Cam-driven feed yogurt additive spraying device for meat and poultry breeding

A spraying device and additive technology, applied in the forming or processing of animal feed, animal feed, feed, etc., can solve the problems of uneven spraying, coated feed, large yogurt, etc., to improve the coating quality, coating uniformity, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

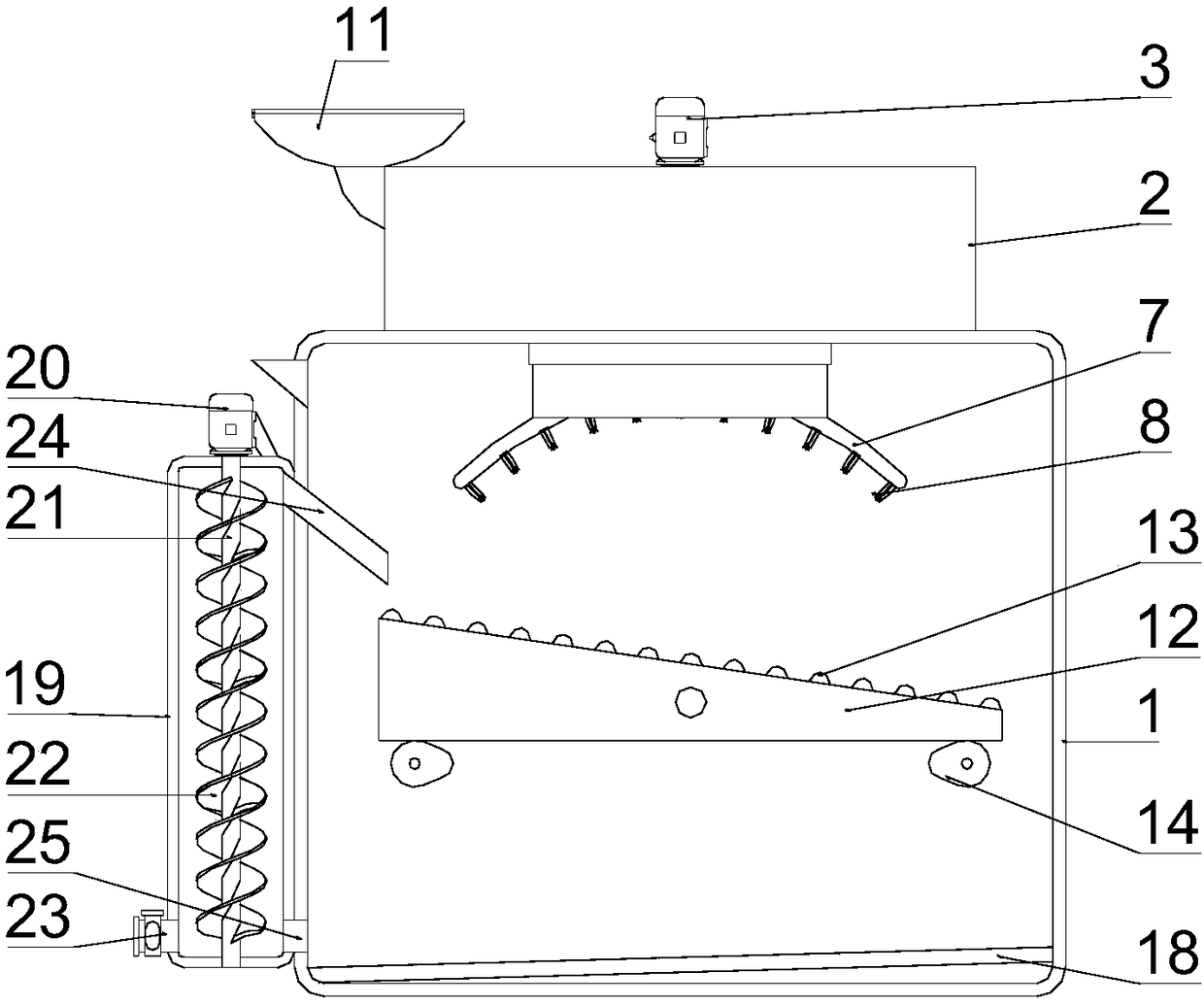

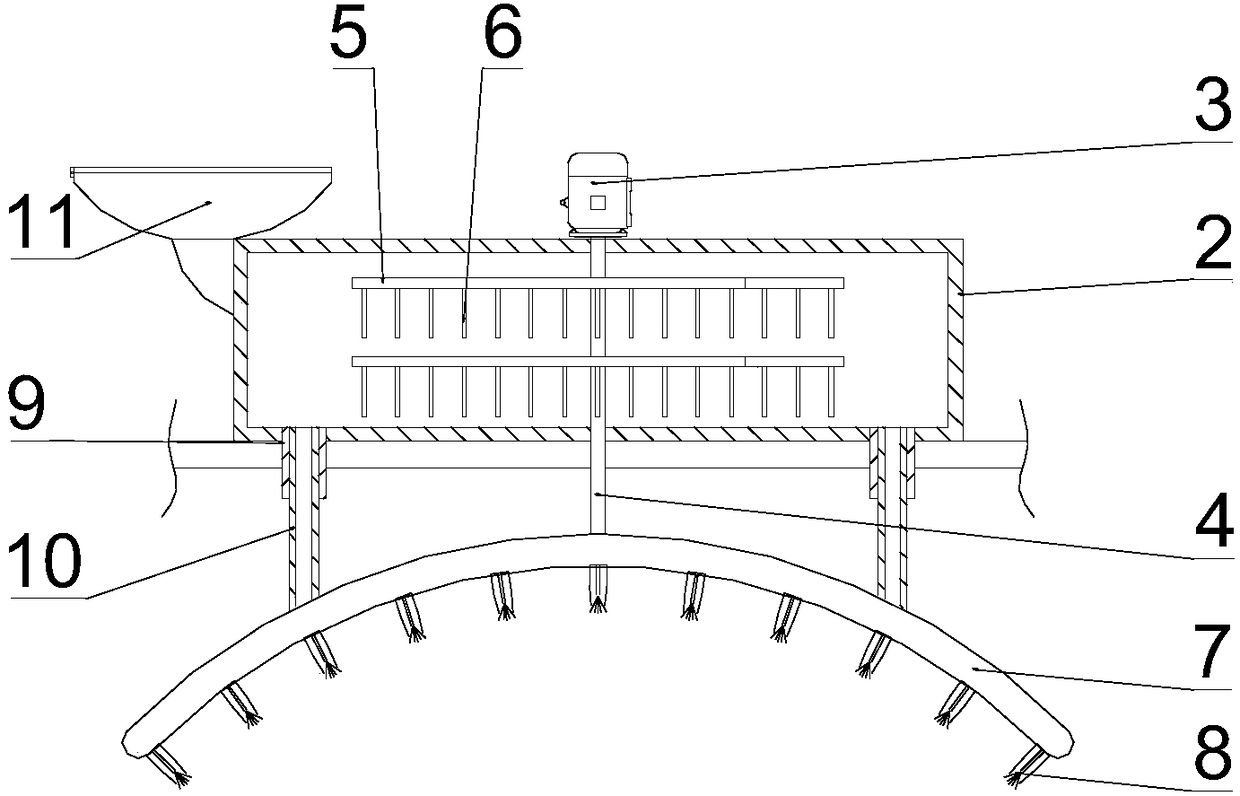

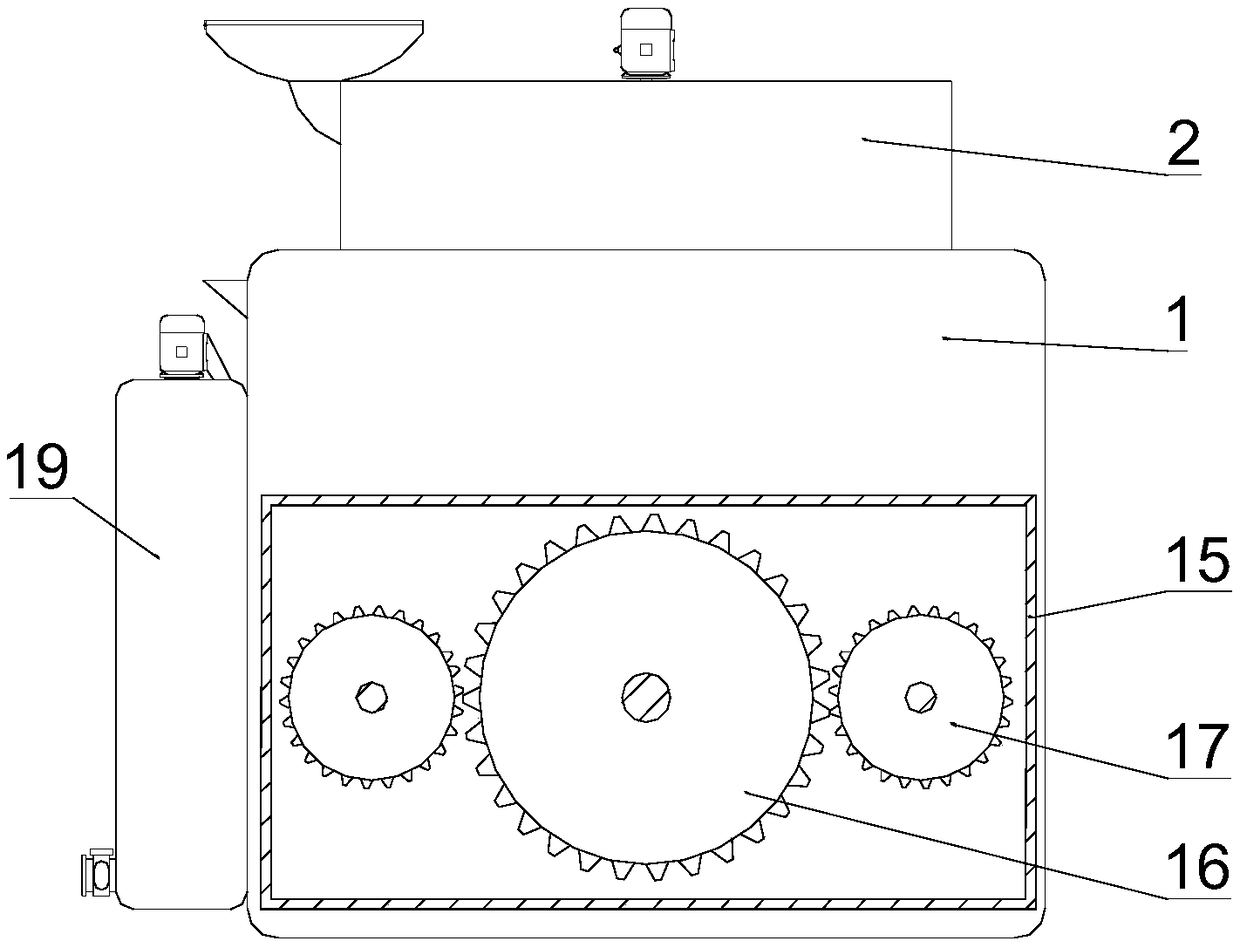

[0025] See Figure 1-4 , A cam-driven feed yogurt additive spraying device for meat and poultry breeding, comprising a casing 1, an additive mixing box fixedly connected to the upper part of the casing 1, a circulating blanking device installed on the left side of the casing 1, and a The blanking table 12 inside the body 1, the additive mixing box 2 is provided with a rotating shaft 4, an elastic mixing mechanism is installed on the rotating shaft 4, the rotating shaft 4 is rotatably connected with the upper and lower side walls of the additive mixing box 2, and the rotating shaft 4 extends The upper and lower sides of the additive mixing box 2 are installed. The additive mixing box 2 is equipped with a first motor 3, and the output end of the first motor 3 is fixedly connected with the rotating shaft 4, and the inner upper side of the housing 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com