Manufacturing method of NTO-based PBX explosive molding powder

A manufacturing method and technology of molding powder, which are applied in the directions of explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of easy cracking, large loss of NTO, and increase the danger of press-fitting process, etc. Tensile strength and compressive strength, reducing NTO loss, green and pollution-free process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

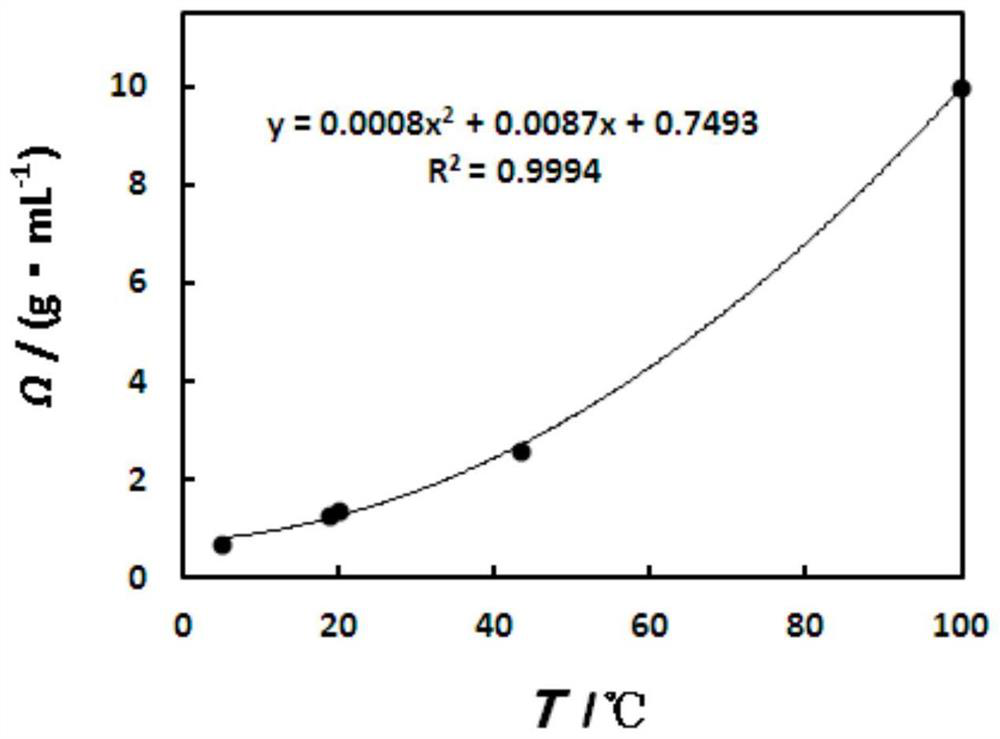

[0047] In this example, three parts of the research work are carried out: establishment of method, quality characterization of NTO recrystallized product, and quality characterization of NTO-based PBX molding powder.

[0048] "Establishment method" includes determining the solvent and ratio for NTO recrystallization, removing residual acid in NTO, and determining the holding temperature of PBX modeling coarse powder; "NTO recrystallization product quality characterization" includes the detection of moisture content, purity and residual acid content; "Quality characterization of NTO-based PBX molding powder" includes the influence of coating process on the quality of NTO crystals, the impact of coating process on the purity of NTO and the content of residual acid (nitric acid), coating quality characterization, and thermal safety characterization.

[0049] Finally, the research results of the examples are summarized. Through these test results, it can be illustrated that the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com