Preparation method of graphene primary coated copper wire

A graphene and copper-clad technology, which is used in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, electrical components, etc., and can solve problems such as secondary damage of graphene, multiple layers, and environmental pollution. , to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment provides a kind of preparation method of graphene original coating copper wire, and concrete steps are as follows:

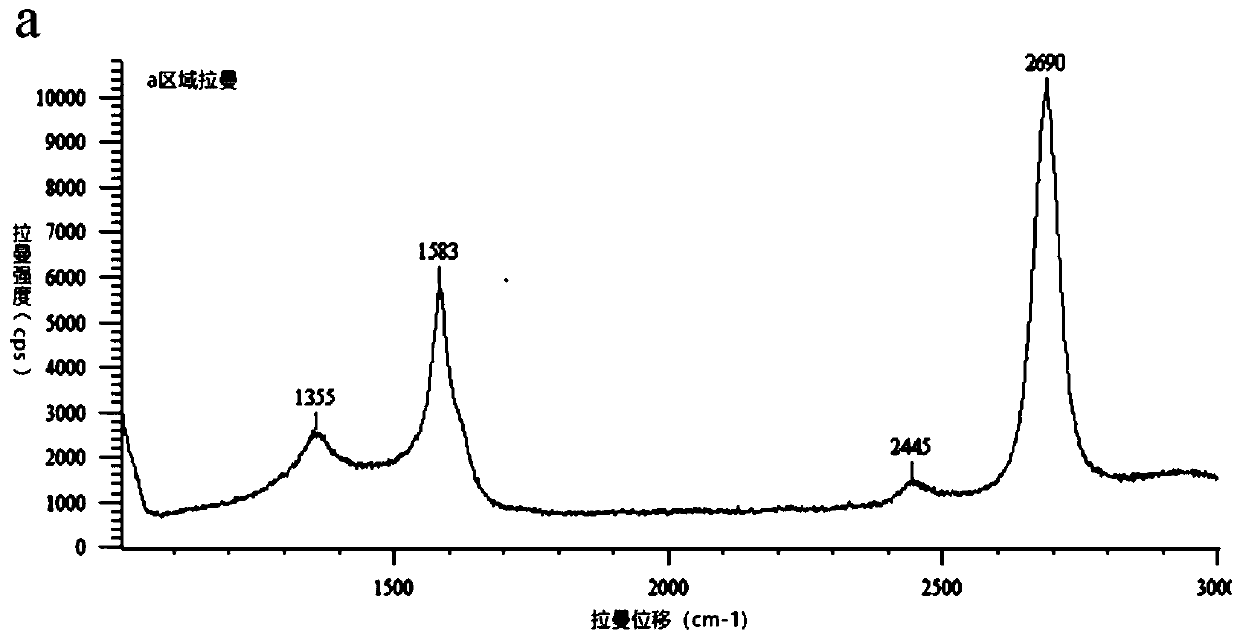

[0023] 1) Preparation of induced slurry: mix graphene oxide: water: additives at a ratio of 4.5%: 99: %: 0.5% and add to the homogenizer; wherein the graphene sheet diameter D90 is 1.7 μm, the thickness is 2 nm, and the specific surface area is 350 m 2 / g; the auxiliary agent is a mixed solution of polyvinylpyrrolidone and phosphate ester 1:1; the homogenizer process adopts a low-pressure homogenization pressure of 40bar and a time of 25min; a high-pressure homogenization of 900bar and a time of 35min; To wrap evenly;

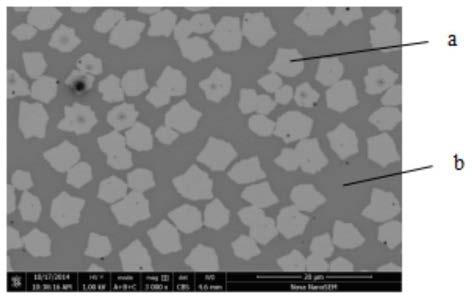

[0024] 2) Reduction: The copper wire wrapped with the induced slurry is pulled to the reduction area at a low speed for drying and reduction, so that the surface of the copper wire is evenly attached to the surface of the copper wire after reduction, discontinuous, high-conductivity graphene microchips; the drying te...

Embodiment 2

[0029] The present embodiment provides a kind of preparation method of graphene original coating copper wire, and concrete steps are as follows:

[0030] 1) Preparation of induced slurry: mix graphene oxide: water: additives in a ratio of 1.5%: 99: %: 0.2% and add to a homogenizer; graphene sheet diameter D90 is 1.5 μm, thickness is 1.5 nm, and specific surface area is 380 m2 / g; the auxiliary agent is a mixed solution of sodium dodecylbenzenesulfonate and polyoxyethylene alkylphenol ether 1:1; the homogenizer process adopts a low-pressure homogenization pressure of 30bar, and a time of 20min; a high-pressure homogenization of 850bar, and a time of 30min ; After the induction slurry is prepared, the surface of the copper wire is evenly wrapped;

[0031] 2) Reduction: Pull the copper wire wrapped with the induced slurry to the reduction area at a low speed for drying and reduction, so that the surface of the copper wire is evenly attached to the reduced discontinuous, high-cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com