Vibrating cladding repair technology for damaged last-stage blades of steam turbine

A last-stage blade and steam turbine technology, applied in the field of steam turbine blade repair, can solve problems such as uneven cladding layer structure and performance distribution, uneven cladding layer stress distribution, cladding layer residual tensile stress, etc., and achieve stable size and Geometric accuracy, reduction of residual stress, effect of elimination of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

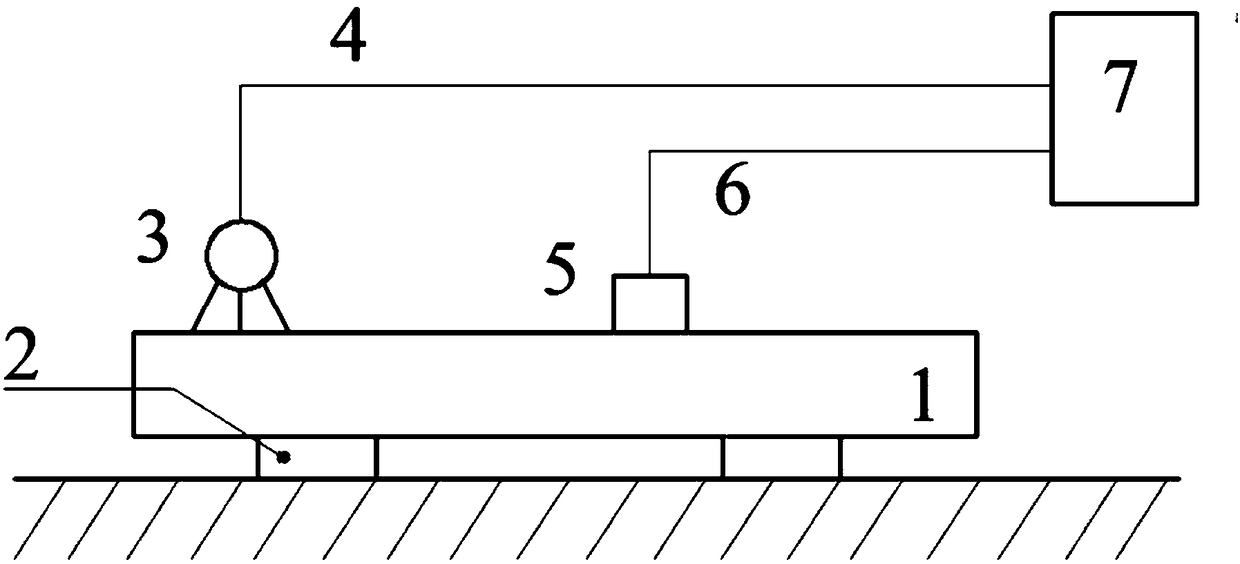

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0029] The sample base material used in this embodiment is 2Cr13 stainless steel, and its geometric size is 60mm×50mm×15mm.

[0030] An example of using the above processing method to repair a specimen, the steps are:

[0031] (1) Put the sample to be processed into a box-type heat treatment furnace for preheating for 1.5 hours at a preheating temperature of 150°C to remove water vapor and oil gas on the surface of the substrate.

[0032] (2) Pretreatment of the defect area or damaged part of the blade surface to be treated: Use sandpaper to remove rust on the surface of the material, and wipe the surface of the material with acetone to remove oil.

[0033] (3) Detect and analyze the surface of the sample to determine that there is a groove with a width of 3mm and a depth of 2mm in the middle part.

[0034] (4) Fix the exciter 3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com