A laser cladding head

A laser cladding and processing head technology, applied in metal material coating process, coating and other directions, can solve problems such as instability, lens ablation damage, protect lens ablation damage, etc., to ensure stability and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

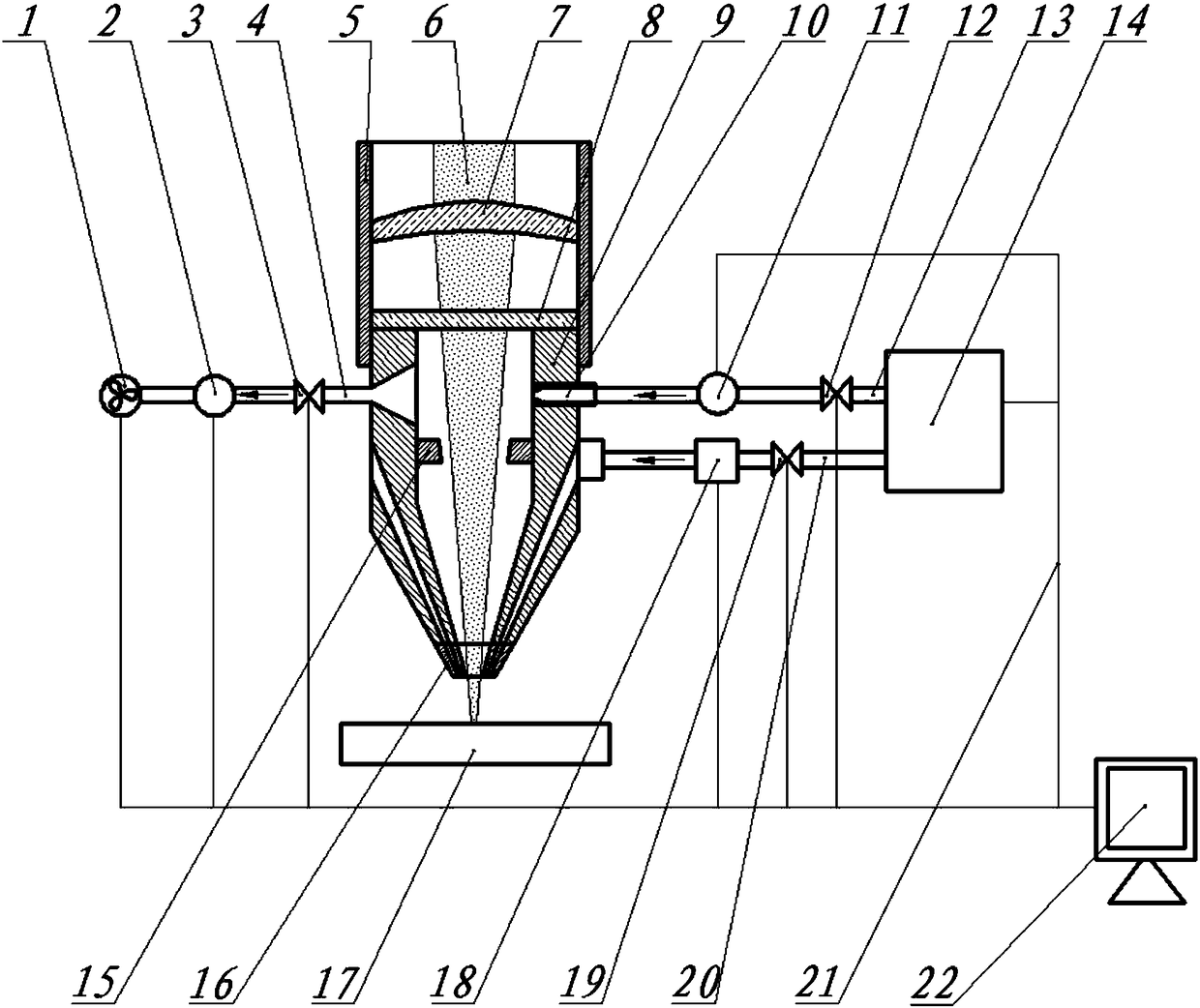

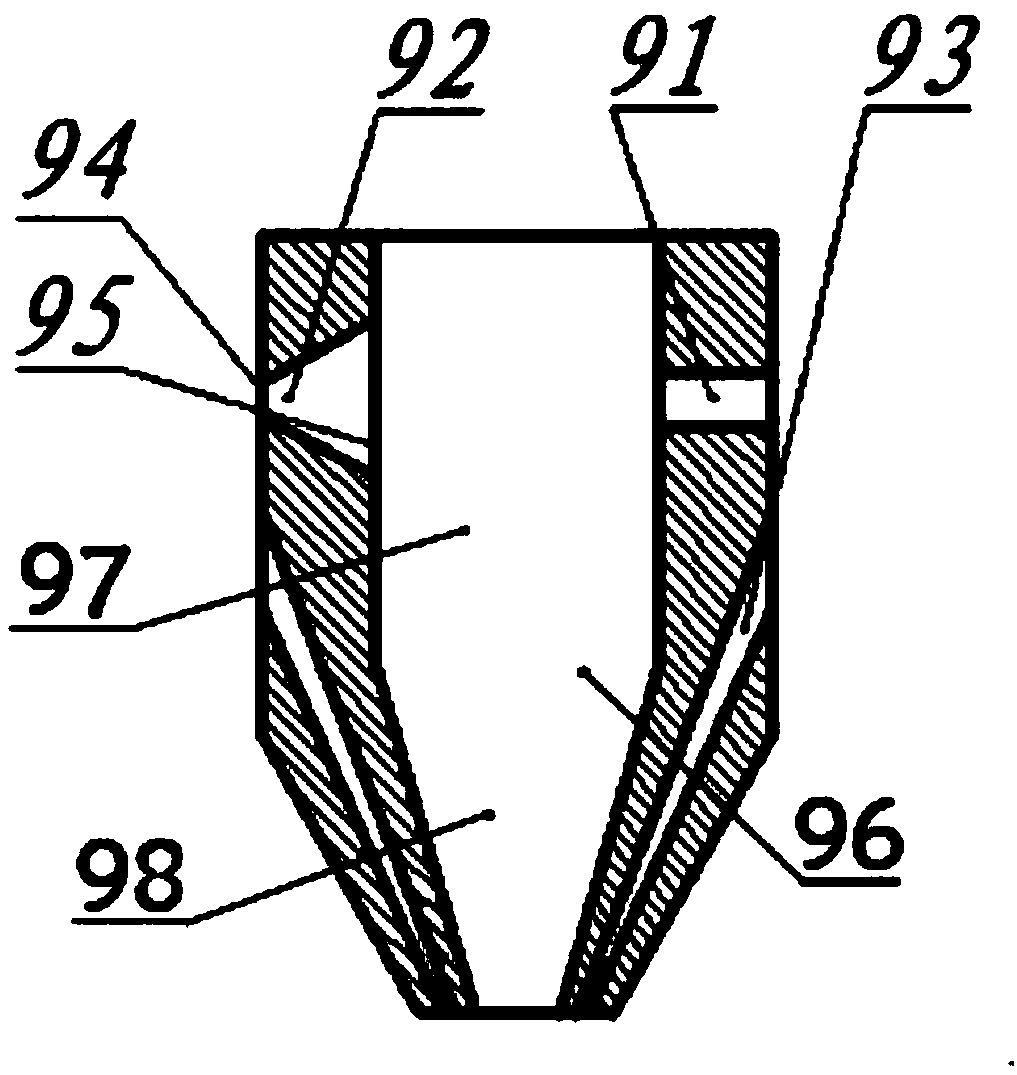

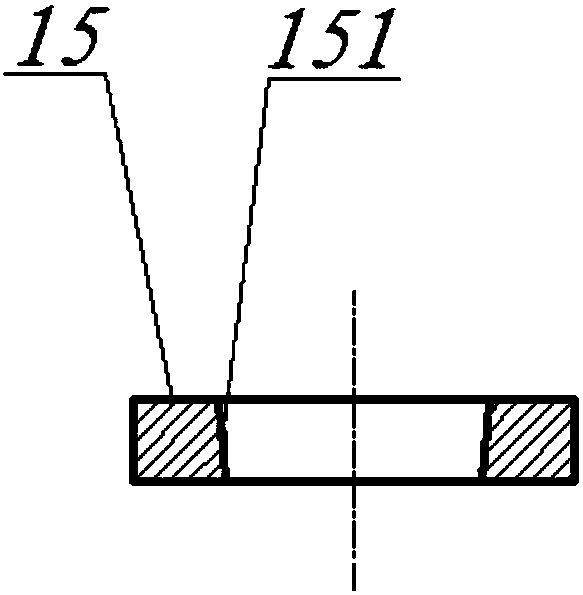

[0019] Example: such as figure 1 As shown, a laser cladding head includes exhaust gas path 4, sleeve 5, focusing mirror 7, protective mirror 8, processing head 9, compressed air gas path 13, gas center 14, powder mixing gas path 20, signal The transmission system 21 and the industrial computer 22, the focusing mirror 7, the protective mirror 8 and the processing head 9 are sequentially installed in the sleeve 5 from top to bottom, and the center of the processing head 9 is provided with a central passage 96 penetrating up and down. The side wall of the processing head 9 is provided with an air nozzle hole 91, a tapered hole 92 and a plurality of powder passages 93 respectively connected to the central passage 96, and the central passage 96 is provided with an annular retaining ring 15 below the tapered hole 91. A cladding nozzle 16 is installed on the lower end of the head 9, and the nozzle hole 91 is provided with a matching gas nozzle 10, and the above-mentioned compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com