machine interfaceControl system

The invention provides a control method of automatic wire harness cladding equipment, including the following steps: S1: establishing a control system of the automatic wire harness cladding equipment,wherein the control system includes a human-computer interface, an industrial robot, an end effector, a control cabinet, a wiring board and a visual inspection system; S2: wire harness cladding preparation stage: placing and fixing wire harnesses on the wiring board, judging whether the optimal cladding path of the wire harnesses has been pre-stored, outputting the optimal cladding path accordingto the ant colony algorithm if no optimal cladding path of the wire harnesses has been pre-stored, and proceeding to the next step; directly proceeding to the next step if the optimal cladding path of the wire harnesses has been pre-stored; S3: wire harness cladding execution stage: starting the industrial robot according to the optimal cladding path obtained by a PLC controller to automaticallyclad the wire harnesses; and S4: wire harness cladding detection stage: detecting the integrity of the wire harness cladding by the visual inspection system in the wire harness cladding process or when the cladding is completed. The control method of the invention has advantages of friendly human-computer interface, high automation degree and accurate control process, can replace manual wire harness cladding, and effectively improves wire harness cladding efficiency.

Owner:SHANGHAI INST OF TECH +1

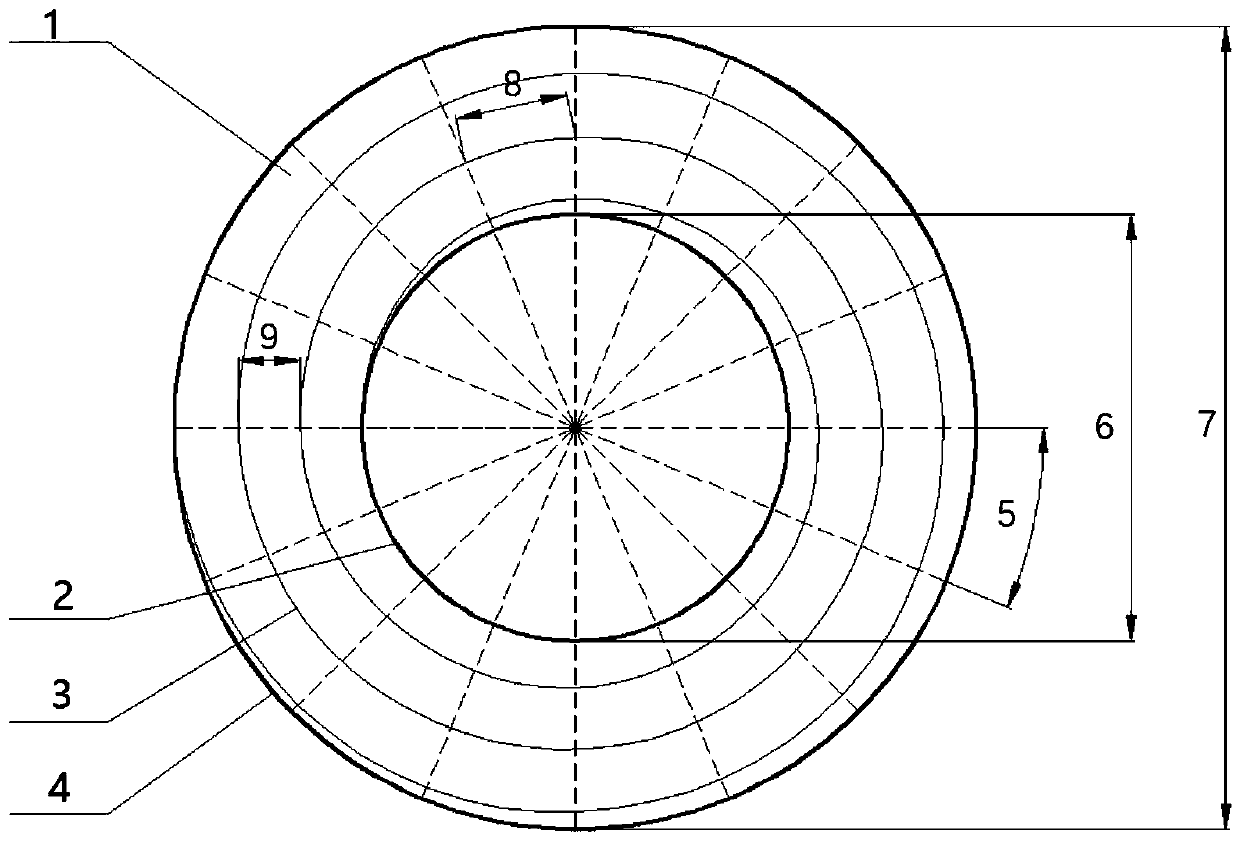

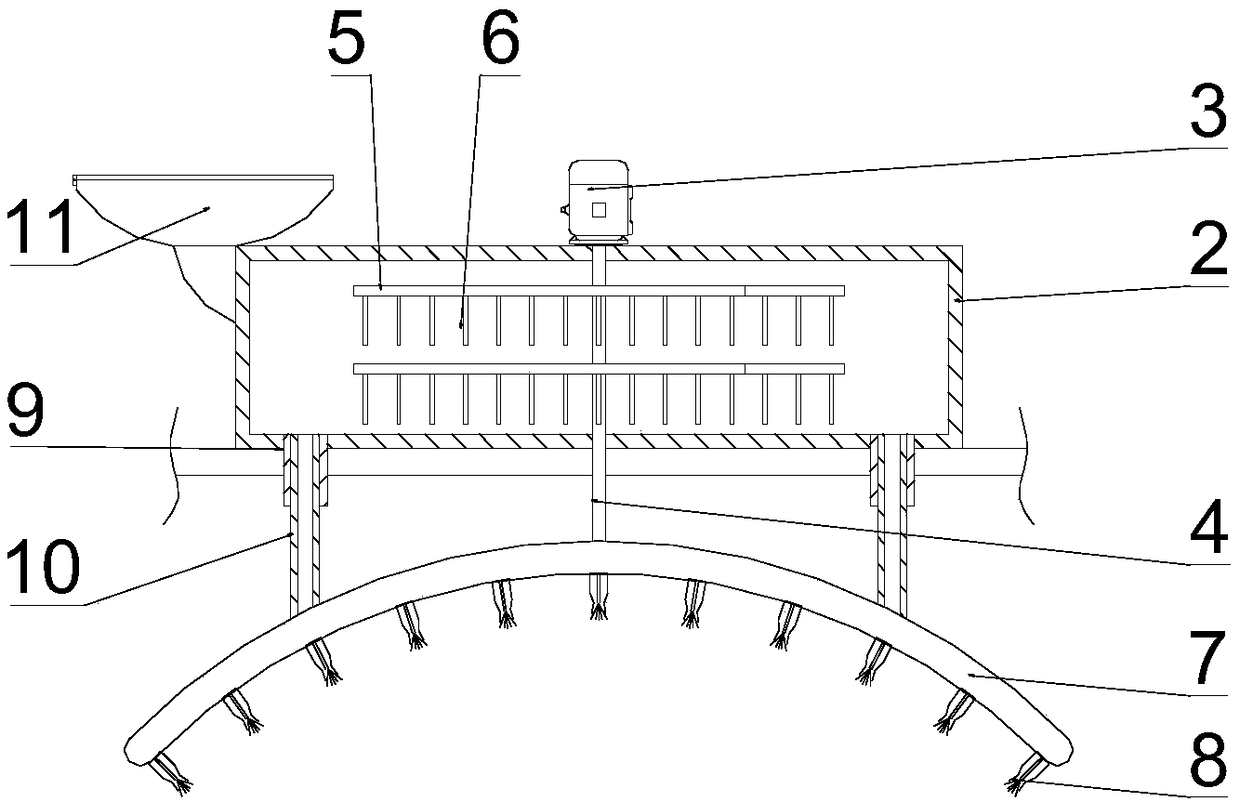

Method used for superspeed laser cladding of end face of disc type part

ActiveCN111334789AGuaranteed cladding efficiencyCladding is widely applicableMetallic material coating processesLaser beamsSpiral line

The invention relates to a method used for superspeed laser cladding of an end face of a disc type part. The method comprises the steps that a gap ring I and a gap ring II are mounted on an outer circle and an inner hole of the disc type part in a sleeving manner, and according to process needs, the cladding rate V1, the cladding lap-joint rate eta, laser beam power P and other parameters are set;according to the cladding lap-joint rate eta, the superspeed laser cladding single way width DL and other parameters, a superspeed laser cladding path is planned that a starting point is located on the section line of an inner hole of the end face of the disc type part, and an end point is located on an equal-distance spiral line on the section line of the outer circle of the end face of the discpart; equal-angle joints are mounted at the same time, the equal-distance spiral line is divided into multiple segments of equal-distance spiral line arcs, and through the manner of changing the disctype part rotating angle speed omega i and the superspeed laser cladding head moving speed during superspeed laser cladding of the all segments of equal-distance spiral line arcs, cladding is carriedout, and it is ensured that in the cladding process, the parameters are kept stable; and finally, through a linear cutting manner, the gap ring I, the gap ring II and the disc type part are separated.

Owner:JIANGSU UNIV

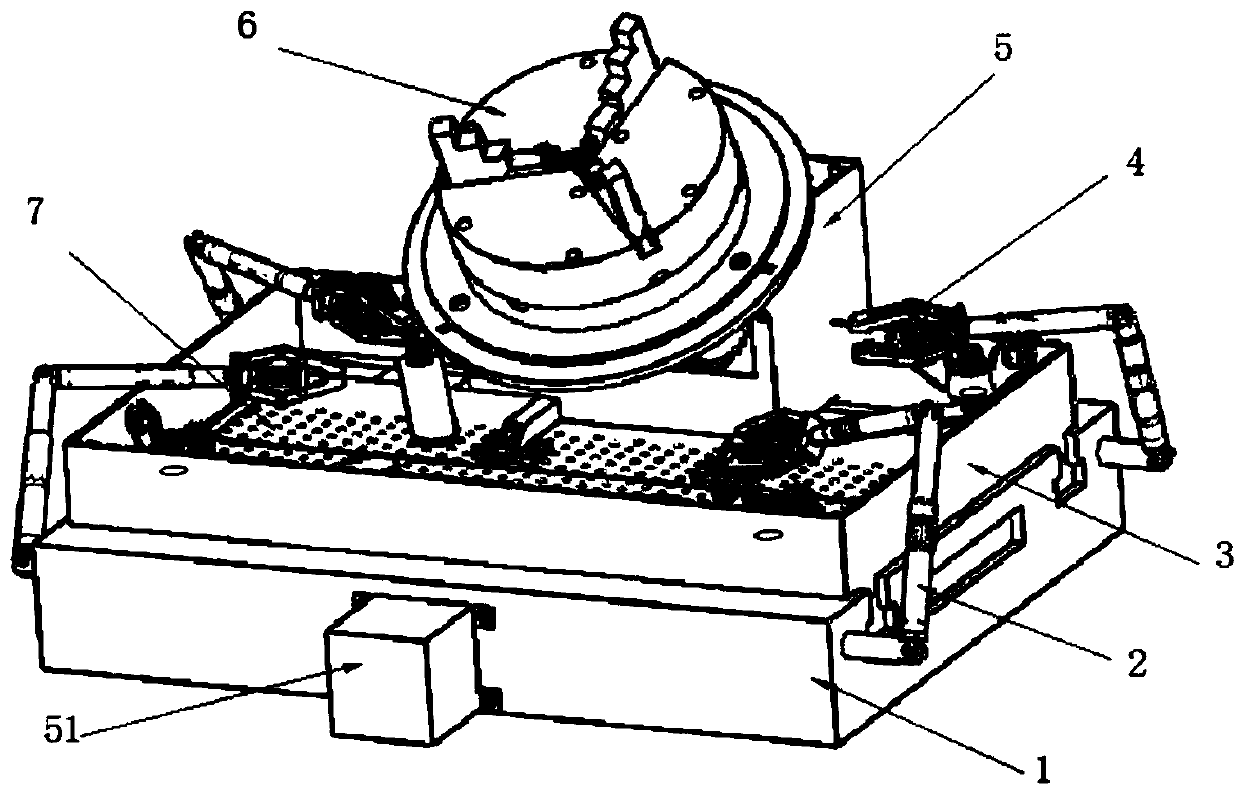

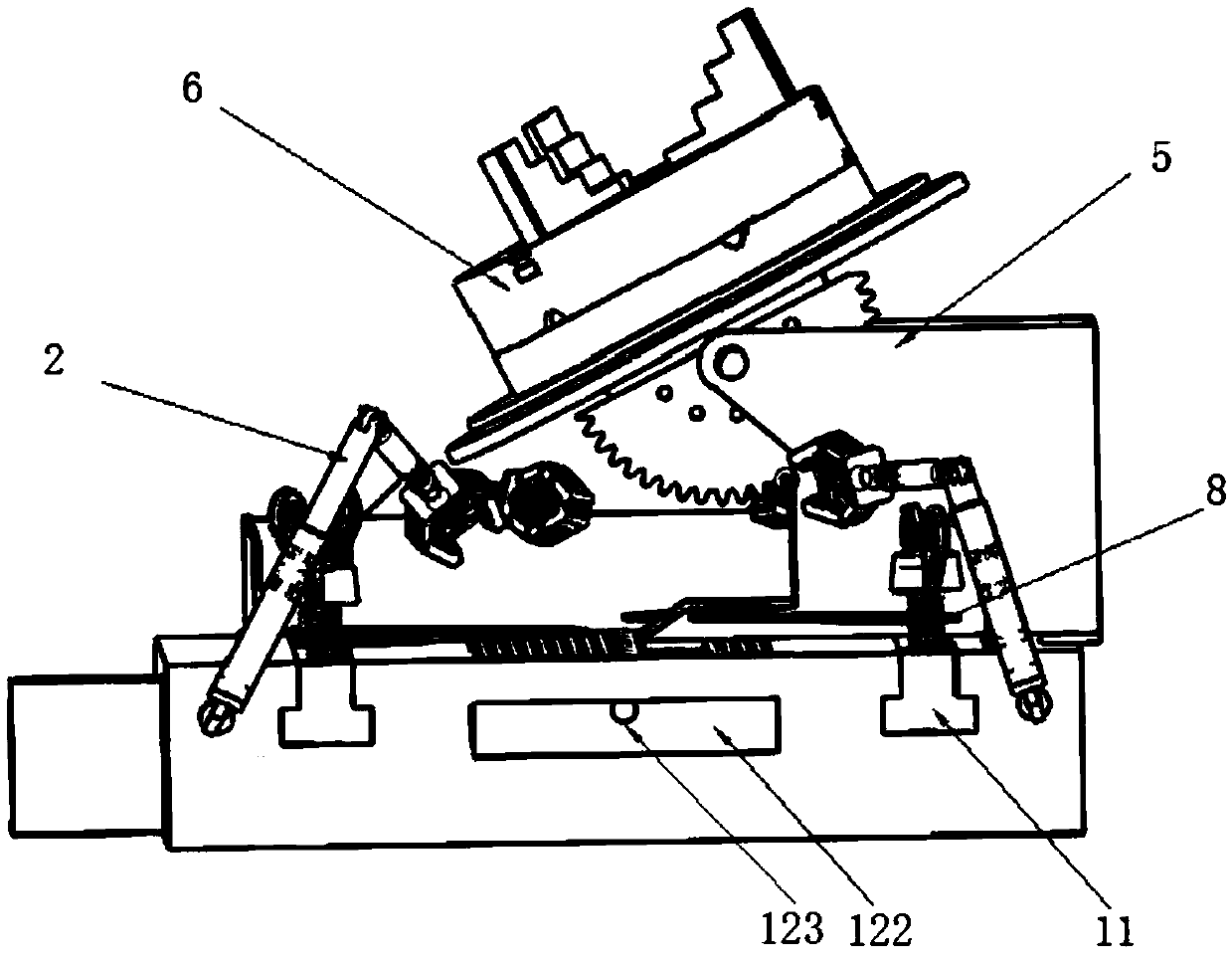

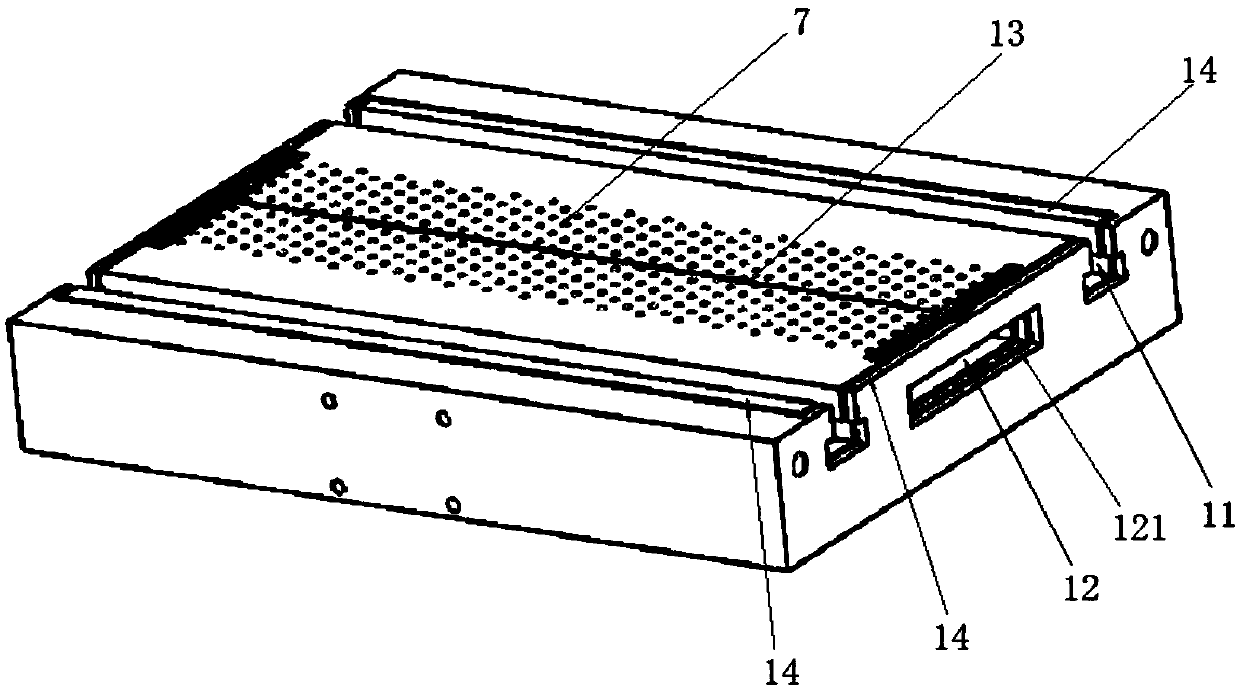

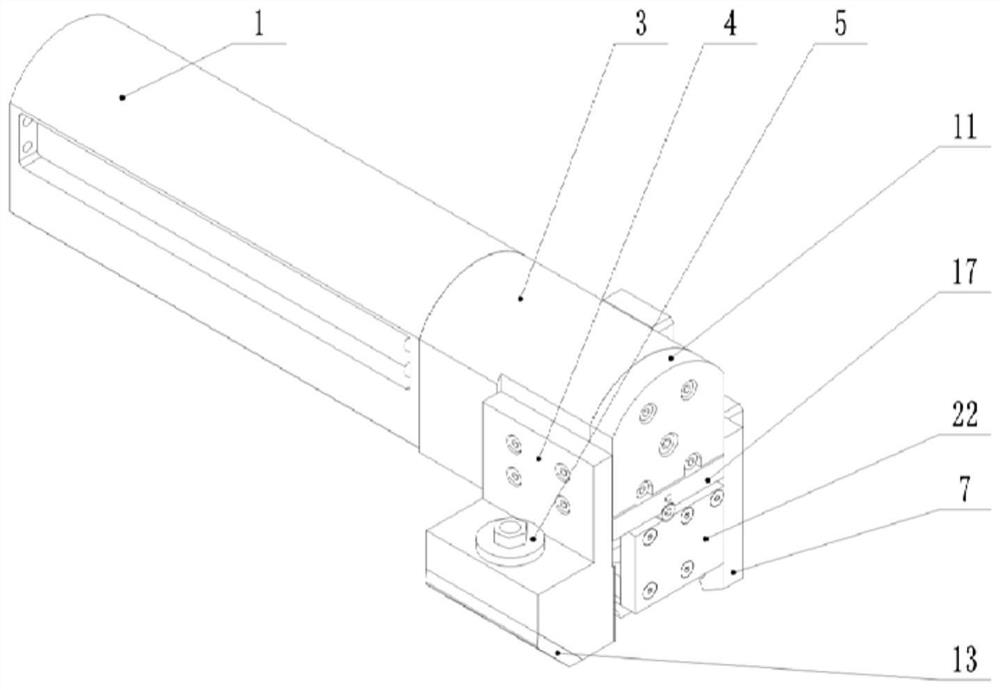

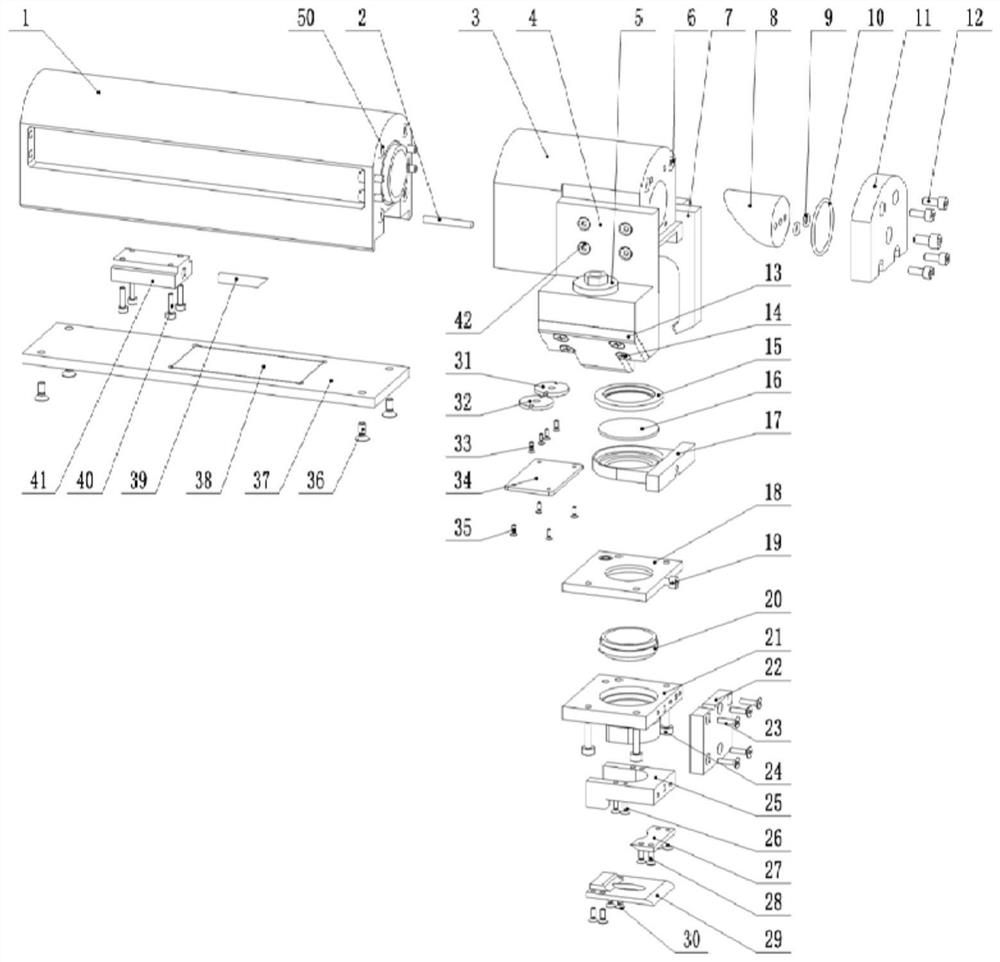

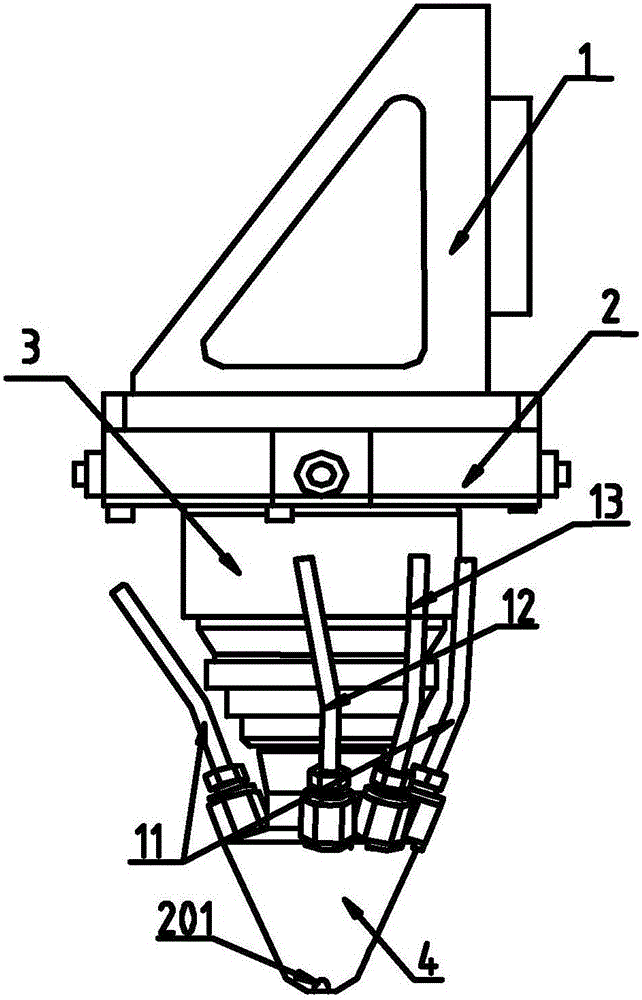

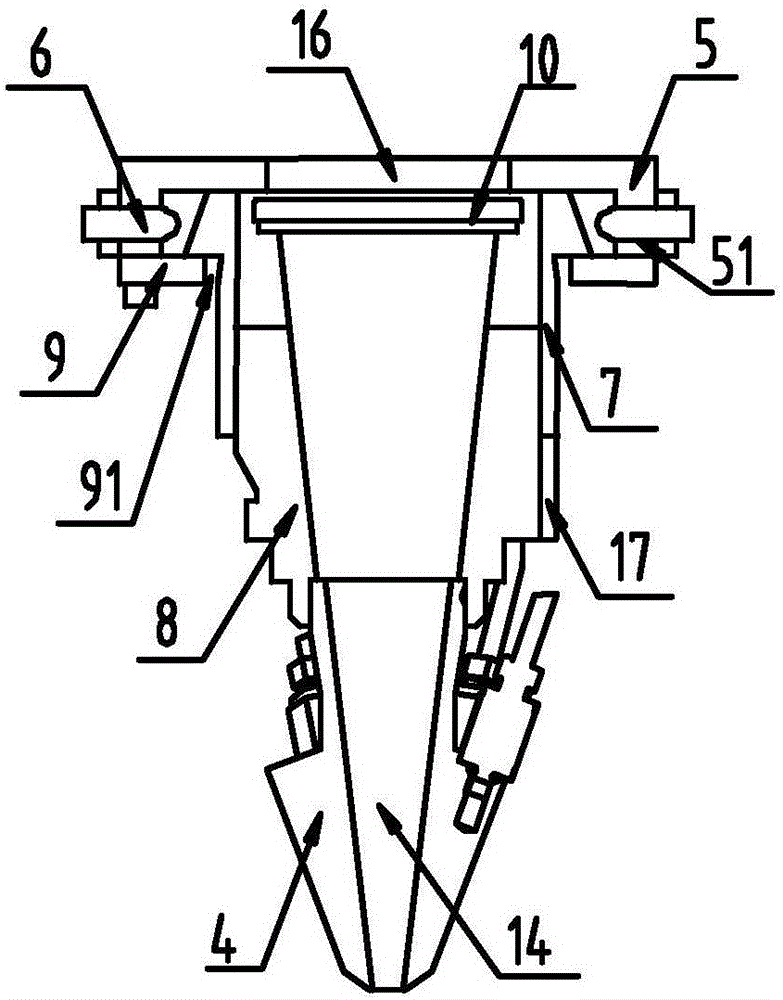

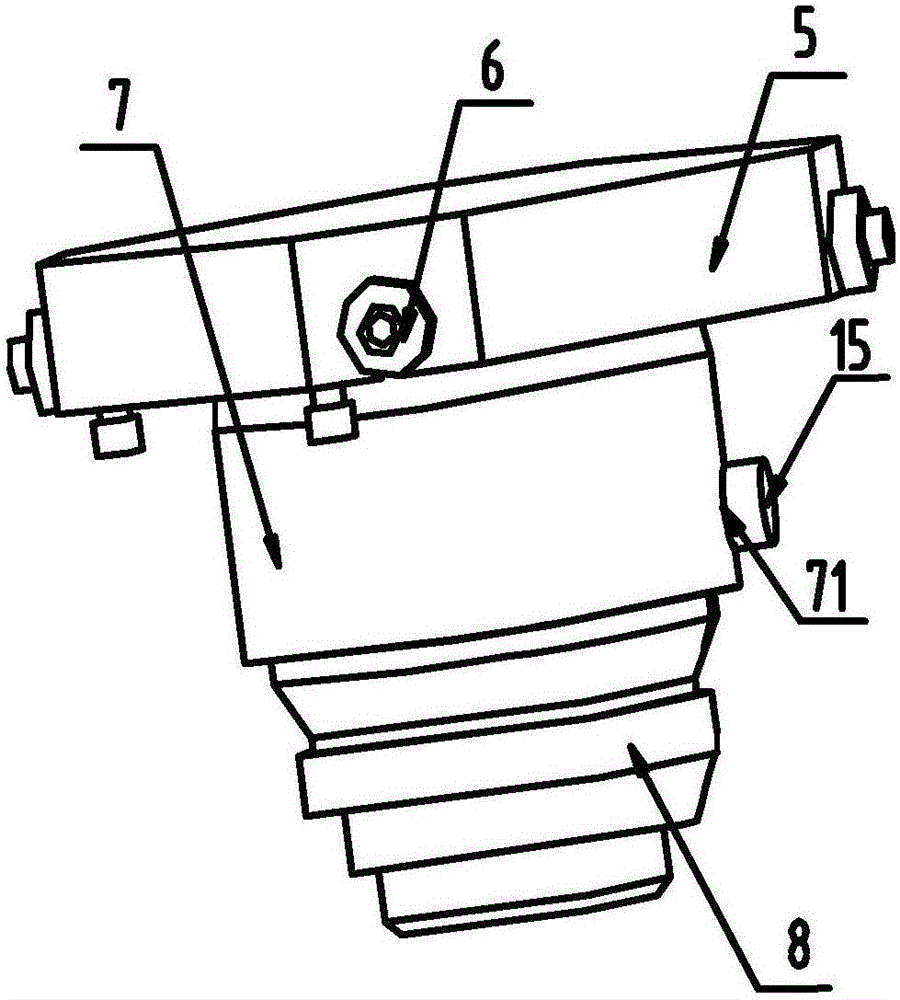

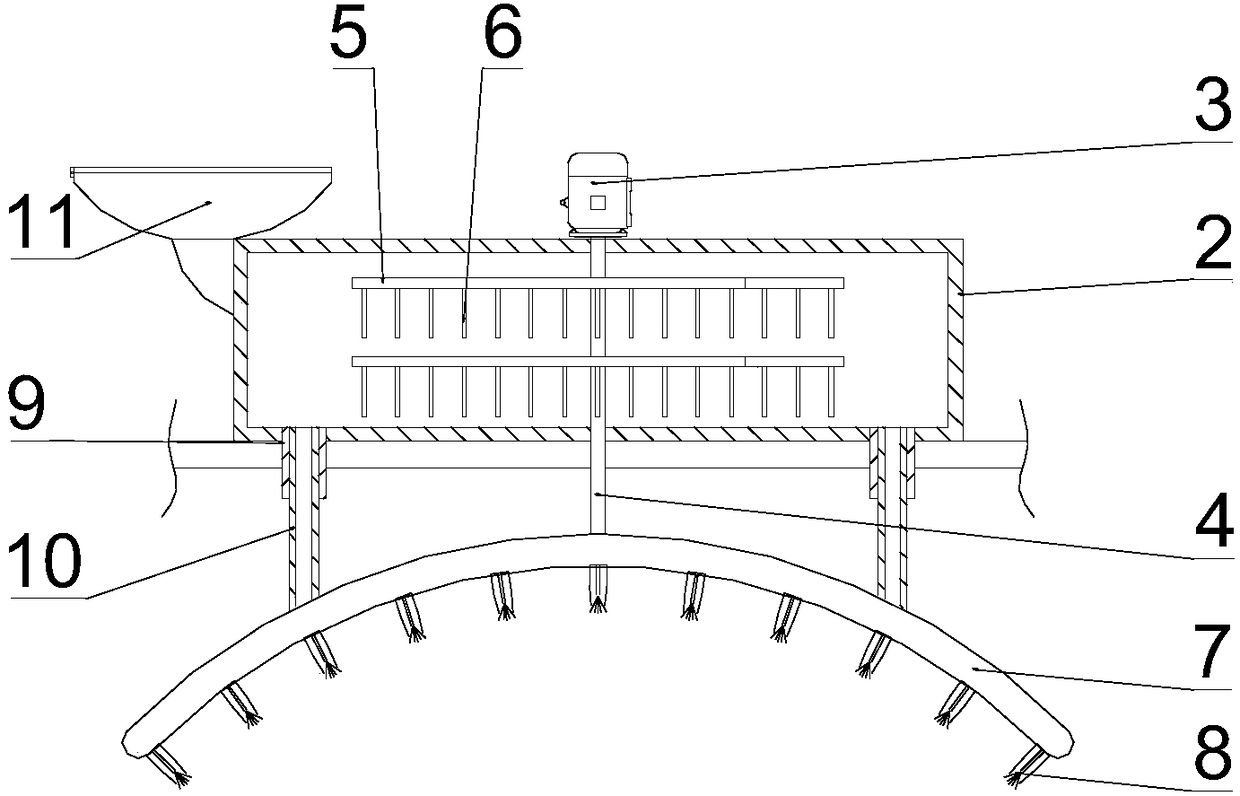

Blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp

ActiveCN108672961AImprove cladding qualityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMachine controlEngineering

The invention discloses a blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp, and relates to the field of laser remanufacturing tool clamps. The blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp comprises a base, mechanical clamping mechanisms, a position changing machine, a three jaw chuck and apressing device. An air storage groove is transversely formed in the base. A through hole array is distributed in the part between the air storage groove and the upper surface of the base. The uppersurface of the base is provided with a penetration type T-shaped guiding groove in the transverse direction. A sliding block is arranged in the guiding groove and connected with the pressing device. The base is provided with the two-freedom-degree position changing machine. A position changing machine control box matched with the position changing machine is arranged in front of the base. The position changing machine is provided with the three jaw chuck. The mechanical clamping mechanisms are arranged at the left end and the right end of the base. The blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp achieves high-precision forming shape and deformation control, and meanwhile the defect eliminating effect is good.

Owner:JIANGSU UNIV OF TECH

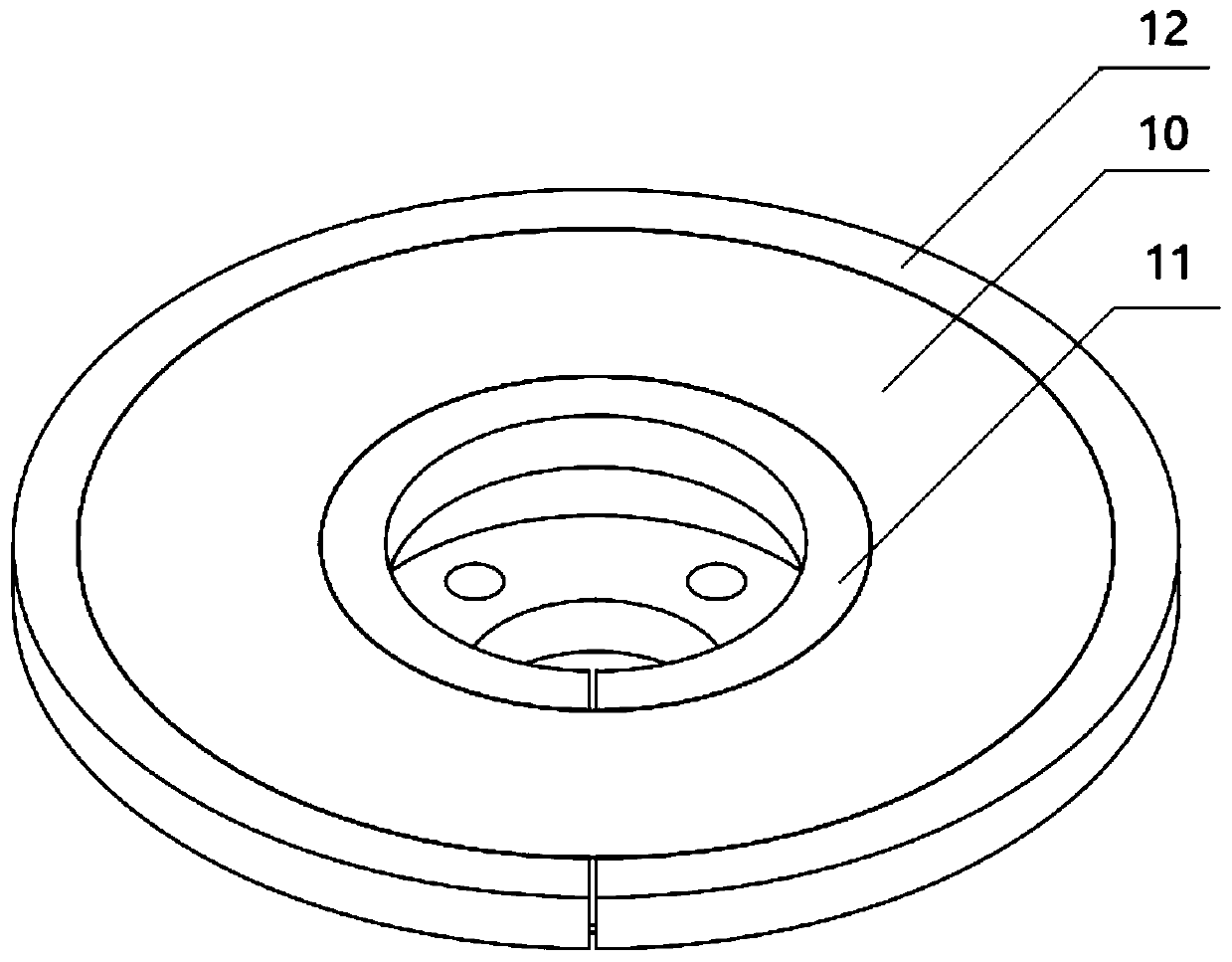

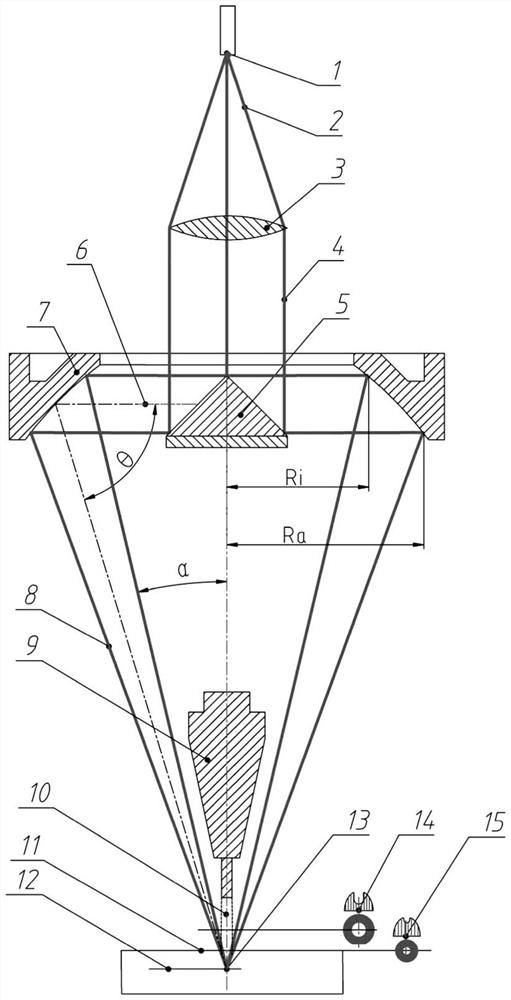

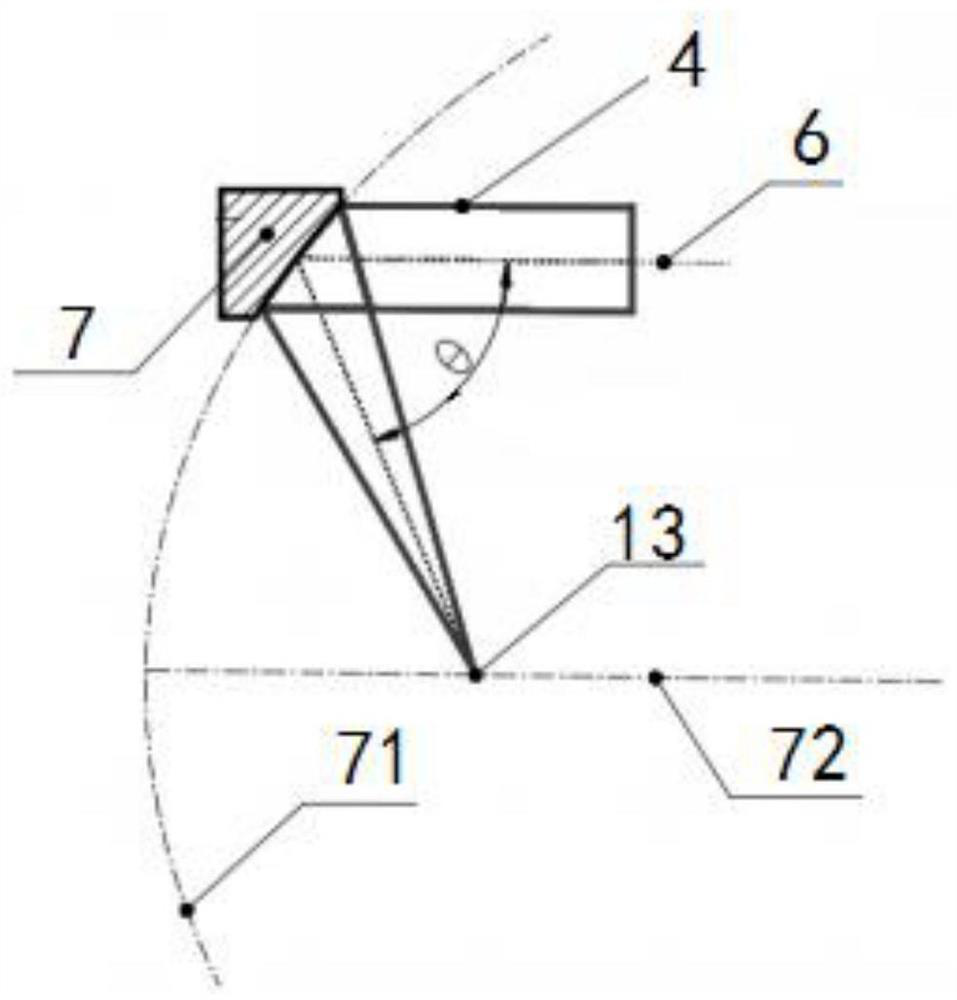

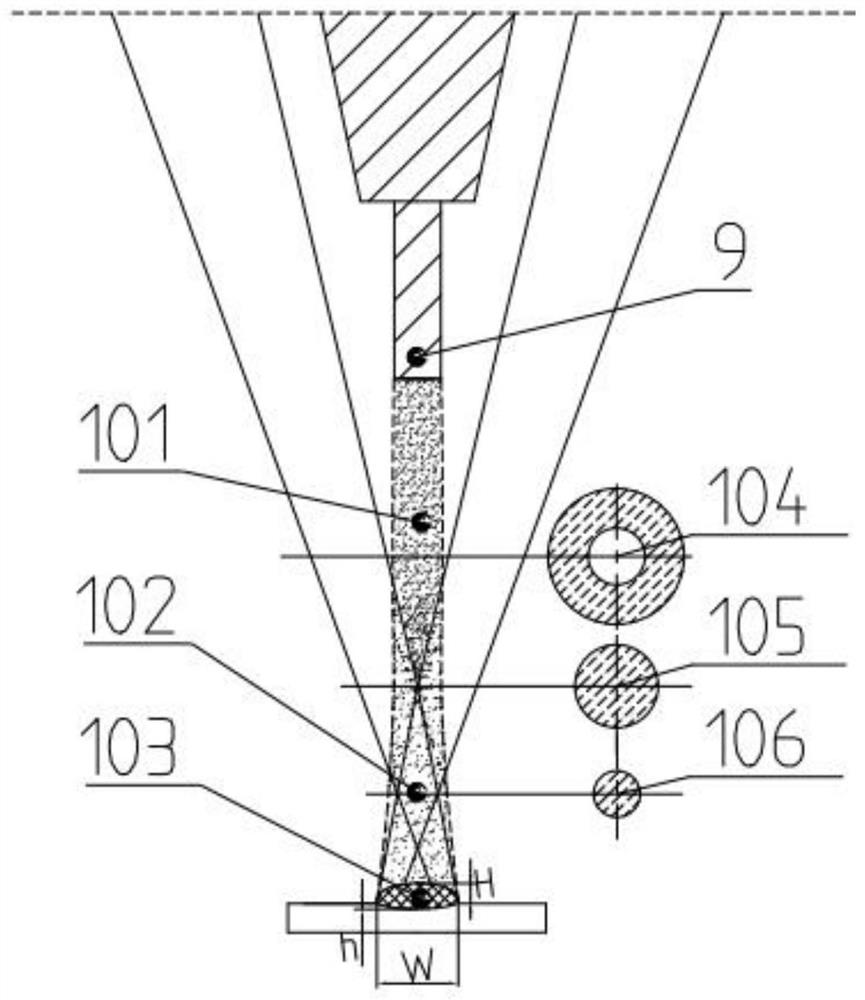

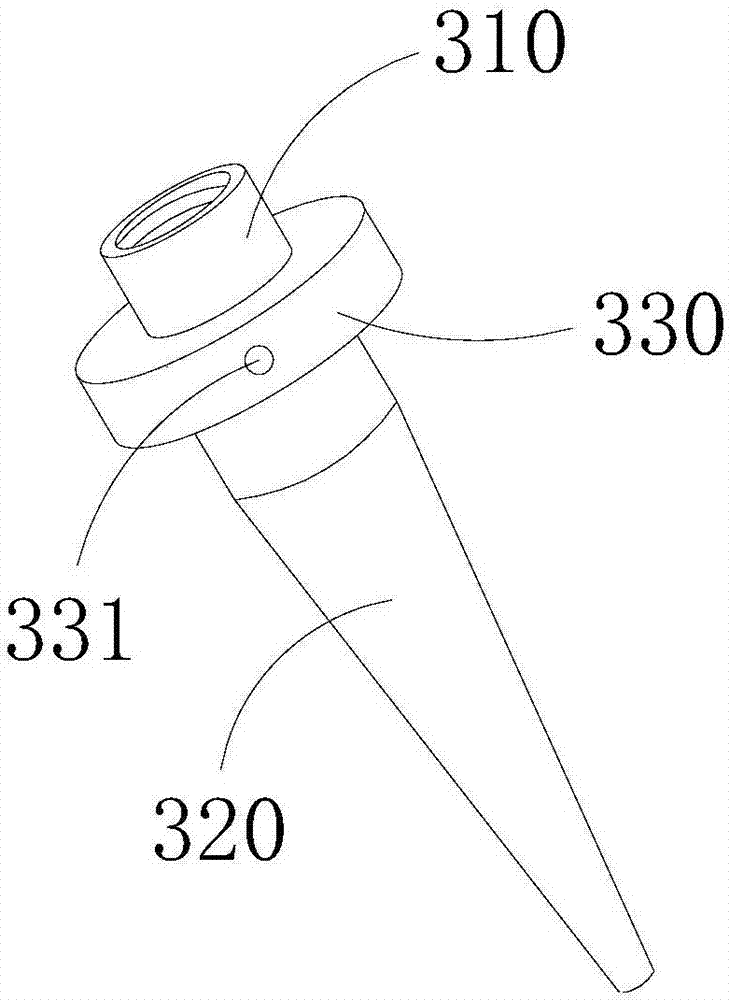

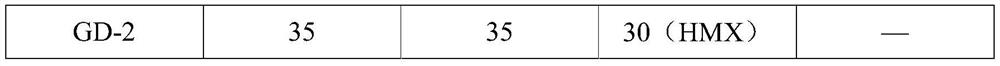

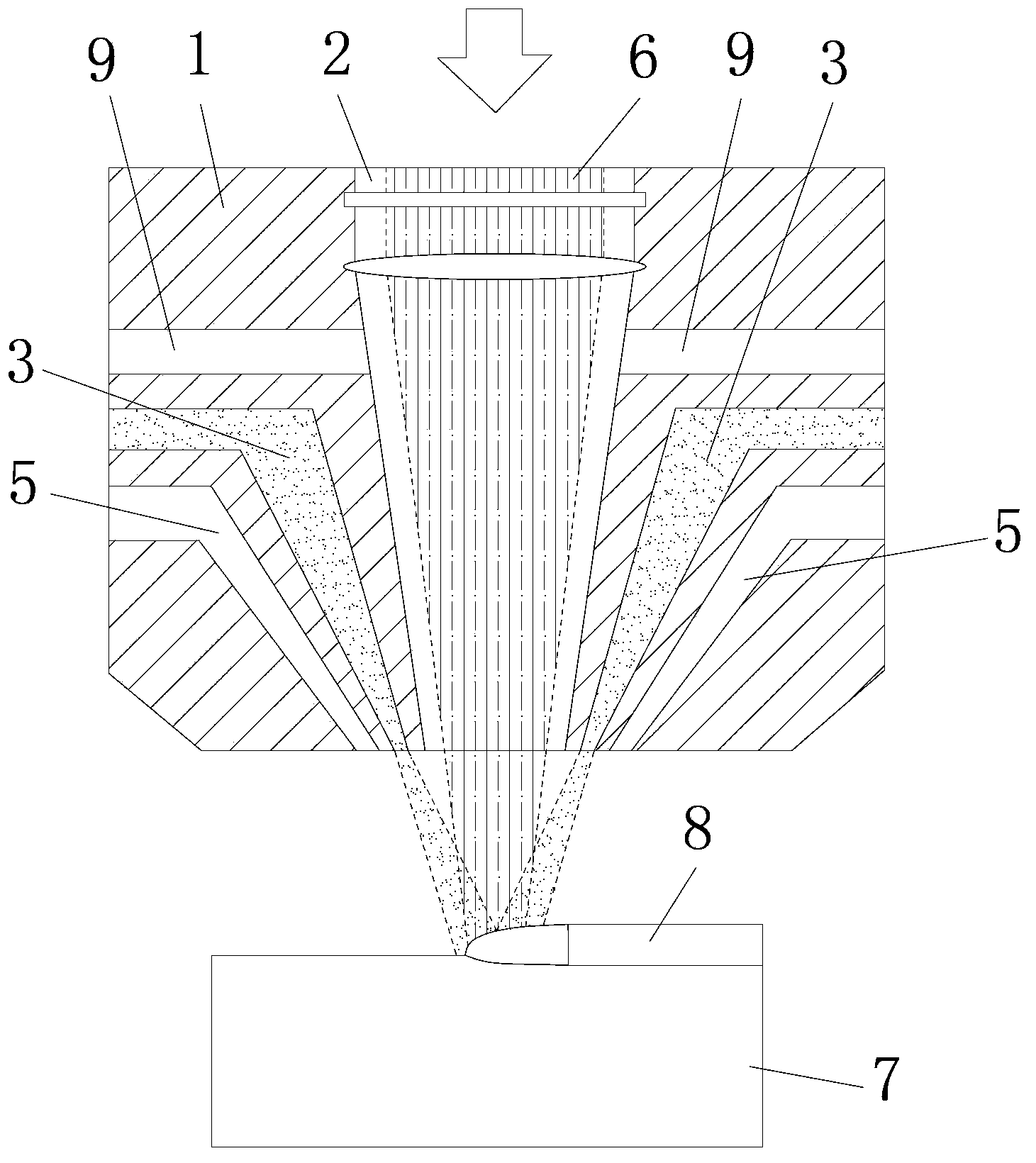

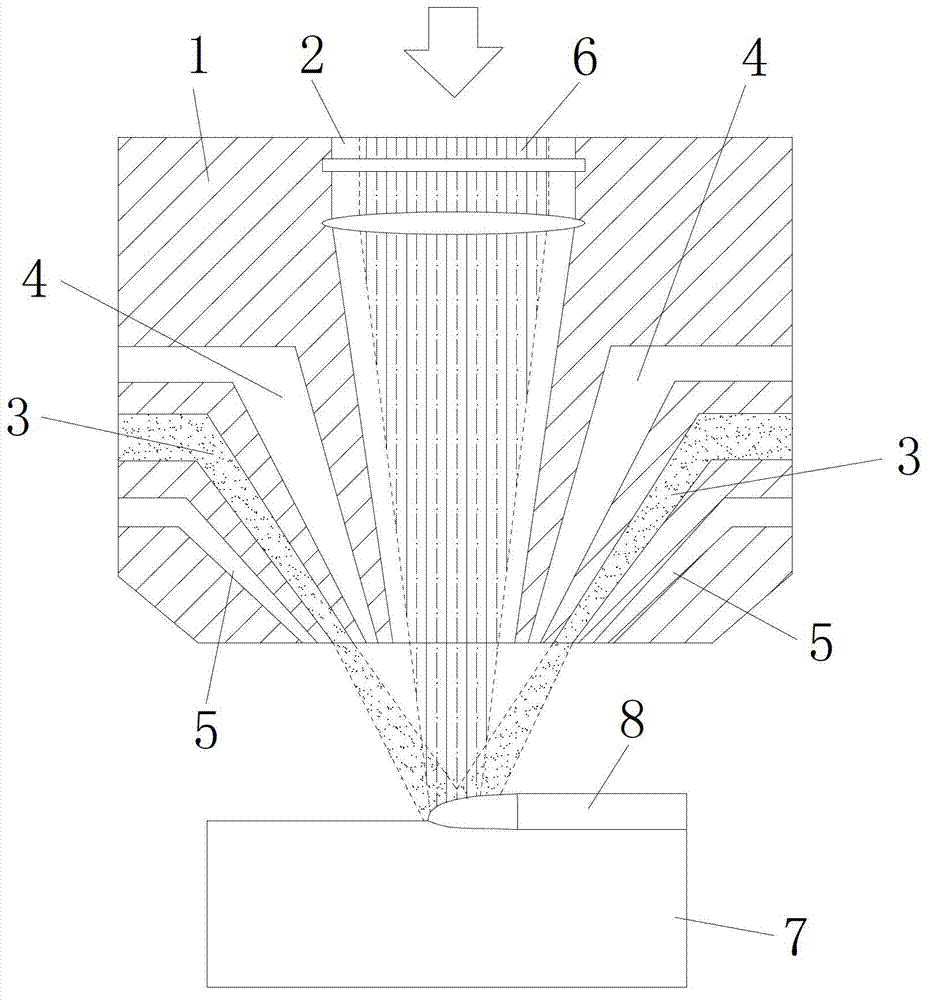

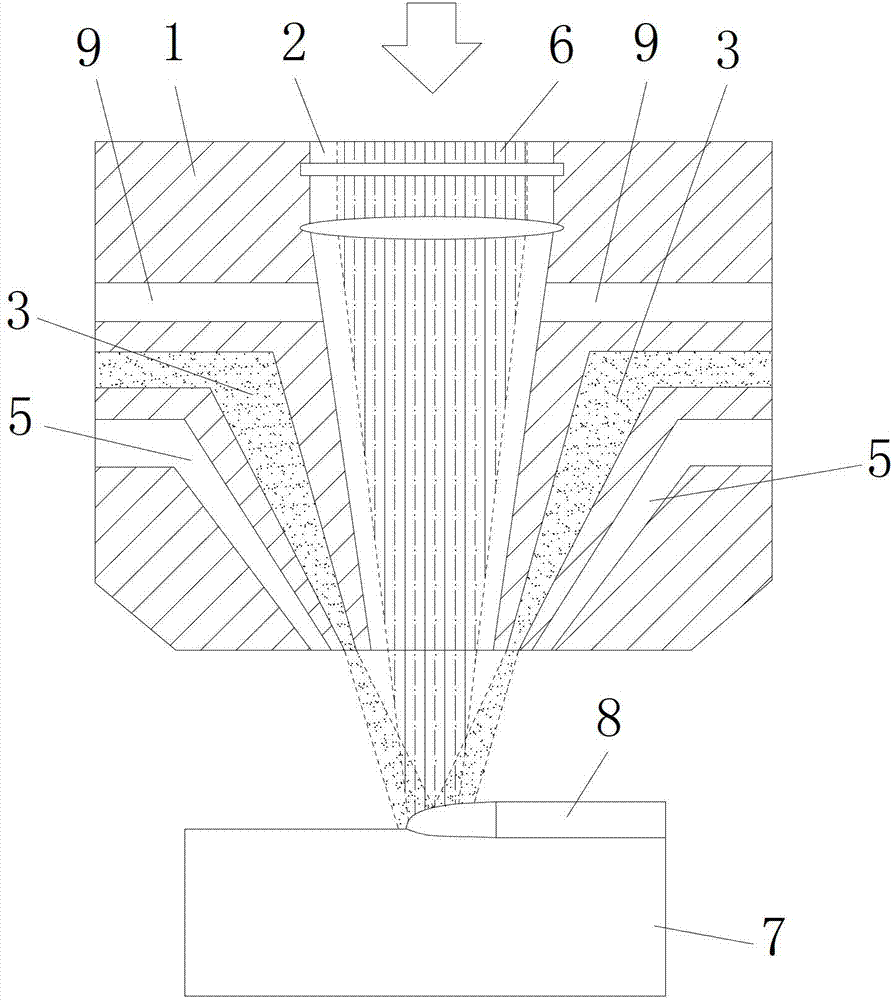

Annular hollow offset-focus laser cladding device

PendingCN113102783AReduce areaUniform energy densityAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingLight spot

The invention discloses an annular hollow offset-focus laser cladding device, and relates to the technical field of laser processing. The annular hollow offset-focus laser cladding device comprises a shell, a conical reflector, an annular off-axis parabolic focus lens, a nozzle and a powder spraying pipe, the top of the shell is provided with a light inlet, the conical reflector is arranged in the shell, and the conical reflector is arranged facing the light inlet; the annular off-axis parabolic focus lens and the conical reflector are oppositely and coaxially arranged; and the nozzle is installed below the conical reflector, the lower end of the nozzle is connected with the powder spraying pipe, the powder spraying pipe is coaxial with annular hollow offset-focus light formed after reflection of the annular off-axis parabolic focus lens, and a collimation protection gas sleeve is arranged on the periphery of the powder spraying pipe. The annular off-axis parabolic focus lens is used for horizontally shifting the focusing focus of the maternal parabola. According to the annular hollow offset-focus laser cladding device, the homogenization of the energy density of an annular light spot is realized, the coupling effect of a laser beam and powder is improved, the utilization rate of the metal powder is improved, and the cladding quality and appearance are improved.

Owner:SUZHOU UNIV

Temperature prediction based control method for precise forming of laser cladding thin-walled workpiece

ActiveCN108907192AStable thicknessSteady increase in heightAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser

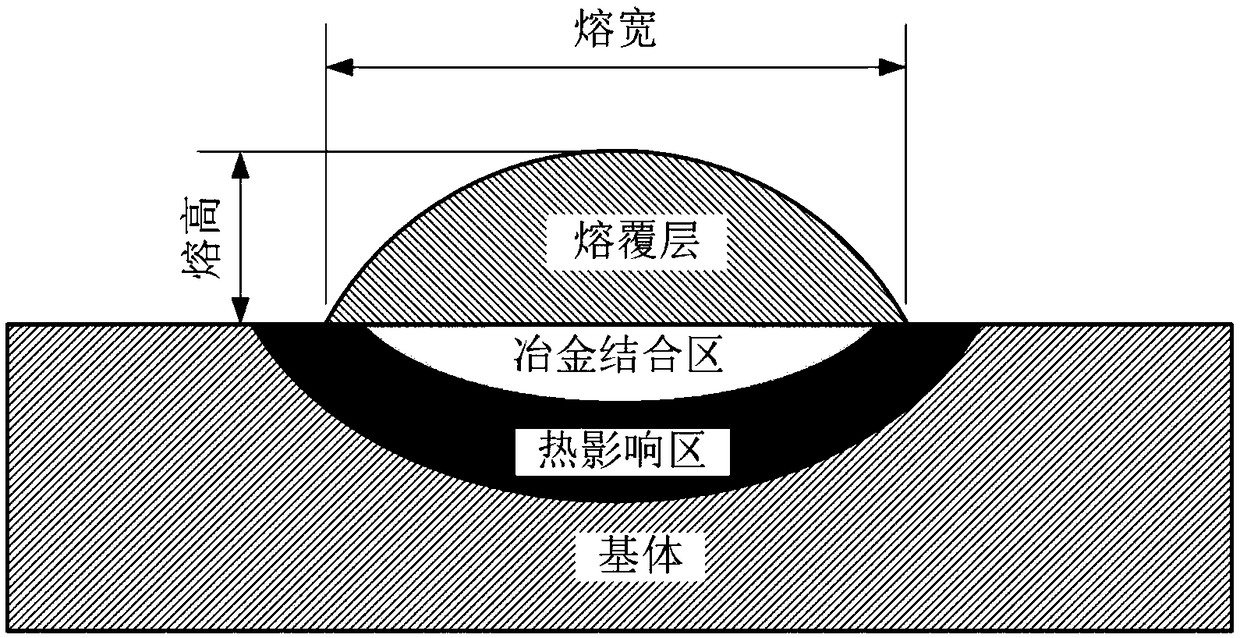

The invention discloses a temperature prediction based control method for precise forming of a laser cladding thin-walled workpiece, and relates to the field of laser cladding forming. The method comprises the three steps that firstly, a regression model of the influences of the powder feed speed, the scanning speed, the laser power and the substrate temperature on the weld width, weld height andaspect ratio parameters of single-channel cladding layers is set up through a response surface method; secondly, a theoretical prediction model of the relation between the cladding temperature and thenumber of the cladding layers during multi-layer cladding is set up; and thirdly, through combination of the regression model, the target weld width and weld height are adopted as compensation targets, the actual forming size is subjected to compensation, and a proper power adjusting curve is determined. According to the method, in the cladding process, the thickness of the thin-walled workpieceis stable, the height is increased stably, the condition of preset programming is met, and finally the thin-walled workpiece high in cladding quality is obtained.

Owner:NORTHEASTERN UNIV LIAONING

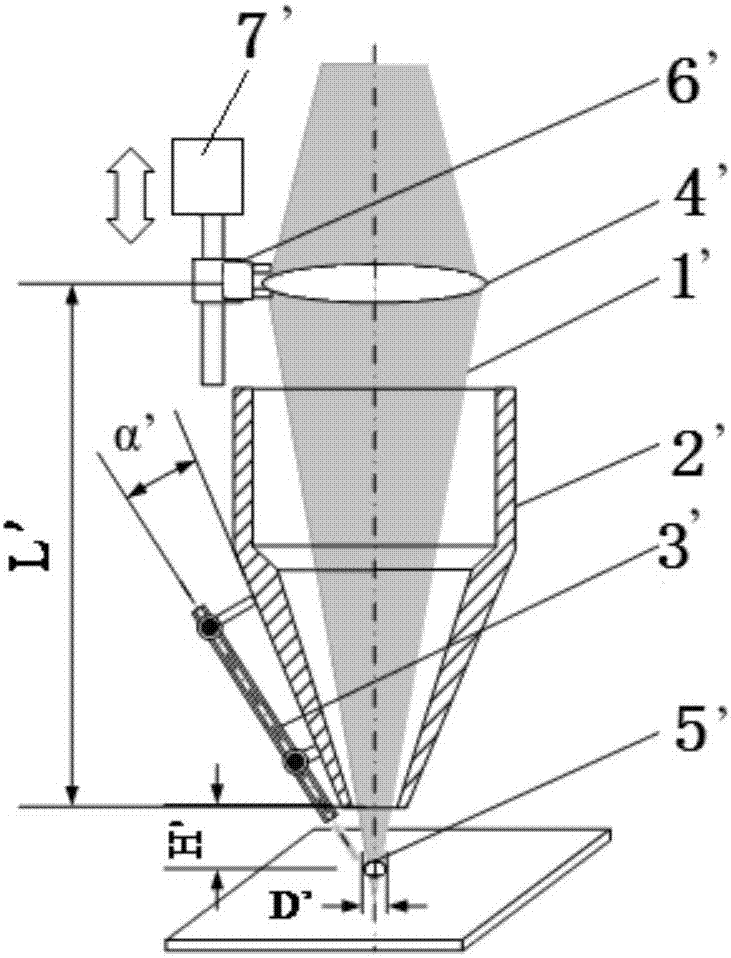

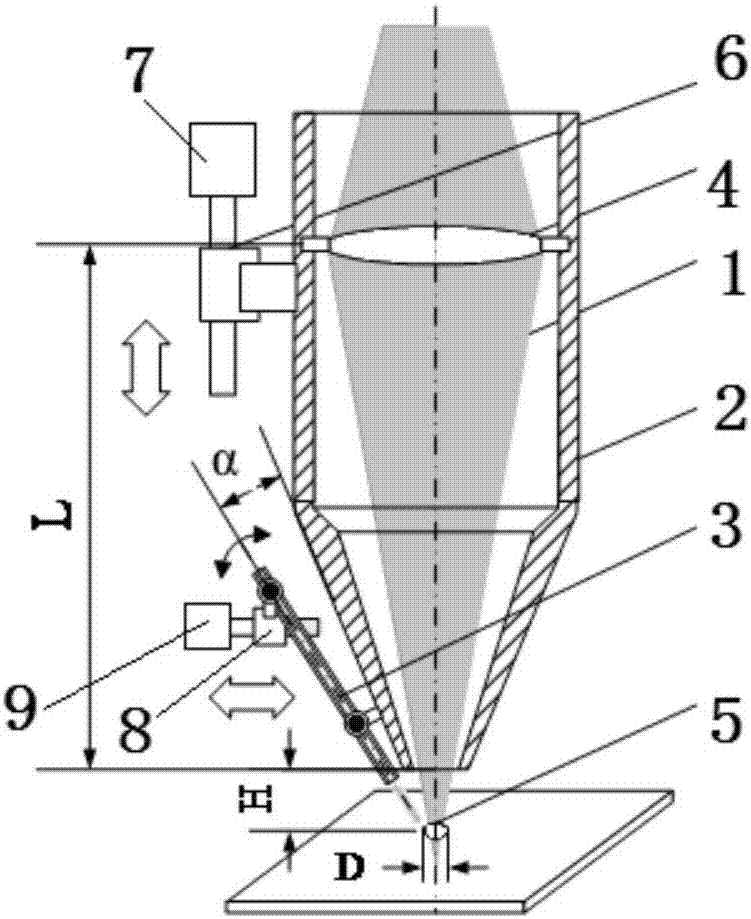

Laser cladding device with adjustable cladding track and method for adjusting width of cladding track

ActiveCN106862769AHeight and cross-sectional shape stabilityImprove cladding qualityLaser beam welding apparatusLaser power densityInstability

The invention discloses a laser cladding device with an adjustable cladding track and a method for adjusting the width of the cladding track. The laser cladding device comprises a laser cladding head component, a laser, a powder feeder and a central controller, wherein the cladding head is mounted on a vertical adjusting device which can drive the cladding head to move up and down in the vertical direction; a lens is arranged in the cladding head; a powder feeding pipe is mounted on the cladding head through an angle adjusting device which can adjust the included angle between the powder feeding pipe and the cladding head; and a signal transformer, a powder feeding controller and a counter are arranged in the central controller. According to the laser cladding device, the width of the cladding track can be adjusted, the powder conveying quantity and powder feeding angle can be adjusted according to the change of the cladding width while the light spot size changes, fluctuation of height and instability of the section shape of the cladding track are avoided, the laser power density remains unchanged, the thickness of a cladding layer remains unchanged, and the cladding effect is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

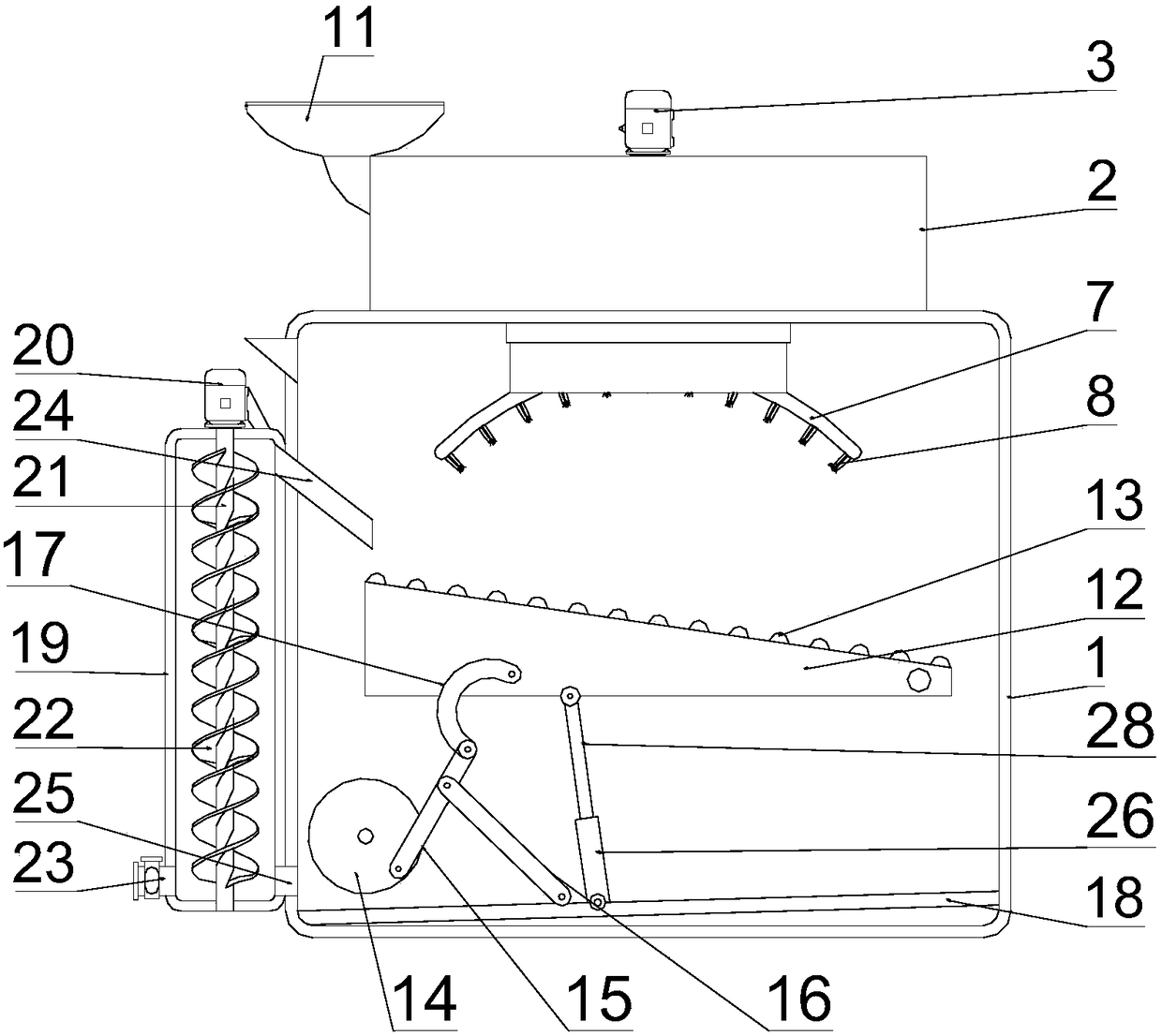

Crank rocker type yoghourt additive spraying device of feed used for breeding of meat poultry

InactiveCN108125268AImprove homogeneityGood quality and effectFeeding-stuffLiquid spraying apparatusMetal stripsEngineering

The invention discloses a crank rocker type yoghourt additive spraying device of a feed used for breeding of meat poultry. The crank rocker type yoghourt additive spraying device comprises a housing,an additive mixing tank which is fixedly connected with the upper part of the housing, a circulating discharging device mounted on the left side of the housing and a discharging platform arranged in the housing, wherein a rotating shaft is arranged in the additive mixing tank. According to the crank rocker type yoghourt additive spraying device disclosed by the invention, under the effect of centrifugal force, metal strips spirally extend outwards, and are cooperated with the effect of mixing plates, the homogenizing effect of the yoghourt additives is obvious; under the transmission effect that rotation of a rotating disk is transmitted by a first connecting rod, a second connecting rod and an arc-shaped rod, the discharging platform swings from left to right in a back-and-forth manner; an extruded feed rolls on the discharging platform, so that the coating effect of the extruded feed and atomized yoghourt is increased, and the coating is uniform; the quality of the feed is obvious ineffect; and under the effect of the circulating discharging device, the extruded feed falls down from a discharging pipe in a circulating manner, and the coating quality is improved.

Owner:储成立

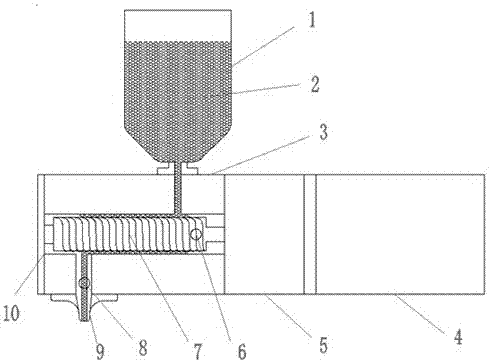

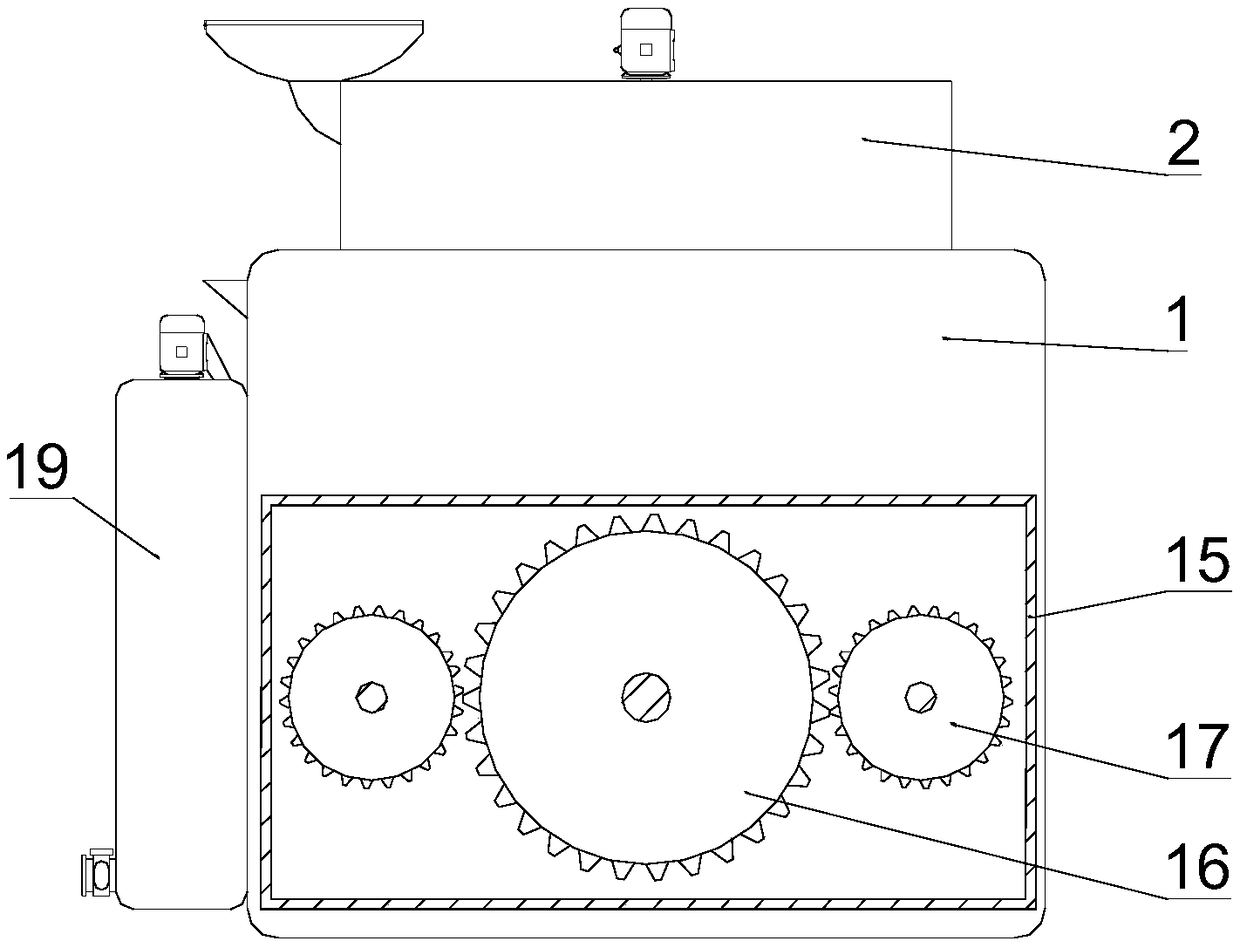

Screw multifunctional powder feeder

InactiveCN107881499AMake sure to flushPlay a role in helping to sprayMetallic material coating processesEngineeringAtmospheric pressure

The invention discloses a screw multifunctional powder feeder for solving the problems in the prior art. The screw multifunctional powder feeder comprises an outer shell and a storage bin hopper arranged on the outer shell. A conveying channel is formed in the outer shell. A screw is arranged in the conveying channel. A power device is connected with one end of the screw. The conveying channel further communicates with a powder outlet. A cleaning powder pressure inlet communicating with the conveying channel is formed in the outer shell. A synchronous powder feeding pressure inlet communicating with the powder outlet is further formed in the outer shell. The cleaning powder pressure inlet and the synchronous powder feeding pressure inlet communicate with an inert gas storage device throughgas pipes. Valves are arranged on the gas pipes correspondingly.

Owner:成都大陆激光技术有限公司

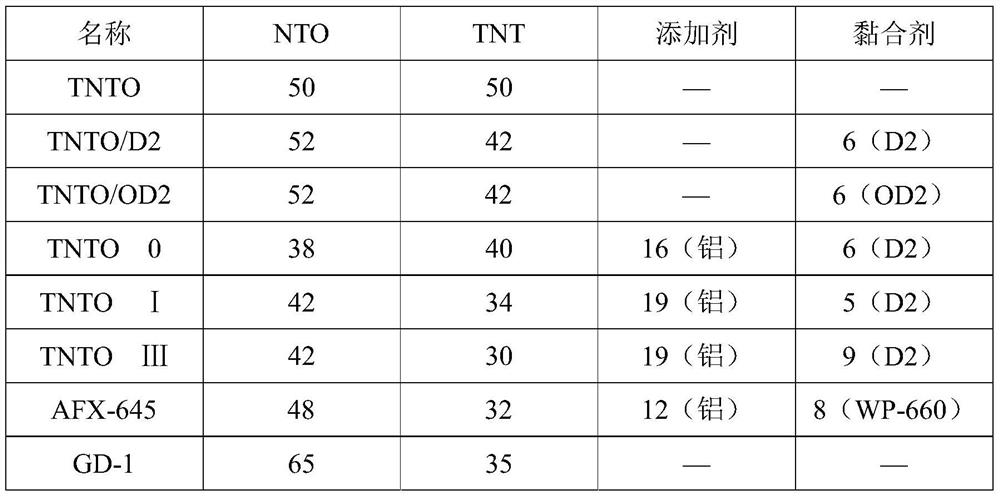

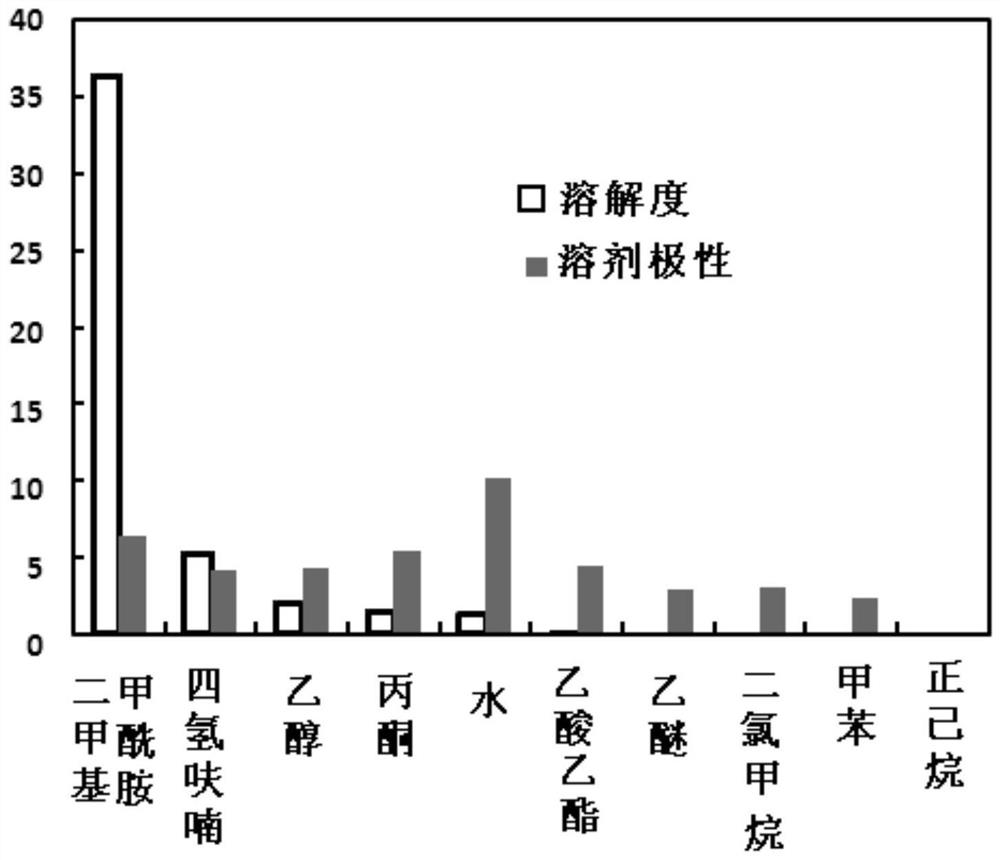

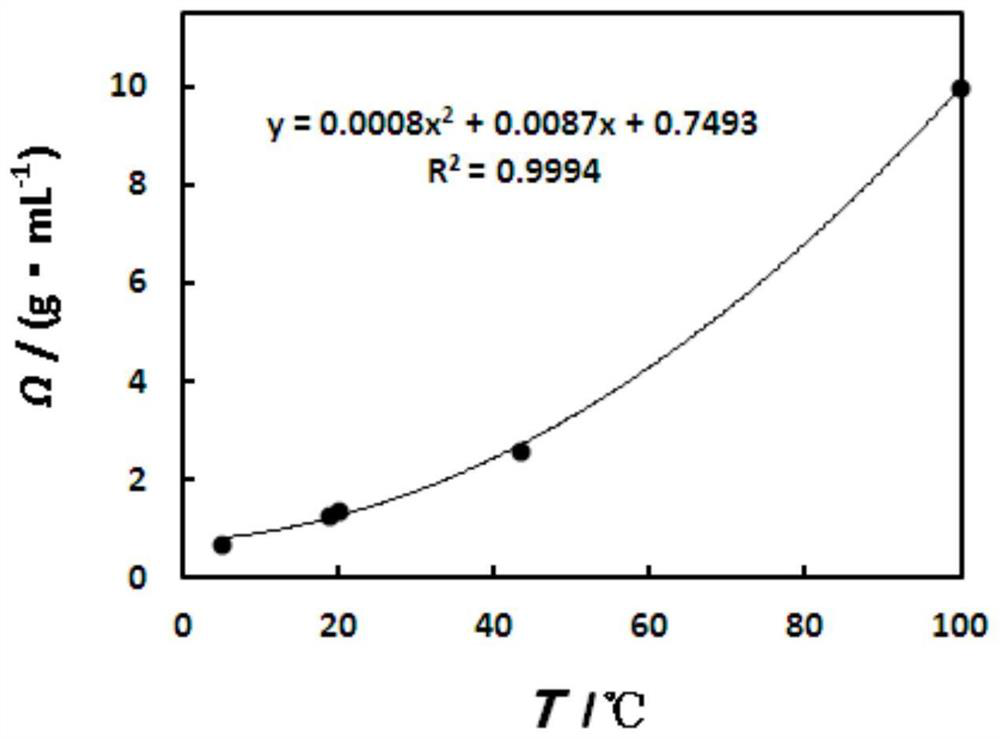

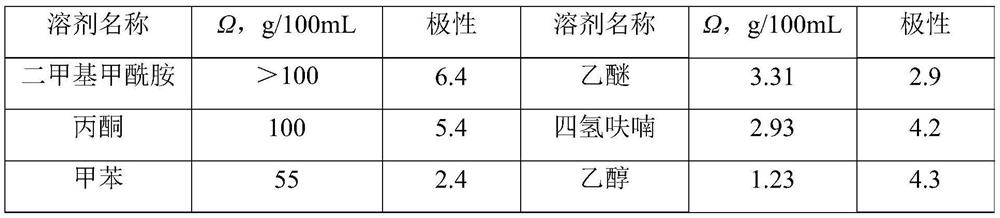

Manufacturing method of NTO-based PBX explosive molding powder

ActiveCN111875455ASolve the problem of incomplete wrappingImprove securityProductsReagentsExplosive AgentsSodium hydrogencarbonate

The invention discloses a manufacturing method of NTO-based PBX explosive molding powder. The method includes following steps: dissolving the NTO crude product in hot water, dropwise adding a sodium bicarbonate aqueous solution to neutralize residual acid, rapidly cooling and stirring the mixture at a high speed to separate out NTO solid, and filtering and drying the mixture to obtain an NTO recrystallized product; adding the NTO recrystallized products reaching the particle size requirement into the adhesive solution to form suspension liquid, and carrying out supercritical coating process toprepare the explosive molding crude powder; And carrying out programmed heat preservation at the temperature of 70 DEG C to 120 DEG C to 70 DEG C to obtain the NTO-based PBX explosive molding powder.The purity of the NTO recrystallized product is 99.4%, the residual acid content is 0.03%, and the water content is 0.05%. The manufactured PBX explosive molding powder is completely coated, so thatthe safety of a subsequent press-fitting process and the tensile strength and compressive strength of a press-fitting grain can be ensured.

Owner:XIAN MODERN CHEM RES INST

Integrated wide-light-spot deep-hole laser cladding head

ActiveCN111926324AExtended service lifeAvoid contamination damageIncreasing energy efficiencyMetallic material coating processesAir knifeMaterials science

The invention discloses an integrated wide-light-spot deep-hole laser cladding head. The integrated wide-light-spot deep-hole laser cladding head comprises a connection rod, a fixed seat, a powder feeding unit, a cleaning unit, an integral mirror unit, a protective mirror unit, a flow-guide air knife unit, an illumination unit and a camera shooting unit, wherein the connection rod is connected tothe rear end of the fixed seat; the integral mirror unit is installed at the front end of the fixed seat; the powder feeding unit is installed at one side of the fixed seat; the cleaning unit is installed at the other side of the fixed seat; the flow-guide air knife unit is installed at the lower side of the fixed seat and located between the powder feeding unit and the cleaning unit; the protective mirror unit is installed between the fixed seat and the flow-guide air knife unit; the illumination unit is installed on the fixed seat; the camera shooting unit is installed on the connection rod;and the illumination unit is located between the camera shooting unit and the powder feeding unit. According to the integrated wide-light-spot deep-hole laser cladding head, through innovative arrangement for an upper air knife structure and a lower air knife structure, the laser cladding head is effectively protected, and the cladding efficiency is increased; and through innovative arrangement for a camera shooting function, a molten pool, a powder spreading state, and the quality of a cladding surface can be observed in real time, so that an operator can find cladding quality problems in real time.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Preparation method of graphene primary coated copper wire

InactiveCN111276295AQuality improvementLower nucleation energyApparatus for manufacturing conducting/semi-conducting layersReduction treatmentCopper wire

The invention discloses a preparation method of a graphene primary coated copper wire. The preparation method is characterized by comprising the following steps: coating the surface of a copper wire with graphene induction layer slurry in a soaking area, then carrying out drying and reduction treatment in a reduction area, and finally introducing a carbon source into a growth area to carry out plasma-induced in-situ coating on a graphene induction layer on the surface of the copper wire to grow graphene, so as to obtain the graphene primary coated copper wire. The liquid carbon source is usedas the precursor carbon source, and the plasma in-situ induction process is added, so that the surface of the copper wire can be primarily coated with the graphene layer with better quality quickly atlower temperature, and the performance of the copper wire is improved.

Owner:上海超碳石墨烯产业技术有限公司

Sealing process of turbine rotor blade cover plate top hole of gas turbine

InactiveCN109261965AImprove conductivityImprove thermal conductivityIncreasing energy efficiencyEngineeringAlloy

The invention discloses a sealing process of a turbine rotor blade cover plate top hole of a gas turbine. The process comprises the steps that (1), top hole pre-processing is conducted; (2), a red copper bar cooperates with the top hole is prepared to be used as a lining; (3), the red copper bar is installed at the bottom of the top hole, sealing alloy powder is delivered into the top hole througha coaxial gas carrying powder delivering device to perform laser cladding process, and the path is single-passage and multi-layer; (4), the red copper bar is separated from the cover plate, and castmodification processing is conducted on the cover plate of which the top hole is sealed; (5), nondestructive examination is conducted on the cover plate on which cast modification is conducted. According to the sealing process, a traditional vacuum brazing process is abandoned, a laser cladding technology is adopted to seal the turbine rotor blade cover plate top hole of the gas turbine, metallurgical bonding is formed between the sealing alloy powder and the top hole inner wall, the bonding strength is high, the bonding does not easily fall in the using process, vacuum does not need to be ensured, the sealing cost is low, and the cladding quality is improved by multi-layer clading.

Owner:成都青石激光科技有限公司

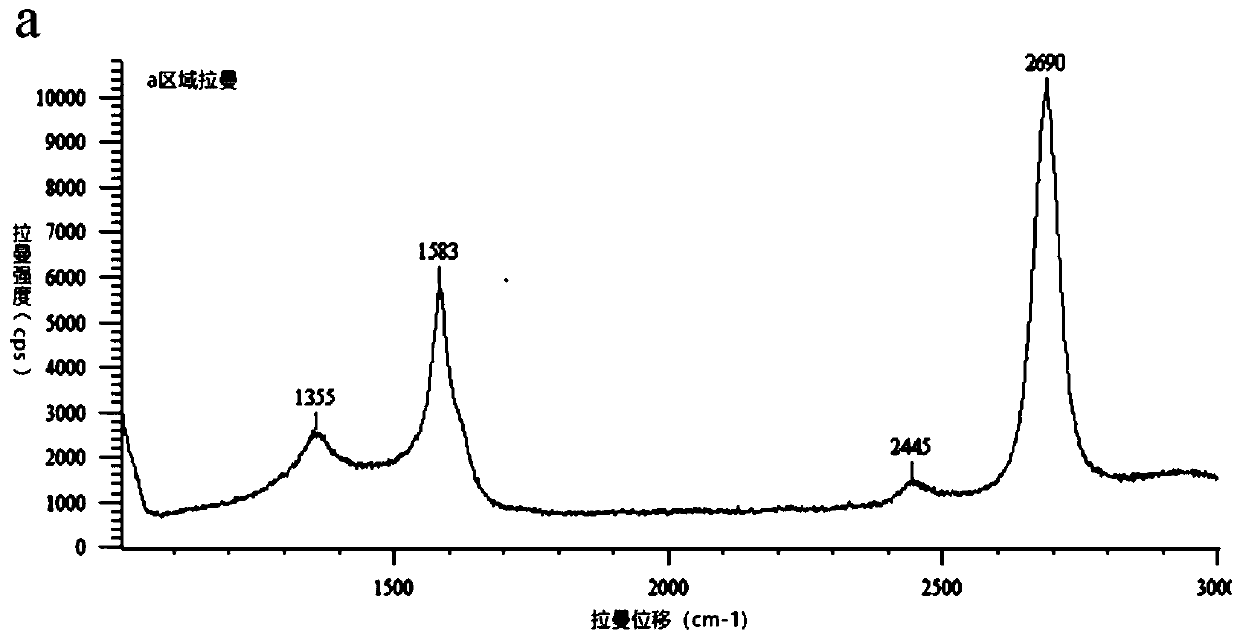

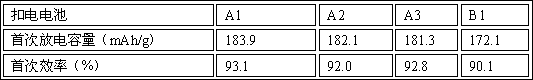

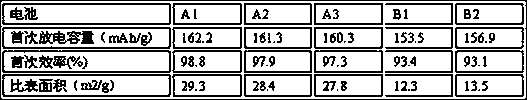

Method for modifying ternary composite material

InactiveCN108899509AImprove electronic conductivityControl Ph valueCell electrodesSecondary cellsWater bathsHigh rate

The invention belongs to the field of lithium ion battery materials, and particularly relates to a method for modifying a ternary composite material. The preparation method comprises the following steps: firstly uniformly stirring silver sulfate and thiourea which respectively serve as a silver source and a sulfur source, ammonium chloride serving as a buffering agent, ammonia water and hydrazineserving as a combined complexing agent, adding a ternary material precursor; performing a water bath reaction; and finally preparing the ternary composite material having an inner core of LiNixCoyMn(1-x-y)O2 and shell of silver sulfide. The ternary composite material has high rate performance and cycling performance.

Owner:JIANGSU LENENG BATTERY INC

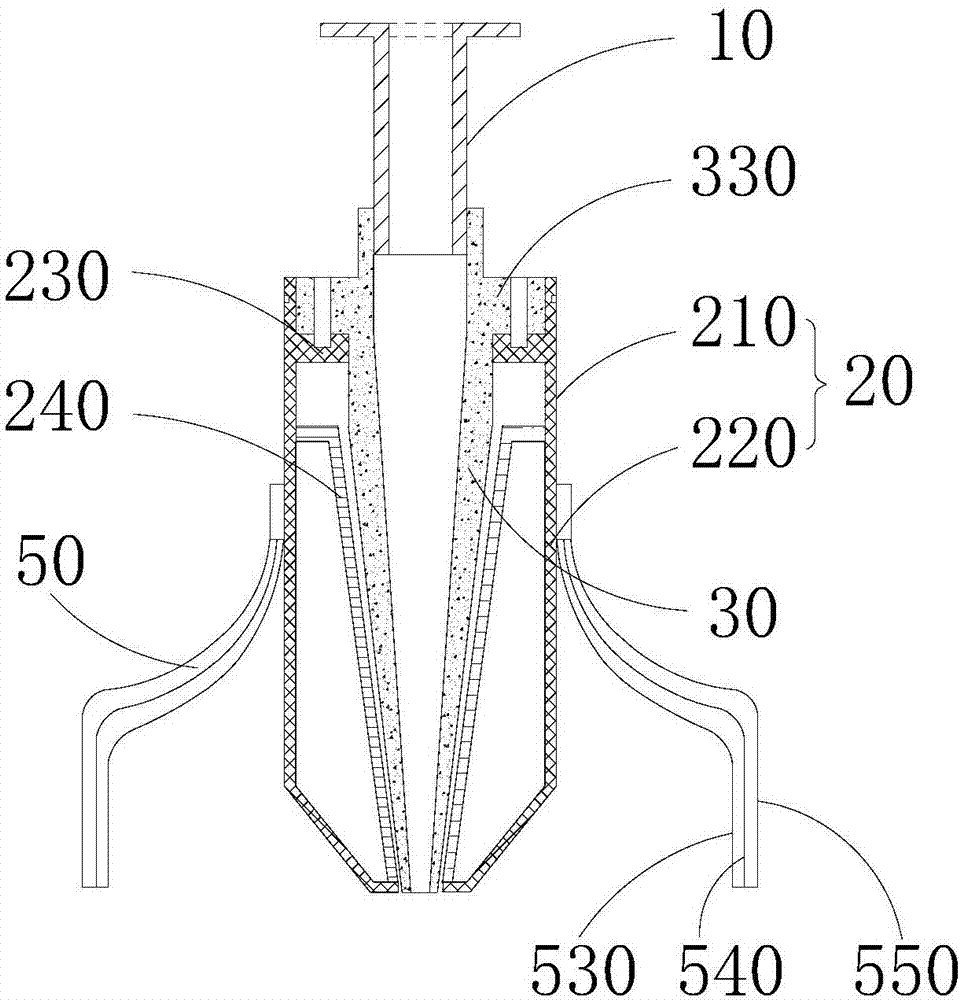

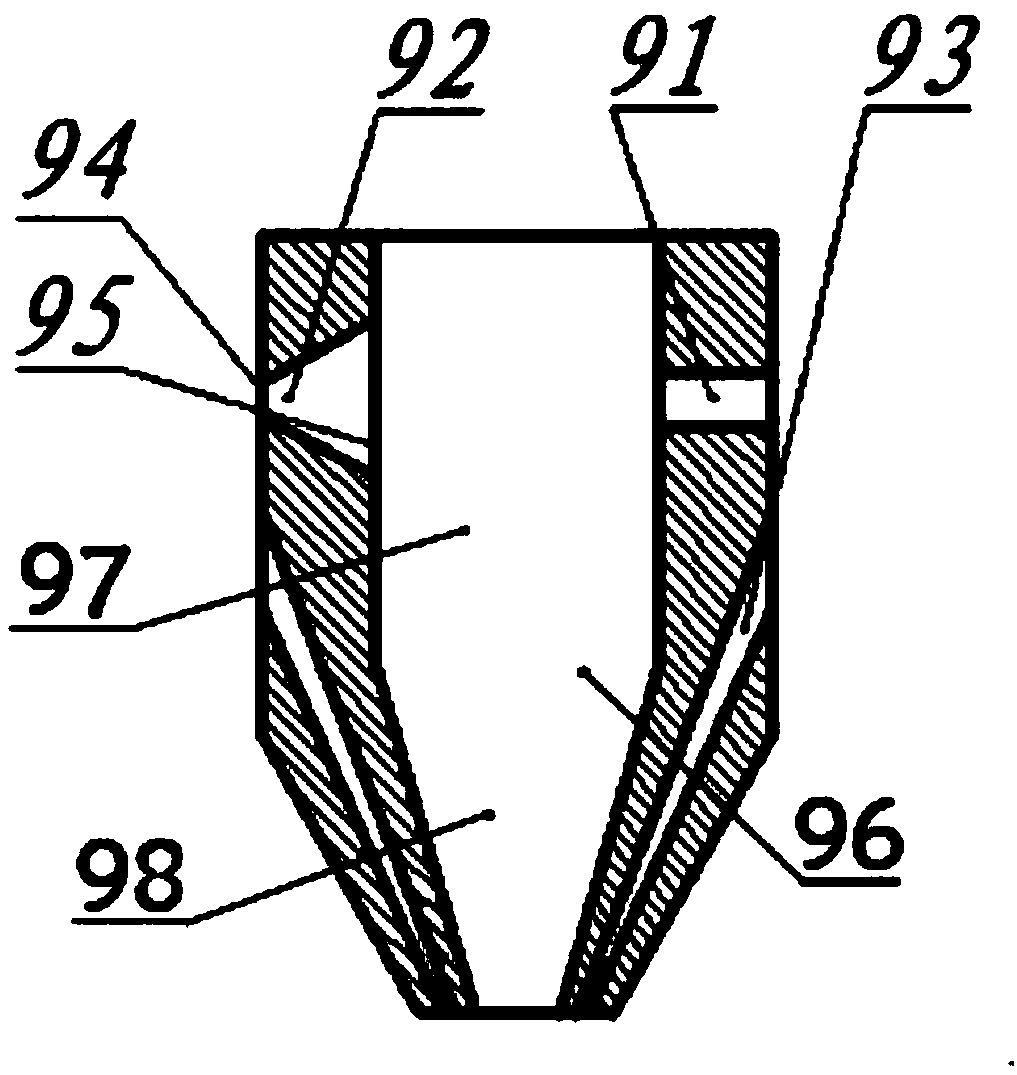

Laser cladding nozzle and laser cladding device and laser cladding method

PendingCN107130240AImprove cladding qualityFully protectedMetallic material coating processesMaterials scienceLaser

The invention provides a laser cladding nozzle and a laser cladding device and a laser cladding method, and relates to the technical field of laser cladding. The laser cladding nozzle comprises a nozzle outer sleeve, a nozzle wick and a protective cover, the nozzle wick is sleeved with the nozzle outer sleeve, the nozzle outer sleeve is sleeved with the protective cover, and a powder feeding channel is formed between the nozzle outer sleeve and the nozzle wick; the protective cover comprises an inner layer, a middle layer and an outer layer, the inner layer, the middle layer and the outer layer are sequential distributed from inside to outside, a first cavity body is formed between the inner layer and the middle layer, and a second cavity body is formed between the middle layer and the outer layer; and a first liquid inlet opening and a first liquid outlet opening communicating with the second cavity body are formed in the outer layer, a first air inlet opening communicating with the first cavity body is further formed in the outer layer, and a first air outlet opening communicating with the first cavity body is formed in the inner layer. The laser cladding nozzle and the laser cladding device and the laser cladding method have functions of inert gas shielding and self-cooling, can well meet requirements of a laser cladding technology, and promote the quality of laser cladding.

Owner:WENZHOU UNIVERSITY

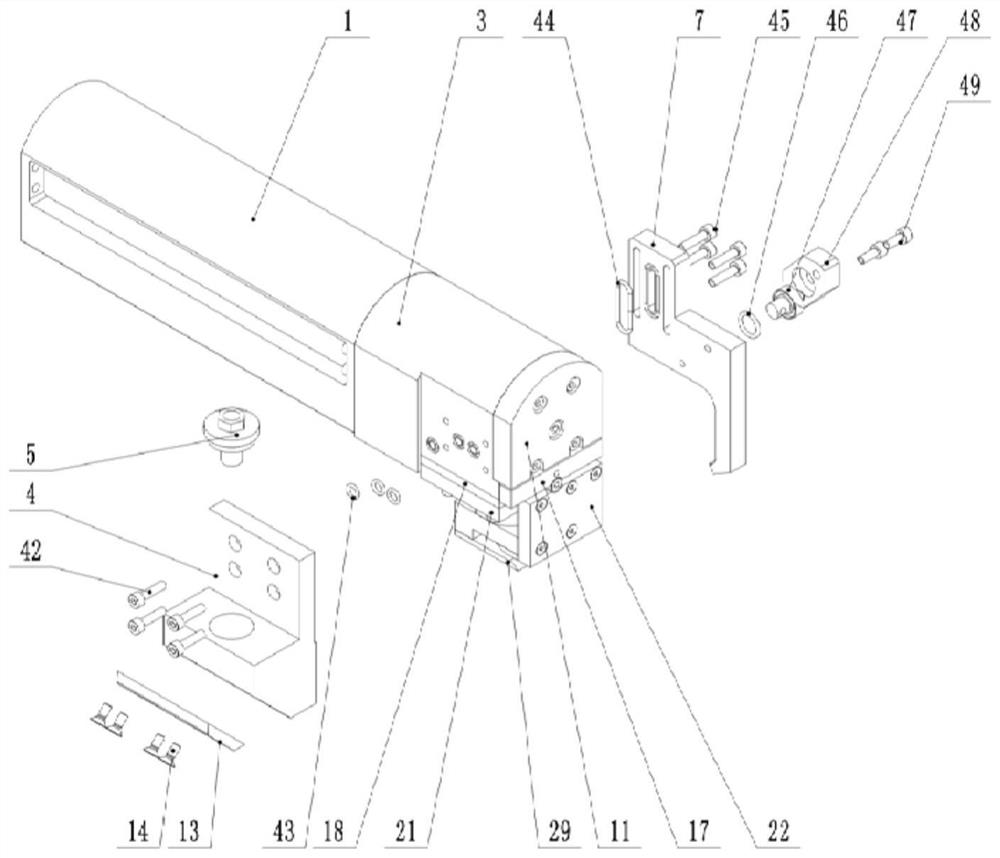

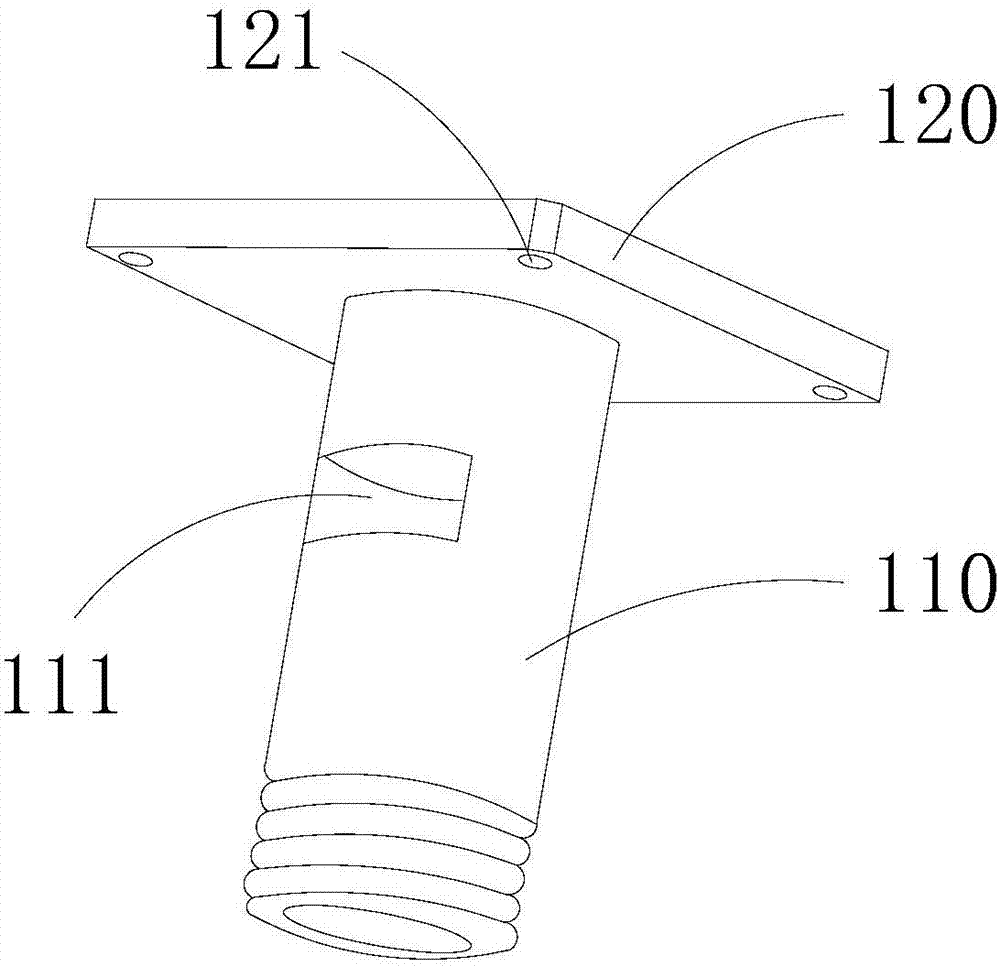

Powder feeding device and using method thereof

InactiveCN105803451AHigh flexibilityImprove cladding qualityMetallic material coating processesEngineeringNozzle

The invention relates to a powder feeding device and a using method thereof and belongs to the technical field of laser cladding. The powder feeding device comprises a fixing part and a powder feeding nozzle, wherein a regulation device is arranged between the fixing part and the powder feeding nozzle and is composed of a horizontal regulation part and a vertical regulation part; and the vertical regulation part is arranged in the horizontal regulation part. The powder feeding device is capable of regulating the distance between a powder outlet and the surface of a substrate, has the characteristics of high regulation accuracy, convenience and rapidness in operation, strong practicability and high economic benefit and is beneficial to improving the effective availability of cladding powder and the cladding quality.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

Lithium iron phosphate/lithium metaaluminate compound anode material and preparation method thereof

ActiveCN108899511AIncrease the difficulty of dryingImprove bindingMaterial nanotechnologyCell electrodesSupercritical dryingOrganotitanium compound

The invention belongs to the preparation field of an anode material for lithium ion batteries and specifically relates to a lithium iron phosphate / lithium metaaluminate compound anode material and a preparation method thereof. The compound material has a core-shell structure; an inner core is made from lithium iron phosphate; a shell is formed by coating with titanium oxide, porous lithium metaaluminate and carbon thereof. The preparation method thereof comprises the following steps: firstly, preparing a porous lithium metaaluminate gel according to a supercritical drying method; mixing the porous lithium metaaluminate gel with an organic titanium compound, thus obtaining an alkaline solution; coating the surface of a lithium metaaluminate precursor; spray-drying and carbonizing, thus obtaining the lithium iron phosphate / lithium metaaluminate compound material. According to the invention, the titanium oxide formed by carbonizing an organic titanium compound is doped into lithium iron phosphate so as to improve the specific capacity of the material and is doped into the porous lithium metaaluminate so as to improve the transmission rate of lithium ions in the charging and discharging process of the material, the liquid-absorbing liquid-holding capacity of the material and the cycling performance of the material.

Owner:JIANGSU LENENG BATTERY INC

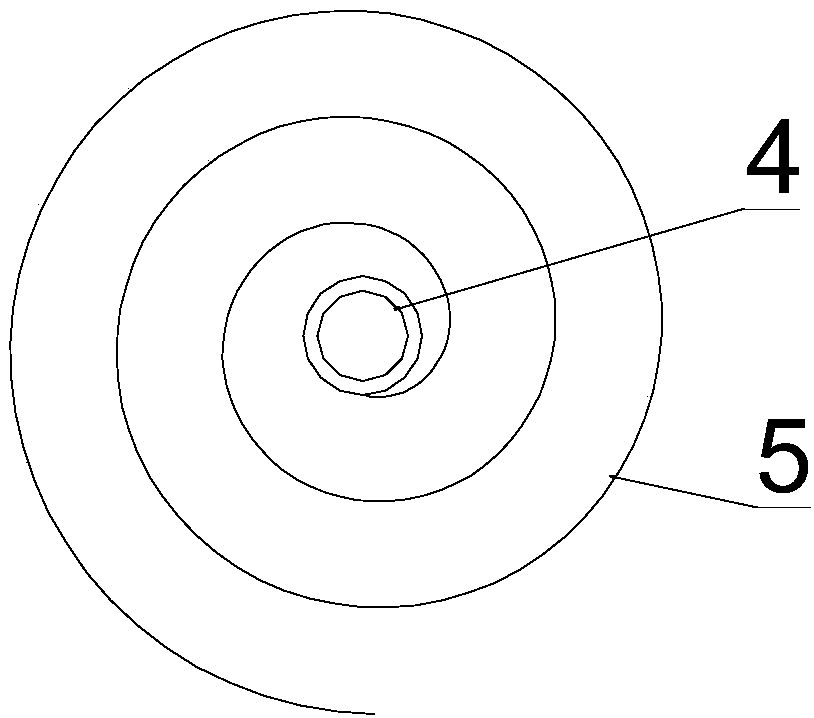

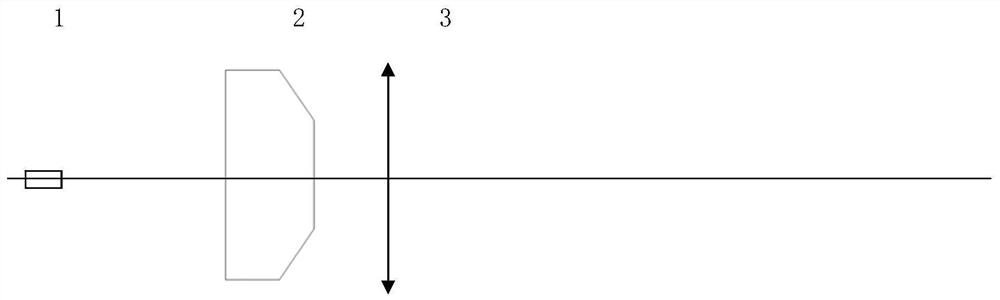

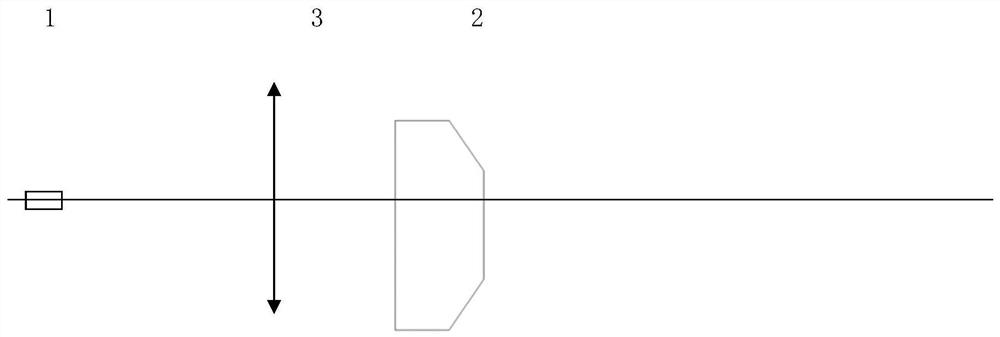

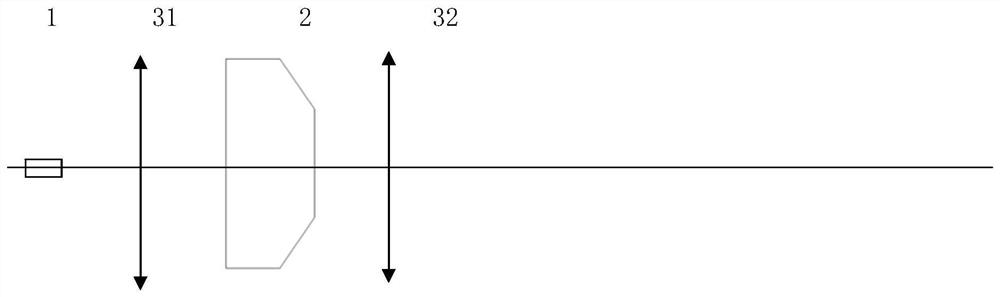

Optical system for forming point ring light spot

PendingCN113798662ASmall working surfaceReduce energy lossLaser beam welding apparatusOptical elementsOptical processingLight spot

The invention discloses an optical system for forming a point ring light spot. The optical system comprises an optical fiber, a frustum-shaped optical deflection element and an optical imaging system; the frustum-shaped optical deflection element and the optical imaging system are arranged on an optical fiber output light path, and the optical imaging system is arranged on the front side and / or the rear side of the frustum-shaped optical deflection element; and after light emitted by the optical fiber passes through a system composed of the frustum-shaped optical deflection element and the optical imaging system, a light spot of a point ring structure is formed on a certain surface. According to the optical system, various light spot structure requirements can be met, meanwhile, elements forming the system can be manufactured through a traditional optical processing technology, the manufacturing difficulty of the system is reduced, and then the manufacturing cost of the system can be greatly reduced.

Owner:方笑尘

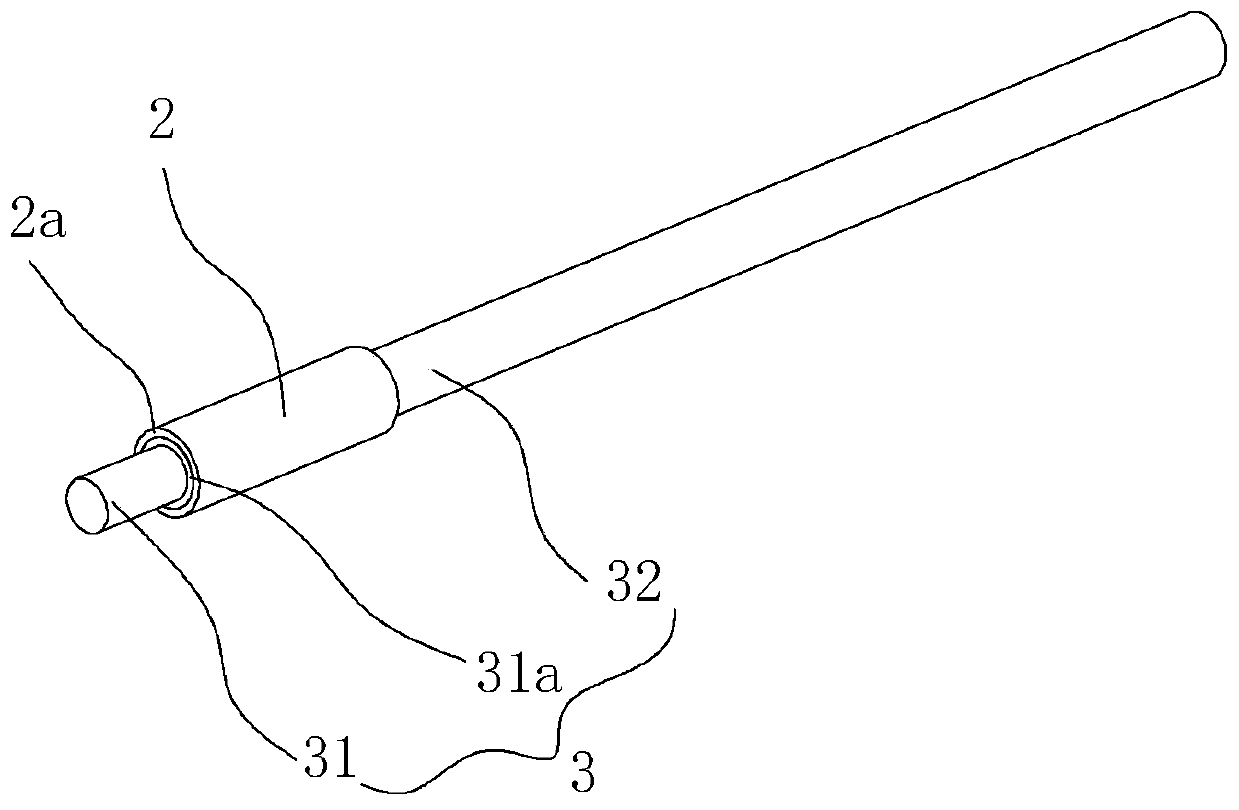

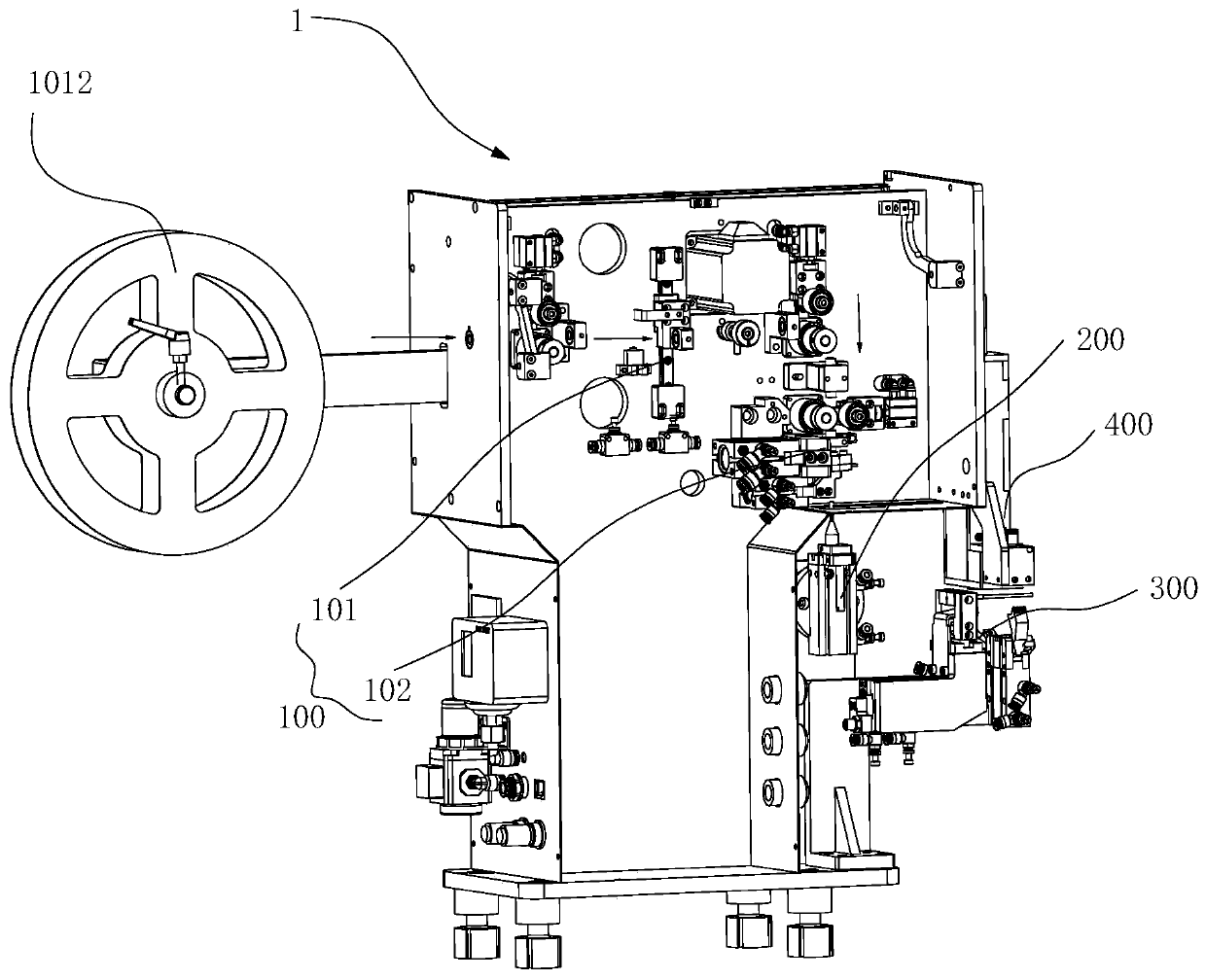

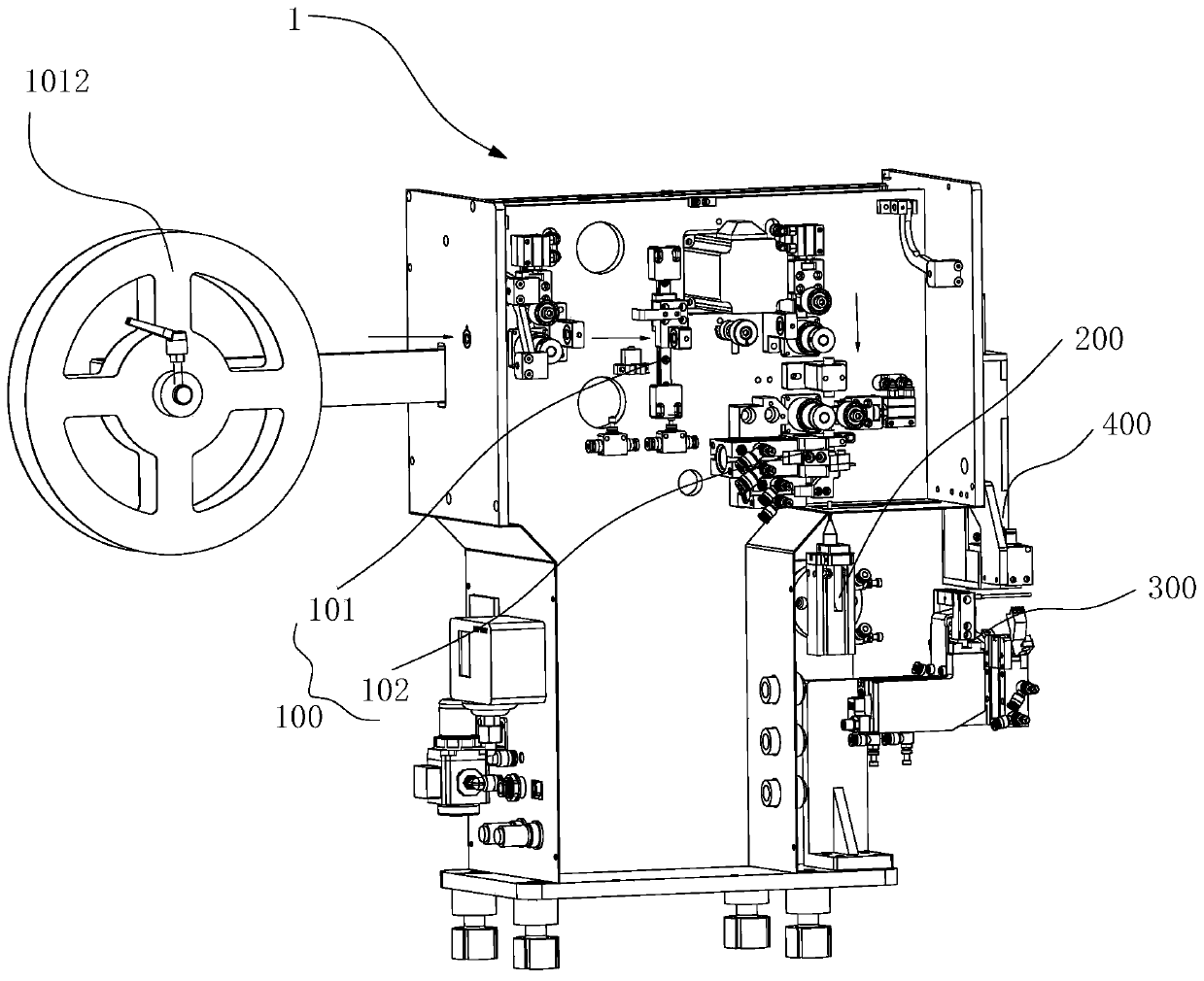

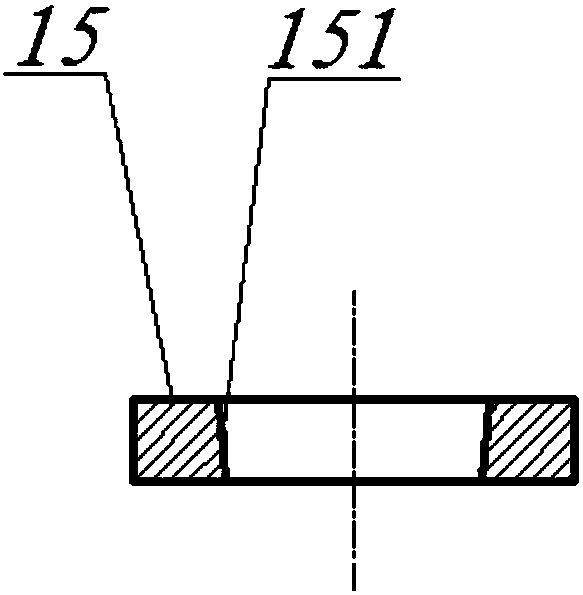

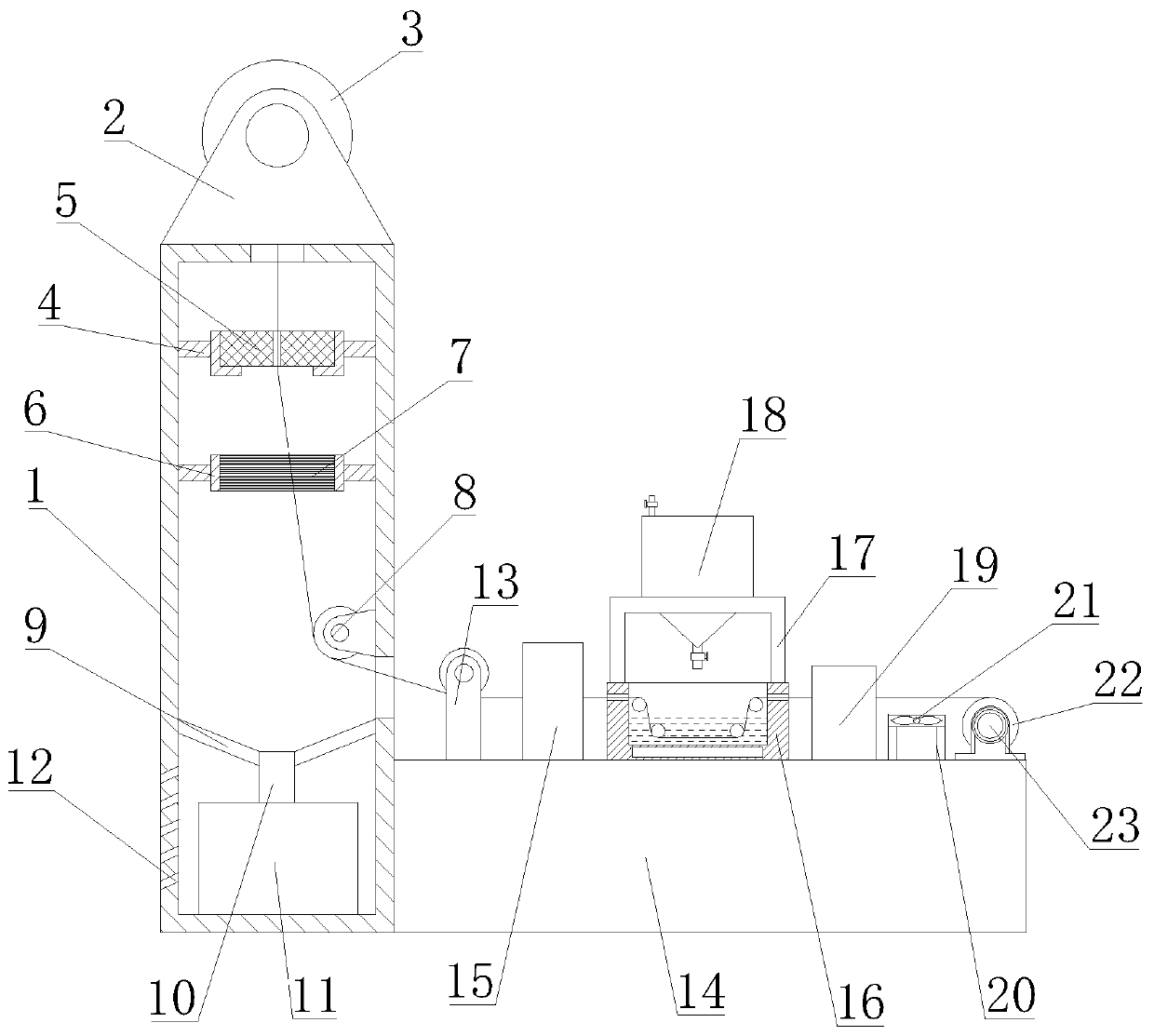

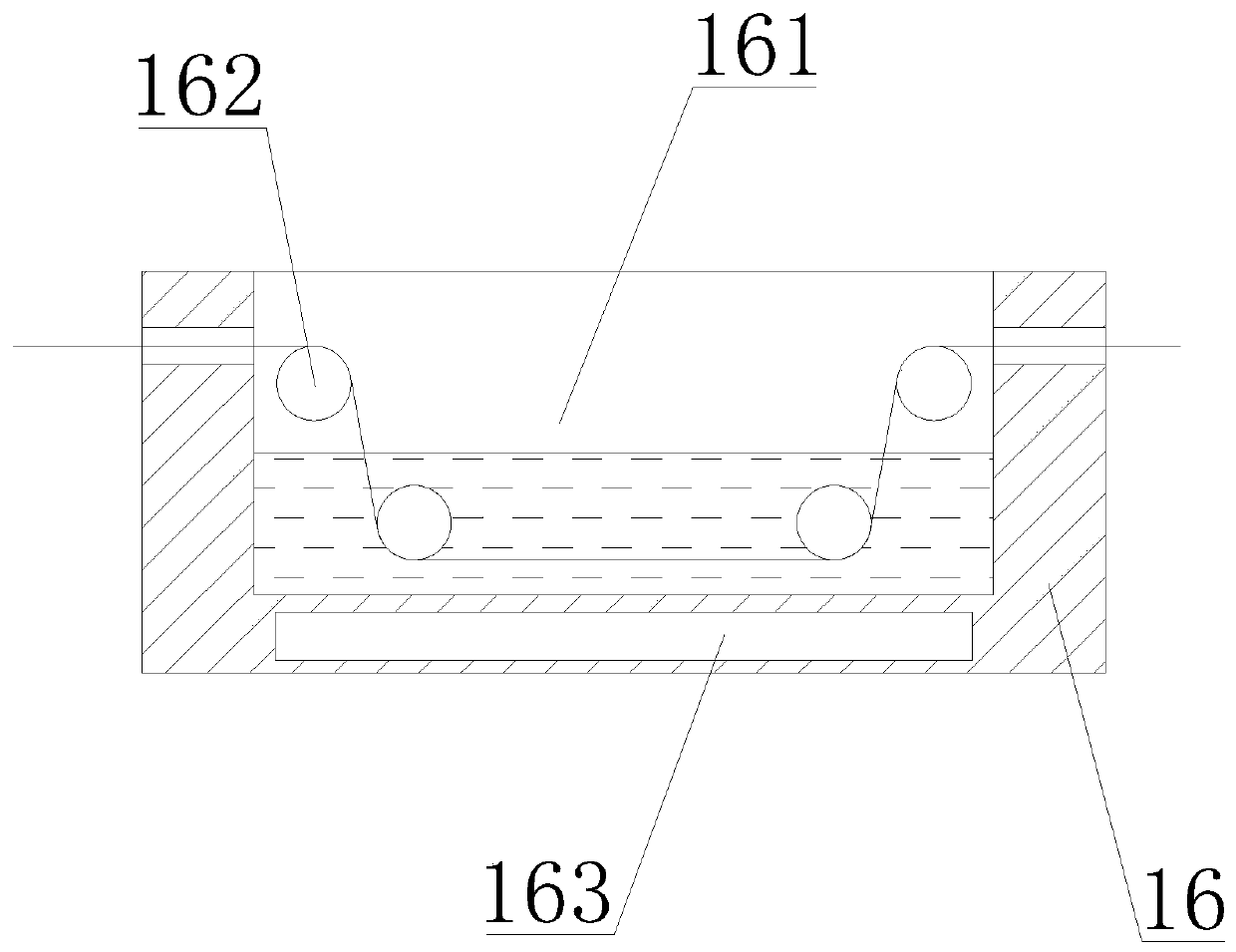

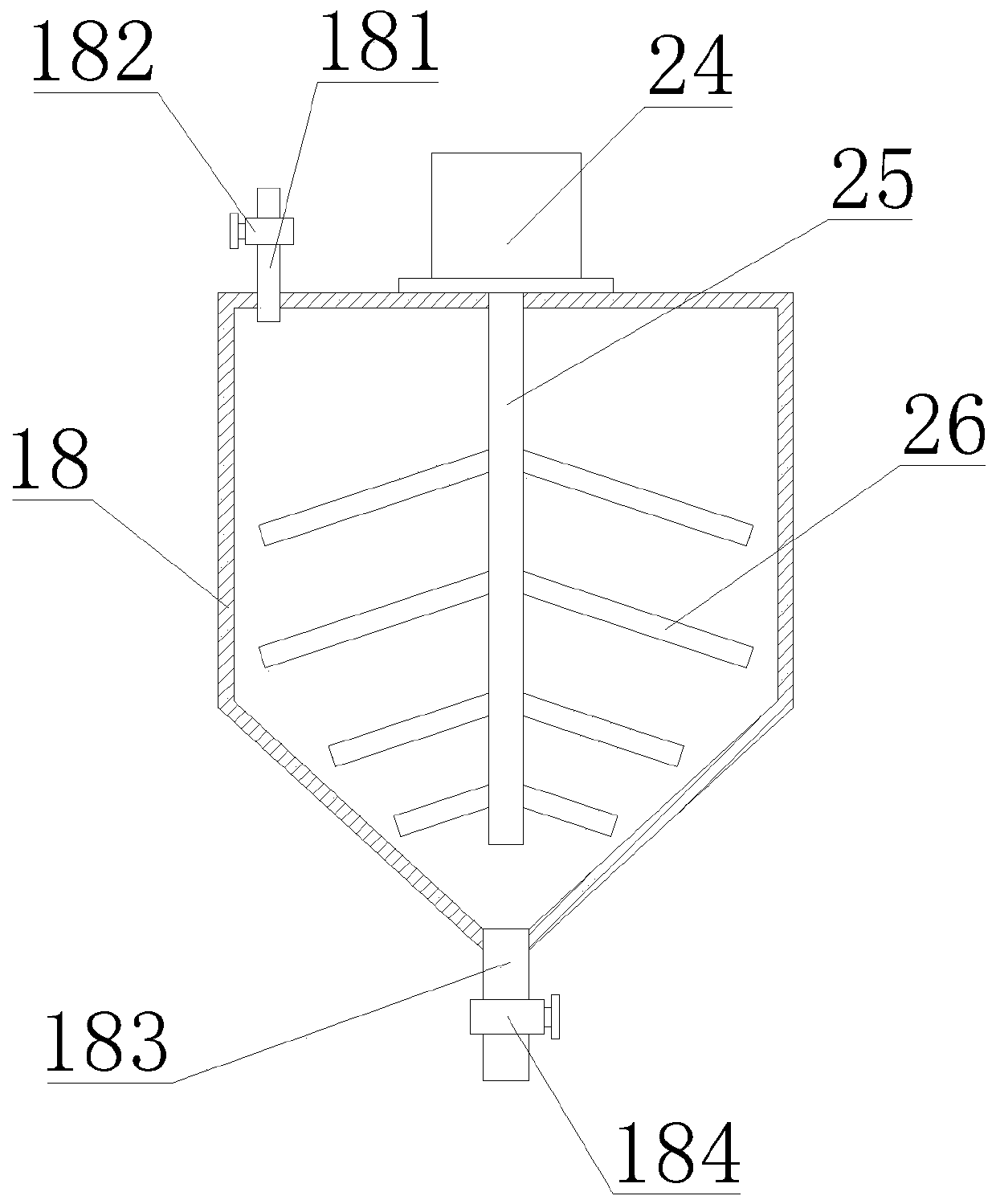

Full-automatic heat-shrinkable pipe jacketing machine and heat-shrinkable pipe jacketing method

PendingCN111070660APrecise casing positionImprove cladding qualityMetal working apparatusPhysicsHeat-shrink tubing

The invention provides a full-automatic heat-shrinkable pipe jacketing machine and a heat-shrinkable pipe jacketing method. The full-automatic heat-shrinkable pipe jacketing machine comprises a heat-shrinkable pipe feeding part, a heat-shrinkable pipe transferring part, a pipe penetrating part and a hot air flow supply part, wherein the heat-shrinkable pipe feeding part is suitable for supplying aheat-shrinkable pipe; the heat-shrinkable pipe transferring part is provided with a fixing rod; the fixing rod is suitable for fixing the heat-shrinkable pipe and transferring the heat-shrinkable pipe to a predetermined pipe penetrating position; the pipe penetrating part is provided with a clamping channel; a first opening of the clamping channel allows a wire harness to be inserted into; a second opening of the clamping channel allows the fixing rod to be pulled out; through holes communicating with the outside are formed in the clamping channel; a limiting unit is arranged on the second opening and is used for limiting the heat-shrinkable pipe at the pipe penetrating position when the fixing rod leaves the clamping channel and feeding and inserting the wire harness into the heat-shrinkable pipe at the pipe penetrating position until a terminal of the wire harness penetrates out of the second opening; hot air flow is supplied into the clamping channel through the through holes, so that the wire harness is fixedly connected with the heat-shrinkable pipe; and the hot air flow supply part is used for supplying the hot air flow to the pipe penetrating part. Therefore, the coating quality of the heat-shrinkable pipe to a conductor terminal can be improved, and the jacketing precision of the heat-shrinkable pipe is improved.

Owner:XIAMEN HIPRECISE TECH CO LTD

Modified glass material for repairing carbon/carbon composite material SiC coating based on laser cladding method and preparation and use methods

ActiveCN112341000AReduce energy lossImprove absorption rateGlass furnace apparatusCarbon compositesRare-earth element

The invention relates to a modified glass material for repairing a carbon / carbon composite material SiC coating based on a laser cladding method as well as a preparation method and a use method of themodified glass material. Borosilicate glass is modified by rare earth element samarium, so that the absorptivity of the material to a laser band covered by an optical fiber laser is remarkably improved; on one hand, the cladding quality of the modified borosilicate glass can be improved, and the oxidation resistance of a repaired carbon / carbon composite material SiC coating sample is improved; and on the other hand, the energy loss of laser can be effectively reduced, and the development goals of greenness, environmental protection and cost saving are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

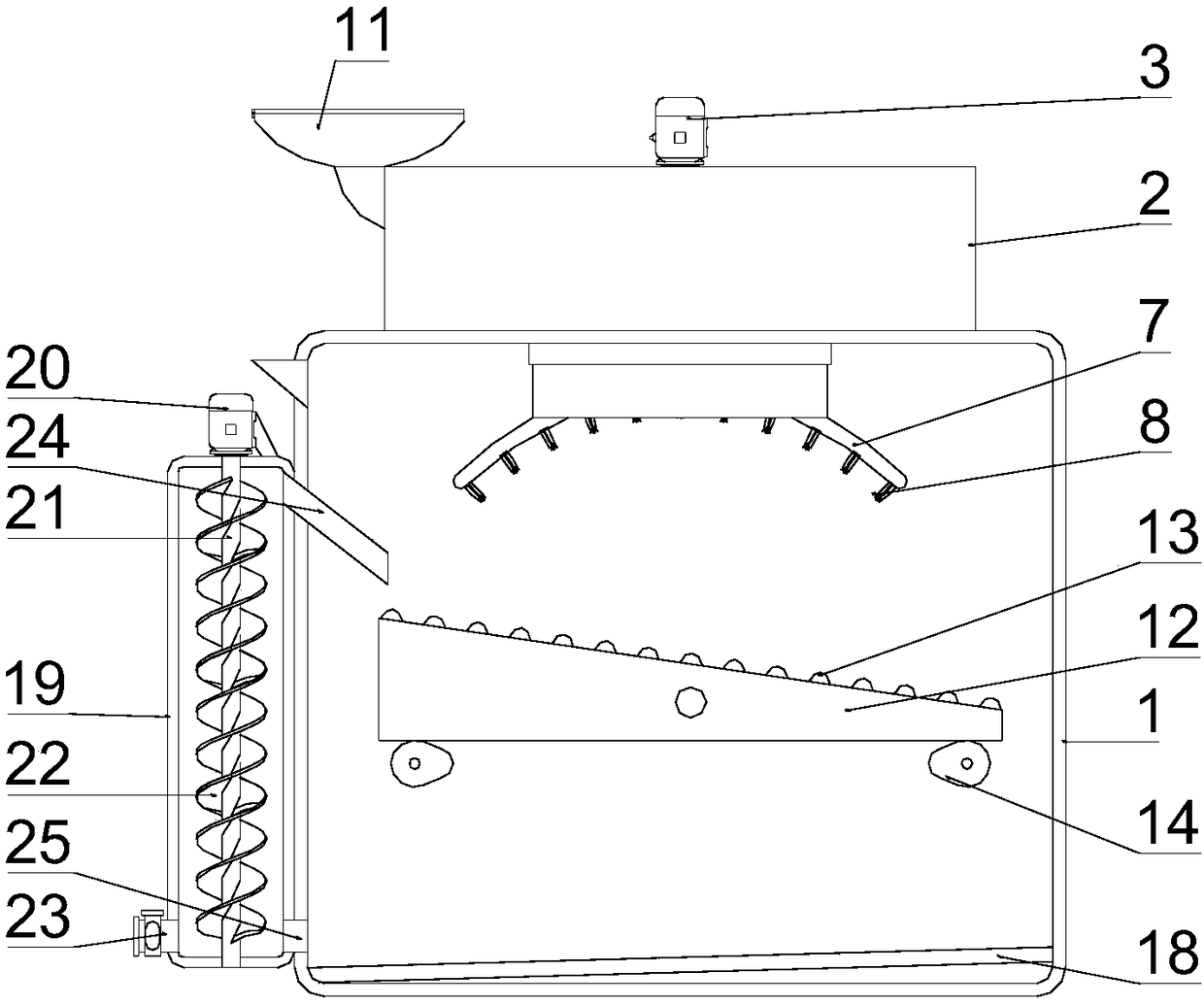

Cam-driven feed yogurt additive spraying device for meat and poultry breeding

InactiveCN108185478AImprove homogeneityGood quality and effectFeeding-stuffWorking-up animal fodderFowlMetal strips

The invention discloses a cam-driven feed yogurt additive spraying device for meat and poultry breeding. The cam-driven feed yogurt additive spraying device comprises a housing, an additive mixing boxfixedly connected to the upper part of the housing, a circulating blanking device mounted on the left side of the housing and a blanking table arranged in the housing. A rotating shaft is arranged inthe additive mixing box; an elastic mixing mechanism is mounted on the rotating shaft; the rotating shaft is connected with the upper side wall and the lower side wall of the additive mixing box in arotating manner; under the effect of centrifugal force, a metal strip spirally extends out, and cooperates with the action of a mixing plate, so that the homogenization effect of the yogurt additiveis obvious; due to the action of a driving device, a pair of cams can synchronously rotate, so that the blanking table reciprocates in a left-and-right manner and extruded feeds roll on the blanking table, and the coating effect of the extruded feeds and atomized yogurt is improved and uniform, and the quality effect of the feeds is obvious; under the action of the circulating blanking device, theextruded feeds fall down from a discharge pipe in a circulating manner and the coating quality is improved.

Owner:储成立

A laser cladding head

ActiveCN106283044BGuaranteed stabilityWon't interfereMetallic material coating processesShielding gasEngineering

Owner:东台城东科技创业园管理有限公司

Electric wire and cable coating device capable of improving product performances

InactiveCN110277200AImprove surface qualityImprove coating efficiencyApparatus for heat treatmentInsulating conductors/cablesBristleBiochemical engineering

The invention belongs to the technical field of wire and cable coating, and particularly relates to a wire and cable coating device capable of improving the product performances. A connecting frame is arranged on a coating pretreatment box and is rotationally connected with a pay-off roller; a burr removing part and a dust removing part are both arranged in the coating pretreatment box; a burr removing filler is arranged in the burr removing part, and dust removing bristles are arranged in the dust removing part; a first guide roller is arranged in the coating pretreatment box; the base is arranged at the right side of the coating pretreatment box and provided with a second guide roller. A coating pool and an electric heating piece are arranged in the coating box; a plurality of groups of guide coating rollers are arranged in the coating pool; the supporting frame is arranged on the coating box, and a storage box is arranged on the supporting frame; a cooling and drying device is arranged on the base and located at the right side of the coating box. A take-up roller is arranged on the base and connected with a take-up motor. The surface quality of wires and cables is improved through pretreatment, the coating effect is ensured, and the cable coating efficiency is high.

Owner:扬州利家科技有限公司

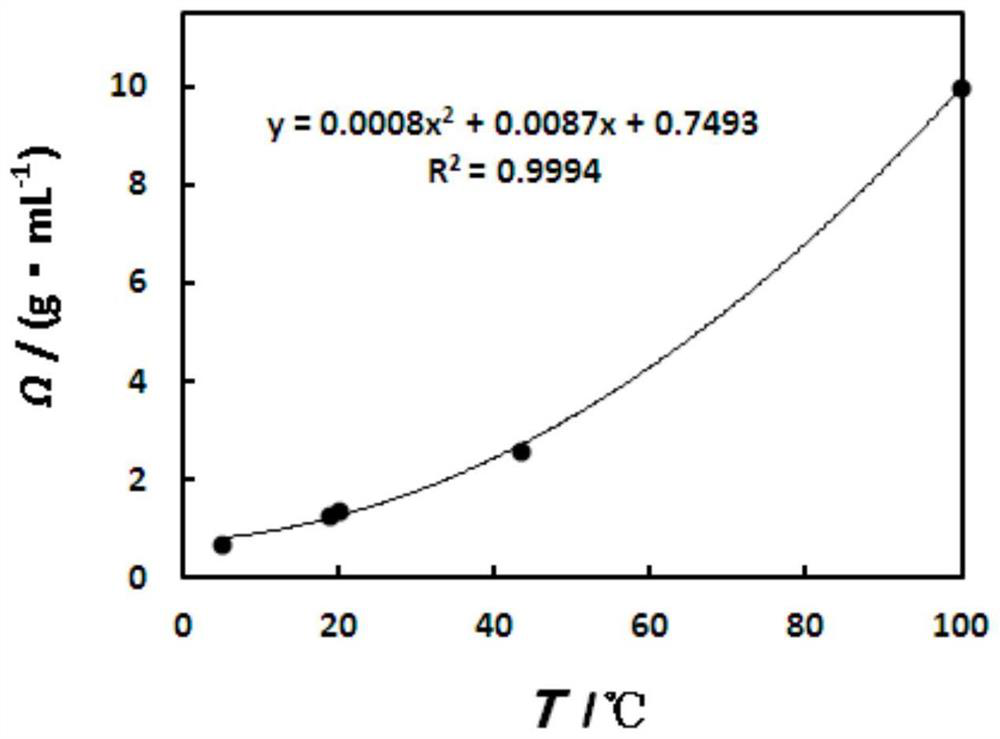

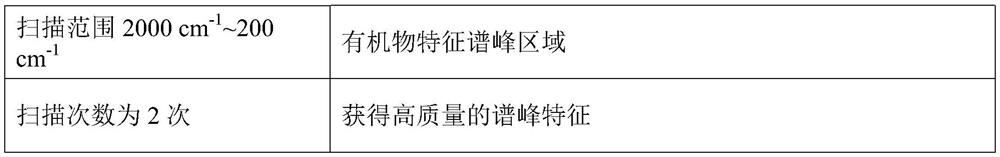

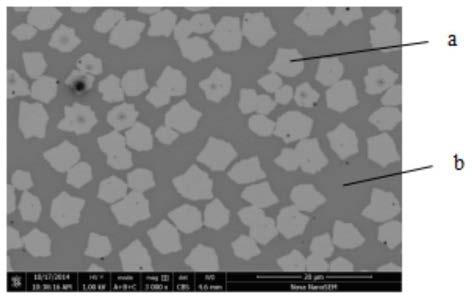

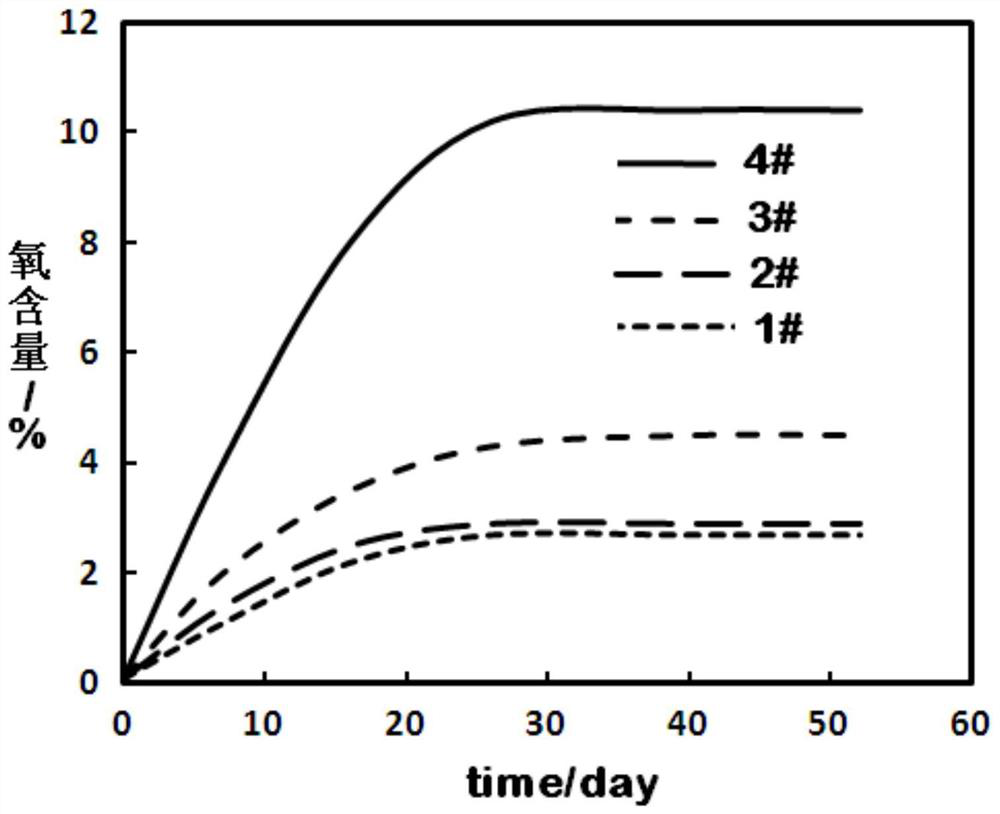

Method for evaluating coating quality of passivated NTO prepared by supercritical method

ActiveCN111948369AComparableImprove cladding qualityMaterial analysis using wave/particle radiationFuel testingExplosive AgentsMagnifying glass

The invention discloses a passivation NTO coating quality evaluation method prepared by a supercritical method. The method includes steps of: observing the debonding number of the passivated NTO particles through a magnifying lens, preparing an NTO aqueous solution to detect the pH value, detecting the corrosion degree of the passivated NTO to the Al sheet after preserving heat in a 60 DEG C RH 65% damp and hot environment for 30 days, and classifying the coating quality of the passivated NTO to be poor, IV-grade, III-grade, II-grade and I-grade. The method is mainly used for evaluating the passivation NTO prepared by the supercritical method. The passivated NTO with good coating quality does not show acidity, is suitable for manufacturing Al-containing press-fitting explosives, and does not corrode a metal shell of a warhead. In addition, passivation process parameters can be determined and insensitive agents can be screened by comparing detection values of passivation NTO.

Owner:XIAN MODERN CHEM RES INST

Method and sprayer for improving laser cladding effect

ActiveCN102864451BQuality improvementImprove densification performanceMetallic material coating processesCrazingSprayer

The invention discloses a method and a sprayer for improving a laser cladding effect. According to the method, multiple protective gases are used in the laser cladding process, different protective gases have different gas pressure, and the gas pressure of protective gases with low molecular weight is lower than that of protective gases with high molecular weight. The cladding quality can be improved greatly by using different chemical ingredients and the protective gases under different gas pressure and protecting a powder flow field and work environment; multiple protective gas channels are formed inside a sprayer, so that the protective gases with different ingredients under different gas pressure can be used during cladding, the quality of a cladding layer is improved, the phenomena of cracks, shrinkage porosity and shrinkage cavities are reduced, and the compactness of the cladding layer is improved.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Method for manufacturing molding powder by recycling NTO in waste cast explosives

ActiveCN111943788ASimple processHigh penetration rateNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsSodium bicarbonateExplosive Agents

The invention discloses a method for manufacturing molding powder by recycling NTO in waste cast explosives. The method includes: extracting the cast explosive with hot water, and cooling, filtering and drying the cast explosive; washing thecast explosive with methylbenzene, and filtering and drying the cast explosive to obtain an NTO crude product; dissolving the NTO crude product in hot water, dropwise adding a sodium bicarbonate aqueous solution to neutralize residual acid, rapidly cooling and stirring the mixture at a high speed to separate out NTO solid, and filtering and drying the mixture to obtain an NTO recrystallized product; adding NTO with a certain particle size into the adhesive solution to form a suspension, and preparing a shaped coarse powder by adopting a supercritical coating technology; and carrying out programmed heat preservation at the temperature of 70-120 DEG C and 70 DEG C to obtain the NTO-based PBX explosive molding powder. The purity of the recovered NTO isgreater than 99%, the recovery rate is greater than 82%, and the recovery process is simple, green and environment-friendly. According to the method disclosed by the invention, the coating degree ofthe NTO crystal by the adhesive is improved, the thermal safety is improved, and the acid corrosion of NTO to the warhead shell can be prevented.

Owner:XIAN MODERN CHEM RES INST

Method and nozzle improving laser cladding effect

ActiveCN102899660AQuality improvementImprove densification performanceMetallic material coating processesChemical compositionShielding gas

The invention discloses a method and a nozzle improving a laser cladding effect. According to the method for improving the laser cladding effect, during laser cladding, a mixed gas of helium and nitrogen is delivered into a channel of the nozzle as a protection gas; high-pressure nitrogen is simultaneously delivered into another channel of the nozzle as a protection gas, wherein the gas pressure of the mixed gas is lower than that of the high-pressure nitrogen. According to the technical scheme of the method and the nozzle improving the laser cladding effect, protection gases with no chemical component and different gas pressures are adopted, a powder flow field and a working environment are protected simultaneously, and cladding quality can be greatly improved; multiple protection gas channels are designed in the nozzle, such that multiple protection gases with different components and different gas pressures can be applied in cladding. Therefore, clad layer quality is improved, cracking is reduced, shrinkage loosening is reduced, shrinkage porosity is reduced, and clad layer compactness is improved.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com