Casting method for inhibiting bottom crack of ingot

An ingot and crack technology, applied in the field of aluminum alloy semi-continuous casting, can solve problems such as troublesome operation, achieve the effect of inhibiting cracking, reducing internal stress value and avoiding cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

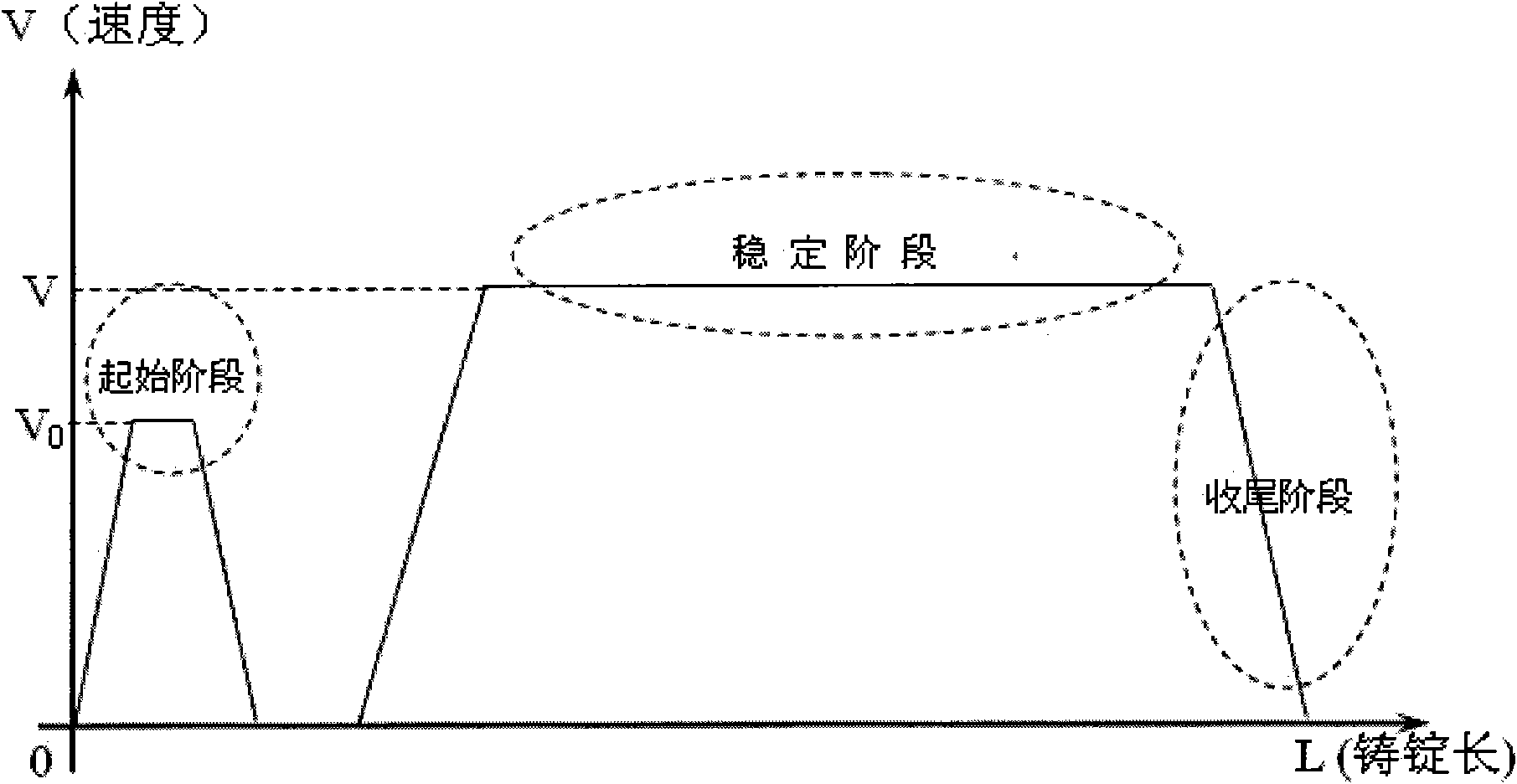

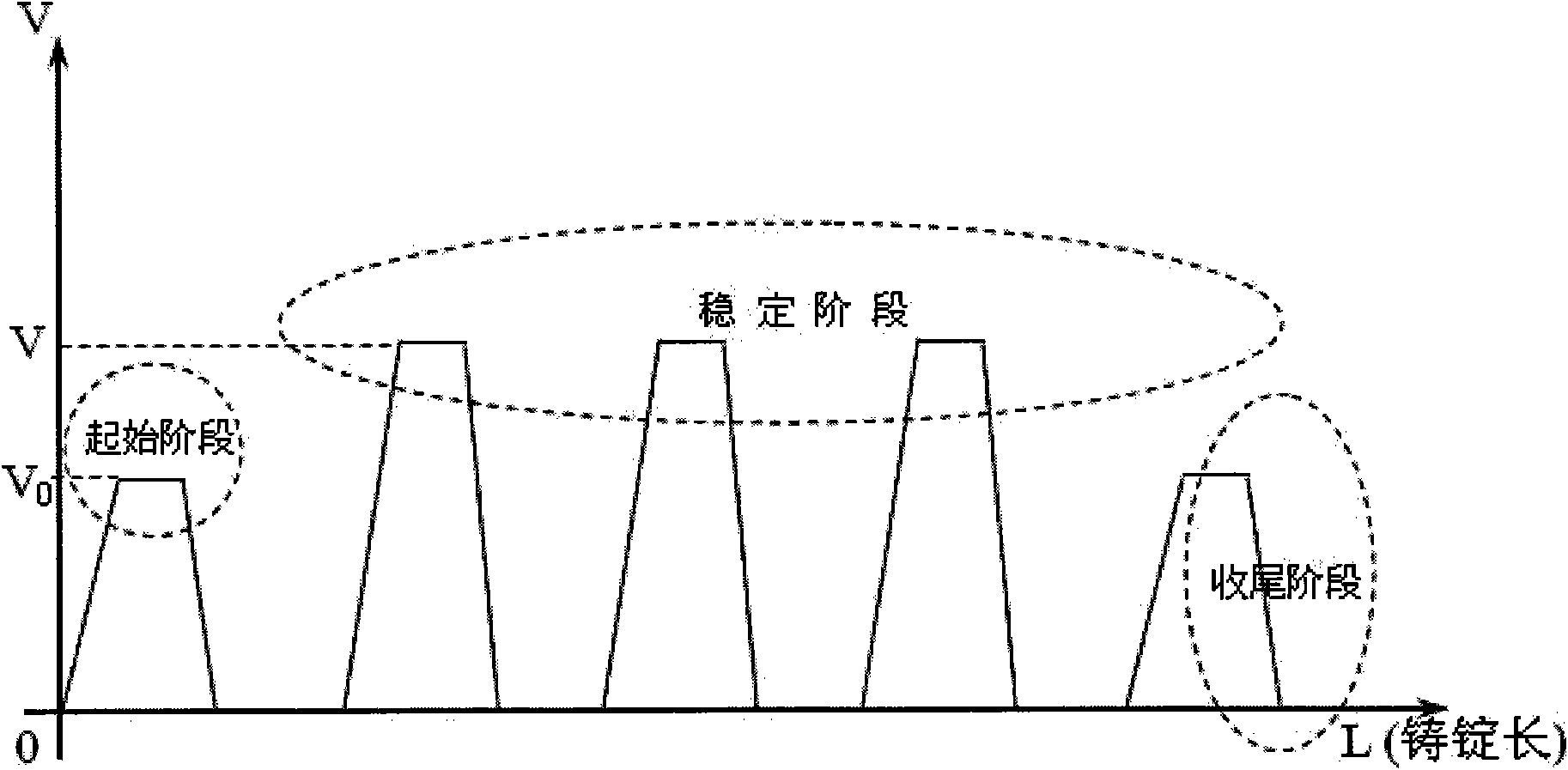

[0016] Aluminum alloy semi-continuous casting process generally includes three stages:

[0017] 1) The initial stage of casting: the aluminum alloy melt slowly flows into the casting mold composed of the crystallizer and the dummy ingot base through the launder, and solidifies under the joint cooling of the dummy ingot base and the inner wall of the crystallizer to form a thin metal shell. When the metal shell is strong enough to support the liquid metal, the dummy base is lowered, the solidified metal surface contacts the cooling water in the mold, and the semi-continuous casting process begins;

[0018] 2) Stable casting stage: At this stage, the casting process is carried out stably according to the requirements of alloy ingot casting. The casting machine continuously decreases according to the set value of casting speed, and the cooling water changes linearly with the casting speed according to the set process. The liquid level remains unchanged, and the melt temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com