Method for making modeling powder from NTO in recycling waste melting and casting explosives

A technology for melting and casting explosives and modeling powder, which is applied in the directions of explosives, non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, etc. , Incomplete coating of PBX explosive modeling powder, increasing the danger of press-packing process, etc., to achieve the effect of green and pollution-free process, ensuring the power of explosives, and reducing the loss of NTO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In order to recover NTO from smelting and casting explosives and manufacture NTO-based PBX molding powder, this example carried out research work in three parts: establishment of method, quality characterization of recovered NTO recrystallized products, and quality characterization of molding powder. Finally, the research results of the examples are summarized: through these test results, it can be shown that the method of this patent can be used to reclaim qualified NTO recrystallized products from waste melting and casting explosives, and can produce NTO-based moldings with high coating quality pink.

[0066] The following takes a waste cast explosive (component content: TNT / NTO / binder = 52 / 42 / 6) to recycle and manufacture NTO-based molding powder as an example to describe in detail.

[0067] 1. Establishment method

[0068] 1.1 Select the solvent for NTO recovery

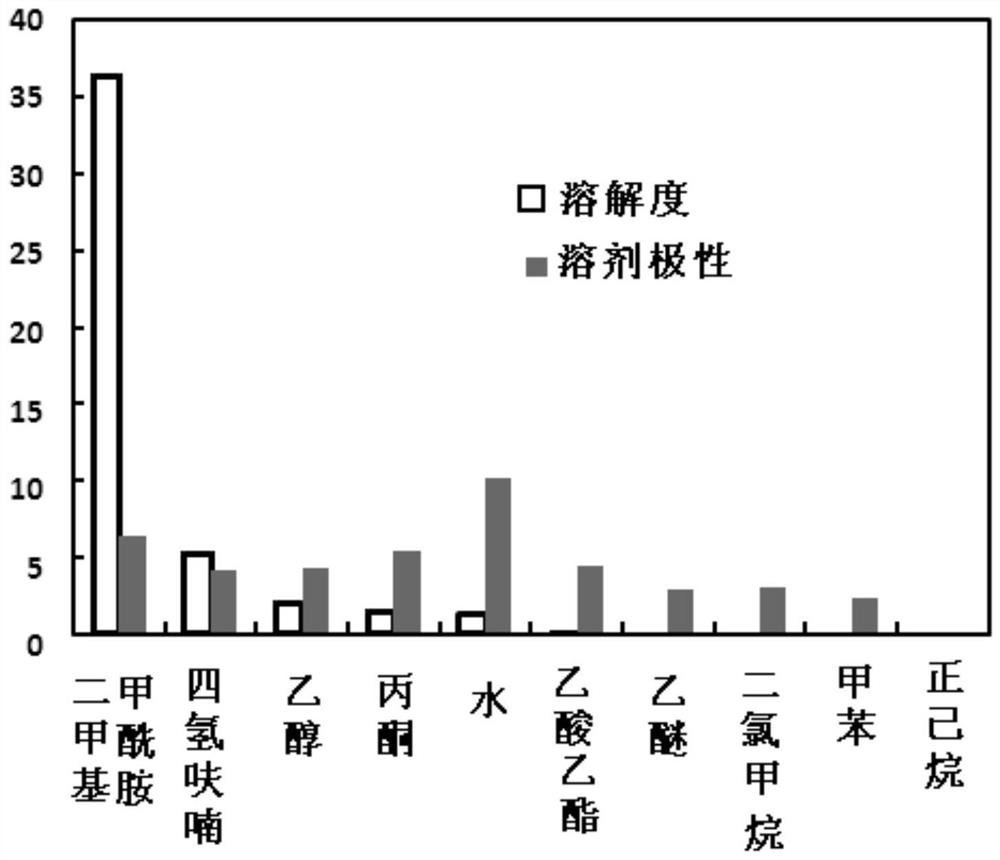

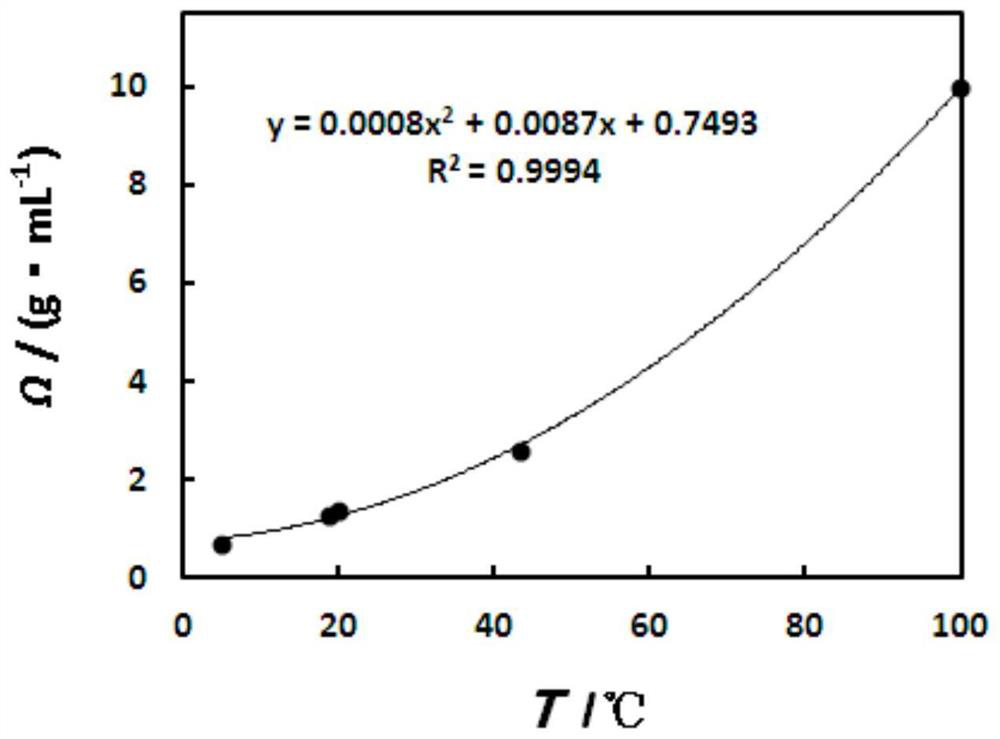

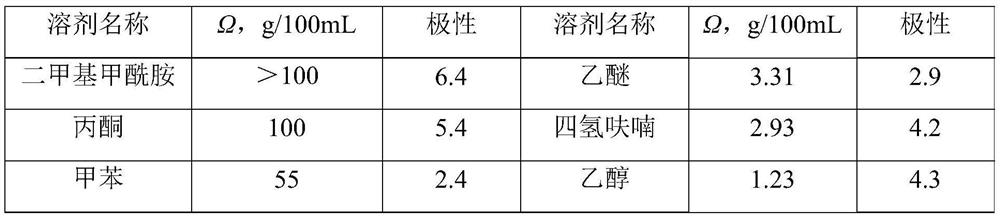

[0069] This patent uses a solvent extraction method to recover NTO in molten and cast explosives. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com