Blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp

A technology of laser remanufacturing and tooling and fixtures, which is applied in the direction of manufacturing tools, laser welding equipment, auxiliary devices, etc., can solve the problems of air holes in the forming layer, collapse of blade tip and edge, and complex shape structure, so as to improve the quality and improve the process The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

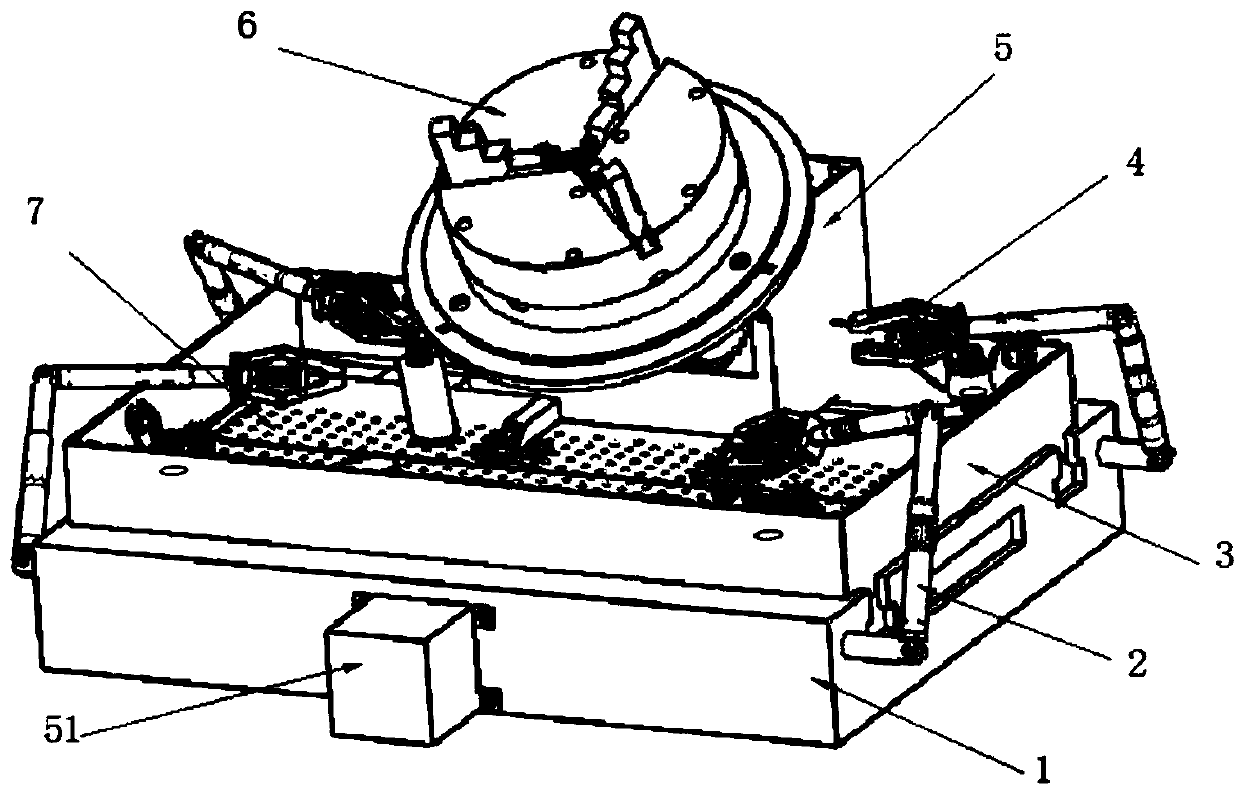

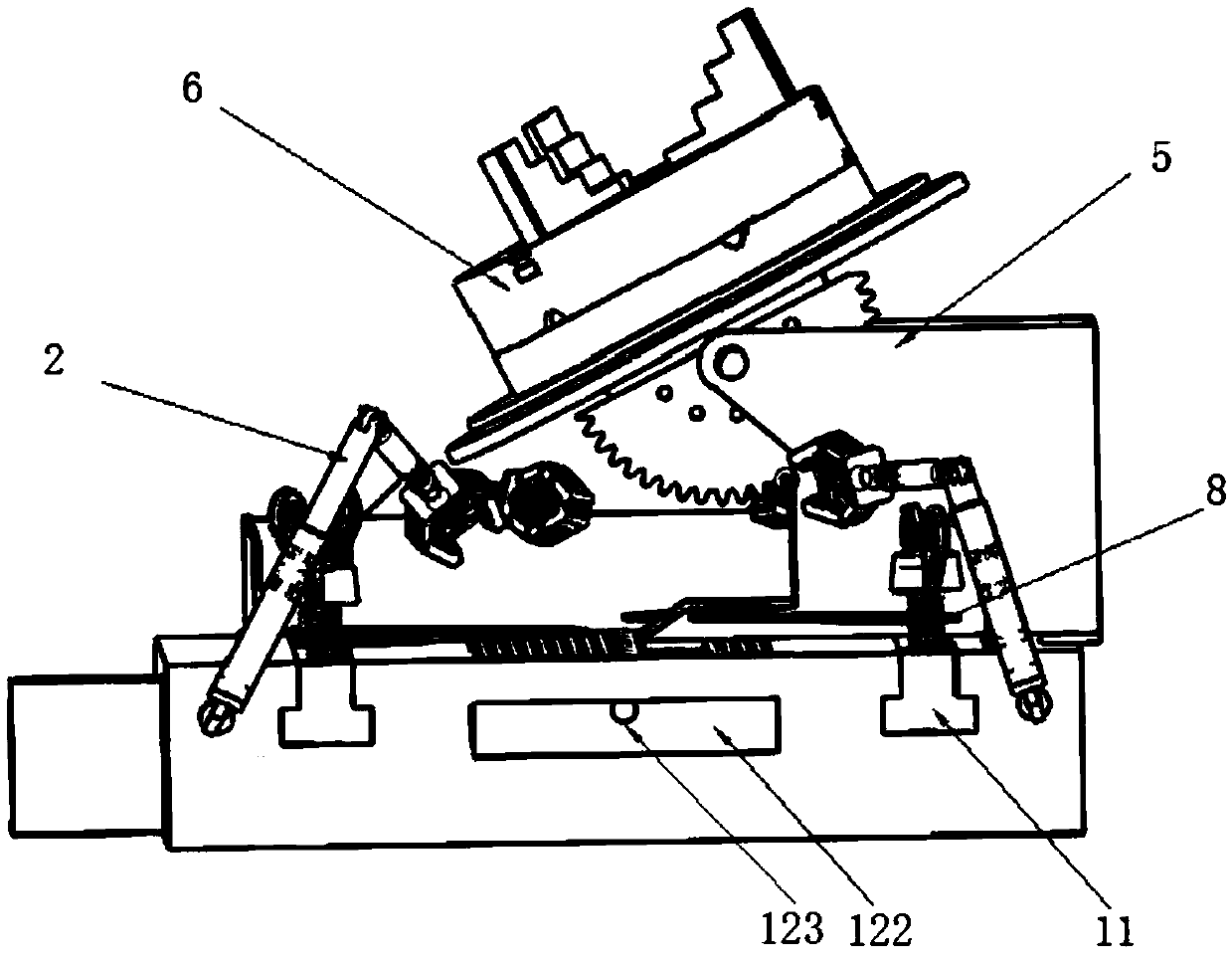

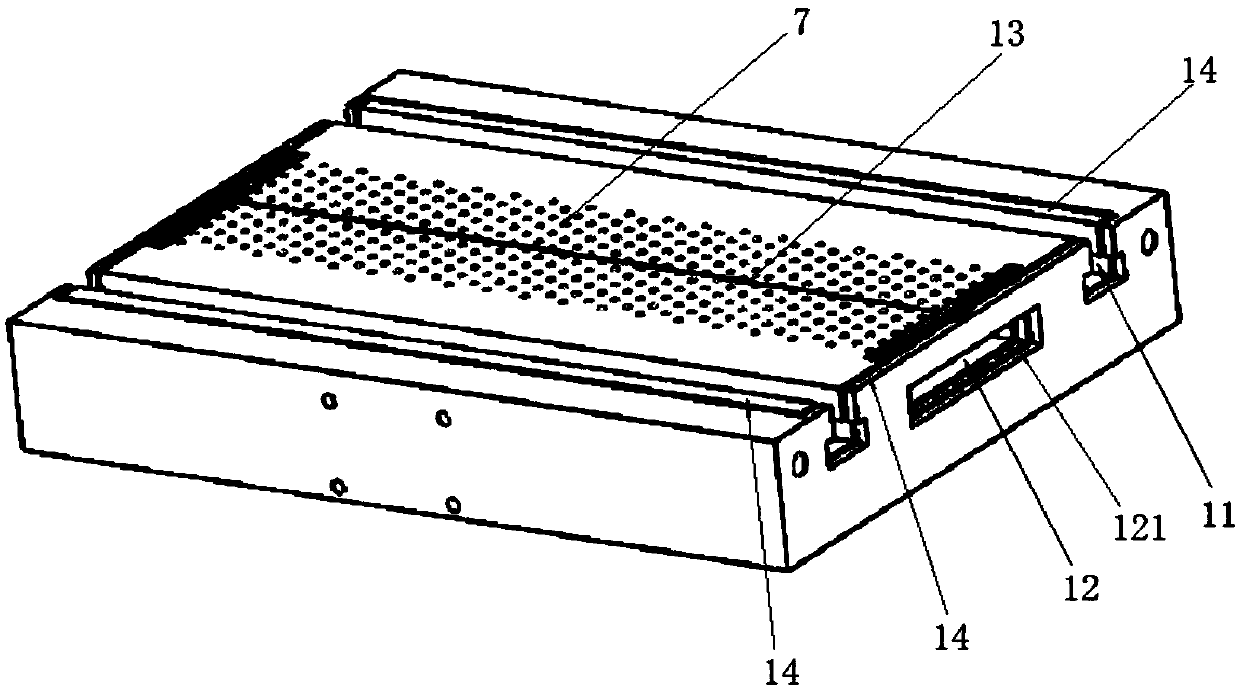

[0029] In this embodiment, a kind of laser remanufacturing multifunctional tooling fixture for thin-walled parts with irregularly curved surfaces of blades, such as Figure 1-2 As shown, it includes a base 1, a mechanical clamping mechanism, a positioner 5, a three-jaw chuck 6 and a pressing device. The three-dimensional size of the base 1 is 50×40×10cm, and the upper surface of the base 1 is surrounded by There are four slots 14 ( image 3 ), which can collect metal powder flying out during processing;

[0030] The central position on the upper surface of the base 2 is provided with a positioning groove 13 ( image 3 ), the groove width is 1mm, and the groove depth is 1mm for positioning during processing;

[0031] The base 1 is provided with an air storage tank 12 ( image 3 ), the three-dimensional size of the air storage tank 12 is 36 × 22 × 6cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com