Laser cladding nozzle and laser cladding device and laser cladding method

A laser cladding and nozzle technology, which is applied in the coating process and coating of metal materials, can solve the problems of deterioration of the comprehensive performance of materials, high chemical activity of lithium and magnesium elements, and decreased plasticity and toughness of coatings, etc., to meet the requirements of Laser cladding process requirements, the effect of improving the quality of laser cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

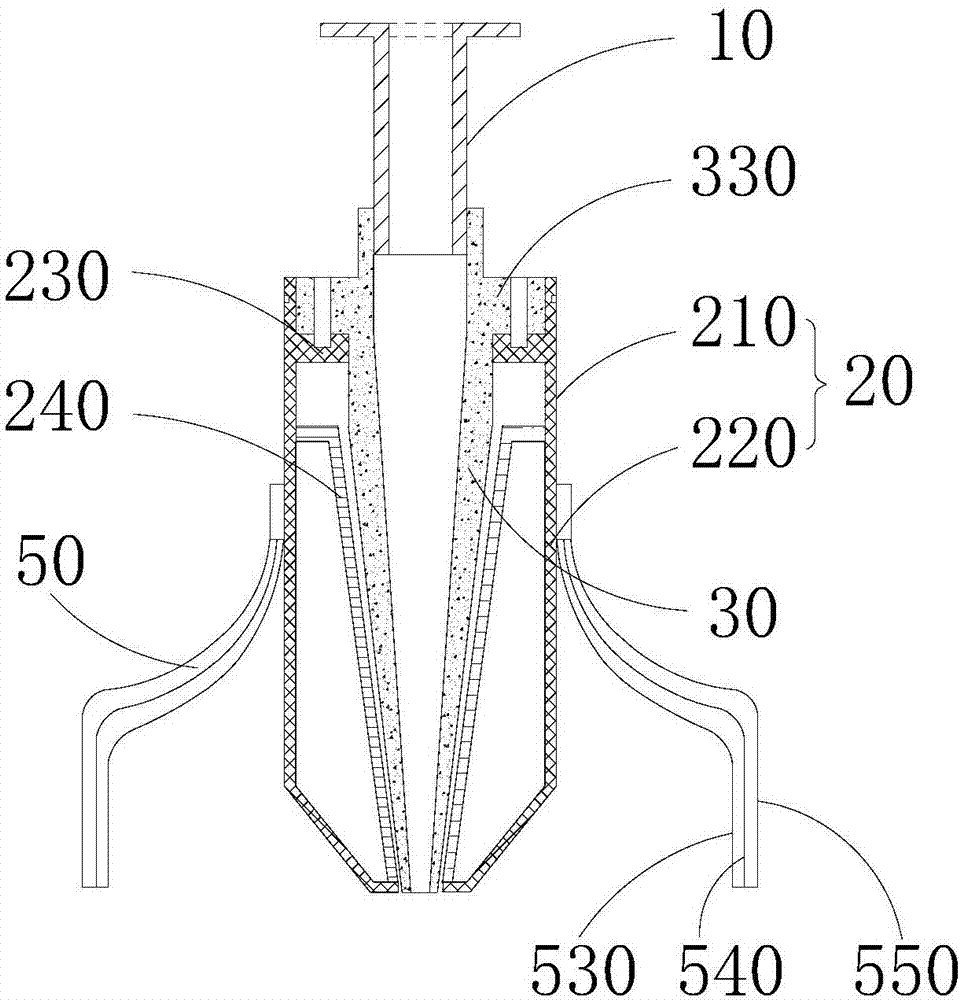

[0046] The embodiment of the present invention provides a laser cladding device. The laser cladding device is especially suitable for laser cladding on the surface of low melting point and high active materials represented by magnesium, aluminum, titanium and their alloys. The laser cladding The cladding device includes a laser cladding nozzle and a laser. The laser is connected to the laser cladding nozzle. The laser is used to generate a laser beam. The laser beam generated by the laser passes through the laser nozzle, and the metal powder sprayed from the laser nozzle to the surface of the metal substrate is melted to form a certain shape. And the size of the molten pool, so that a layer of metal coating with special physical, chemical or mechanical properties is deposited on the area scanned by the laser beam on the surface of the substrate.

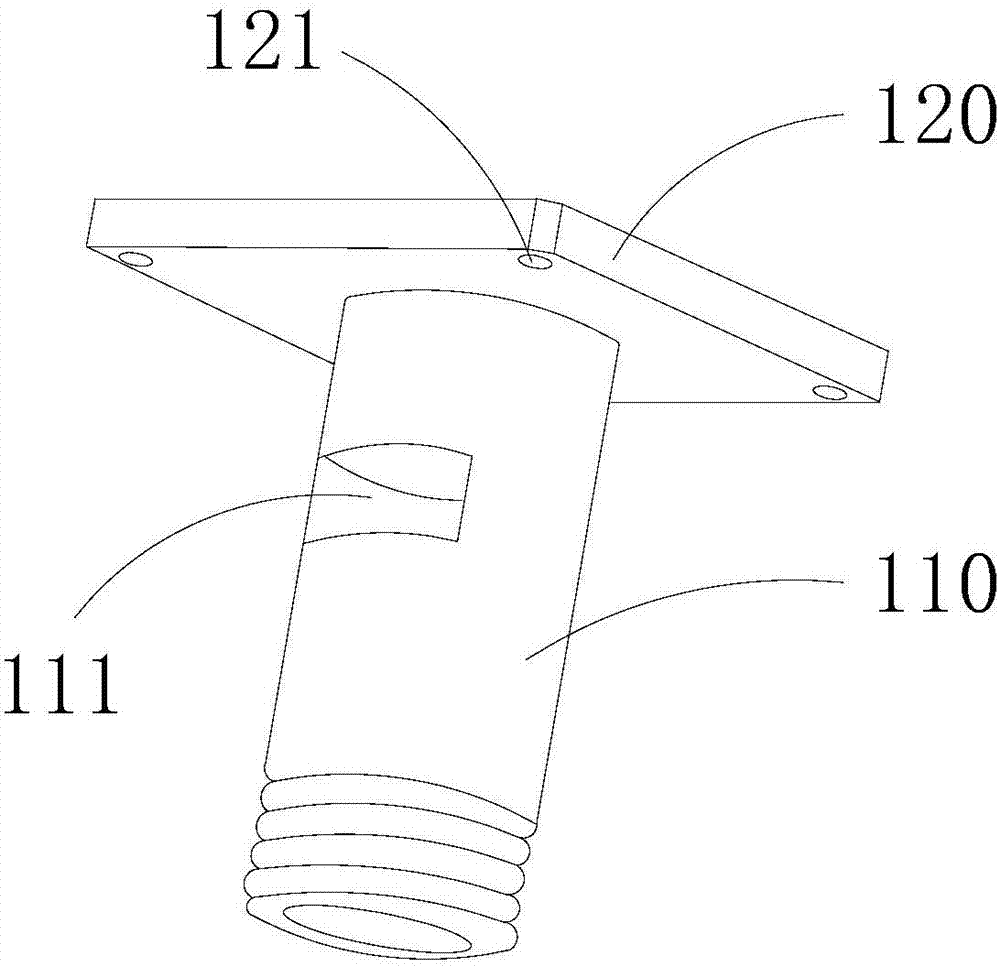

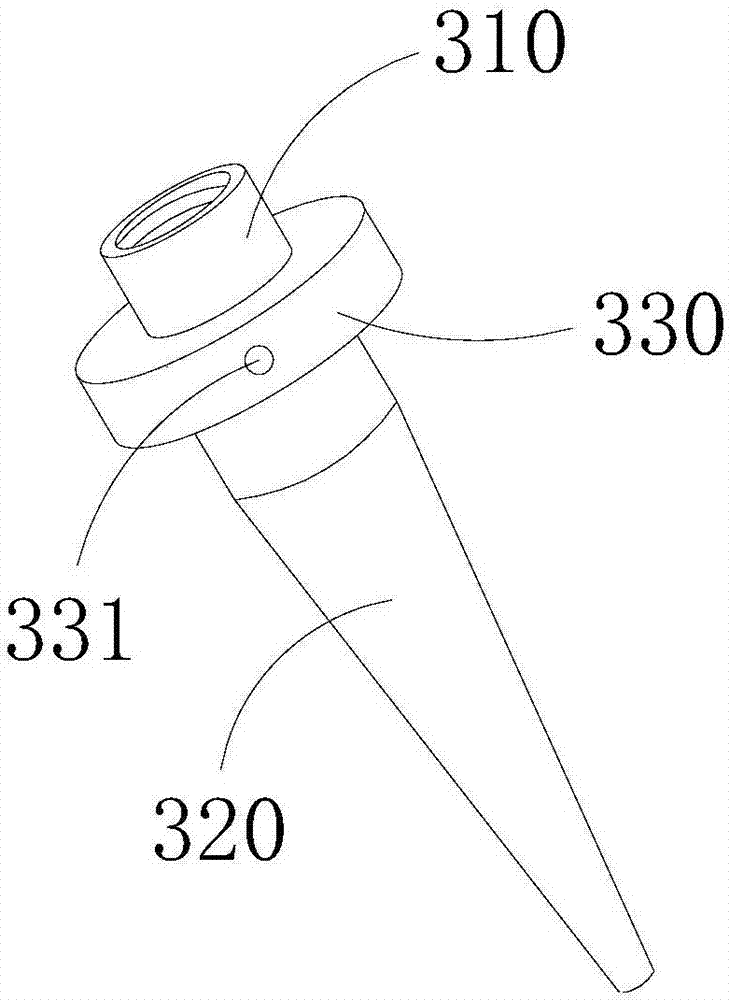

[0047] see figure 1 , is a cross-sectional view of the laser cladding nozzle provided by the embodiment of the present invention. ...

no. 2 example

[0065] see Figure 6 to Figure 8 , the laser cladding nozzle provided in the embodiment is an improvement made on the basis of the first embodiment. For details not involved in this embodiment, please refer to the description in the first embodiment. and figure 1 The laser cladding nozzle shown is different in that the laser cladding nozzle provided in this embodiment also includes a fastening sleeve 40, and the fastening sleeve 40 includes a circular top surface 410 and a side surface 420 arranged on the edge of the top surface 410, A through hole matching the size of the nozzle core 30 is provided on the top surface 410 . The side surface 420 disposed on the edge of the top surface 410 forms a ring structure, and the inner diameter of the ring structure just matches the size of the first end 210 of the nozzle housing 20 .

[0066] In the embodiment of the present invention, the end surface of the first end 210 of the nozzle housing 20 is flush with the end surface of the c...

no. 3 example

[0072] see Figure 9 , is a flow chart of the laser cladding method applied to the laser cladding device provided by the embodiment of the present invention, the laser cladding device includes the laser cladding nozzle described in the second embodiment, and also includes a laser, and the laser uses for generating a laser beam that passes through the nozzle core. The following will be Figure 9 The process shown is described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com