Engine

A technology for engines and diesel engines, which is applied to engine components, machines/engines, liquid fuel engines, etc. It can solve problems such as increased plunger stuck, carbon deposits in fuel injectors, and temperature differences, achieving simplified assembly and low cost , the effect of cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

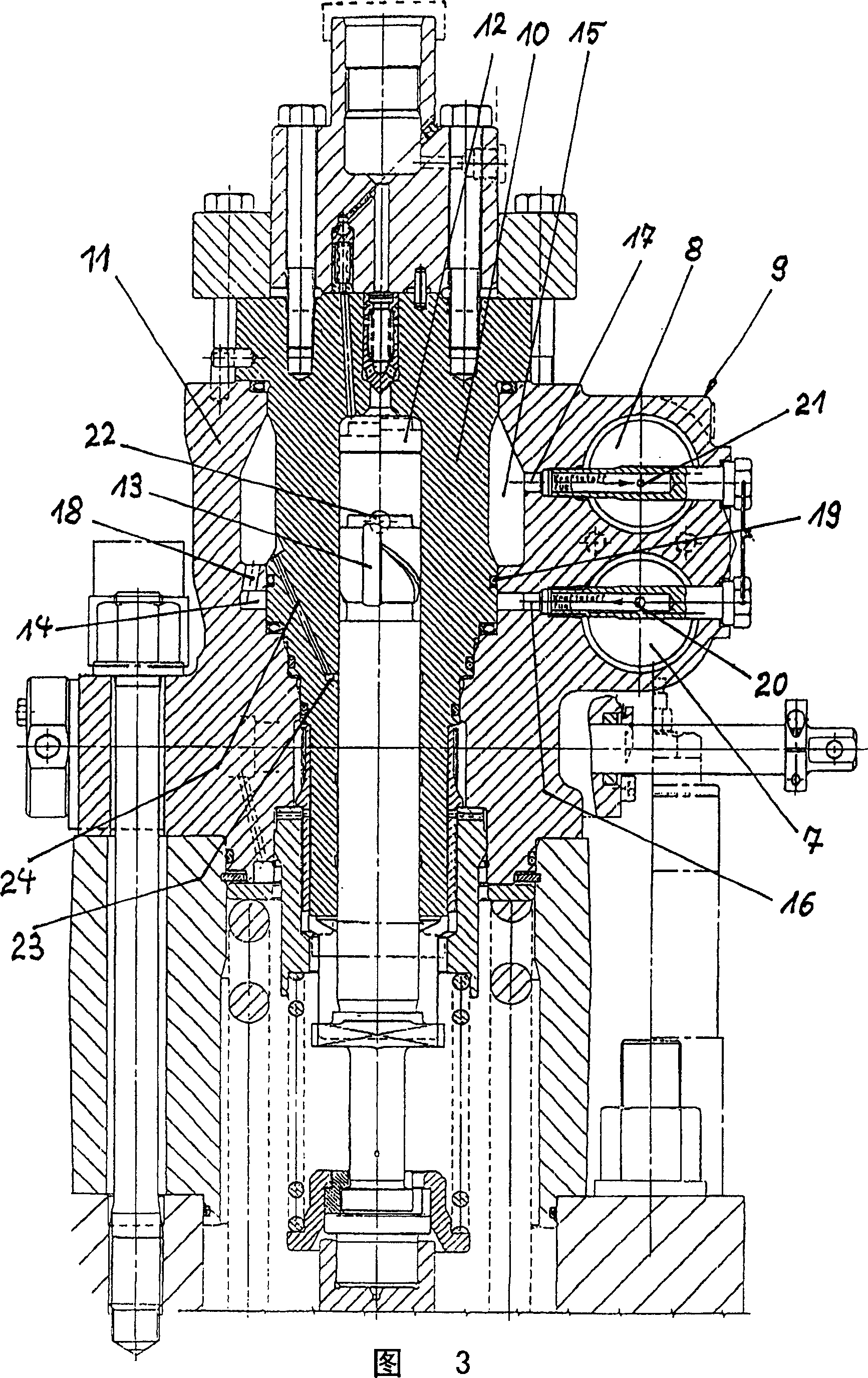

[0015] The main field of application of the invention is large engines with fuel injection pumps, such as large diesel engines, which are used, for example, in ship drives or power plant drives or the like. The basic construction and operating principle of such devices are known per se.

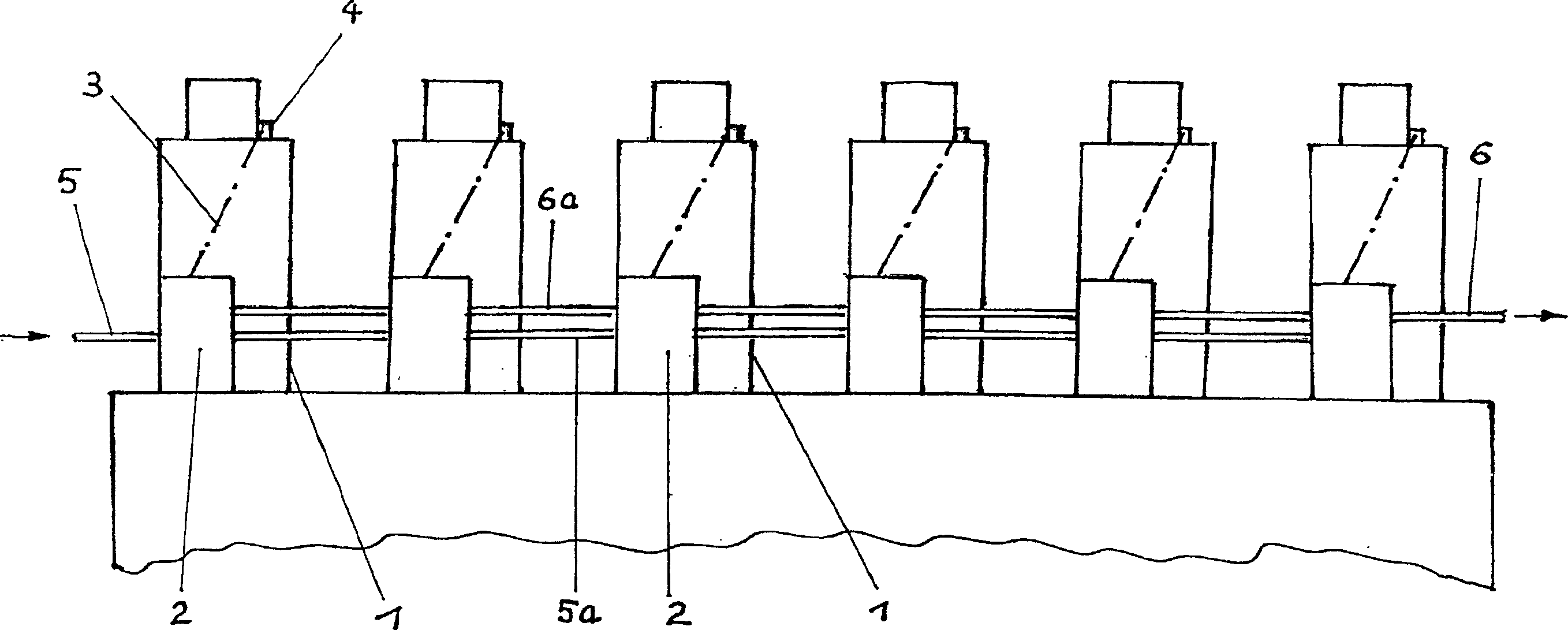

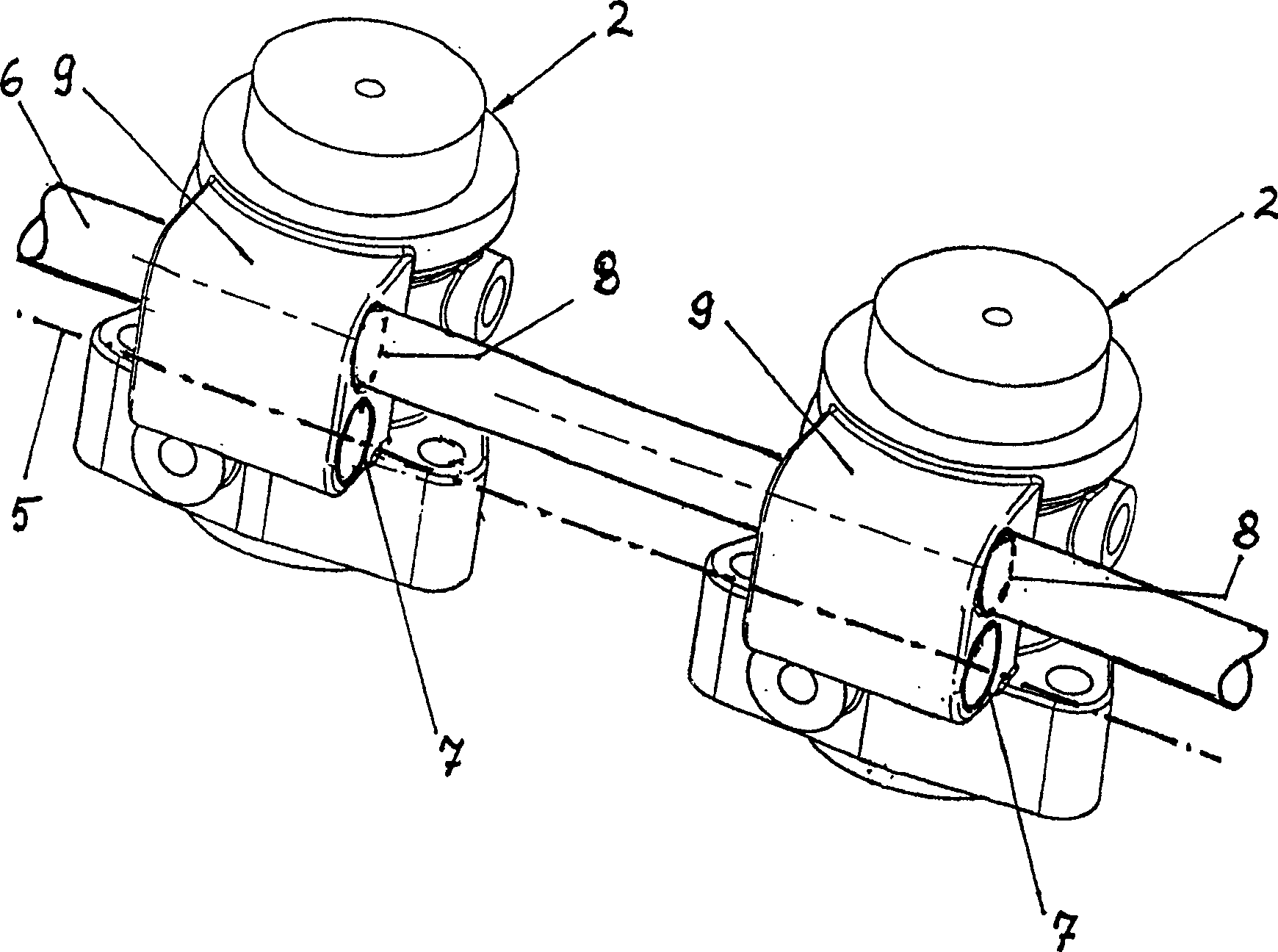

[0016] figure 1 The large diesel engine shown comprises a plurality (here six) of cylinders 1 arranged one behind the other in a row, each of which is associated with an injection pump 2 . The fuel injection pumps 2 assigned to the cylinder 1 are likewise arranged one behind the other. From each fuel injection pump 2 , a fuel injection line 3 leads to at least one respectively associated fuel injector 4 .

[0017] The fuel injection pumps 2 arranged one behind the other are supplied with fuel via a fuel supply line 5 which runs through the entire pump row. Excess fuel is discharged via a discharge line 6 which also runs through the entire pump train. The fuel supply line 5 originates from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com