Screw multifunctional powder feeder

A multi-functional, screw-type technology, applied in the field of laser repair, can solve the problems of high cladding cost, waste of cladding powder, and inconsistency in the spraying area, and achieve the effect of accurate delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

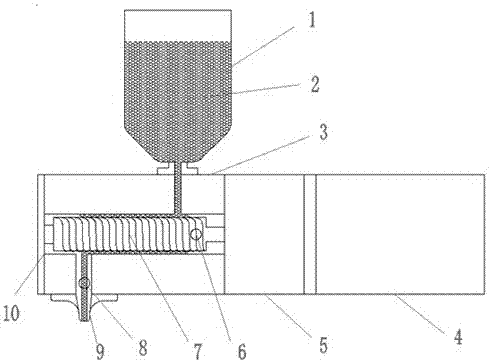

[0021] Such as figure 1 As shown, the screw type multifunctional powder feeder includes a storage bin 1 and a casing 3 for storing cladding powder 2 .

[0022] The storage bin 1 is arranged above the casing 3 . A conveying channel is arranged axially inside the shell 3, and the conveying channel communicates with the storage bin 1, so that the cladding powder 2 loaded in the storage bin 1 can enter into the conveying channel. A screw 7 is arranged axially in the conveying channel, and one end of the screw 7 is sequentially connected to the reducer 5 and the speed-regulating motor 4 arranged on the outer side of the casing 3 .

[0023] In order to facilitate the replacement, maintenance and installation of the screw rod 7, a sealing plate 10 is provided on one side of the housing 3. When the sealing plate 10 is opened, the conveying channel is communicated with the outside world. When the sealing plate 10 is closed, the conveying channel is not communicated with the outside wo...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the powder material outlet funnel 9 is integrally formed with the casing 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com