Method for modifying ternary composite material

A composite material and modification technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of low lithium ion diffusion coefficient and electronic conductivity, low first charge and discharge efficiency of ternary materials, and material rate performance. Deviation and other problems, to achieve the effect of improving the coating rate, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

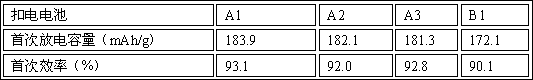

Embodiment 1

[0016] A method for modifying a ternary composite material, comprising the following steps;

[0017] 1. Weigh 31.2g (0.1mol) of silver sulfate, 2.4g (0.075mol) of thiourea and 2.65g (0.075mol) of ammonium chloride, respectively, add 1000ml of deionized water to dissolve to obtain three mixed solutions;

[0018] 2. Then pour the silver sulfate and ammonium chloride solution in step 1 into a beaker and stir evenly, then add 105ml of concentrated ammonia water and 150g of hydrazine and stir evenly, finally add thiourea solution and 100ml of deionized water and stir evenly to obtain Solution A;

[0019] 3. Add 81g (1mol) LiNi 0.6 co 0.2 mn 0.2 o 2 (Manufacturer: Ningbo Jinhe New Materials Co., Ltd., model: S76L) Add the ternary precursor powder material to 1000ml deionized water to form a solution with a concentration of 1mol / L and stir evenly to obtain solution B. Weigh 100ml of solution A Add to the reaction vessel containing solution B to obtain mixed solution C;

[0020]...

Embodiment 2

[0022] 1. Weigh 15.6g (0.005mol) of silver sulfate, 1.6g (0.05mol) of thiourea and 0.265g (0.005mol) of ammonium chloride, respectively, add 1000ml of deionized water to dissolve to obtain three mixed solutions;

[0023] 2. Then pour the silver sulfate and ammonium chloride solution in step 1 into the beaker and stir evenly, then add 52.5ml of concentrated ammonia water and 15g hydrazine and stir evenly, finally add thiourea solution and 100ml deionized water and stir evenly Obtain solution A;

[0024] 3. Add 8.1g (0.1mol) LiNi 0.6 co 0.2 mn 0.2 o 2 Add the ternary precursor powder material to 1000ml deionized water to form a solution with a concentration of 0.1mol / L and stir evenly to obtain solution B, then add 50ml solution A to the reaction vessel containing solution B to obtain mixed solution C;

[0025] 4. Put the reaction vessel into the water bath at the set temperature (the set temperature is 60°C), and feed the functional gas NH 3 (The flow rate is 1ml / min), and...

Embodiment 3

[0027] 1. Weigh 62.4g (0.2mol) of silver sulfate, 32g (1mol) of thiourea and 5.3g (0.1mol) of ammonium chloride, respectively, add 1000ml of deionized water to dissolve to obtain three mixed solutions;

[0028] 2. Pour the silver sulfate and ammonium chloride solution in step 1 into a beaker and stir evenly, then add 525ml of concentrated ammonia and 100g hydrazine and stir evenly, finally add thiourea solution and 100ml deionized water and stir evenly to obtain Solution A;

[0029] 3. Add 162g (2mol) LiNi 0.6 co 0.2 mn 0.2 o 2 Add the ternary precursor powder material to 1000ml deionized water to form a solution with a concentration of 2mol / L and stir evenly to obtain solution B, then add 200ml solution A into the reaction vessel containing solution B to obtain mixed solution C;

[0030] 4. Put the reaction vessel into the water bath at the set temperature (the set temperature is 100°C), and feed the functional gas NH 3 (The flow rate is 10ml / min), and use a magnetic sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com