Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

296 results about "End stages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

End stage: The last phase in the course of a progressive disease. As in end-stage liver disease, end-stage lung disease, end-stage renal disease, end-stage cancer, etc. The term "end stage" has come to replace "terminal".

Visual and inertial navigation fusion SLAM-based external parameter and time sequence calibration method on mobile platform

ActiveCN109029433AReduce mistakesExcellent trajectory accuracyNavigational calculation instrumentsNavigation by speed/acceleration measurementsEnd stagesVision based

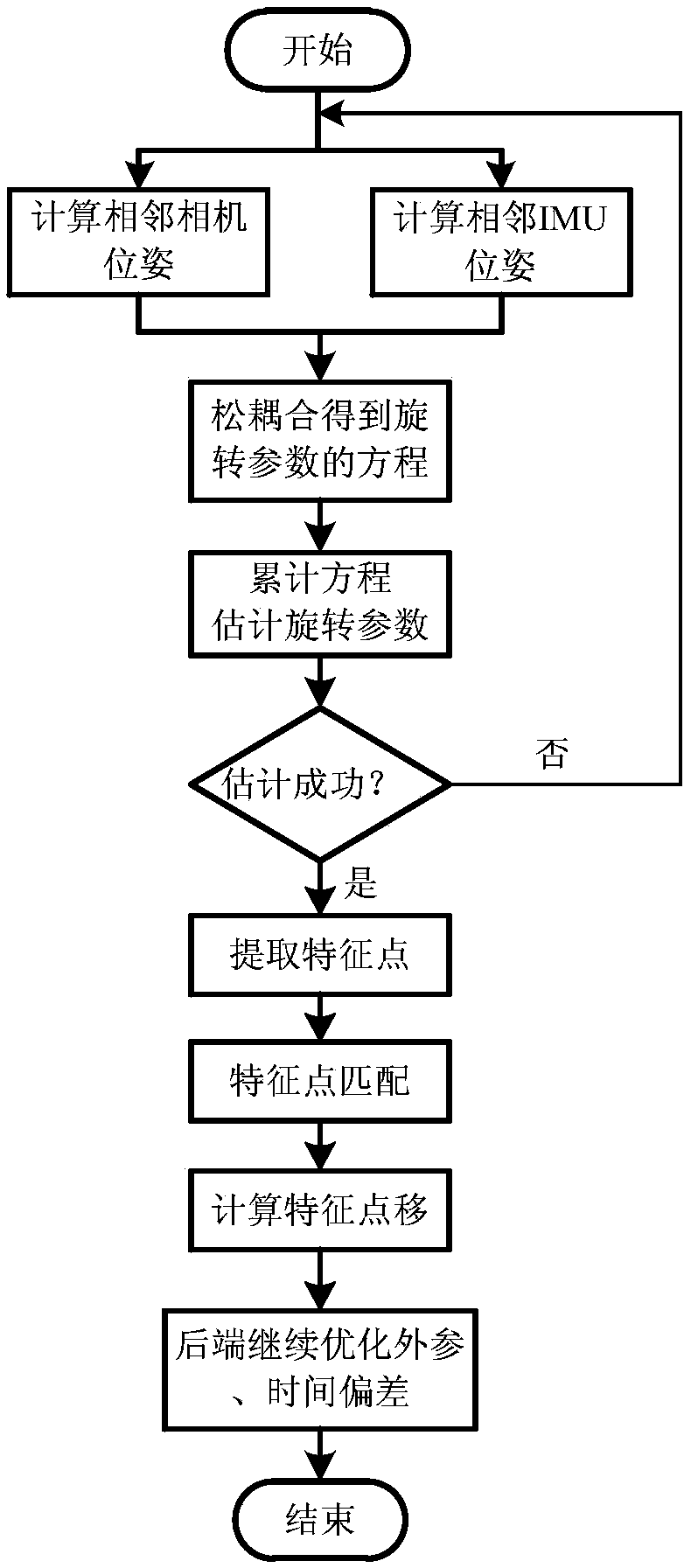

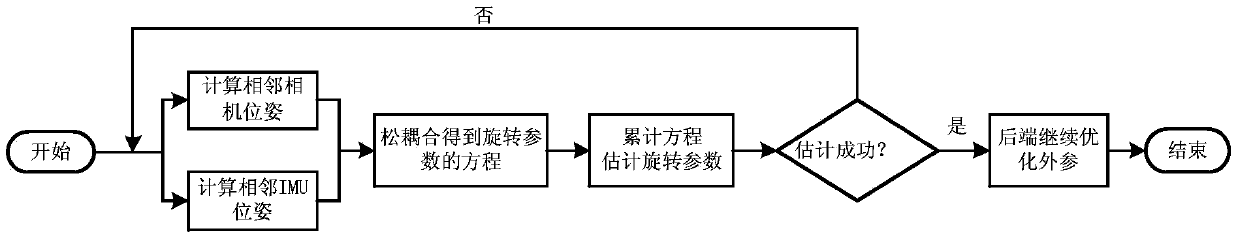

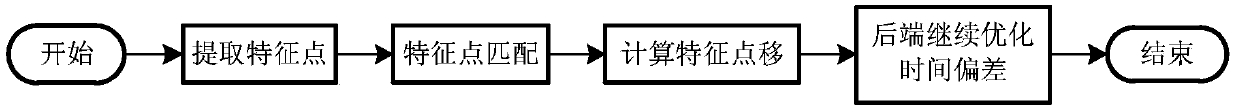

The invention discloses a visual and inertial navigation fusion SLAM-based external parameter and time sequence calibration method on a mobile platform. The method comprises an initialization stage, wherein the relative rotation parameters between two frames estimated by a camera and an IMU are aligned through a loosely-coupled method, and the relative rotation parameters of the camera and the IMUare estimated and obtained; a front-end stage, wherein the front end completes the function of a visual odometer, namely, the pose of the current frame of the camera in the world coordinate system isgenerally estimated according to the pose of the camera in the world coordinate system estimated in the former several frames, and the estimated value serves as an initial value of back-end optimization; a back-end stage, wherein some key frames are selected from all the frames, variables to be optimized are set, a uniform objective function is established, and optimization is carried out according to the corresponding constraint conditions, and therefore, accurate external parameters are obtained. By adoption of the method disclosed by the invention, the error of the estimated external parameters is relatively low, and the precision of the time sequence calibration track is high.

Owner:SOUTHEAST UNIV

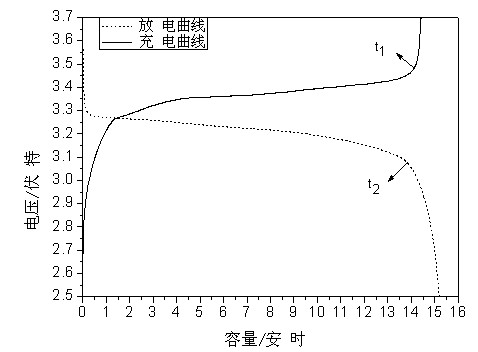

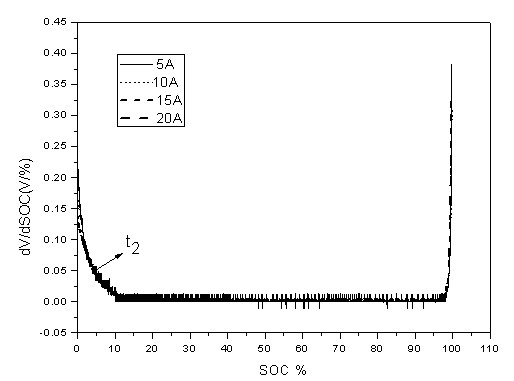

Self-correction method for remaining capacity estimation of lithium iron phosphate power battery

ActiveCN102540096AIncrease cumulative errorAvoid hard-to-define problemsElectrical testingPower batteryEnd stages

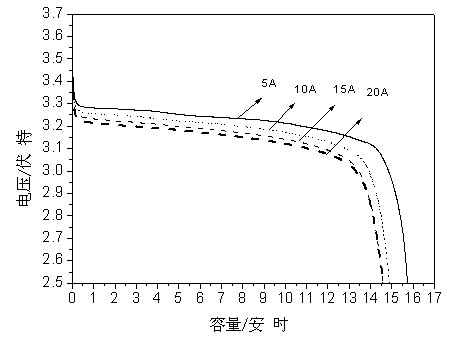

The invention discloses a self-correction method for remaining capacity estimation of a lithium iron phosphate power battery. The conventional method cannot meet national standard well. According to the self-correction method disclosed by the invention, compensation and correction are performed on the basis of estimating the remaining capacity of the lithium iron phosphate power battery by using an ampere-hour method; and according to the characteristic that voltage of the lithium iron phosphate power battery abruptly changes at the end stage of charging or discharging, the actual remaining capacity SOC (State Of Charge) is corrected when dV / dSOC' is detected to be greater than or equal to 0.05, so that accumulative estimation error existing during independent use of the ampere-hour method is reduced. The self-correction method is based on the ampere-hour method, is simple and easy and is easier to apply and generalize. Meanwhile, the invention also provides a calculation method of aging rate gamma. By continuously updating the aging rate, the error for estimation by using the ampere-hour method is reduced again.

Owner:ZHEJIANG UNIV

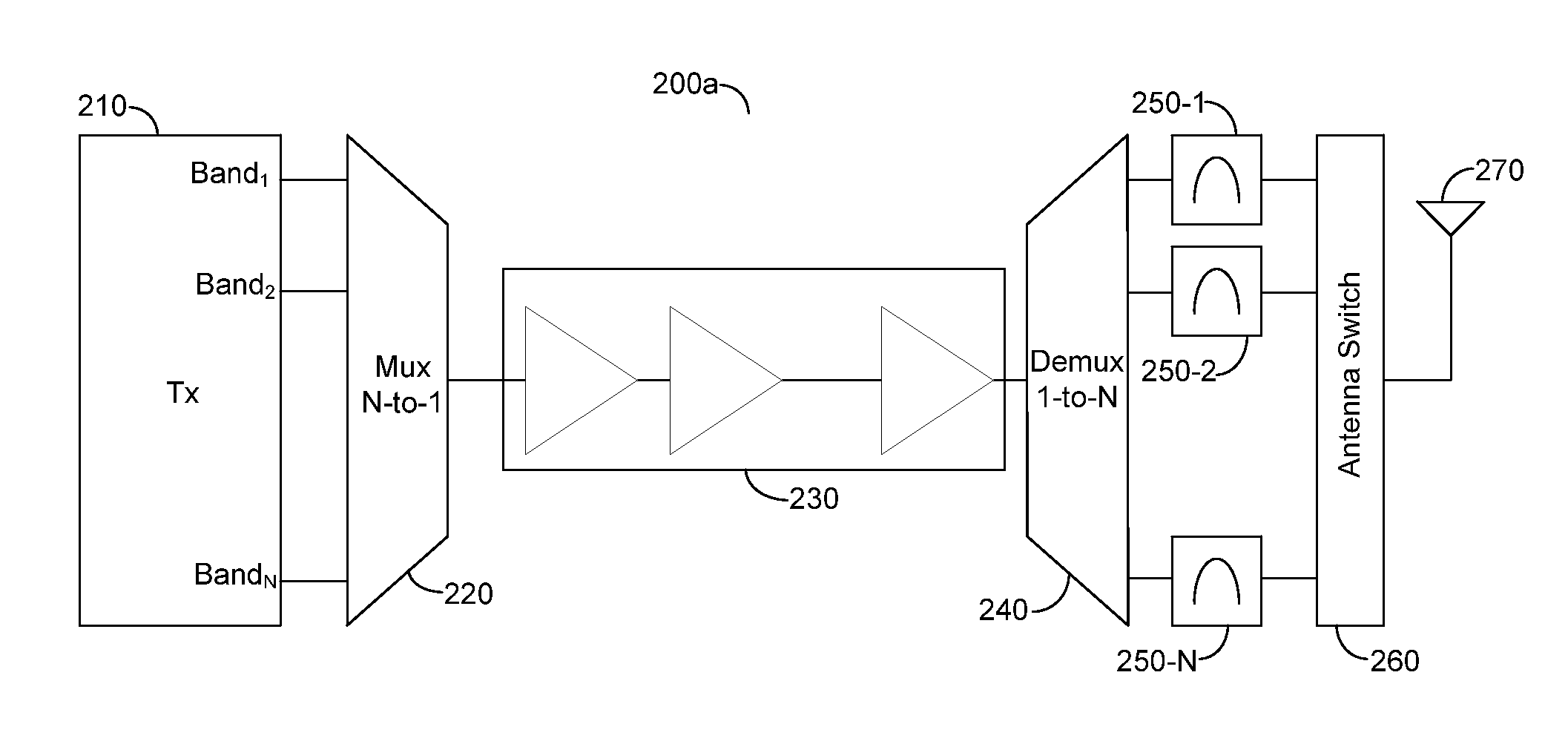

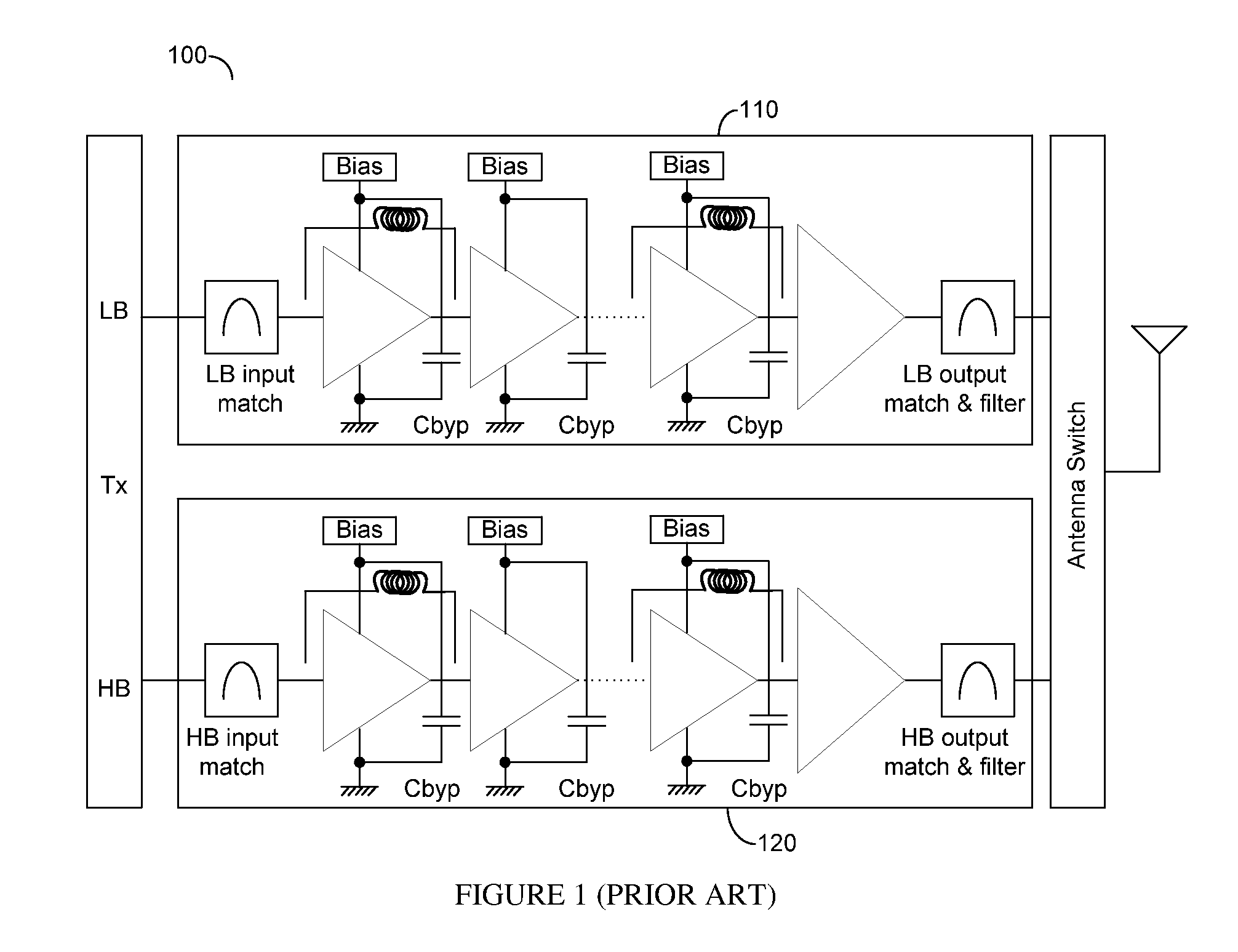

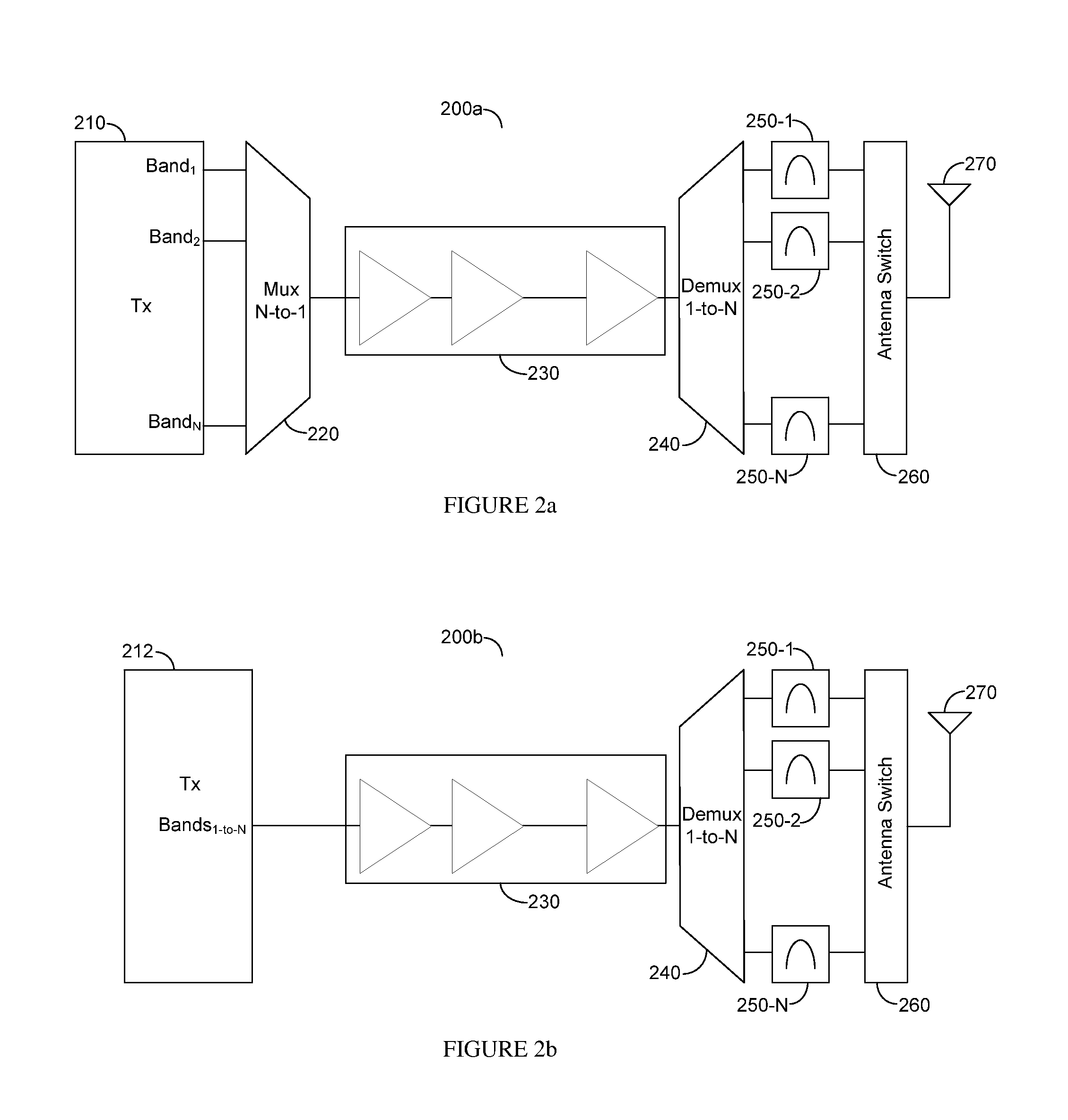

Multi-Band/Multi-Mode Power Amplifier with Signal Path Hardware Sharing

ActiveUS20140015603A1Amplifier modifications to reduce noise influencePower amplifiersMulti bandEnd stages

Existing multi-band / multi-mode (MB / MM) power amplifiers (PAs) use separate signal paths for the different covered frequency bands. This results in a large degree of hardware duplication and to a large die size and cost. Solutions that achieve hardware sharing between the different signal paths of MB / MM PAs are shown. Such sharing includes bias circuit and bypass capacitors sharing, as well as sharing front-end stages and the output stage of the PA. Signal multiplexing may be realized in the transmitter or at the PA front-end while the signal de-multiplexing can be realized either in the PA output stage or at the front-end of the output stage. Such circuits can be applied with saturated and linear MB / MM PAs with adjacent or non-adjacent bands.

Owner:QORVO INT PTE LTD

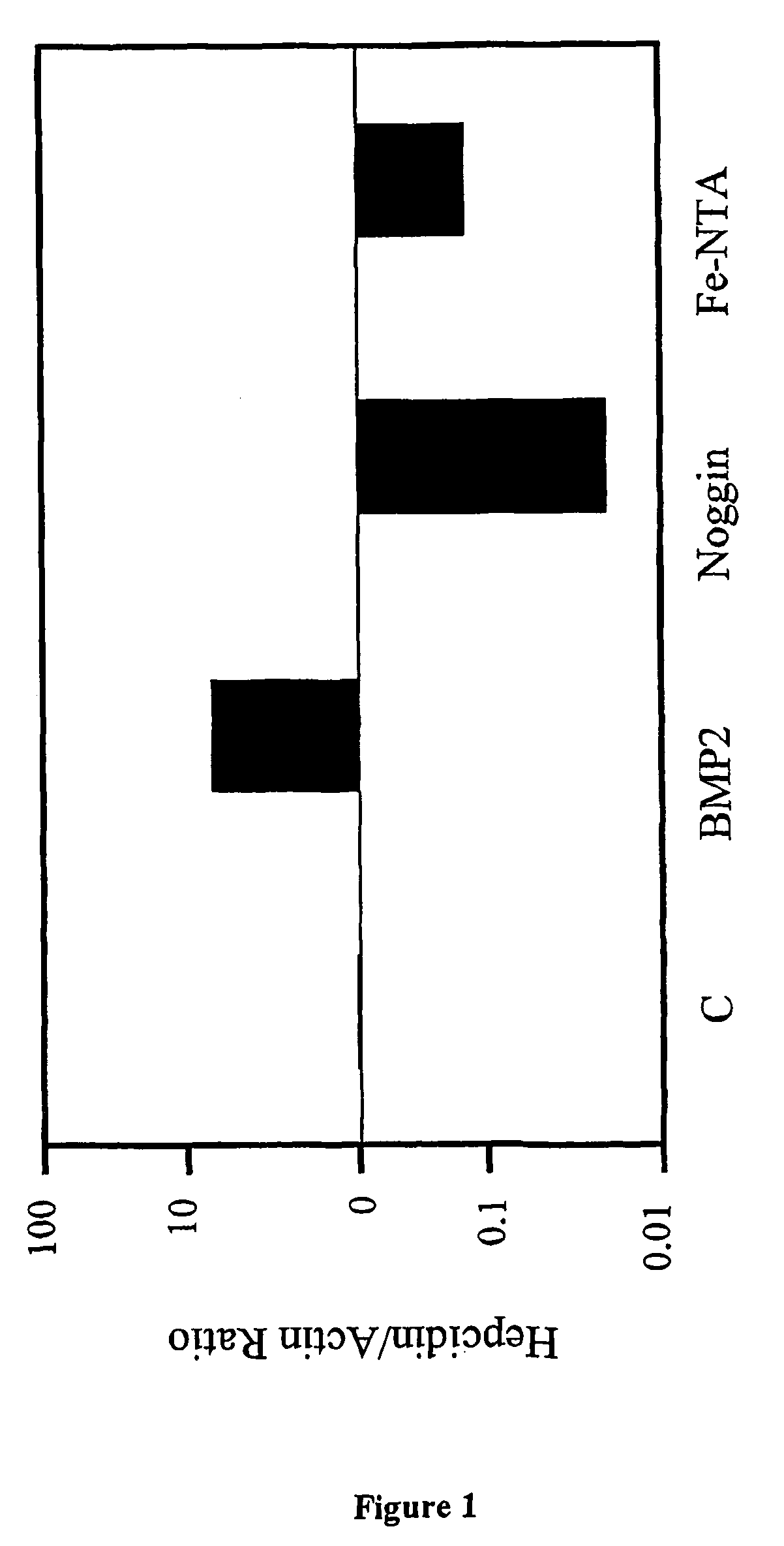

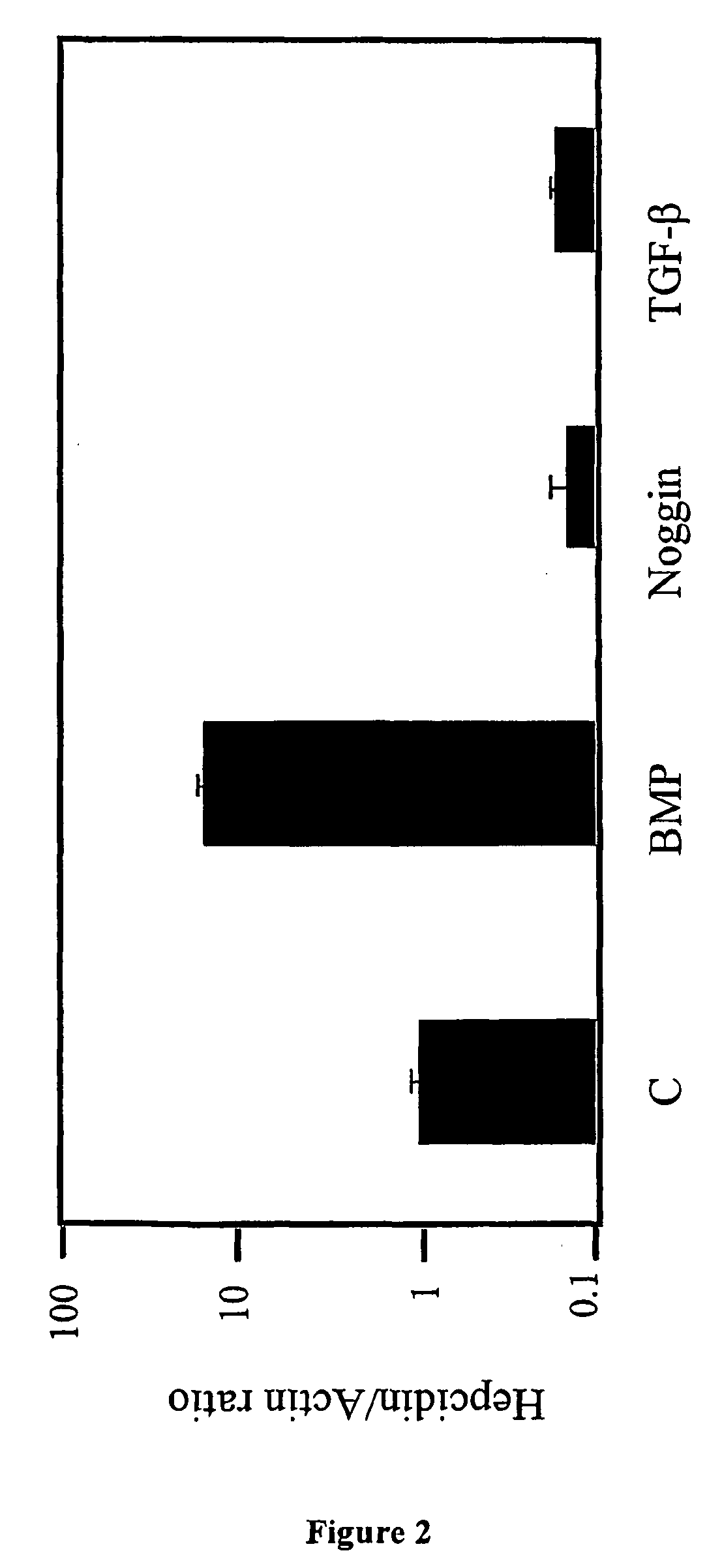

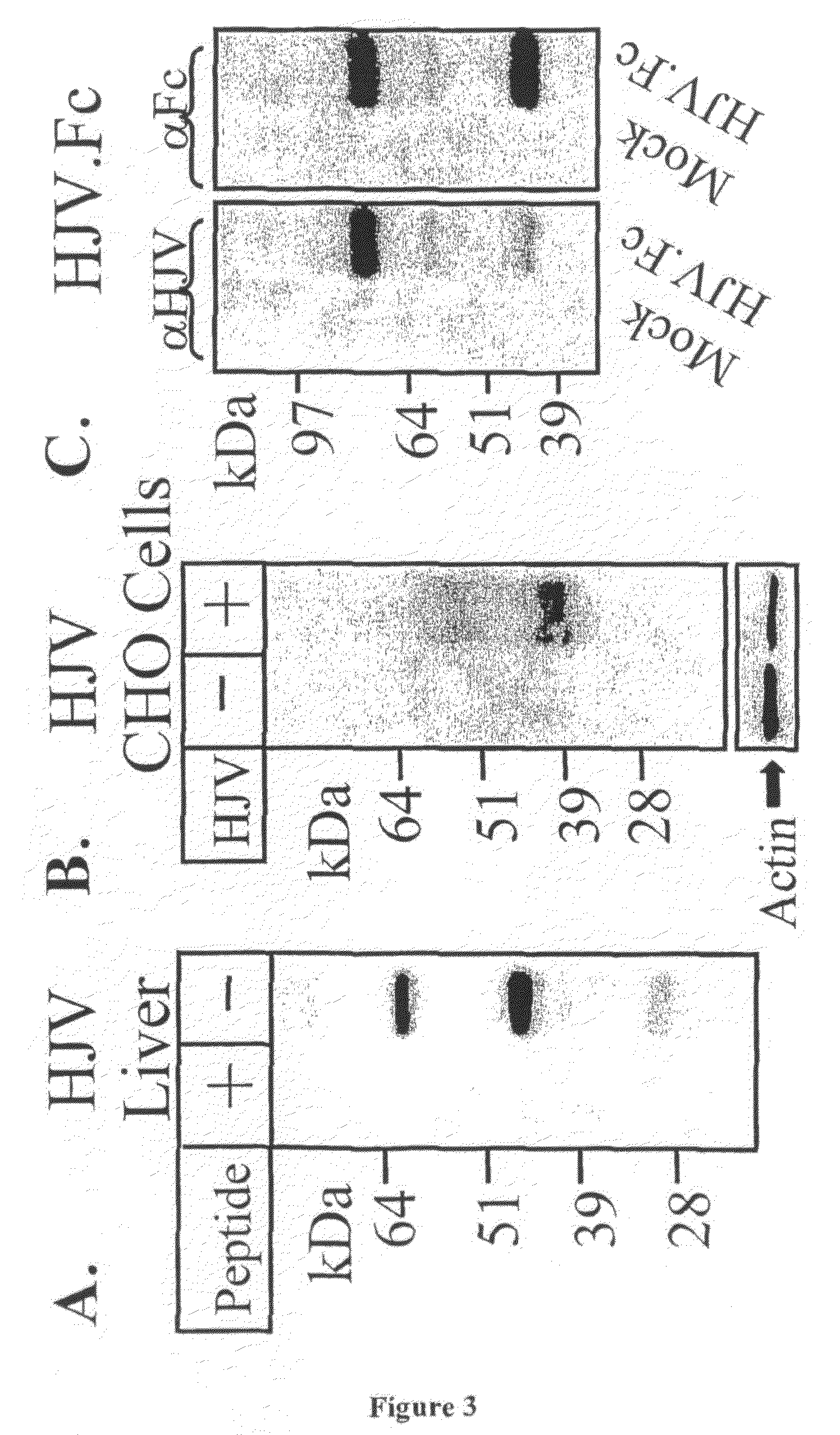

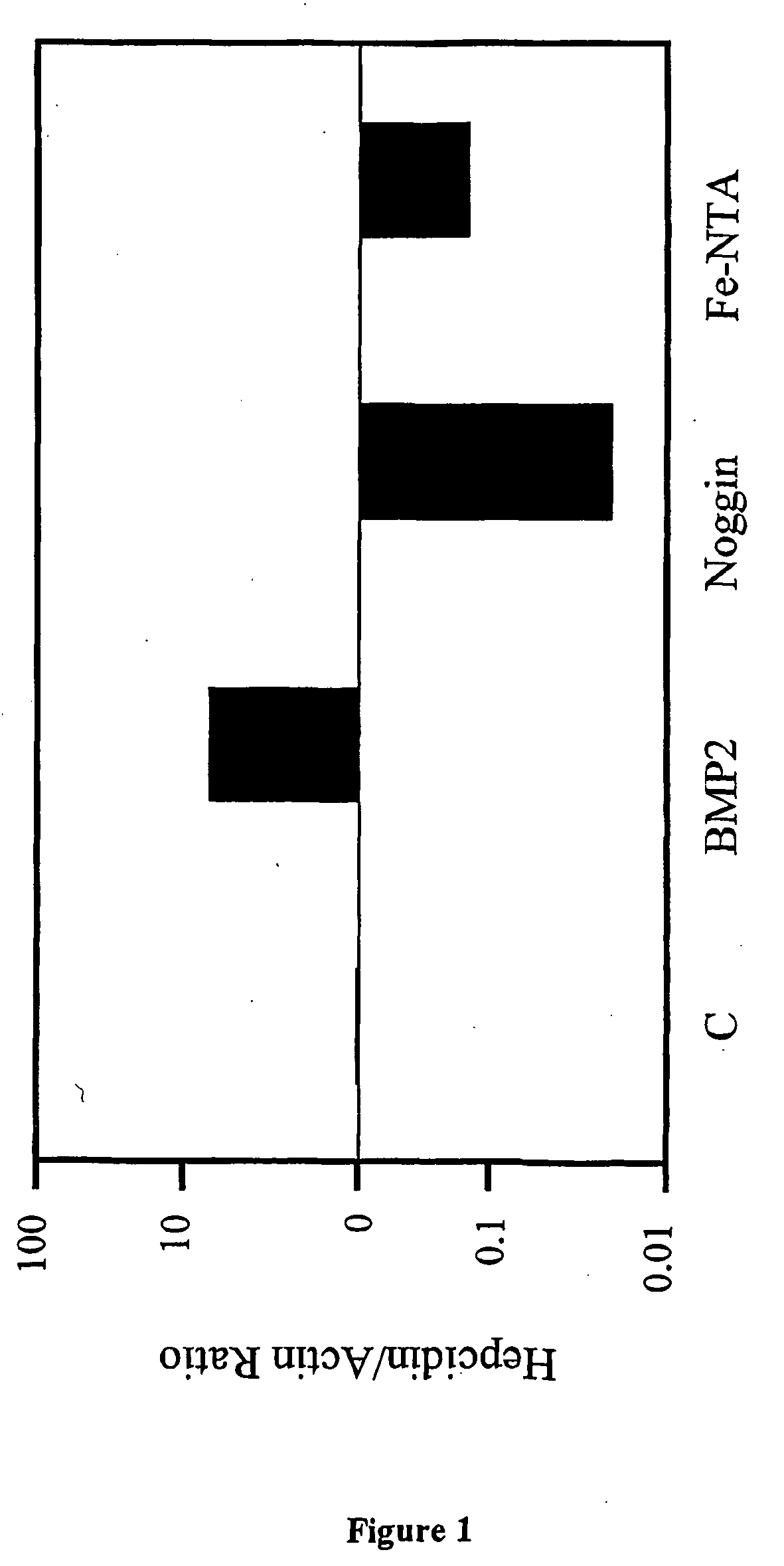

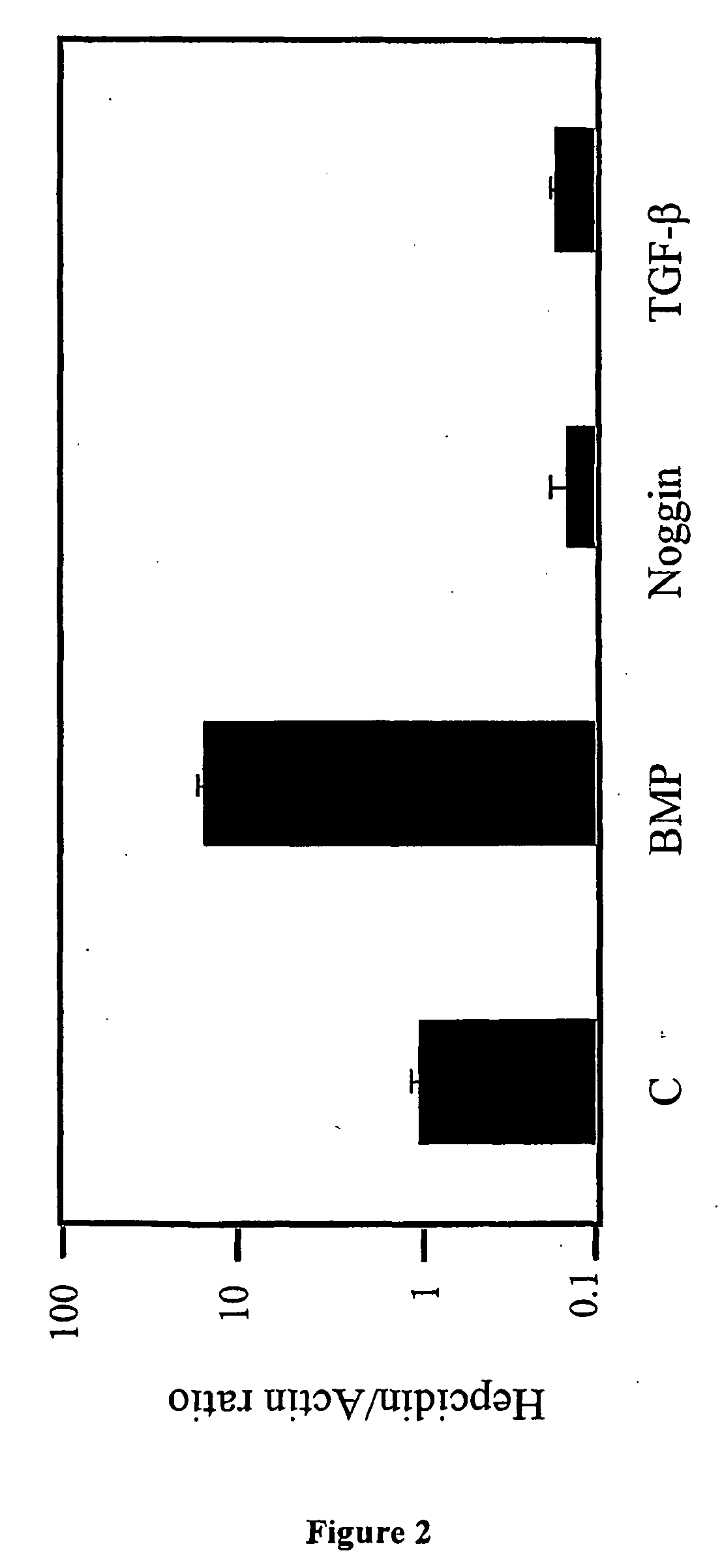

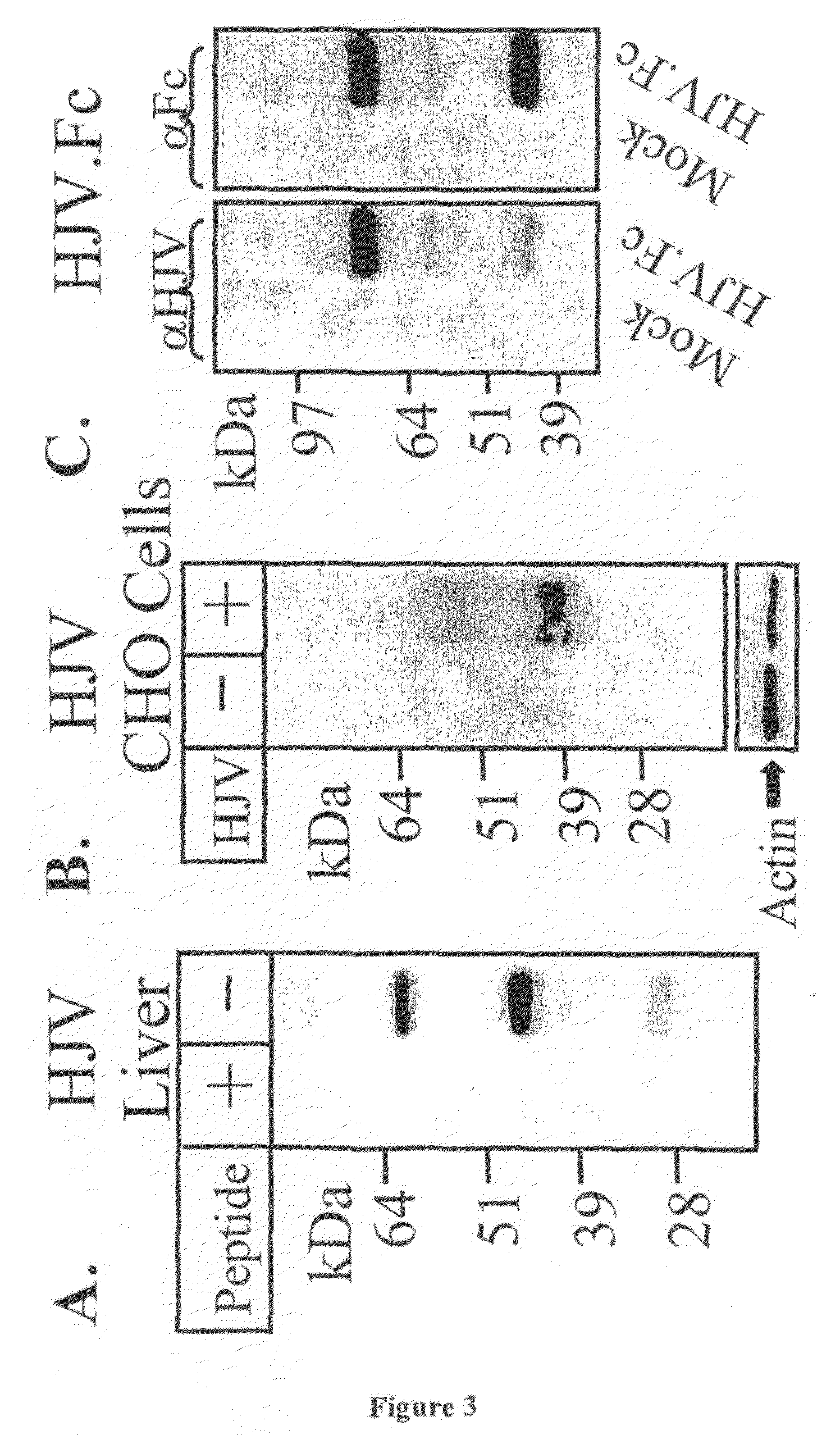

Methods and compositions to regulate iron metabolism

ActiveUS7968091B2Less likely to induce undesirable side-effectsAntibacterial agentsPeptide/protein ingredientsDiseasePhysiology

The present invention provides new systems and strategies for the regulation of iron metabolism in mammals. In particular, methods of using agonists and antagonists of TGF-β superfamily members to modulate the expression or activity of hepcidin, a key regulator of iron metabolism, are described. The inventive methods find applications in the treatment of diseases associated with iron overload, such as juvenile hemochromatosis and adult hemochromatosis, and in the treatment of diseases associated with iron deficiency, such as anemia of chronic disease and EPO resistant anemia in end-stage of renal disease. The present invention also relates to screening tools and methods for the development of novel drugs and therapies for treating iron metabolism disorders.

Owner:THE GENERAL HOSPITAL CORP

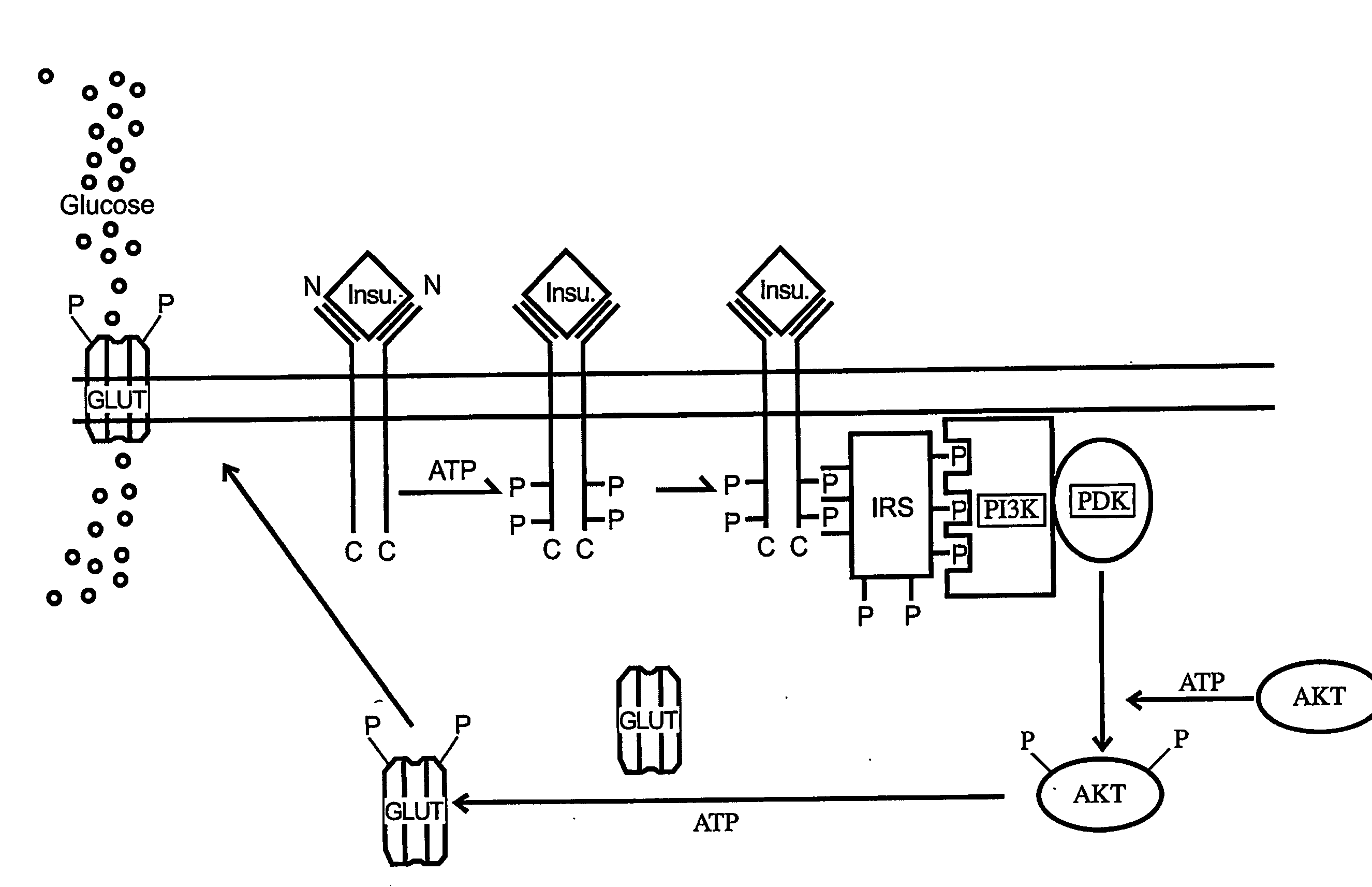

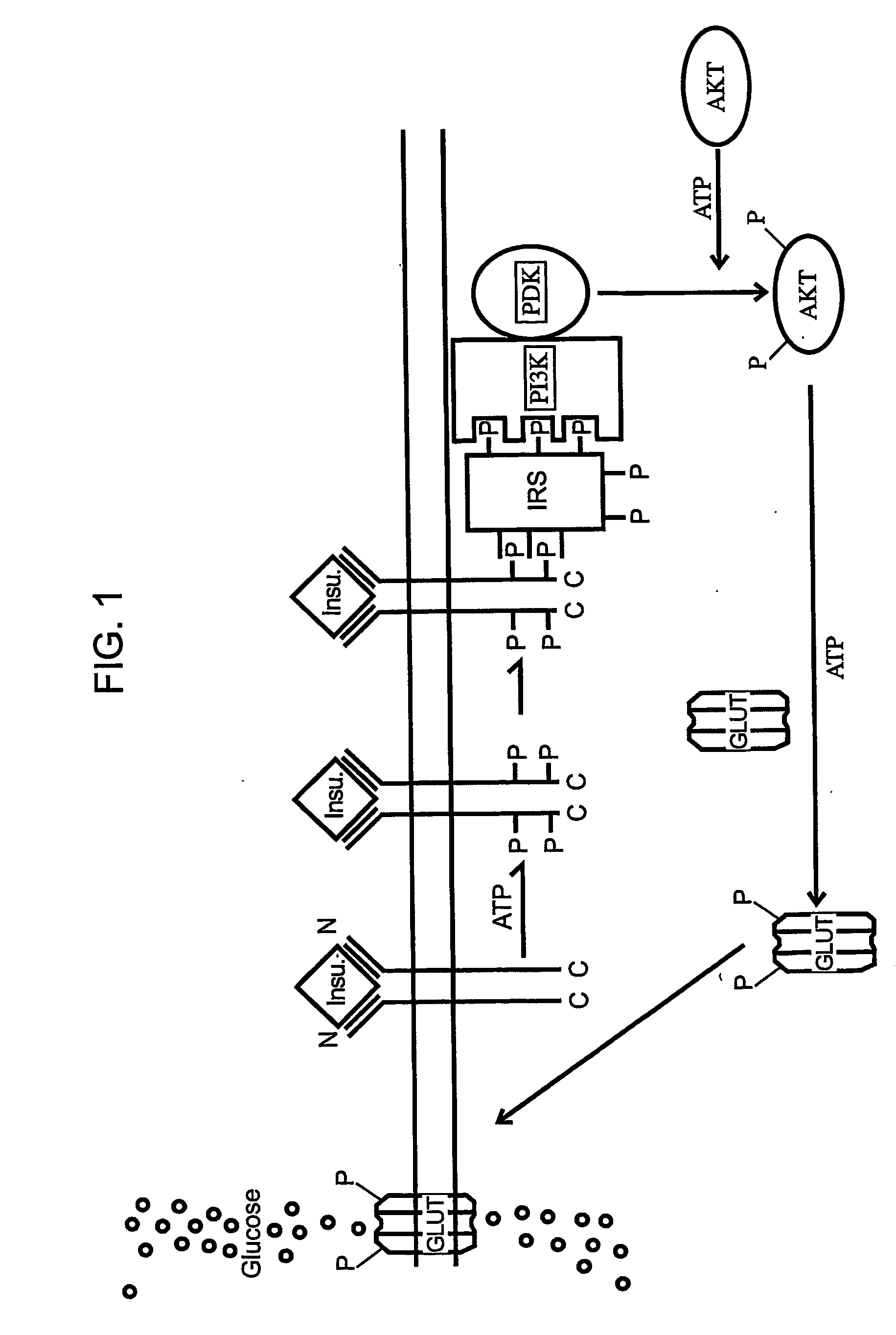

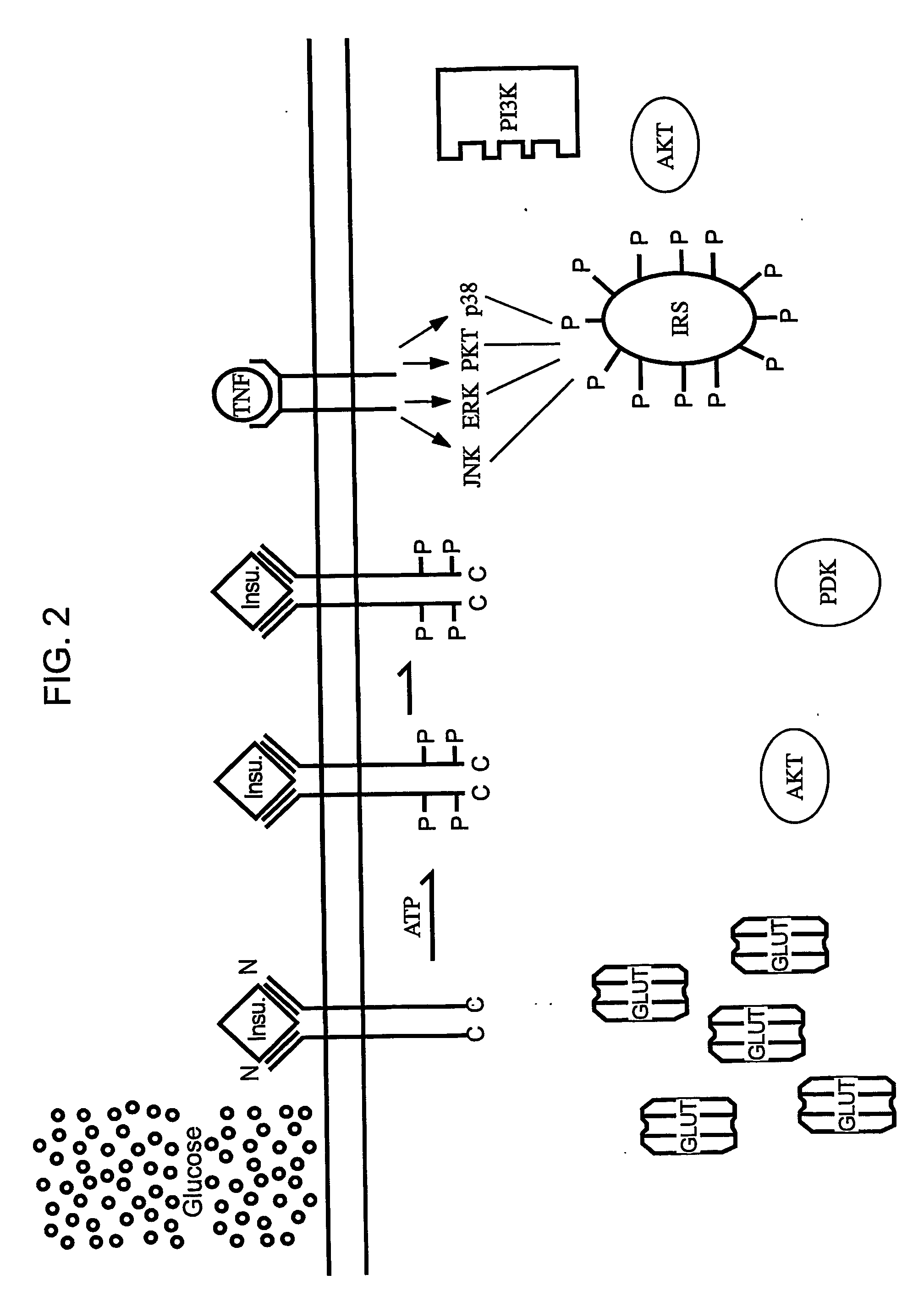

Methods of Treating Tnf-Mediated Disorders

The present invention provides methods of treating TNF-α-mediated disorders, the methods generally involving administering to an individual in need thereof effective amounts of pirfenidone or a pirfenidone analog and a second therapeutic agent that reduces TNF-α synthesis or that reduces TNF-α binding to a TNF receptor. The present invention further provides methods for treating non-alcoholic steatohepatitis, the method generally involving administering to an individual in need thereof an effective amount of pirfenidone. The present invention further provides methods of treating end-stage or advanced Type II diabetes, the methods generally involving administering to an individual in need thereof effective amounts of pirfenidone and insulin.

Owner:INTERMUNE INC

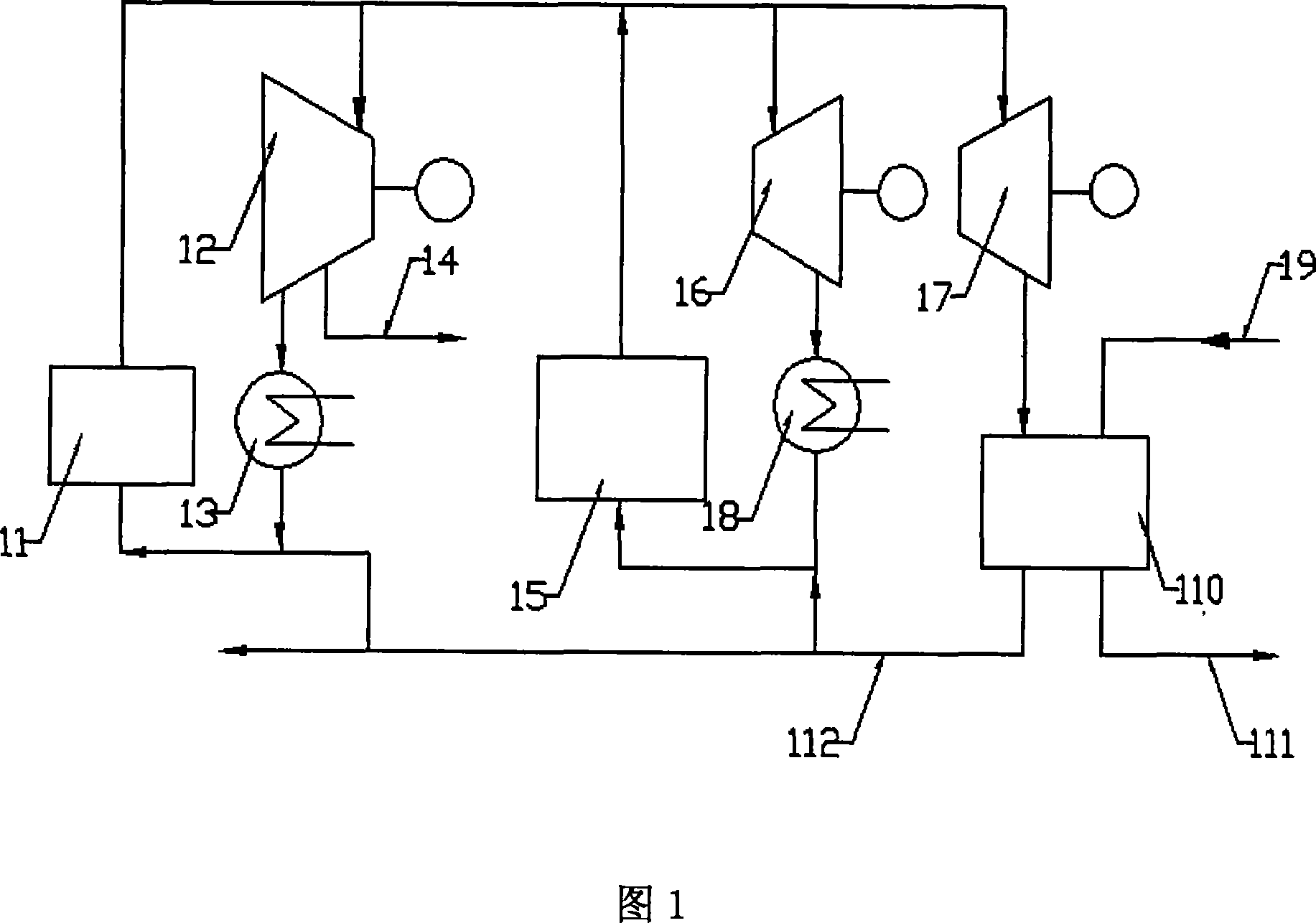

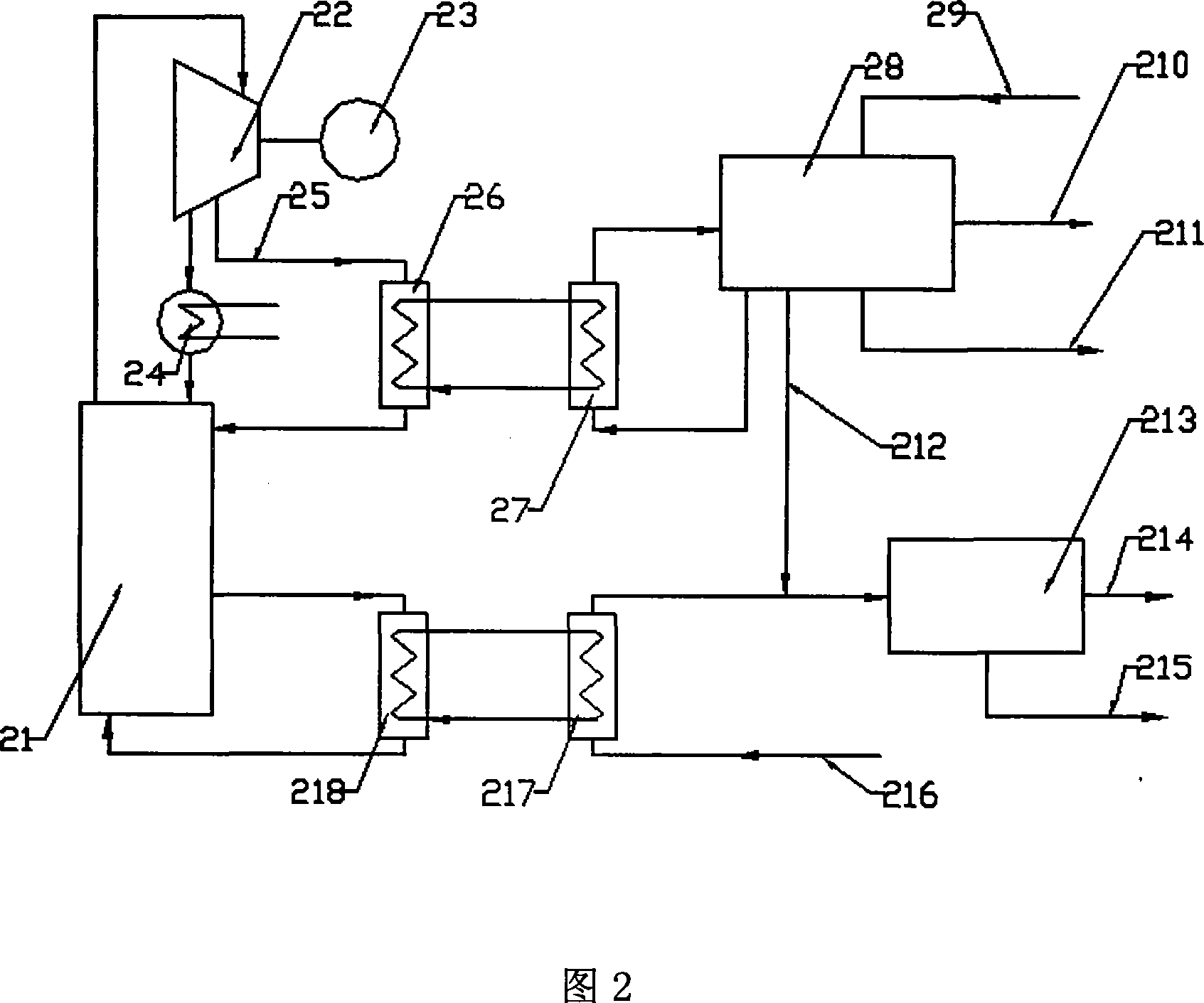

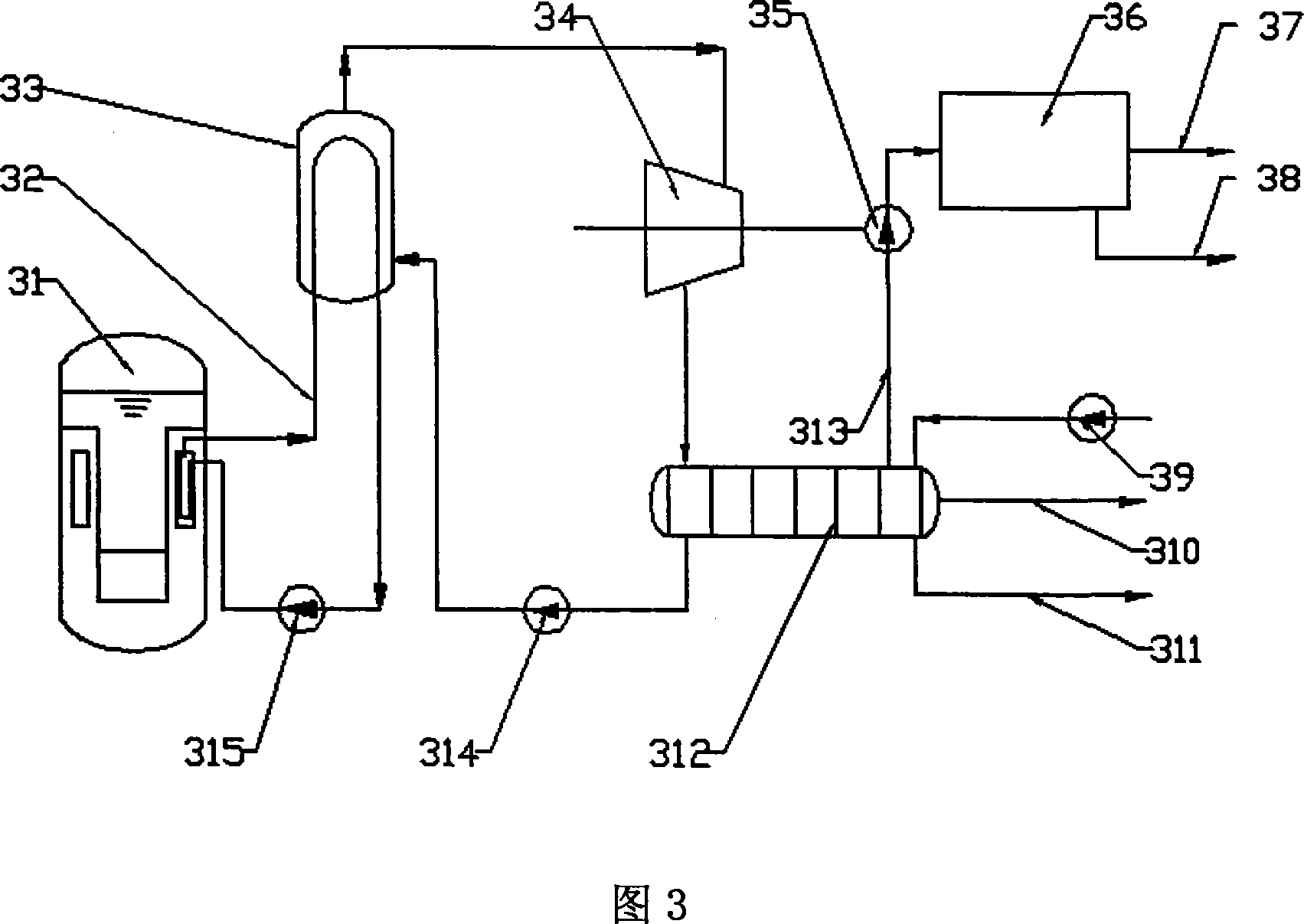

Coupling devices of using nuclear energy for sea water desalination, and method

ActiveCN101049999AEliminate lossesIncrease profitGeneral water supply conservationSeawater treatmentWater desalinationDistillation

This invention relates to coupling apparatus and method for desalting seawater by using nuclear energy. The apparatus comprises: a small-scale nuclear thermal reactor, a reverse osmosis seawater desalting system, a distillation seawater desalting system, and auxiliary apparatus. The method comprises: (1) transferring the heat generated from the small-scale nuclear thermal reactor to the steam generator, and driving the reverse osmosis high-pressure pump with the generated saturated steam in the turbine for seawater desalting; (2) introducing the saturated steam exhausted from the end stage of the turbine to the distillation seawater desalting system for seawater desalting; (3) returning the condensed water to the steam generator; (4) introducing seawater into the distillation seawater desalting system, cooling at the heat discharge section, sending to the reverse osmosis high-pressure pump, pressurizing, sending to the reverse osmosis seawater desalting system, storing the product water in a desalted water tank, and utilizing the condensed seawater or discharging into sea. The method has such advantages as advanced technology, high heat utility, high water productivity and high water quality.

Owner:CHINERGY CO LTD +1

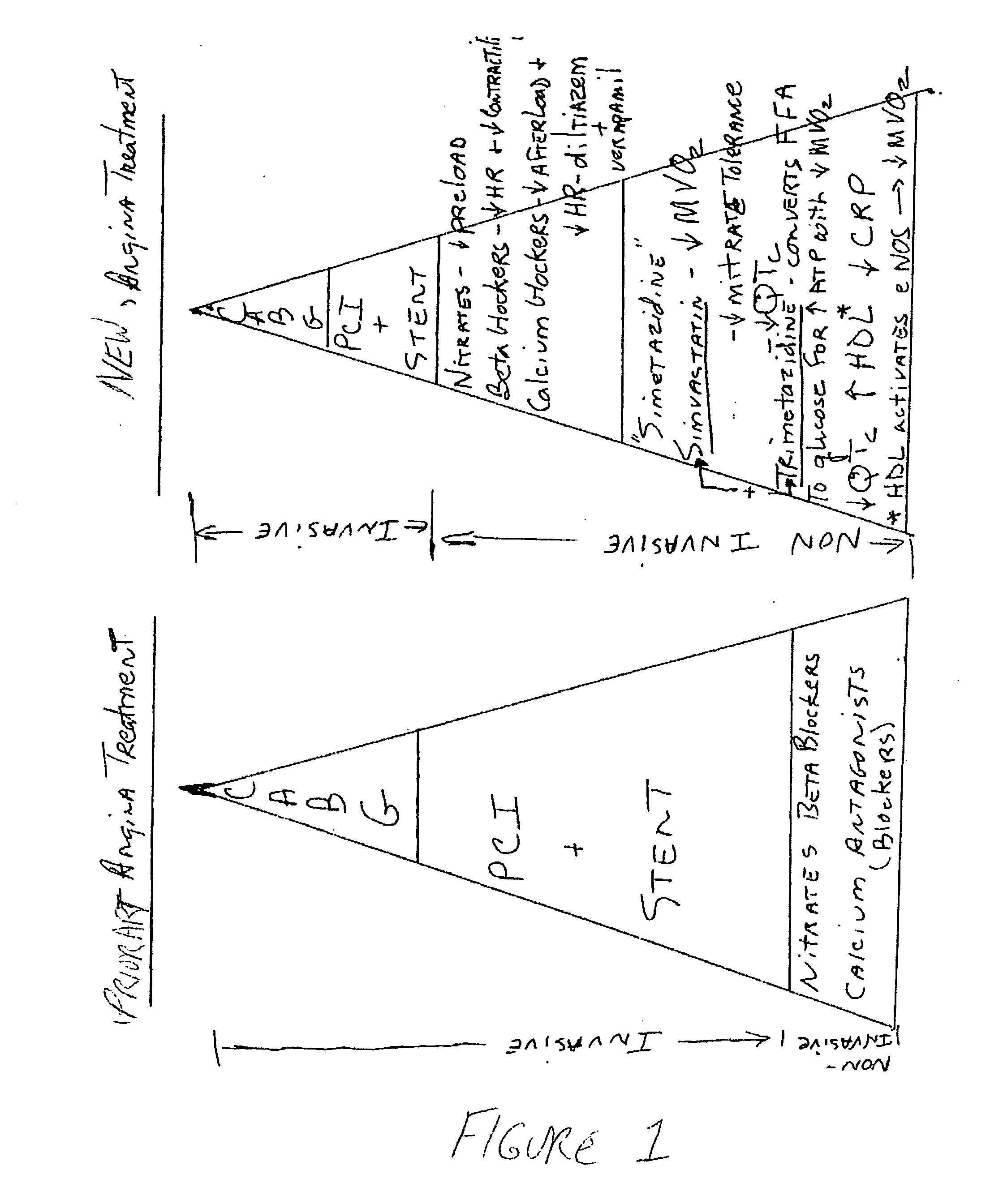

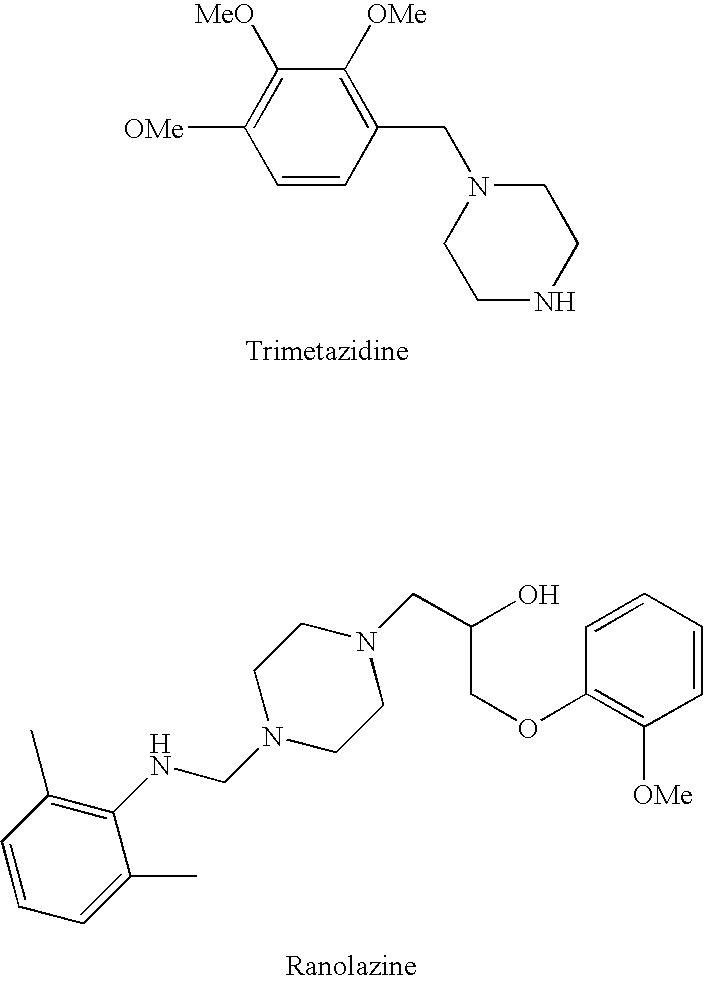

Combination therapy for endothelial dysfunction, angina and diabetes

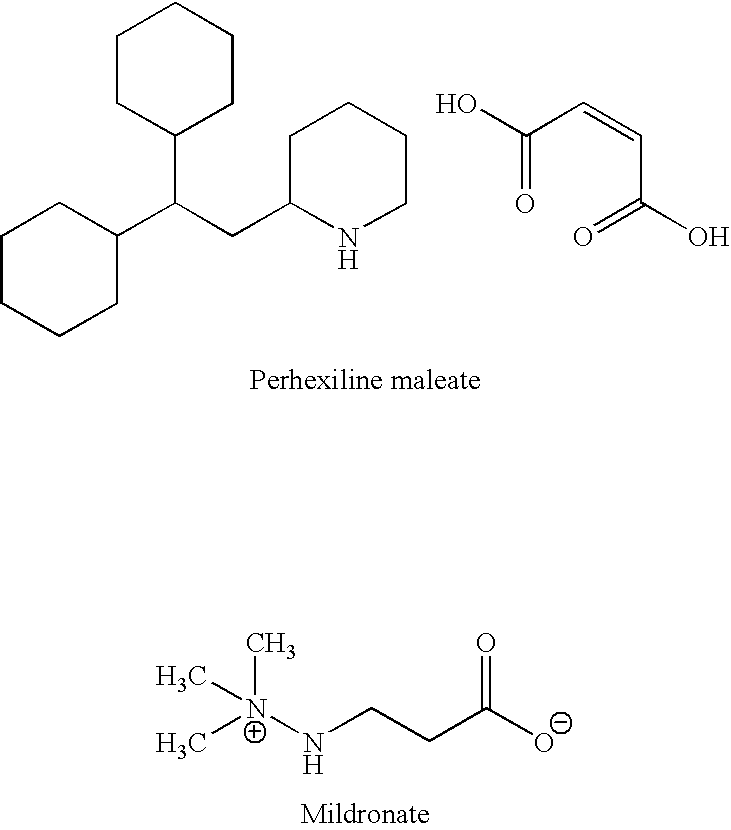

InactiveUS20060205727A1Control blood sugar levelsIncrease productionBiocideMetabolism disorderHMG-CoA reductaseTrimetazidine

The combination of a HMG CoA reductase inhibitor like a statin, such as simvastatin, with a pFox inhibitor such as trimetazidine (“Simetazidine”) is particularly advantageous for treatment of end-stage complications, such as acute coronary syndrome (ACS) and chronic angina, especially in type II diabetics. The combination therapy is also useful in the treatment and / or prevention of chronic heart failure (CHF) and peripheral arterial disease (PAD). The combination of a nitric oxide (NO) mechanism with increased NO production with pFox inhibition simultaneously treats both the effect and the cause of angina. One or more oral hypoglycemic compounds (biguanides, insulin sensitizers, such as thiazolidinediones, α-glucosidase inhibitors, insulin secretagogues, and dipeptidyl peptidase IV inhibitors), protein kinase C (PKC) inhibitors, and acetyl-CoA carboxylase inhibitors can also be used in combination with the HMG CoA reductase inhibitors and / or pFox inhibitors, especially in type II diabetics, to control glucose levels and treat endothelial dysfunction. The drugs can be given in combination (e.g. a single tablet) or in separate dosage forms, administered simultaneously or sequentially. In the preferred form the statin is given in a dose of between 5 and 80 mg / day in two separate doses, and the pFox inhibitor is administered in a sustained or extended dosage formulation at a dose of 20 mg three times a day or 35 mg two times a day. The dose of the oral hypoglycemic, PKC inhibitor, or acetyl-CoA carboxylase inhibitor varies with the type of drug used.

Owner:HONG KONG NITRIC OXIDE

CIK cell, as well as preparation method and cell preparation thereof

InactiveCN101519646AIncrease the number of proliferationPromote cell proliferationMammal material medical ingredientsTissue cultureAbnormal tissue growthPhytohemagglutinins

The invention discloses a CIK cell, as well as a preparation method and a cell preparation thereof. The method for preparing the CIK cell comprises the following steps: placing a separated mononuclear cell in a culture fluid containing phytohemagglutinin; transplanting the mononuclear cell into a culture flask enveloped by antiCD3 monoclonal antibody and antiCD28 monoclonal antibody after the cell is cultured for 24 to 72 hours; and adding a culture fluid containing IL-1alpha and IL-2 into the culture flask to keep on culturing for 5 to 15 days, and separating the cells into different flasks to be cultured every 2 to 3 days. The CIK cell prepared by the method has the characteristics of obvious improved cell proliferation, great increase of CD8 cell proportion, wide antineoplastic spectrum and strengthened antineoplastic activity. The CIK cell and the cell preparation can effectively prevent the metastasis and the recrudescence for of postoperative patients with tumor, can be combined with chemicotherapy to effectively reduce toxic and side effects of the chemicotherapy, strengthens the survivability tolerance of the patients to improve healing efficacy, and can obviously prolong lifecycle to of end-stage patients so as to improve the life living quality.

Owner:上海德嘉生物科技有限公司 +1

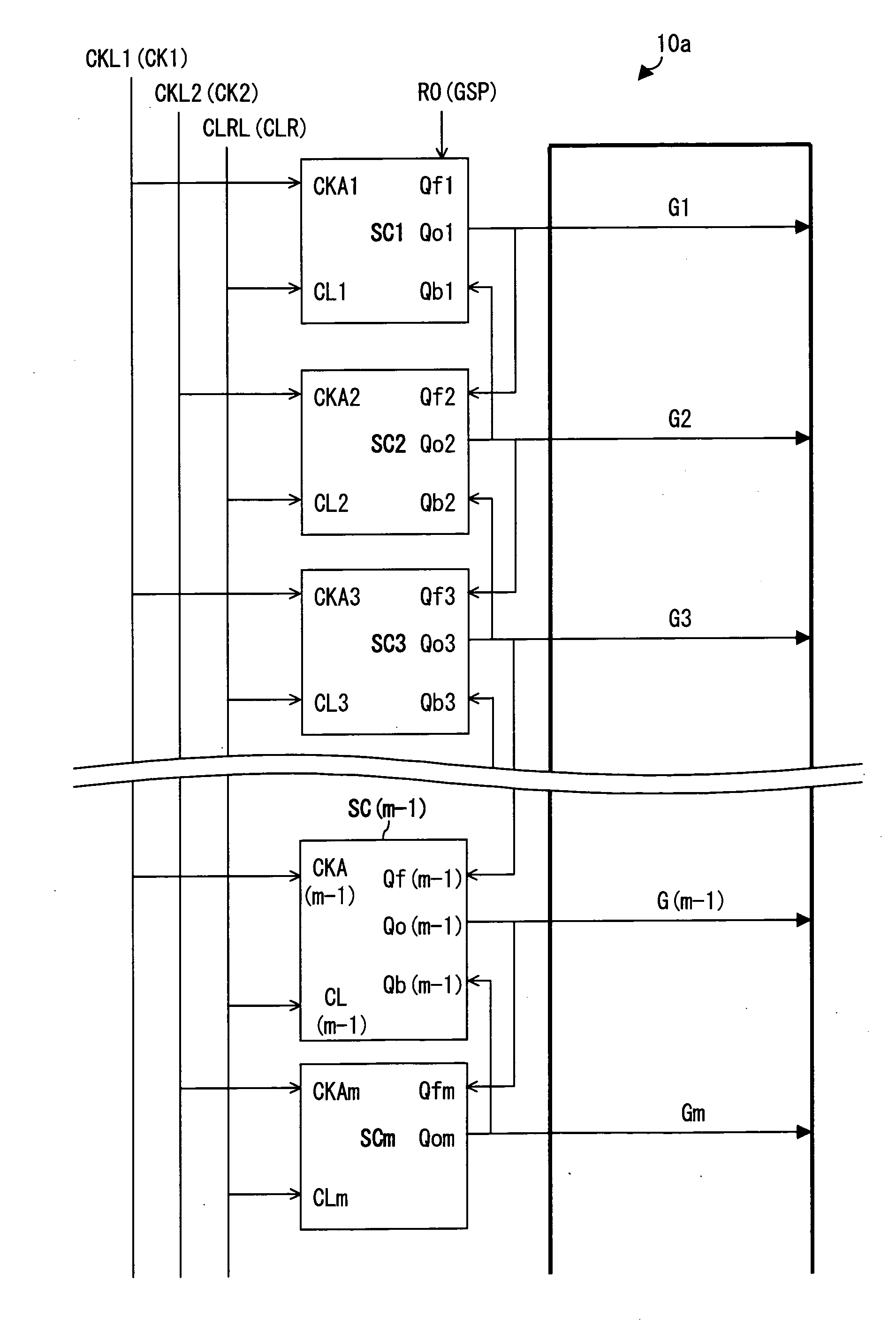

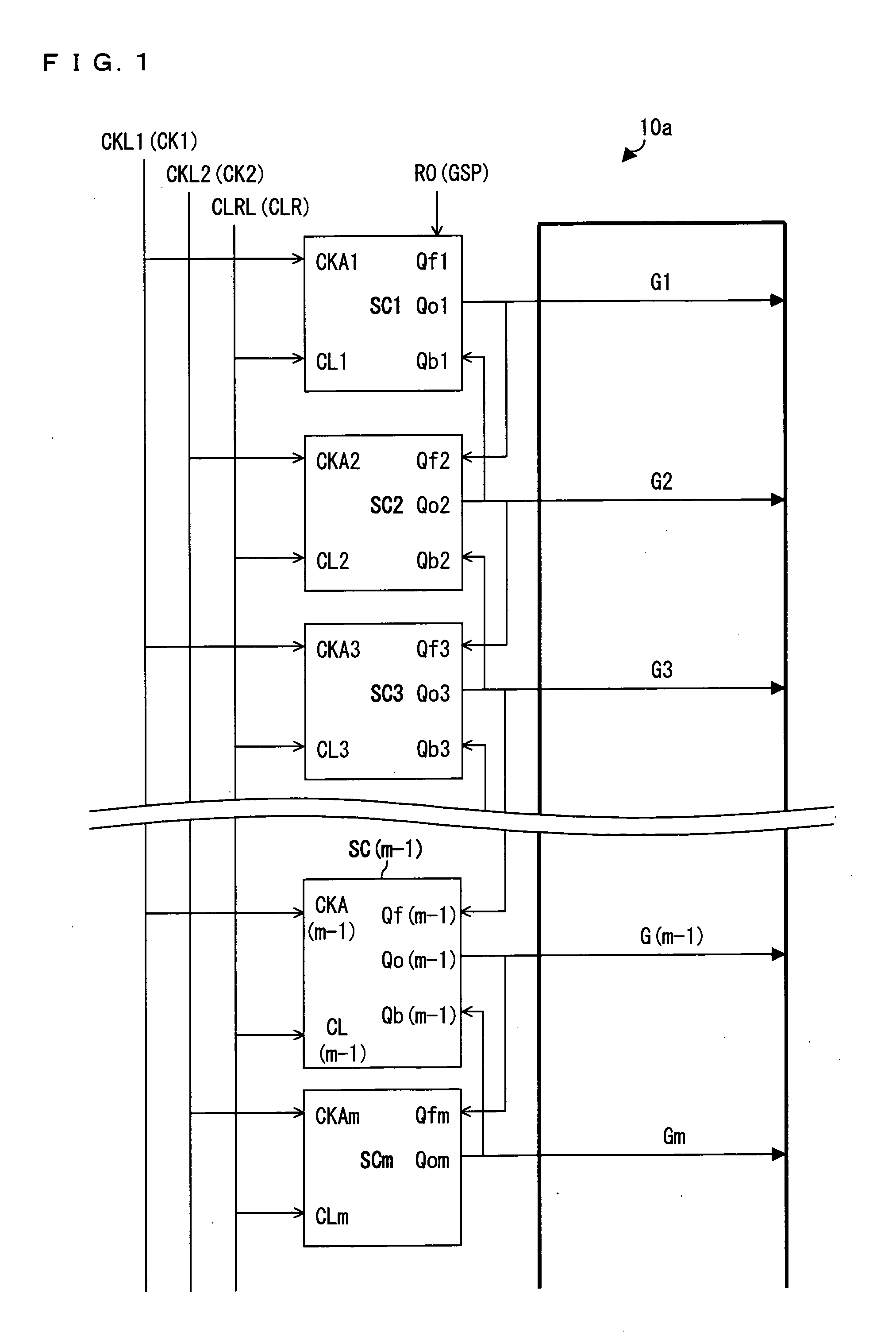

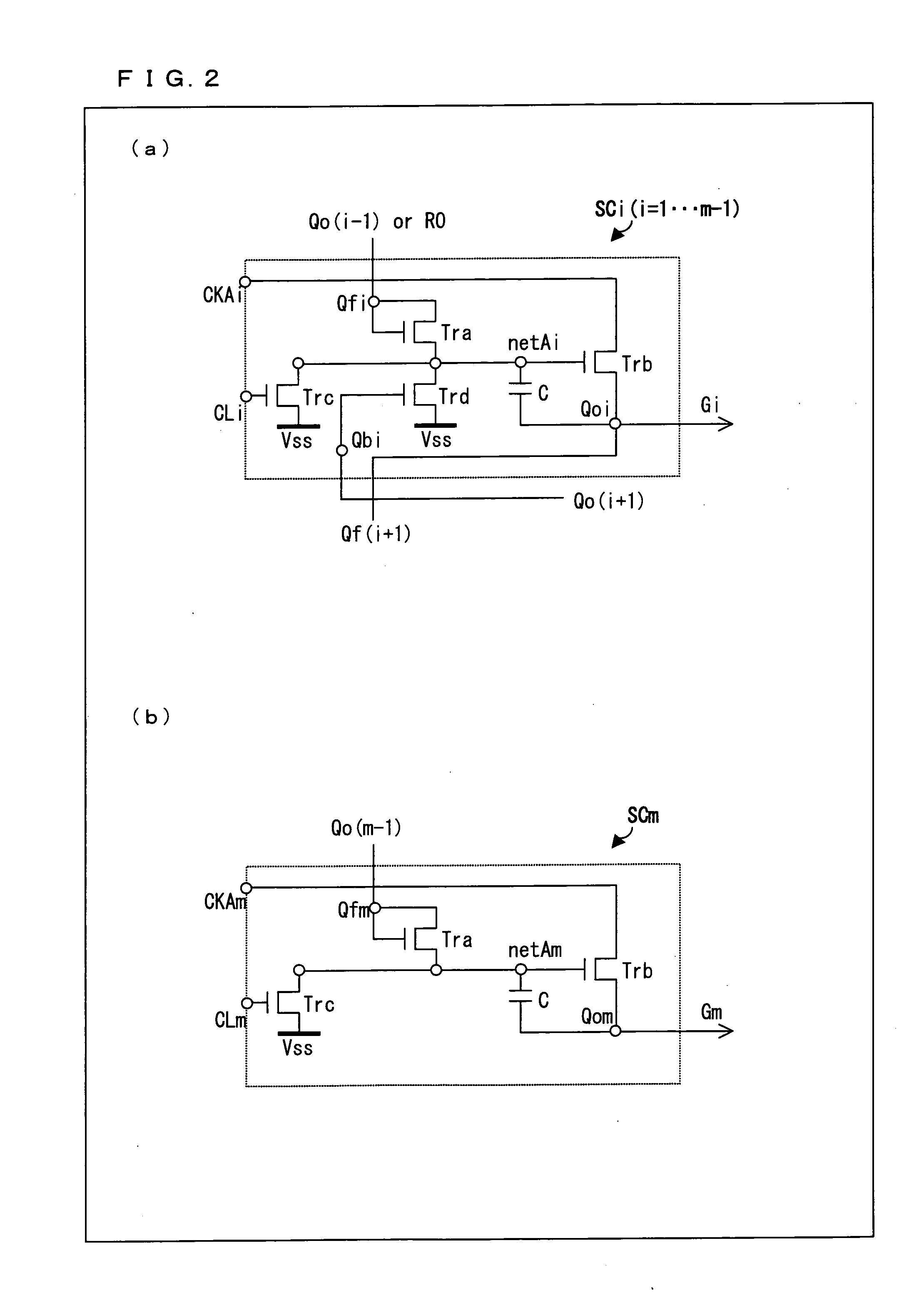

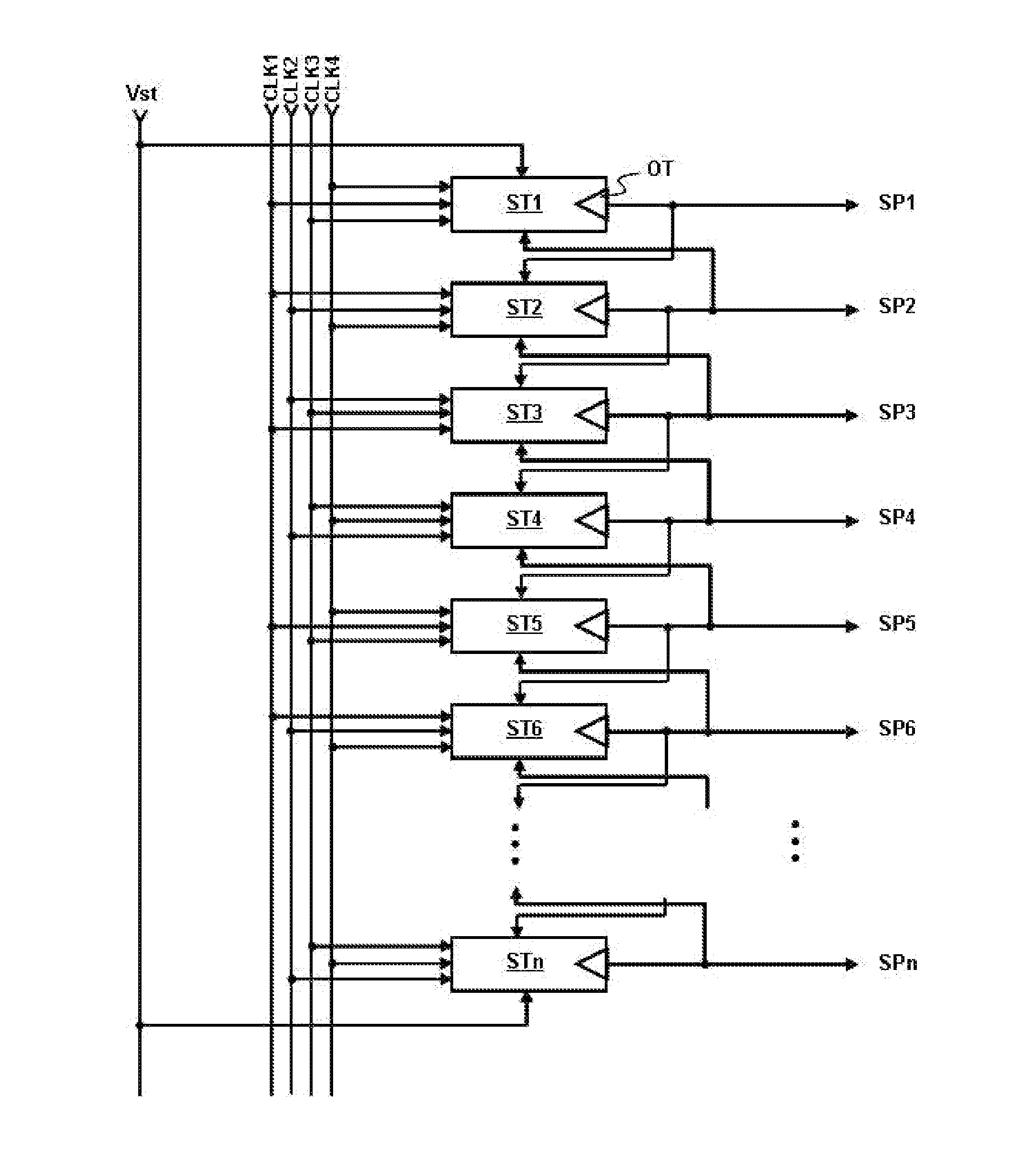

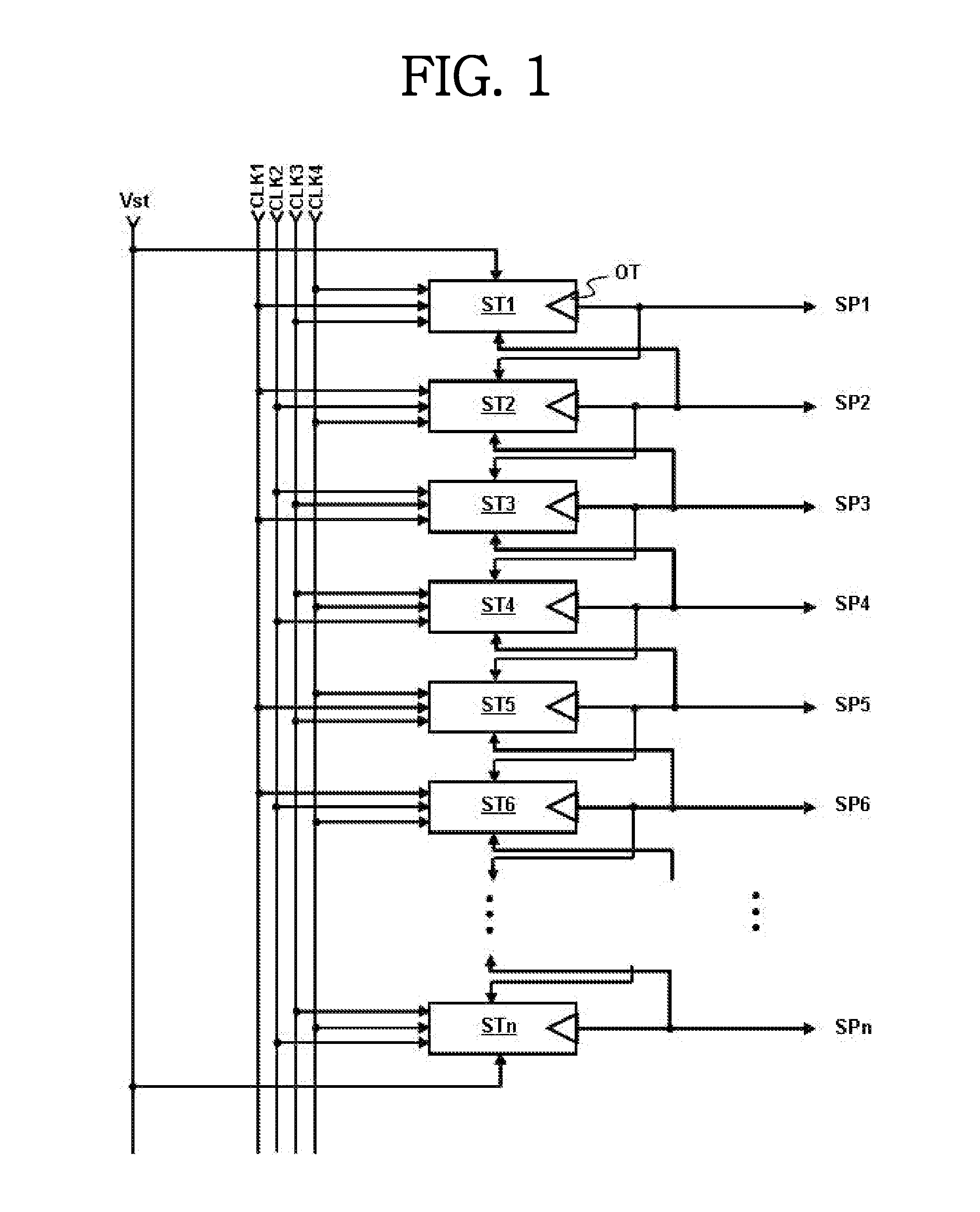

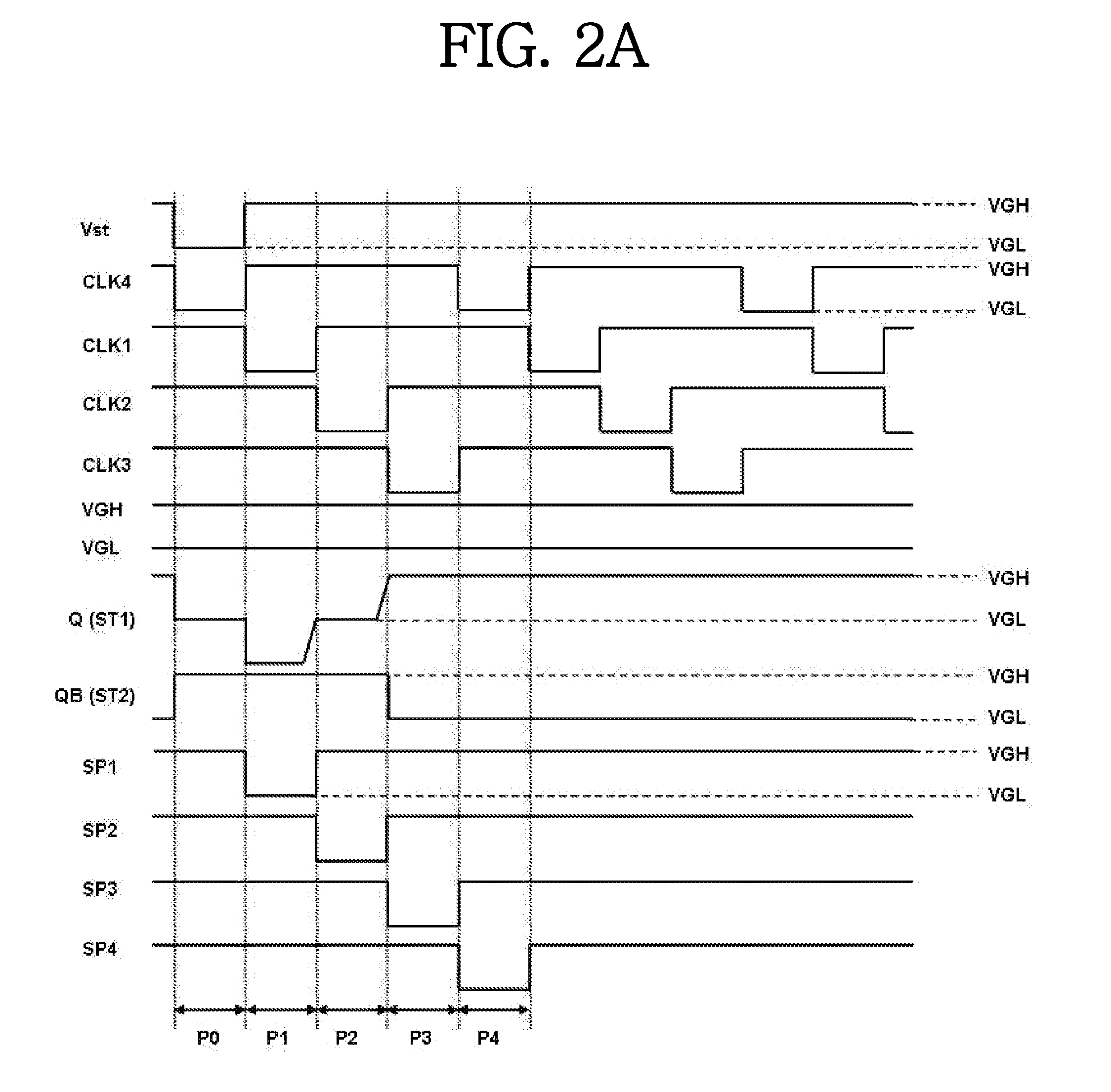

Display panel driving circuit, liquid crystal device, shift register, liquid crystal panel, and driving method of display device

ActiveUS20110018845A1Avoid confusionIncrease loadCathode-ray tube indicatorsDigital storageShift registerEnd stages

A display panel drive circuit includes a shift register constructed of unit circuits connected in stages. The unit circuits generate signal line selection signals, respectively, which signal line selection signals are made active for a respective certain period of time to form a respective pulse, and the pulses are outputted successively from respective unit circuits in order of ordinal number starting from a first stage until an end stage. In at least one embodiment, each of the unit circuits receive (i) clock signals generated based on a sync signal received from outside of the display panel drive circuit, (ii) a start pulse signal generated based on the sync signal, or a signal line selection signal generated in a stage different from its own stage, and (iii) a clear signal. The clear signal is made active in a case where anomalousness is included in the sync signal, and no pulse is outputted from the shift register until a subsequent vertical scanning period starts. This configuration achieves a display panel drive circuit which prevents display disorder or holds down increase in load given to a power source, each of which occurs in a case where anomalousness is included in the sync signal.

Owner:SHARP KK

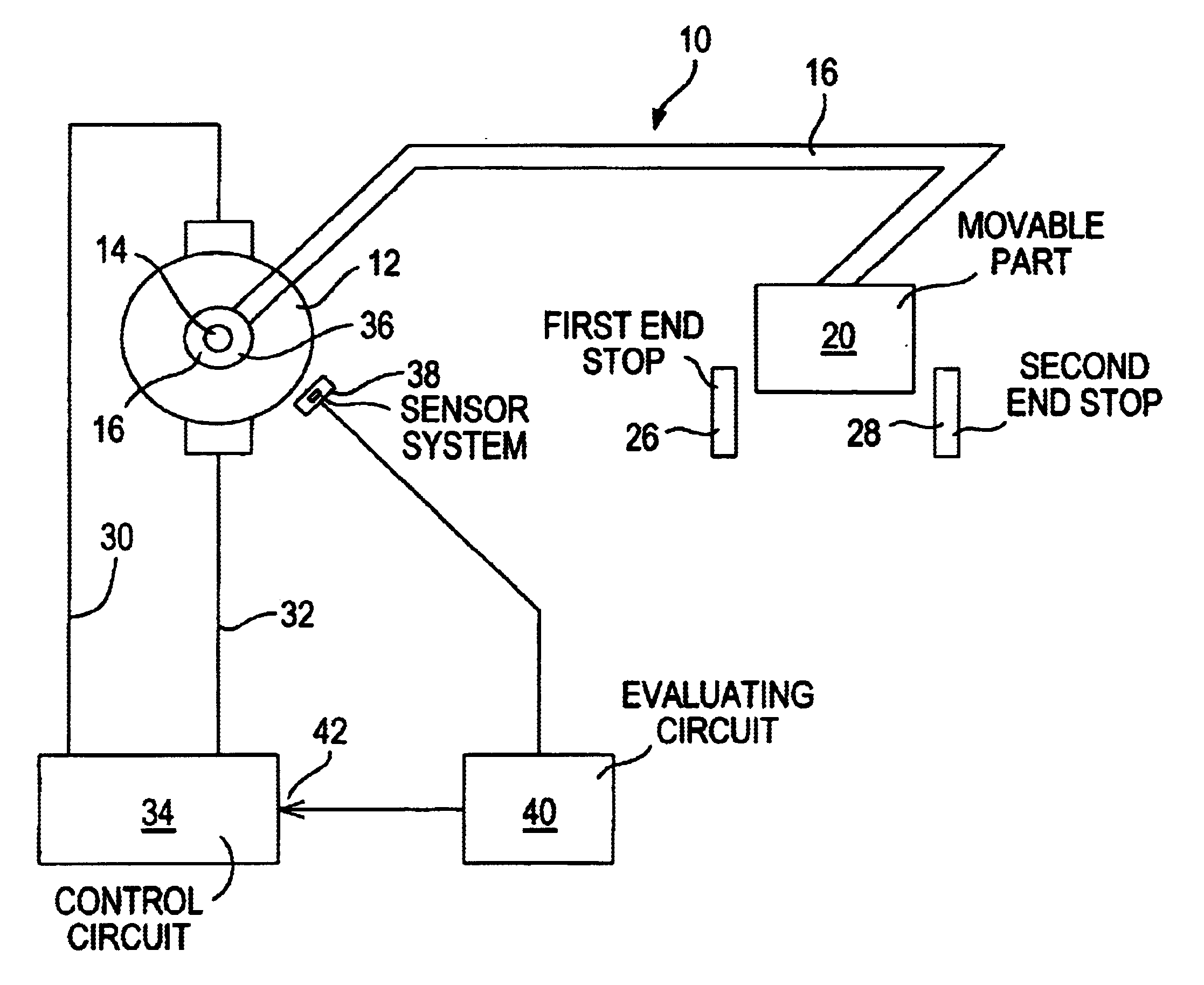

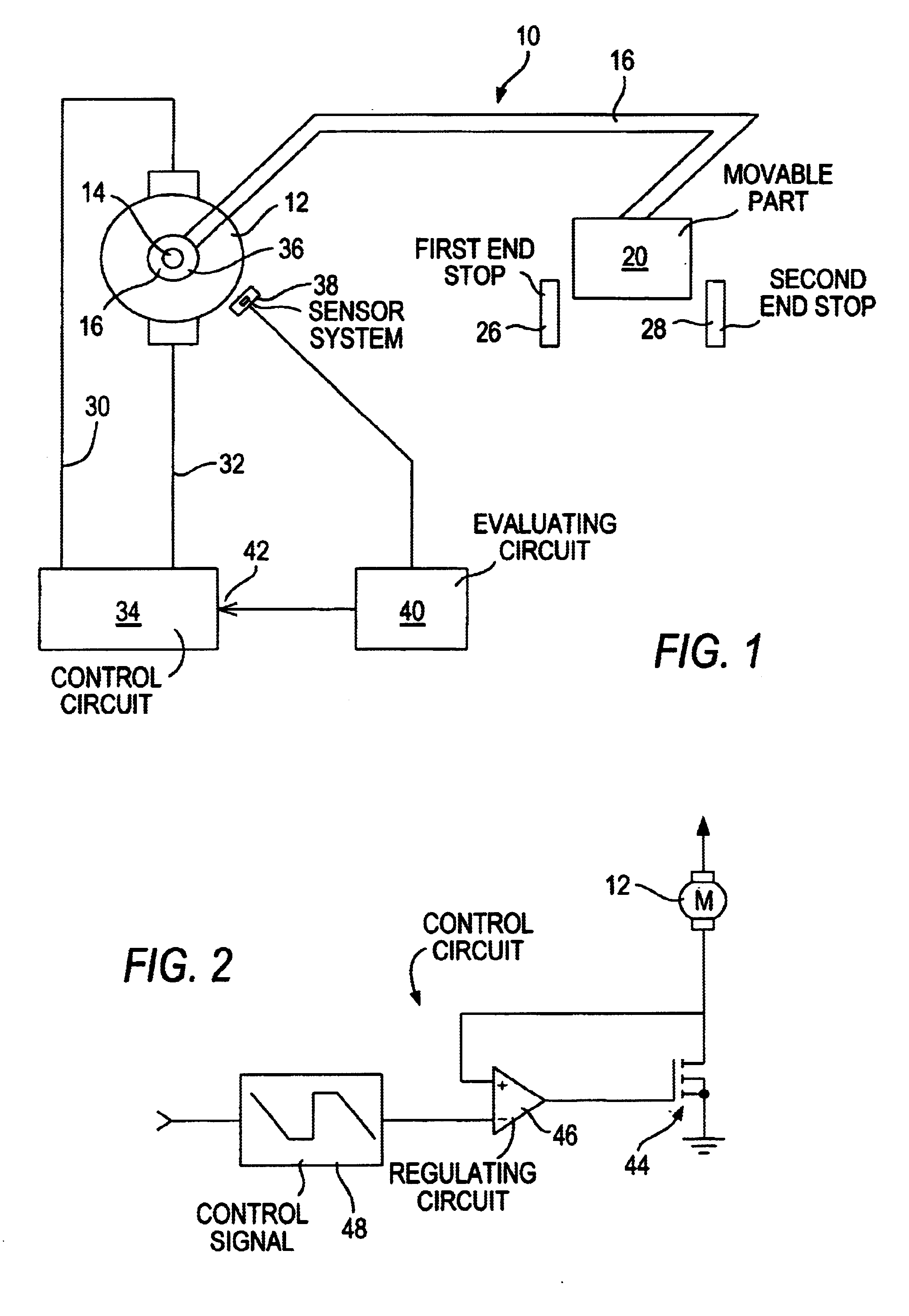

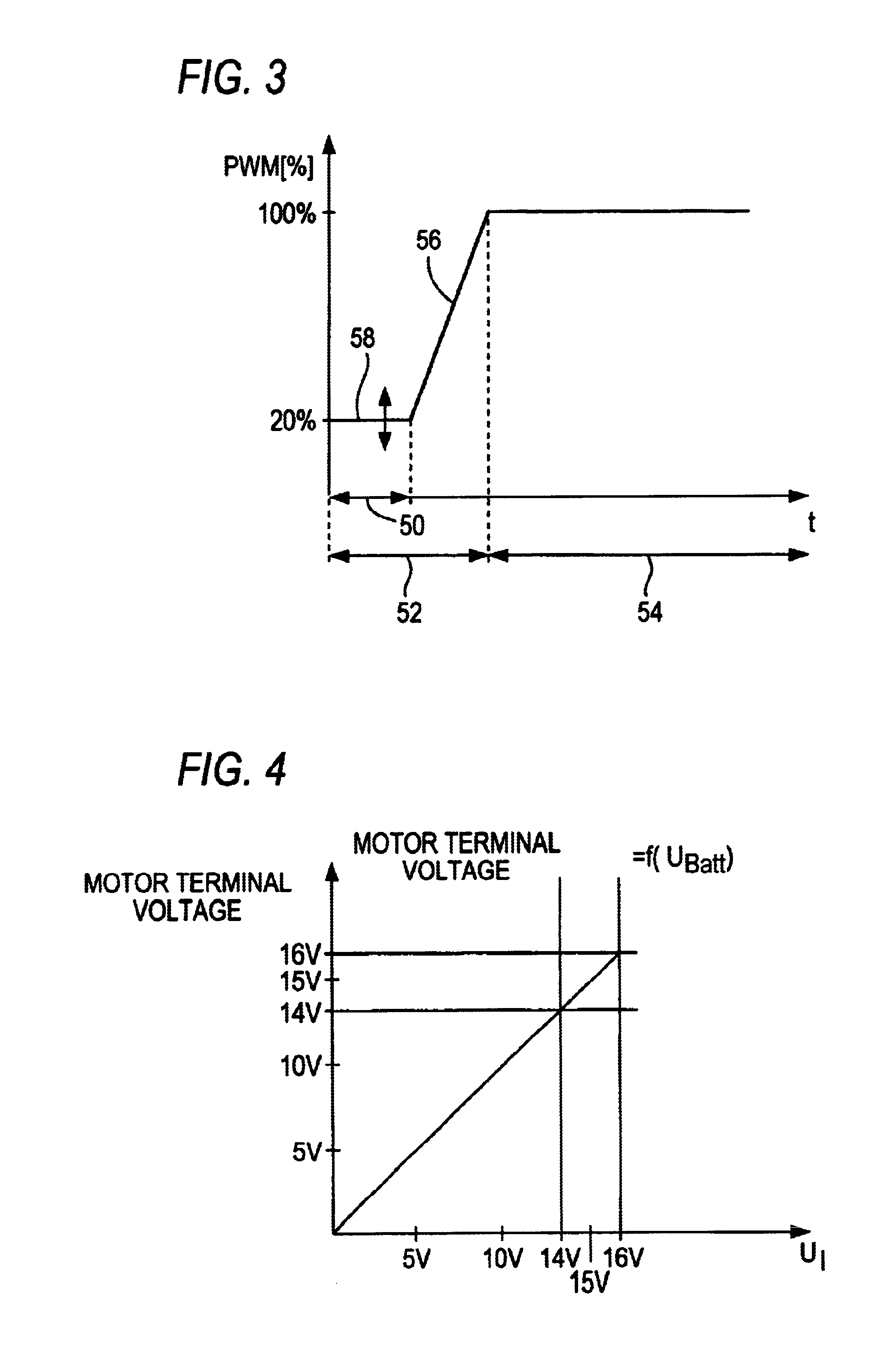

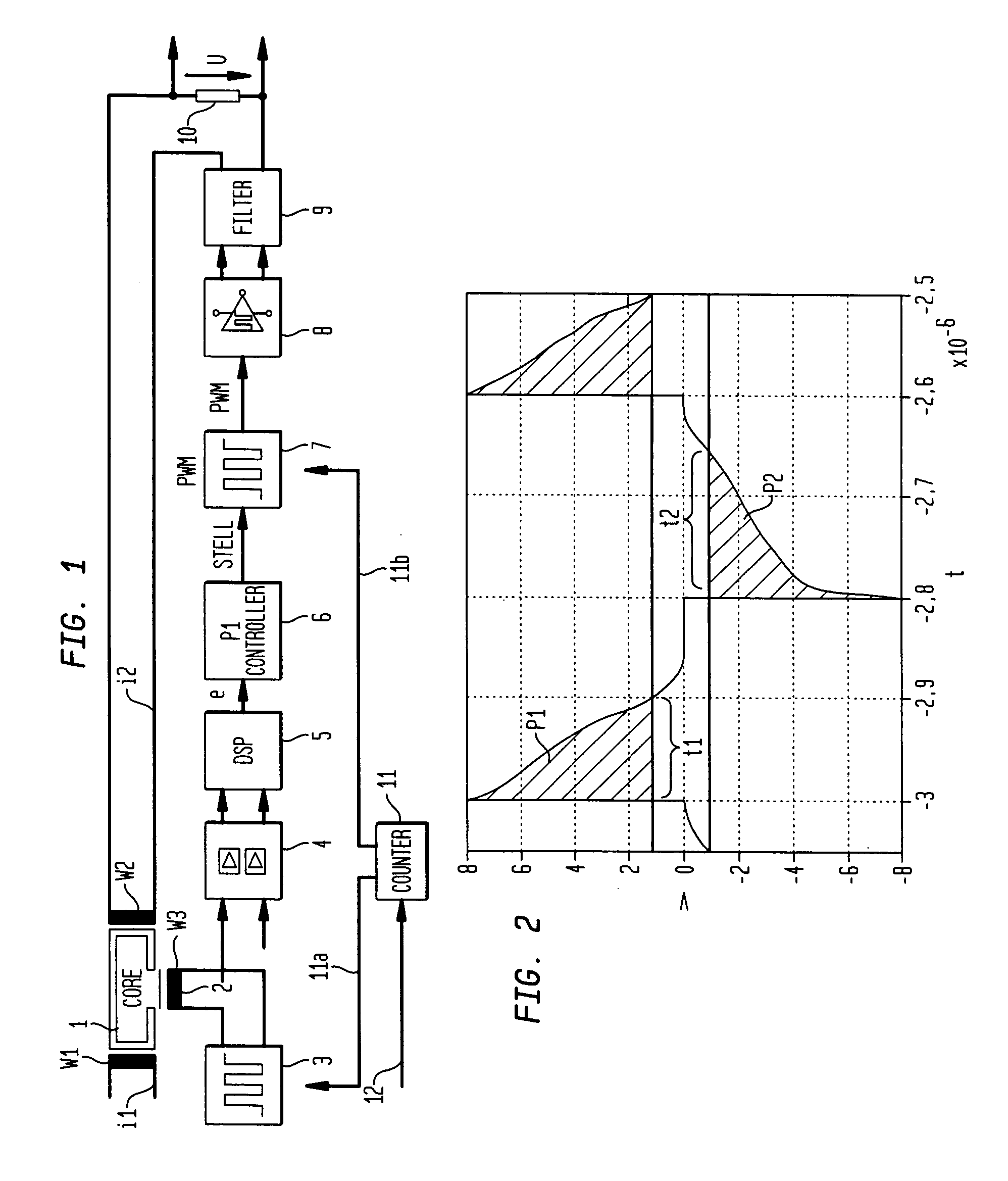

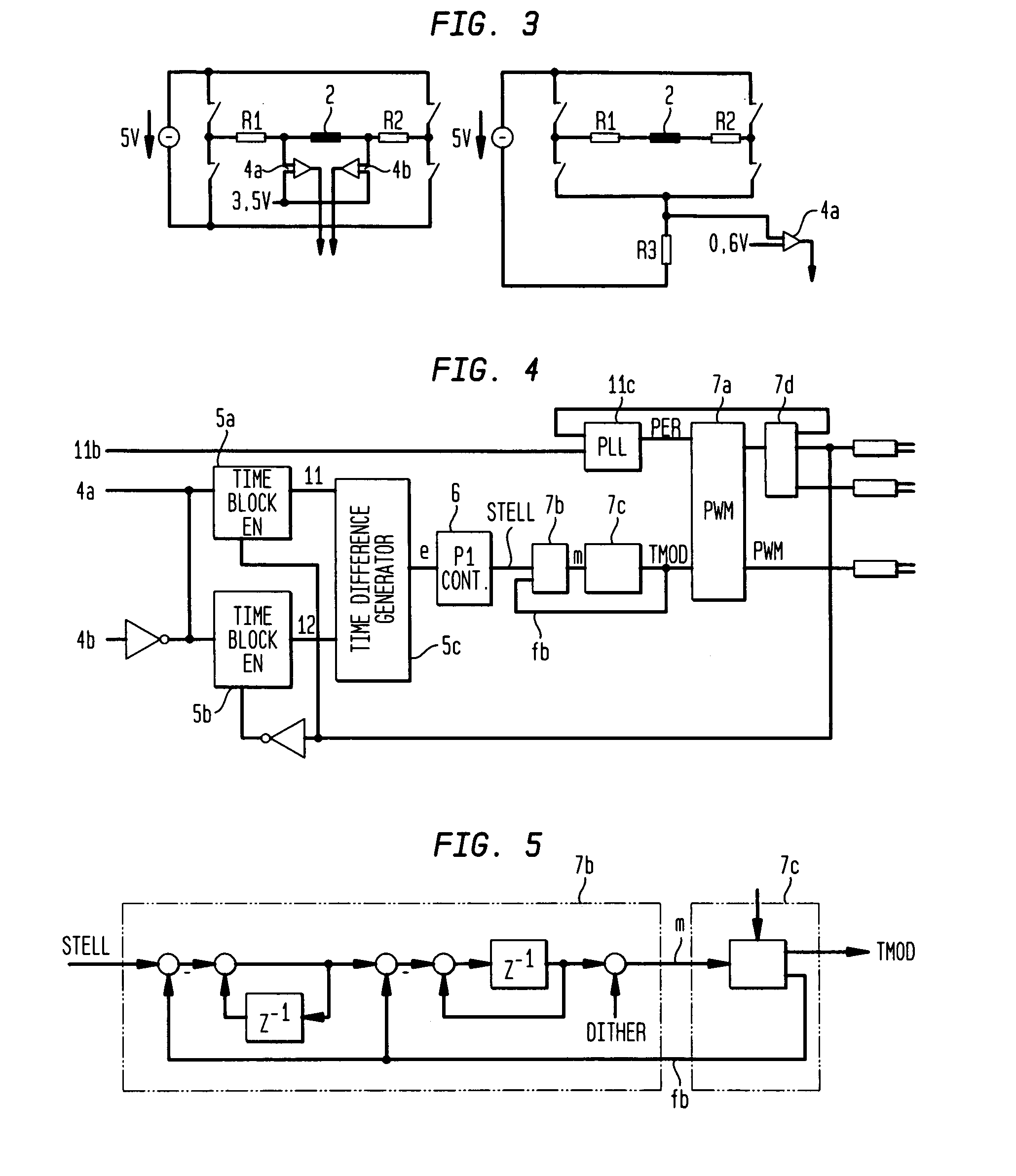

Method for controlling an adjustment process of a part

InactiveUS6952087B2DC motor speed/torque controlAsynchronous induction motorsEnd stagesField-effect transistor

In the method of controlling a process for moving a part (20) by an electric motor (12) against an end stop, pinching events are detected by monitoring a motor operating variable, such as a motor rpm, and if pinching is detected the motor (12) is stopped and / or reversed. The electric power triggering the motor (12) at the start of and during a startup phase while system slack is taken up is controlled so that it is constant and lower than the power triggering the motor in an ensuing operating phase (54) in which the part (20) moves. Preferably power during the startup phase is reduced to power values that are just barely enough to move the motor while system slack is taken up. In a preferred embodiment the applied motor voltage is reduced and controlled by a power end stage that includes a bipolar transistor or a field effect transistor.

Owner:ROBERT BOSCH GMBH

Fluoroscopy-independent, endovascular aortic occlusion system

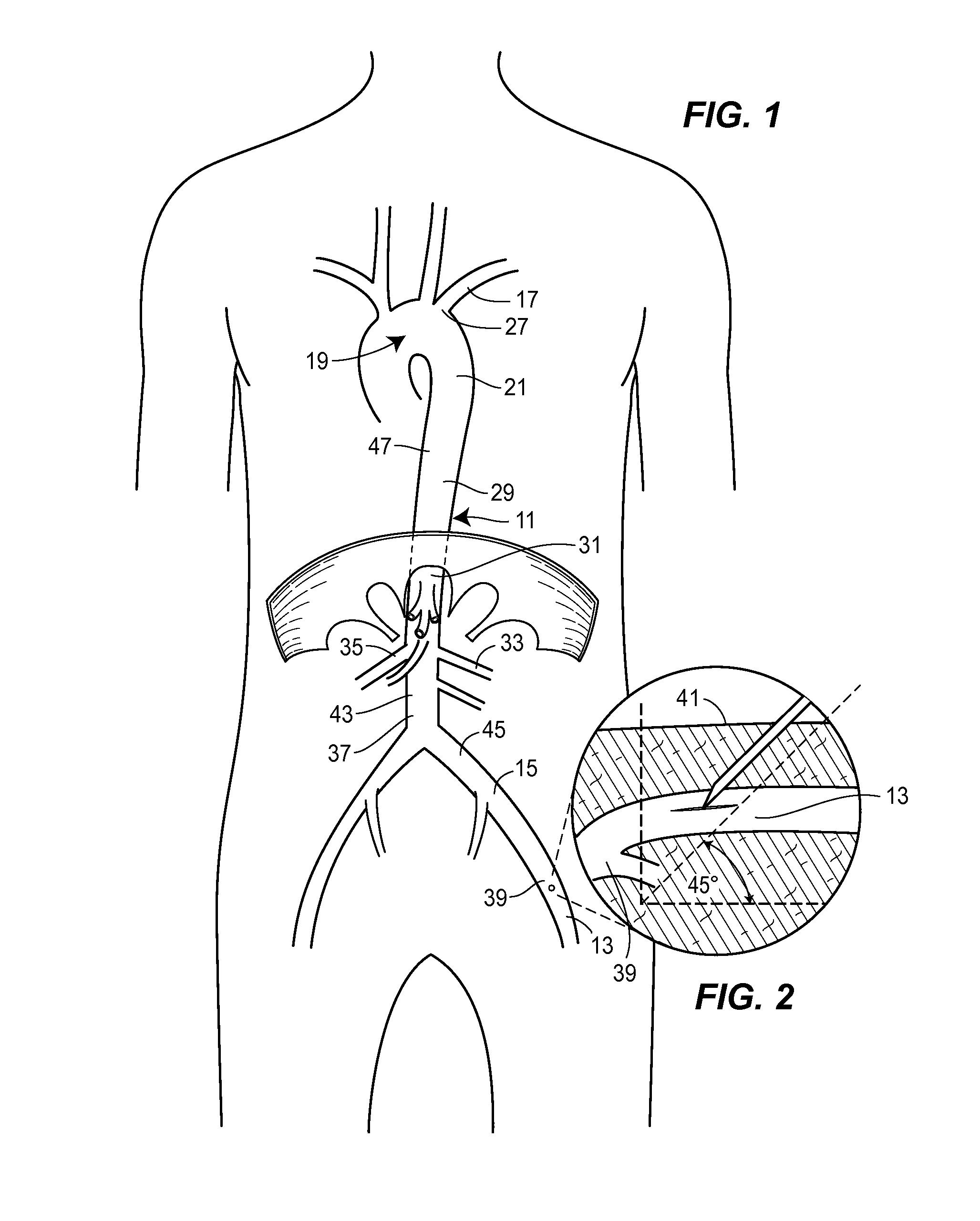

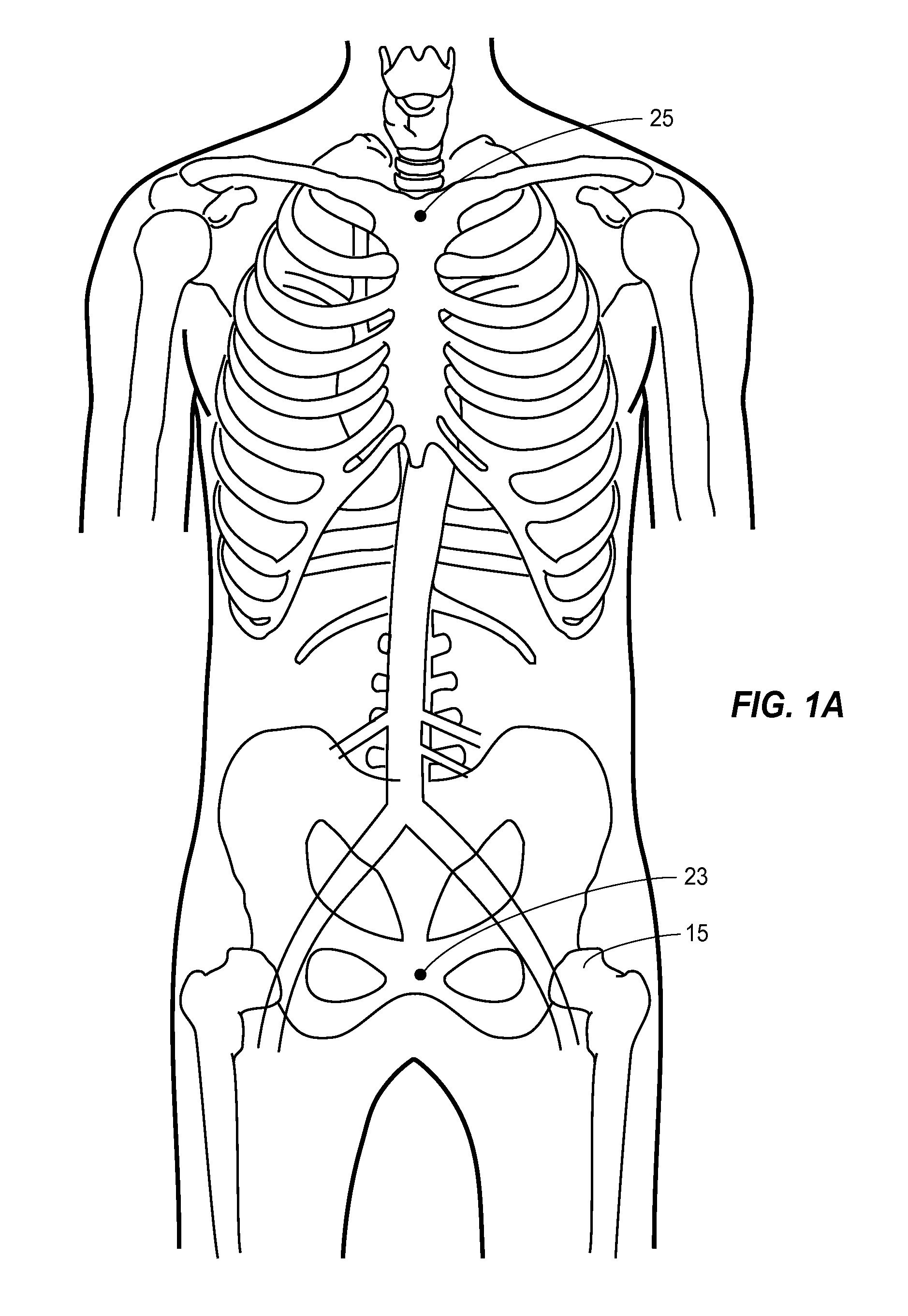

ActiveUS20130102926A1Quick measurementIncrease perfusionBalloon catheterOther printing matterArterial occlusionsLeft subclavian artery

A system for deploying and selectively inflating a thoracic aortic balloon at a desired location within the thoracic aorta for resuscitative aortic occlusion, inferior to the left subclavian artery, without the aid of fluoroscopy is described. Using CT imaging data, a distance between readily identifiable and consistently located external landmarks of torso extent is measured. Next, using the same data, a second distance from the femoral artery to a desired aortic occlusion location inferior to the left subclavian artery is determined. A correlation between the external measure of torso extent and the desired intra-arterial (i.e. endovascular) distance within the torso is made. Using a nomogram, a calibrated endovascular resuscitative thoracic aortic occlusion system can be positioned to this desired location on any injured individual with end-stage shock and impending cardiovascular collapse or death without the aid of fluoroscopy for delivery or balloon inflation.

Owner:RGT UNIV OF MICHIGAN +1

Bidirectional shift register

ActiveUS20130083885A1Improve display qualityAvoid it happening againStatic indicating devicesDigital storageShift registerEnd stages

Disclosed herein is a bidirectional shift register which is capable of preventing multi-outputs from both end stages. The shift register includes a plurality of stages for outputting scan pulses forward or reversely based on a start pulse and a plurality of clock pulses with a phase difference. A last one of the stages includes a forward scan controller for making a set node active and a reset node inactive based on any one of the clock pulses and a scan pulse from an upstream stage, a reverse scan controller for making the set node active and the reset node inactive based on any one of the clock pulses and the start pulse, and an output unit for outputting any one of a corresponding scan pulse and a deactivation voltage based on a voltage at the set node, a voltage at the reset node and any one of the clock pulses.

Owner:LG DISPLAY CO LTD

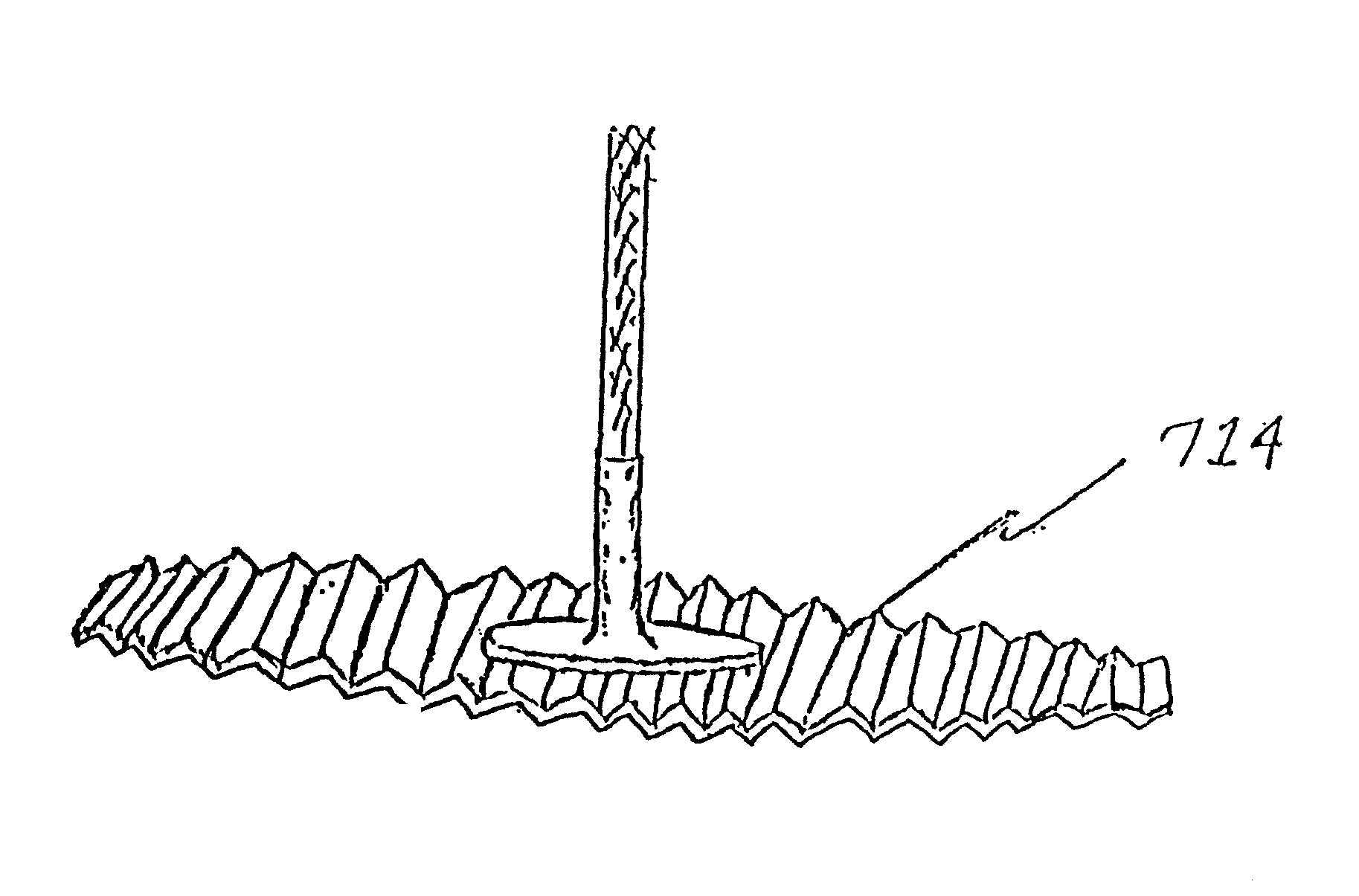

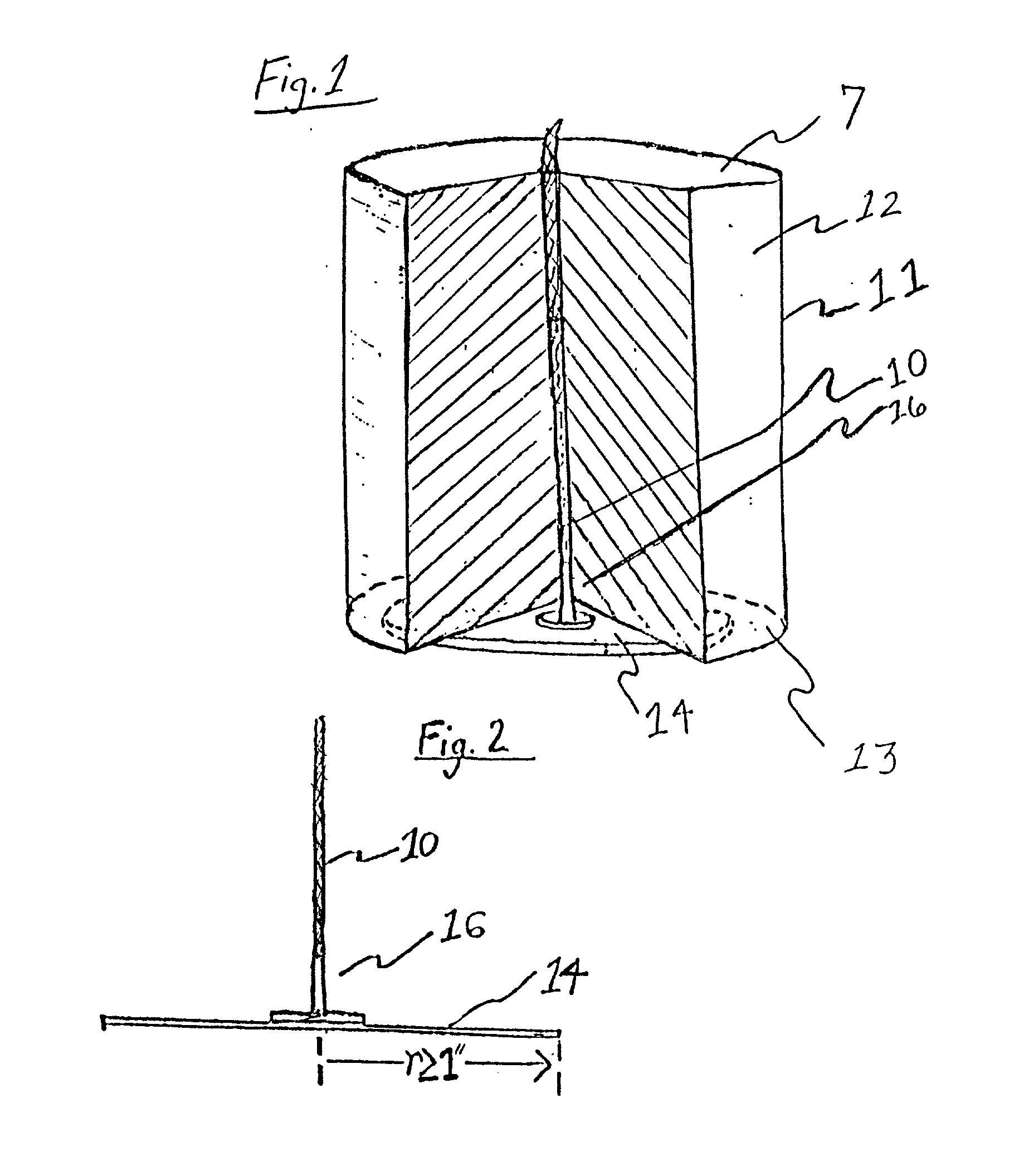

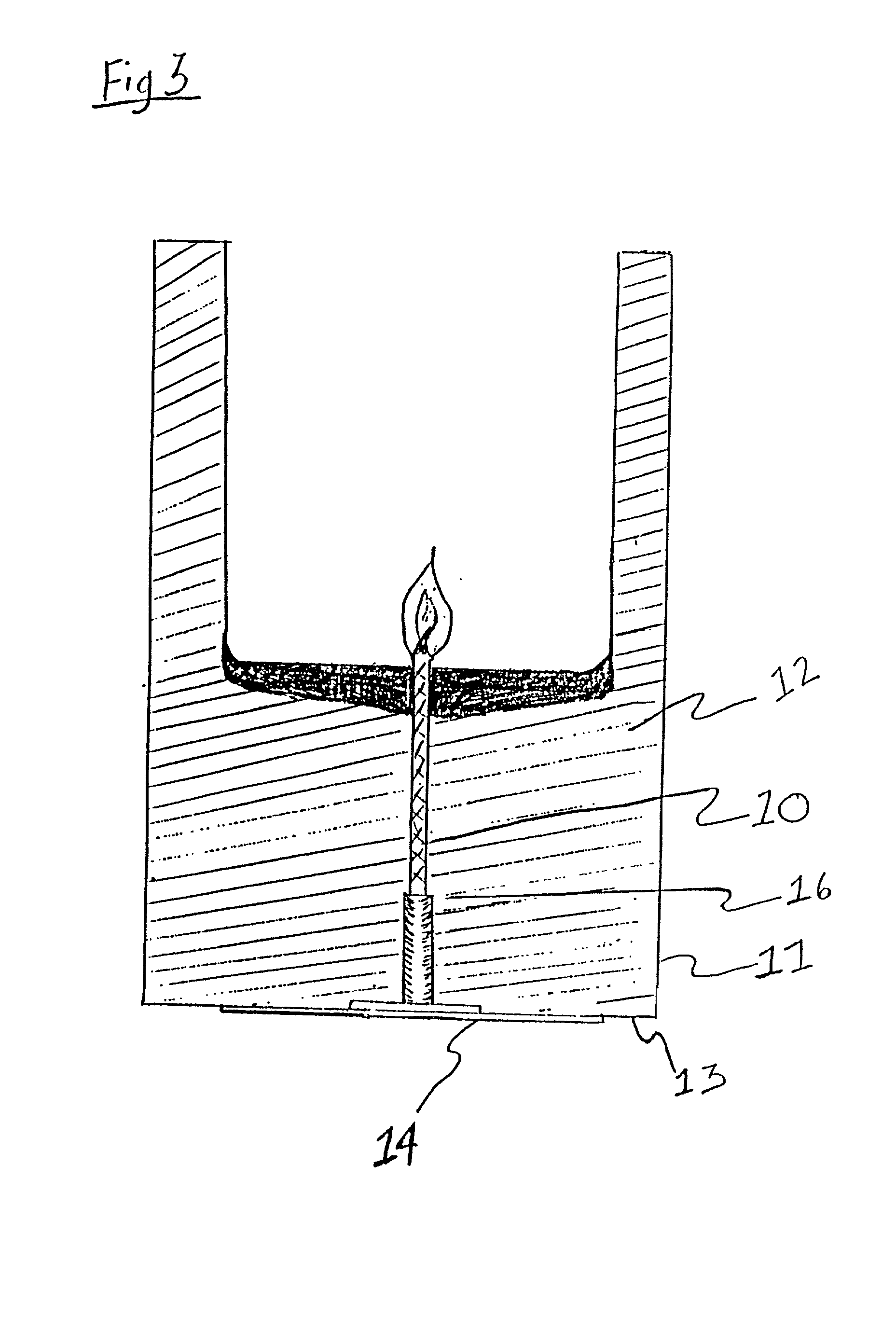

Flame-resistant sheet with candle wick support

A freestanding candle has a flame-resistant sheet adhered to a wick support and to a fuel body in a location proximate to the lower end of a wick. The sheet reduces the risk of fire hazards that arise during the later stages of candle burning, which are characterized by a thin candle floor and a pool of liquid fuel surrounding the wick support. The wick support is made longer and sealingly adhered to the sheet to further reduce the risk of fire hazards. The structural combination of the wick support, the sealant, and the sheet facilitates even burning during the life of the candle and self-extinguishment of the flame at the end stage of burning.

Owner:LUMI LITE CANDLE

Methods and Compositions to Regulate Iron Metabolism

ActiveUS20080260736A1Less likely to induce undesirable side-effectsAntibacterial agentsPeptide/protein ingredientsDiseasePhysiology

The present invention provides new systems and strategies for the regulation of iron metabolism in mammals. In particular, methods of using agonists and antagonists of TGF-β superfamily members to modulate the expression or activity of hepcidin, a key regulator of iron metabolism, are described. The inventive methods find applications in the treatment of diseases associated with iron overload, such as juvenile hemochromatosis and adult hemochromatosis, and in the treatment of diseases associated with iron deficiency, such as anemia of chronic disease and EPO resistant anemia in end-stage of renal disease. The present invention also relates to screening tools and methods for the development of novel drugs and therapies for treating iron metabolism disorders.

Owner:THE GENERAL HOSPITAL CORP

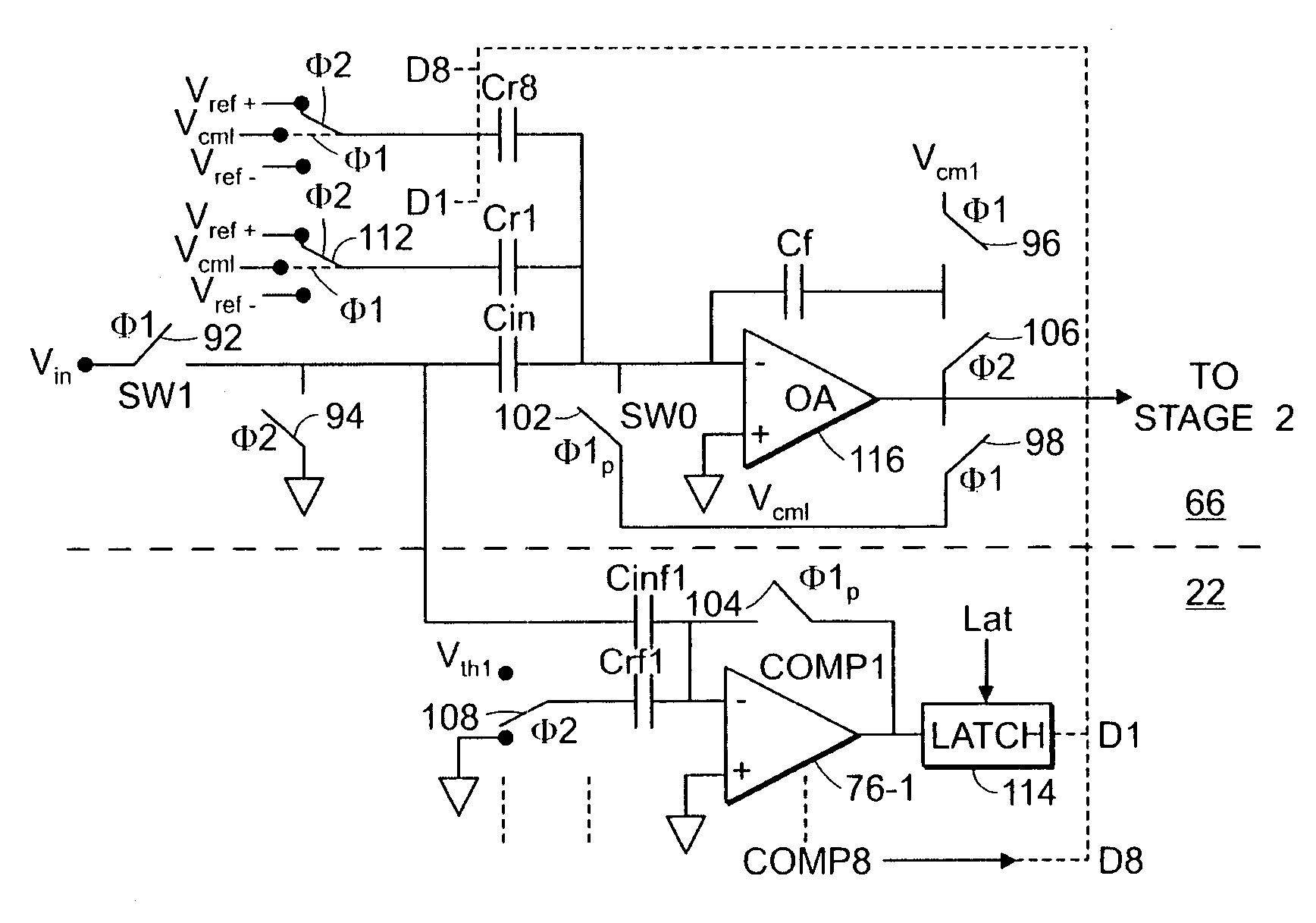

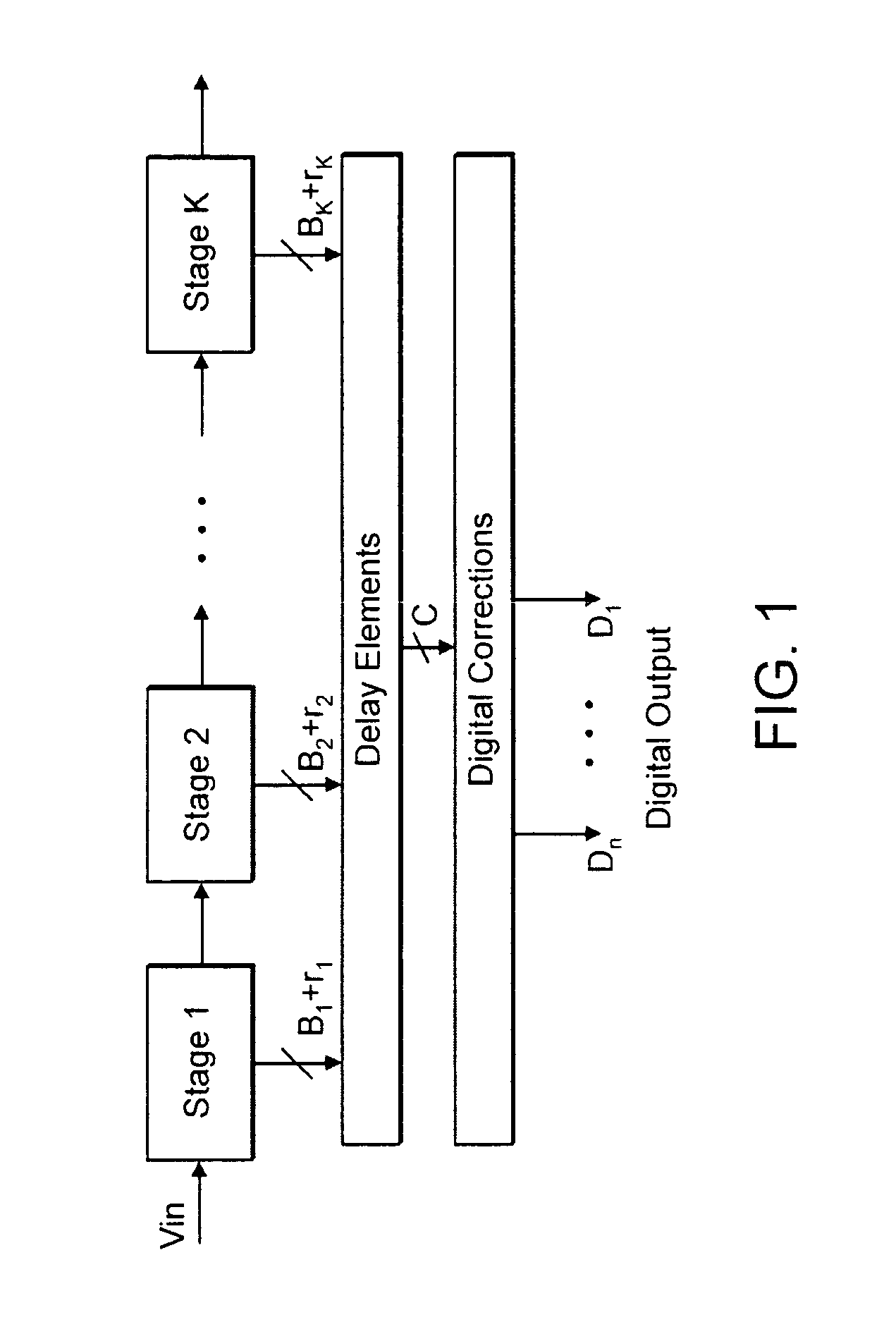

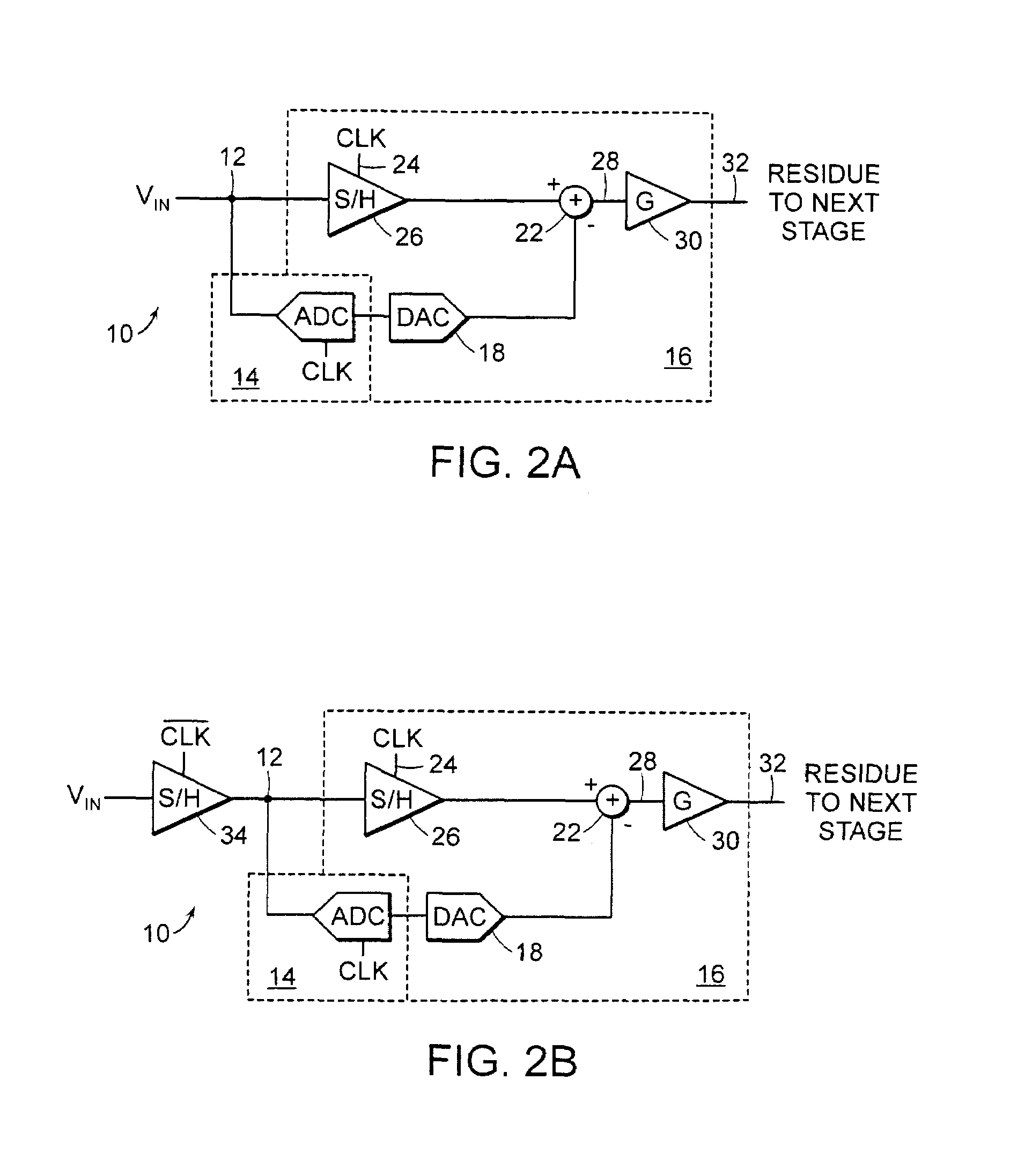

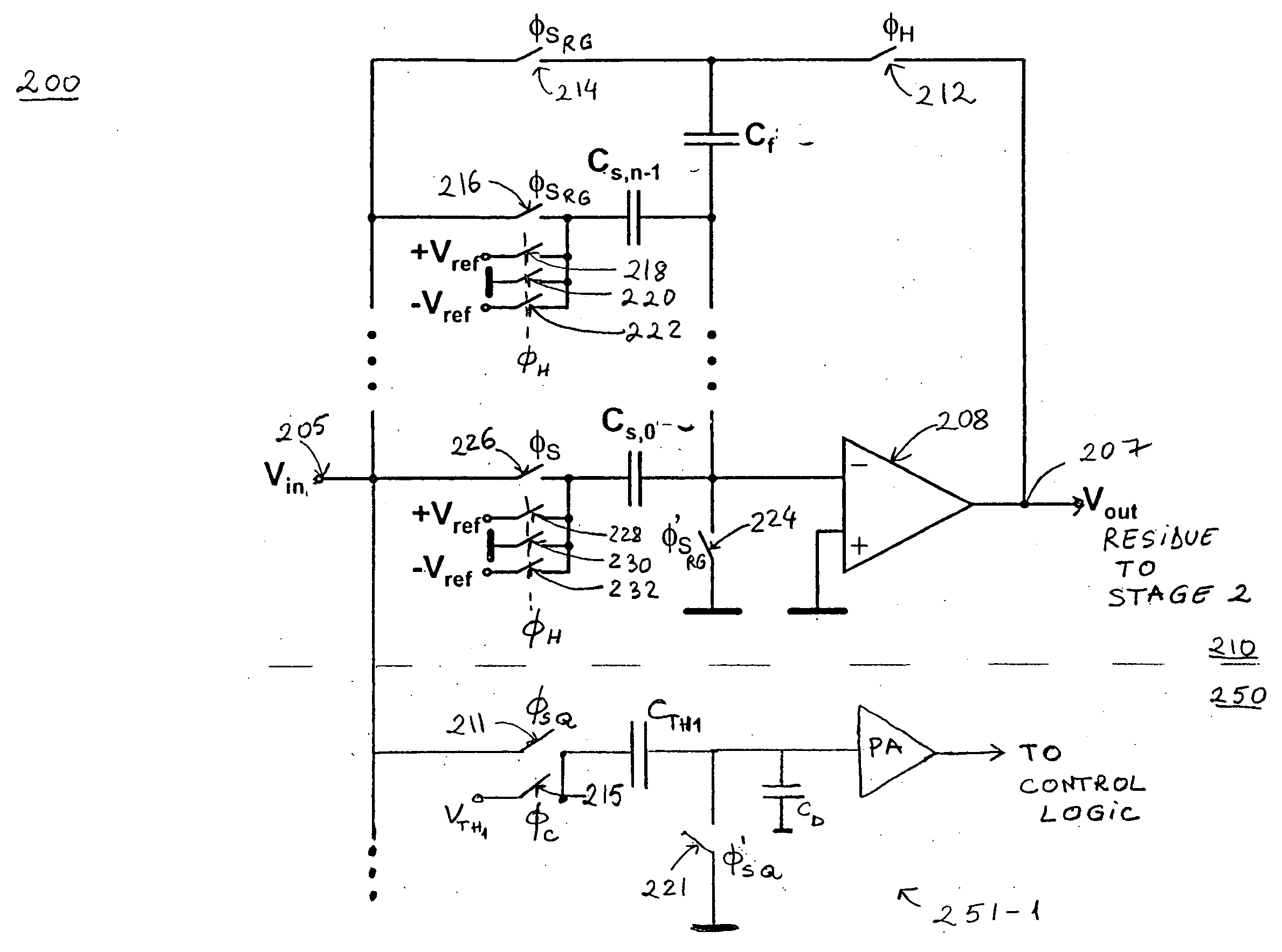

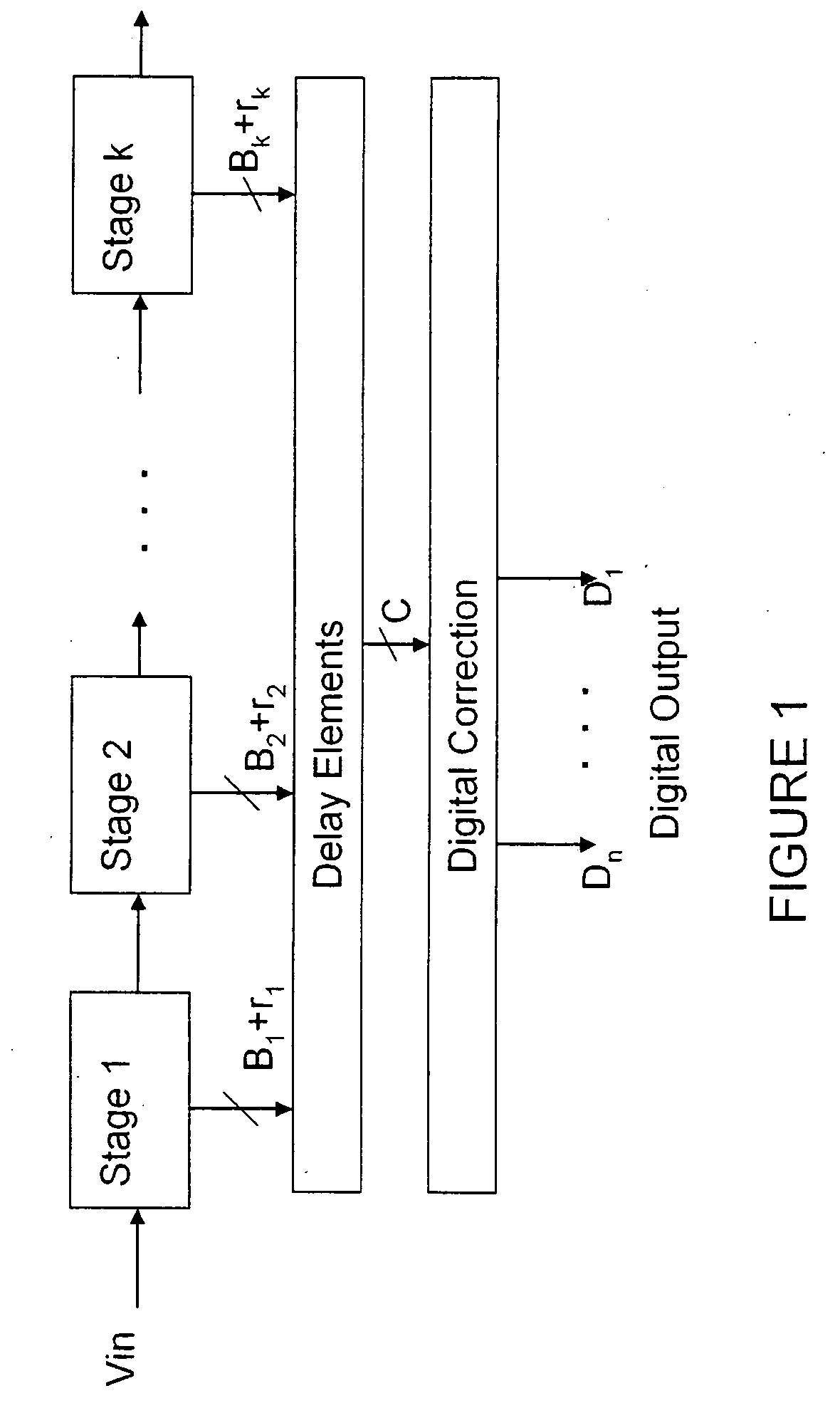

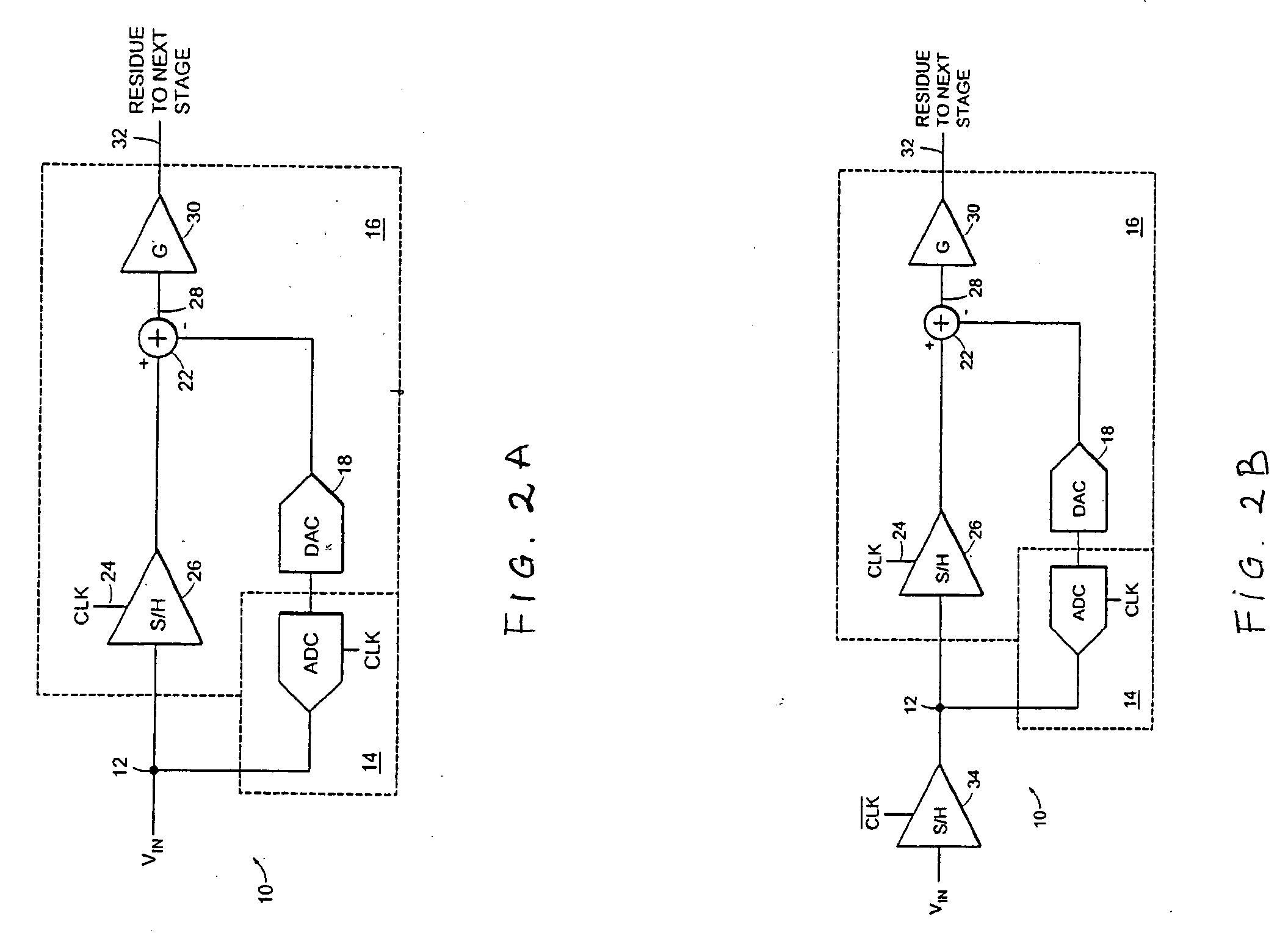

Analog-to-digital converter without track-and-hold

ActiveUS7339512B2Electric signal transmission systemsAnalogue-digital convertersDigital down converterEnd stages

A system and method for converting an analog signal to a digital signal is provided. The analog to digital conversion is achieved without a dedicated sample-and-hold circuit. An ADC stage, preferably the front-end stage in the case of a pipeline ADC, samples the input voltage within a quantizer and within a residue generator. The sampling is performed with associated clocking signals and with switch capacitors also fulfilling the comparison with threshold voltages, within the quantizer and the generation of a residue signal within the residue generator.

Owner:EDGEWATER WIRELESS SYST

Analog-to-digital converter without track-and-hold

ActiveUS20070035432A1Electric signal transmission systemsAnalogue-digital convertersEnd stagesA d converter

A system and method for converting an analog signal to a digital signal is provided. The analog to digital conversion is achieved without a dedicated sample-and-hold circuit. An ADC stage, preferably the front-end stage in the case of a pipeline ADC, samples the input voltage within a quantizer and within a residue generator. The sampling is performed with associated clocking signals and with switch capacitors also fulfilling the comparison with threshold voltages, within the quantizer and the generation of a residue signal within the residue generator.

Owner:EDGEWATER WIRELESS SYST

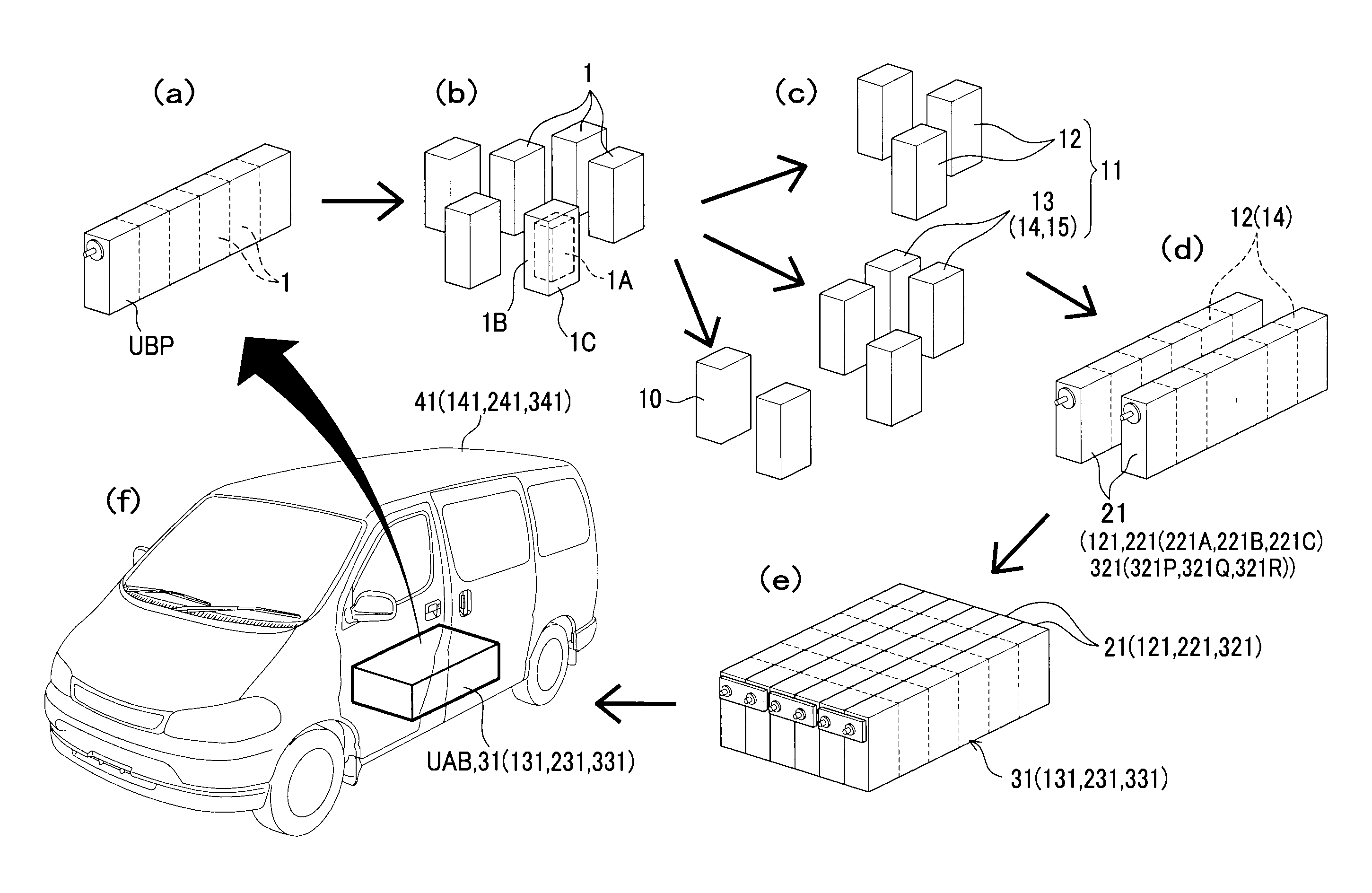

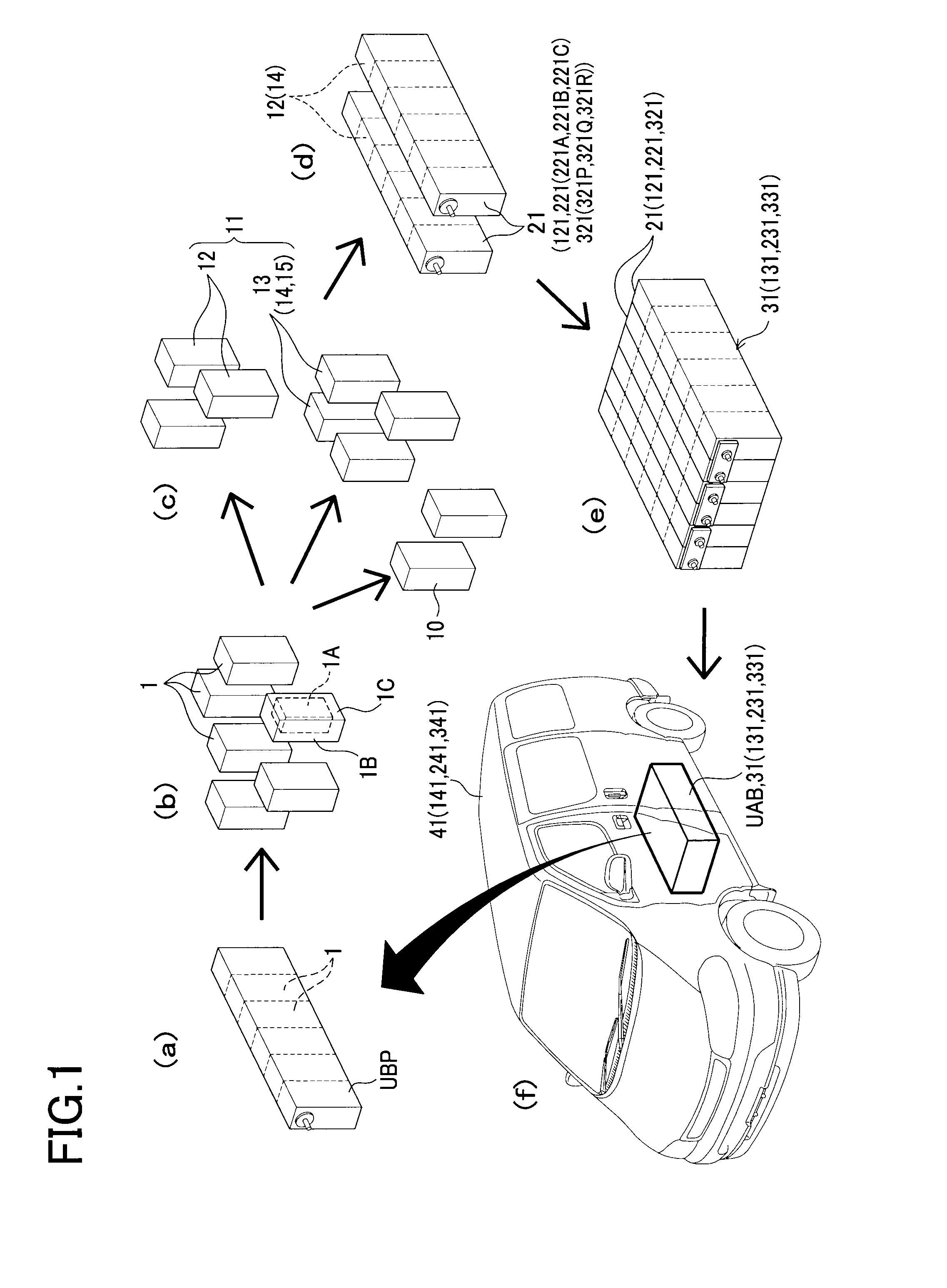

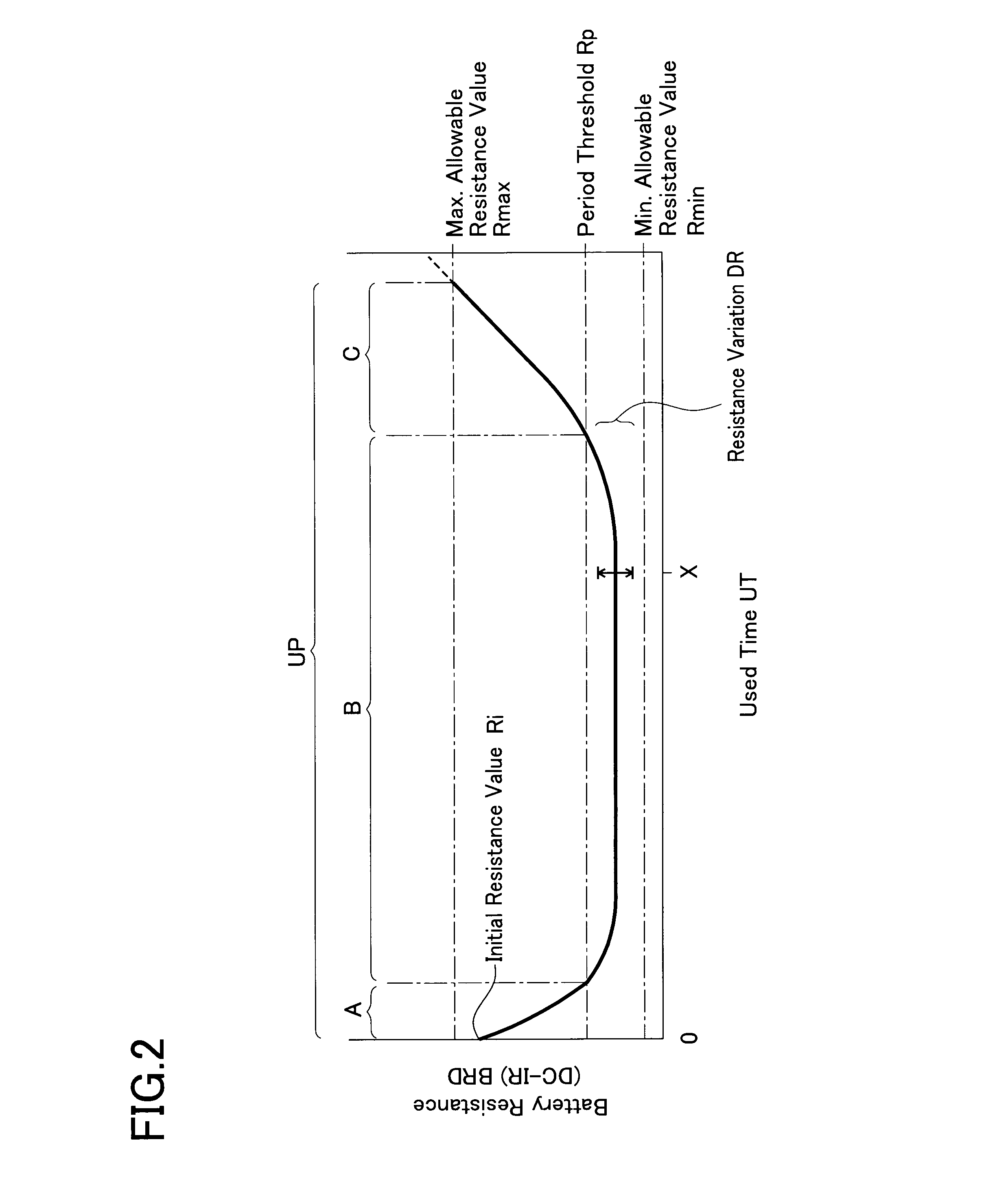

Method for sorting used secondary battery, rebuilt battery pack, vehicle and battery operated device incorporating same, and method for manufacturing rebuilt battery pack

ActiveUS20130015702A1Little changeAvoid disadvantagesPrimary cell to battery groupingDigital data processing detailsHigh resistanceElectrical resistance and conductance

Disclosed are a method for adequately sorting used secondary batteries; a rebuilt battery pack that incorporates the used batteries sorted by the sorting method and have identical characteristics; a vehicle and a battery operated device which use the rebuilt battery pack; and a method for manufacturing a rebuilt battery pack which employs used batteries having identical characteristics. The method for sorting used secondary batteries includes a resistance measurement step for measuring the battery resistance of a battery the characteristics of which show a bathtub curve with respect to the period of use. The method further includes a resistance distinguishing step for distinguishing whether the battery resistance of the battery is greater or less than a period threshold value for identifying to which one of the following periods the battery belongs: an initial-stage high-resistance period, and end-stage high-resistance period, and a middle-stage low-resistance period.

Owner:TOYOTA JIDOSHA KK

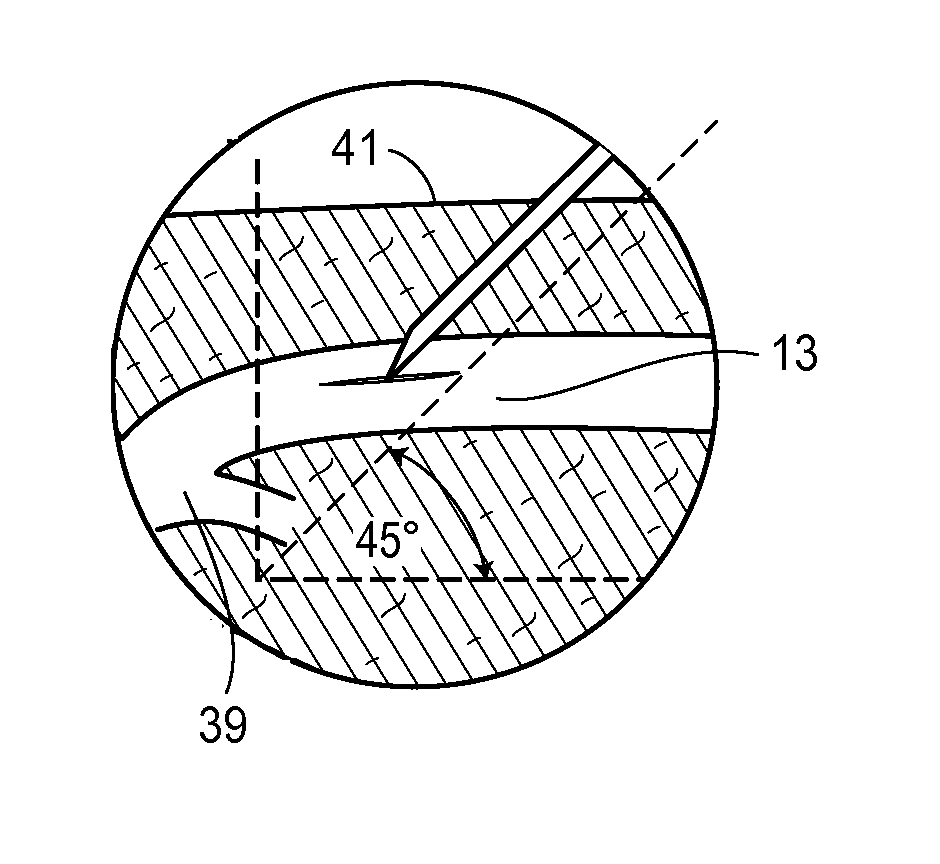

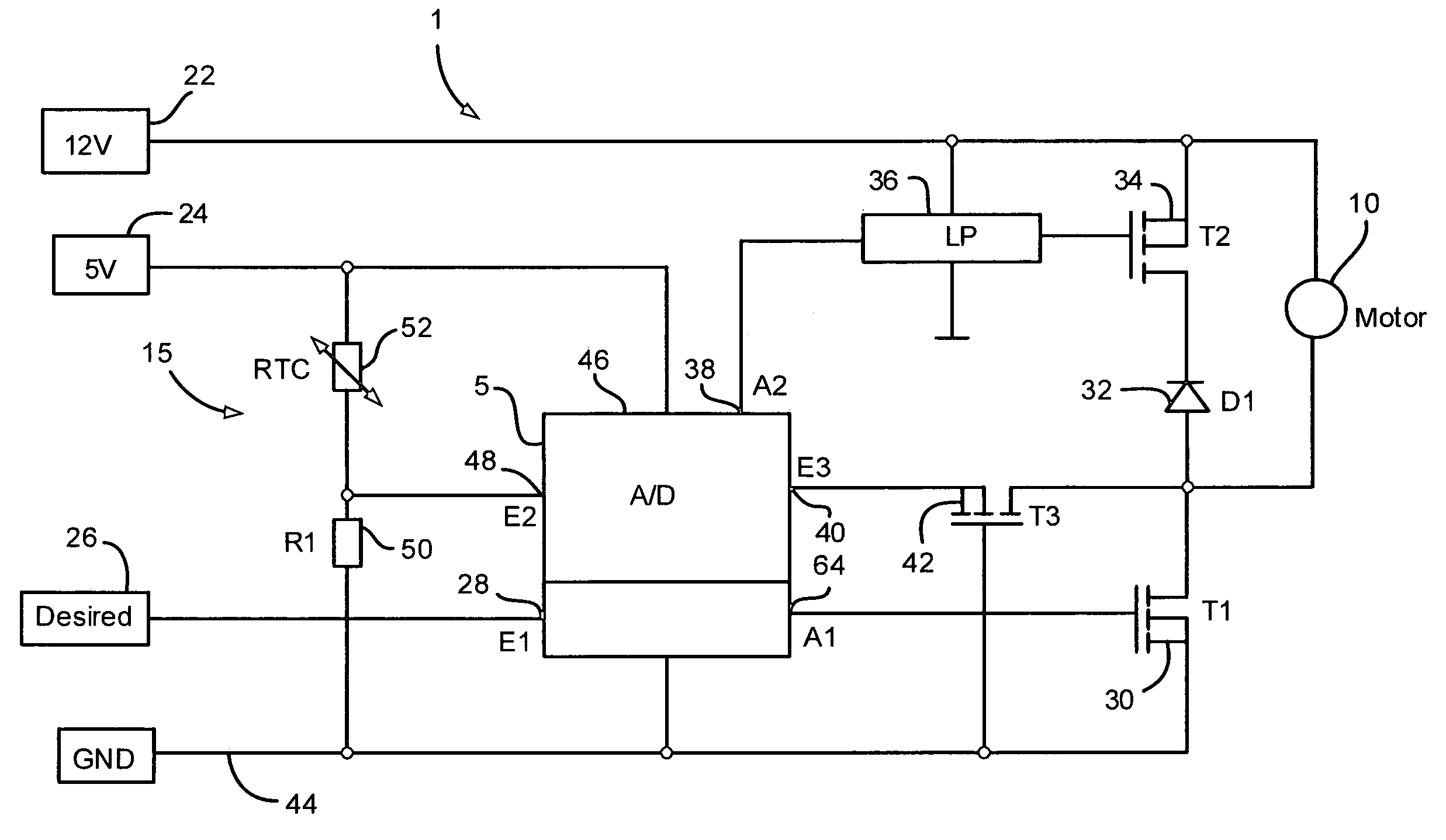

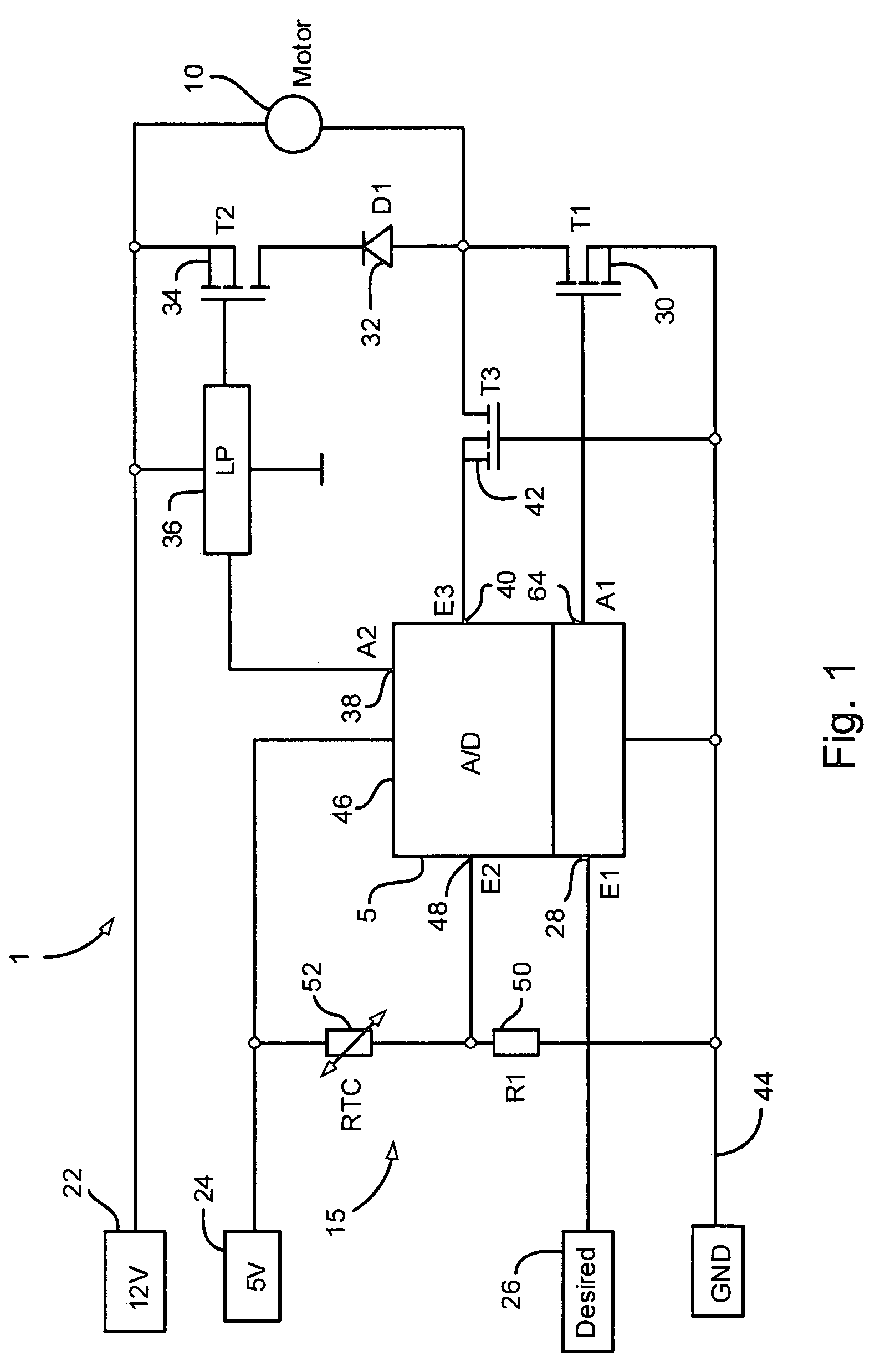

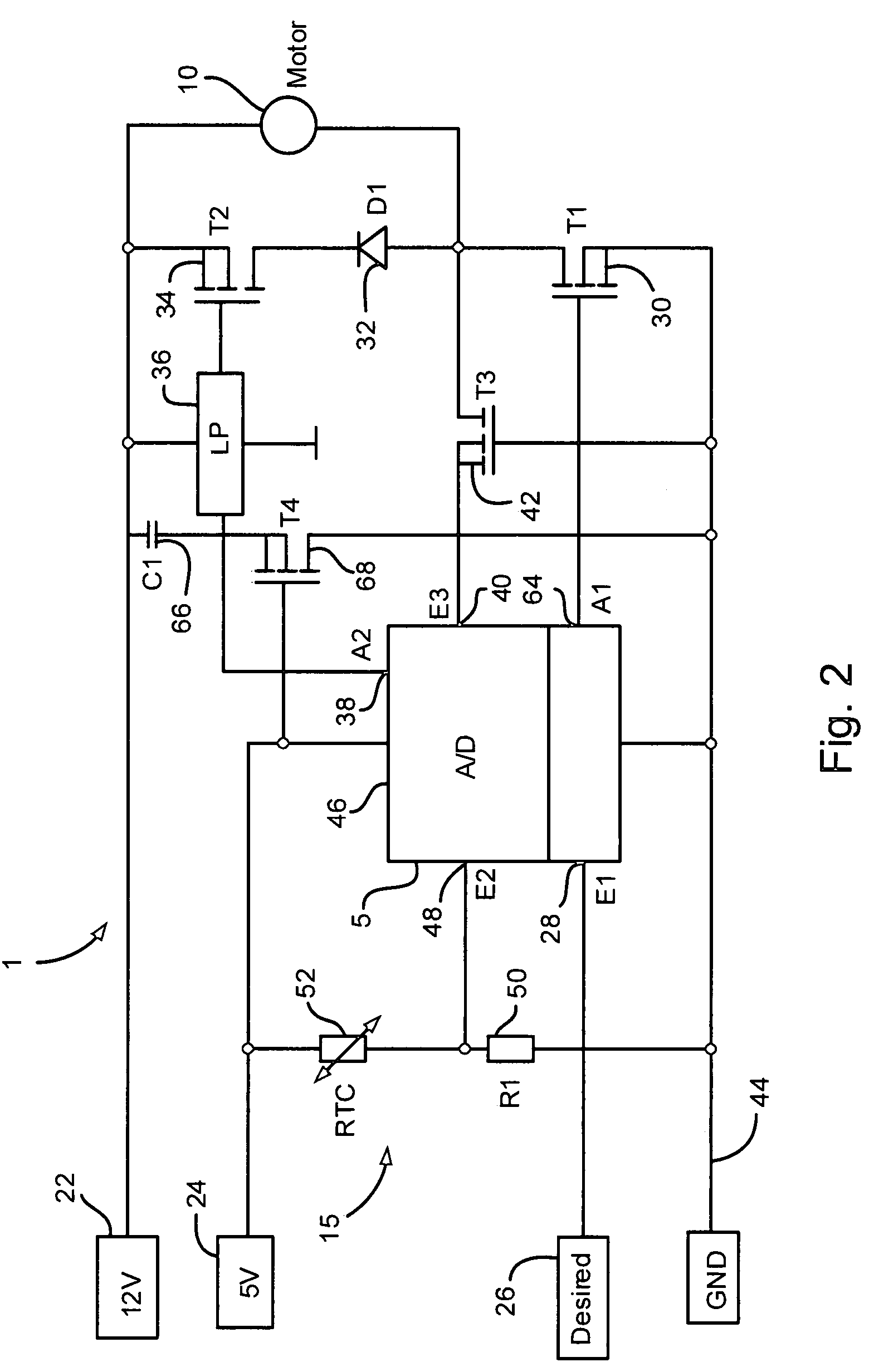

Motor control system for the PWM control of an electric motor

InactiveUS7589490B2Improve accuracyReduce component countMotor/generator/converter stoppersAC motor controlElectrical resistance and conductanceEnd stages

The subject of the present invention is a motor control system having a monitoring circuit for monitoring PWM control for a DC electric motor, the PWM control comprising a power end stage having at least one field effect transistor, which controls the current at the DC electric motor. The motor control system is designed to monitor the current at the DC electric motor. The motor control system detects the voltage drop across the field effect transistor and comprises a temperature sensor for detecting the temperature of the field effect transistor. Furthermore, the motor control system is designed to determine the resistance of the field effect transistor from the detected temperature thereof, and to determine the current at the DC electric motor from the resistance of the field effect transistor and from the voltage drop across the field effect transistor.

Owner:FORD MOTOR CO

Debug method based on substation integrated automation and relaying protection system integration

InactiveCN103576027AImprove the function of integrated automation systemElectrical testingEnd stagesProtection system

The invention discloses a debug method based on substation integrated automation and relaying protection system integration. The method comprises the following steps that at a previous preparation stage, substation primary equipment and secondary equipment are known preliminarily, comprehensive automatic system performance, specific devices and protection screen functions are grasped comprehensively, and the requirement for system debug is met. In a debug stage, comprehensive detailed tests are carried out combined with the design requirement and the system functions, and accordingly pilot run requirements of a substation are met. In a pilot run stage, whether a protection device, a back stage and telecontrol information are correct under the situation that all of the primary equipment and the secondary equipment are put into operation. In a debug ending stage, problems found in pilot run are dealt with, whole work is cleared up and about to end, and the comprehensive automatic system functions are improved.

Owner:ANHUI XINLONG ELECTRICAL

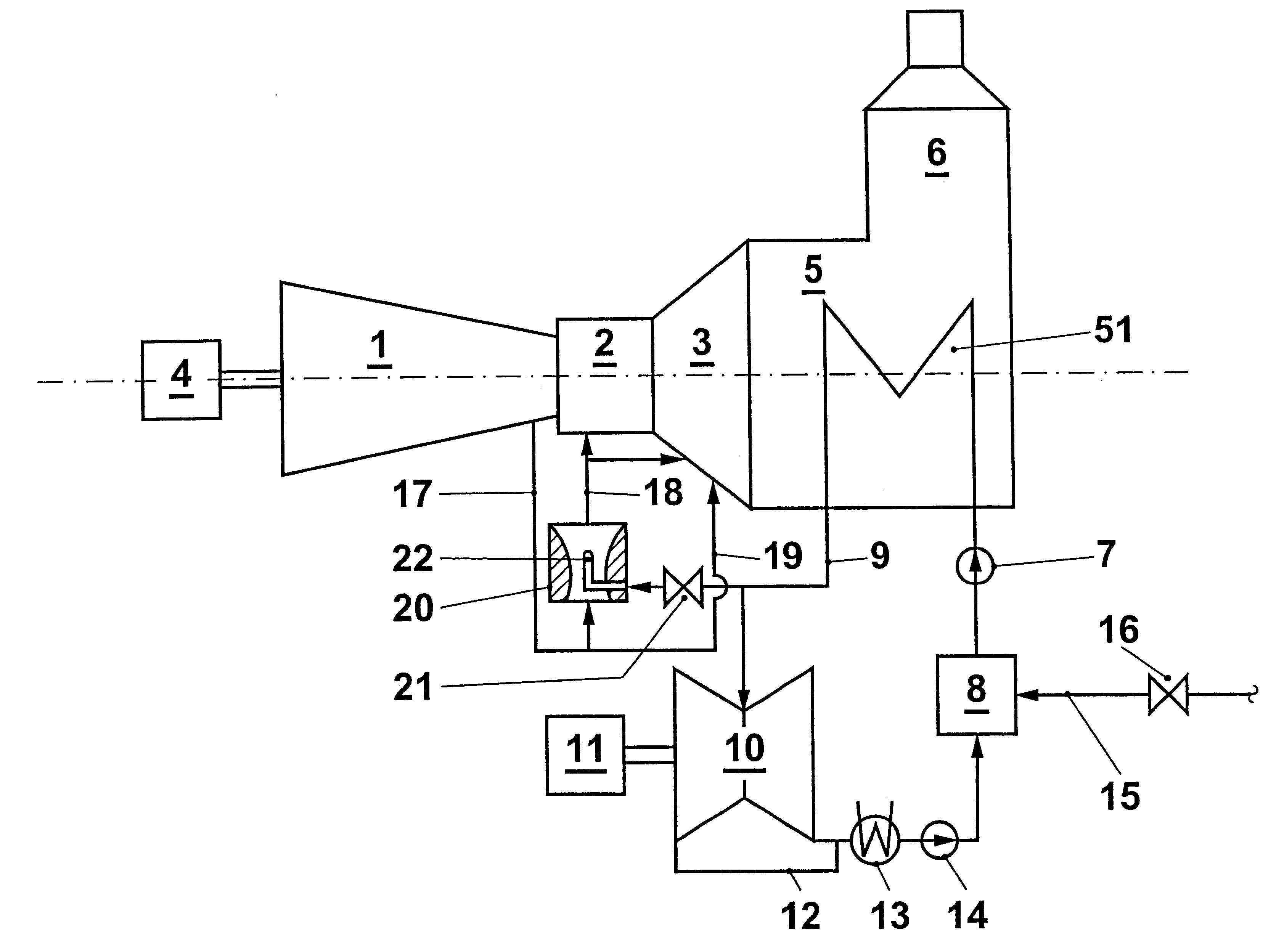

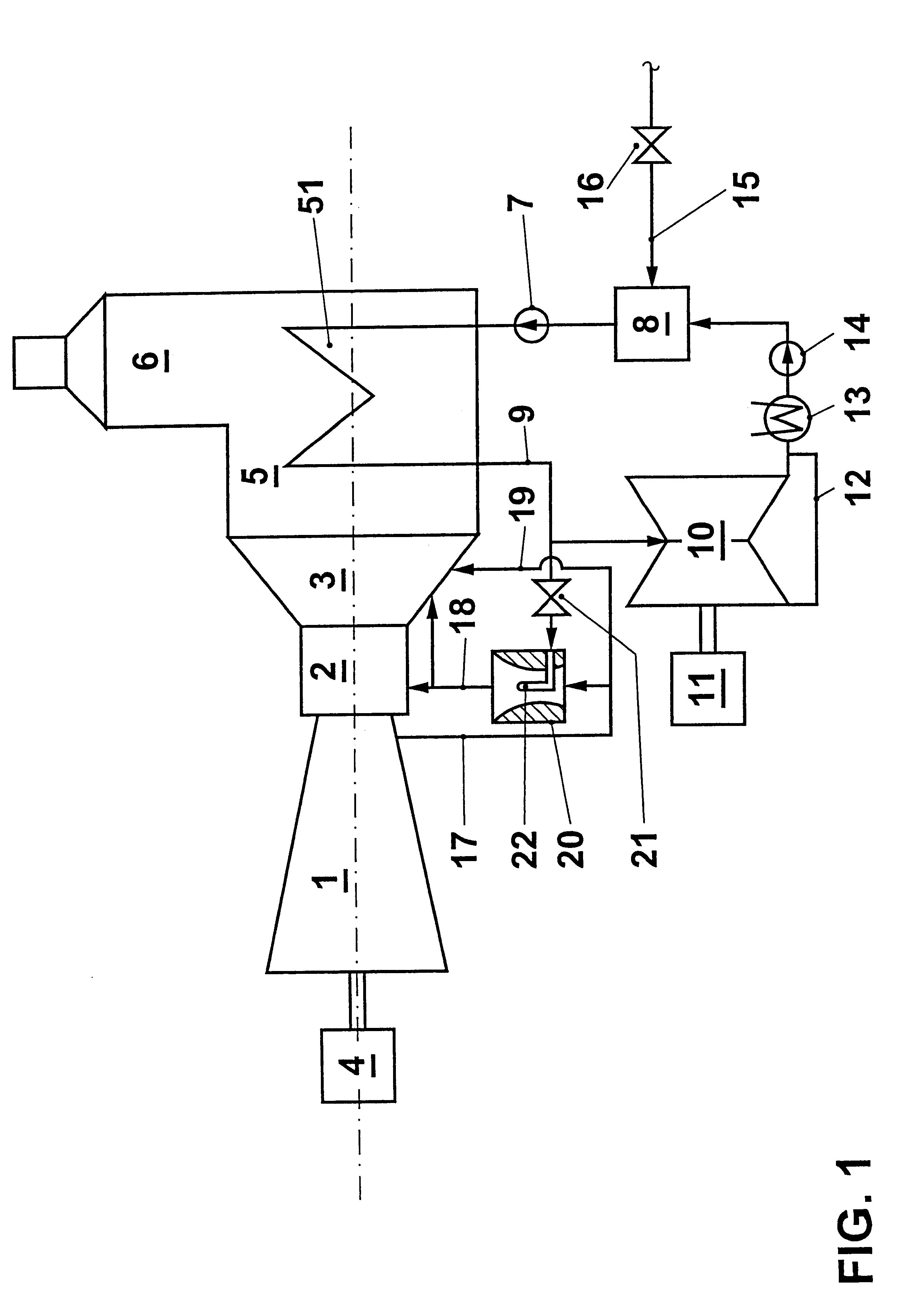

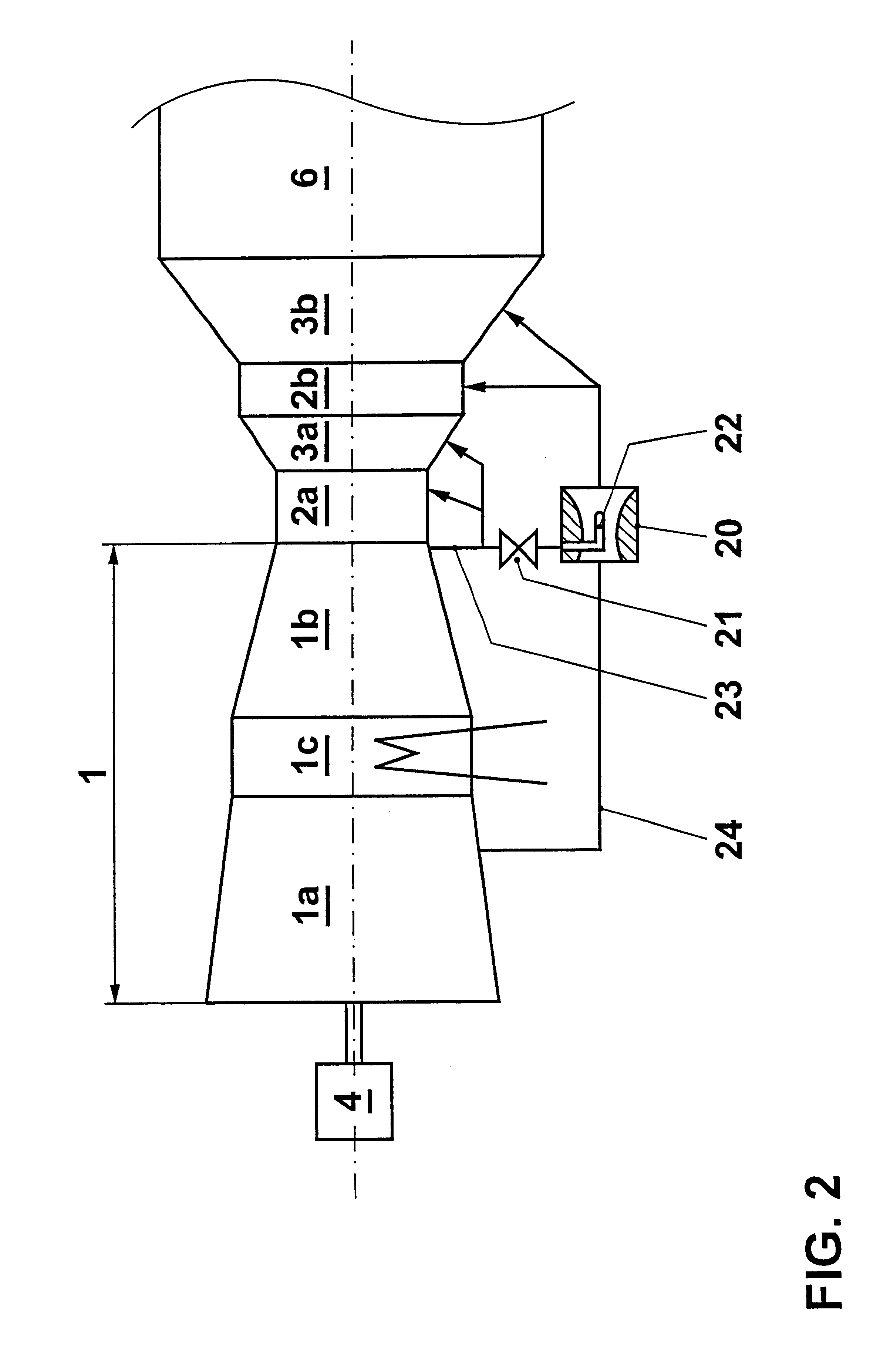

Gas turbine set

For supporting the cooling of an air-cooled gas turbine set, it is proposed to arrange, in the cooling air ducts of the cooling system, means for increasing the pressure of the flowing cooling air. In an embodiment, the cooling system (17) is supplied with high pressure compressor air from the end stages of the compressor (1) of a gas turbine set (1, 2, 3, 4). This cooling system branches into a first branch (18), by means of which the combustor (2) and the first stages, particularly the first guide blade row of the turbine (3), are cooled. A second branch (19) conducts cooling air to the further turbine stages. An ejector (20) is provided for increasing, as needed, the pressure drop available by means of the first branch (18) of the cooling system. Its ejector nozzle (22) is supplied with live steam (9) taken from a waste heat steam generator (51), the live steam supply being adjustable by means of an adjusting member (21). The invention is found to be generally suitable for flexibly configuring the cooling air initial pressure and thereby the cooling air mass flow.

Owner:ANSALDO ENERGIA SWITZERLAND AG

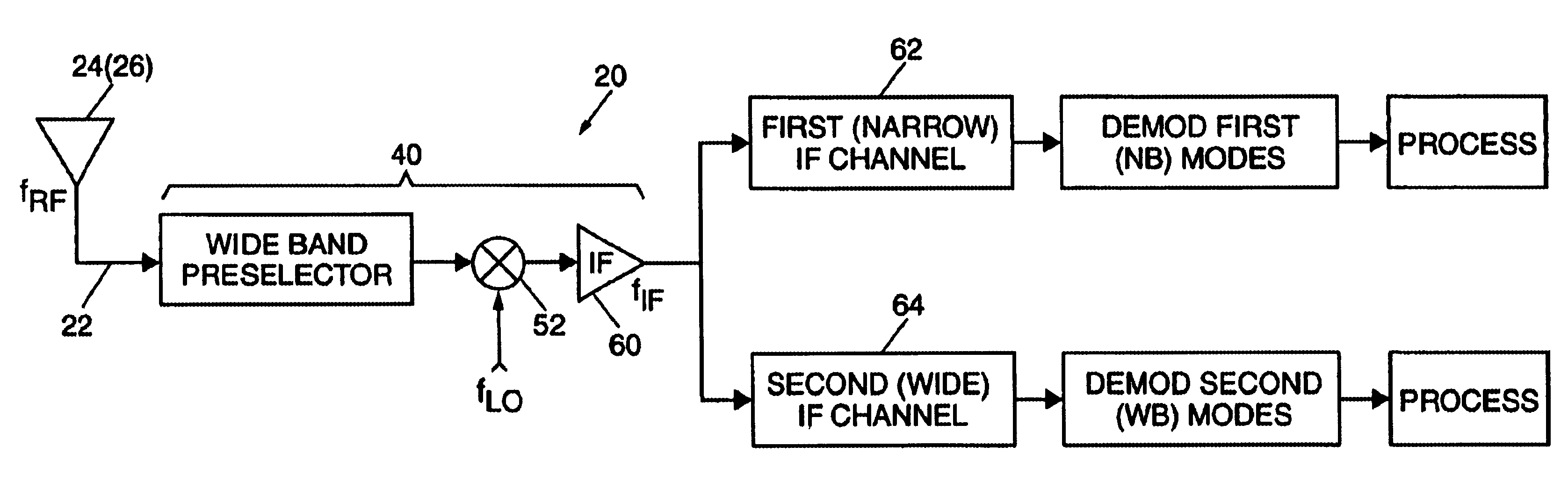

Multi-mode IFF receiver architecture

InactiveUS6885695B1Avoid captureSimultaneous amplitude and angle demodulationAmplitude-modulated carrier systemsIntermediate frequencyRf filters

A transponder receiver for detecting different radio frequency (RF) interrogation mode signals having relatively wide and narrow bandwidths about a common RF center or carrier frequency. A front end stage of the receiver has a preselector with a wide band RF filter for passing both of the wide and the narrow bandwidth interrogation mode signals about the RF center frequency, and a mixer for converting signals from the preselector to frequencies within an intermediate frequency (IF) band. A first IF channel has a narrow band IF filter with a pass band sufficiently wide to pass first IF signals corresponding to the narrow bandwidth interrogation mode signals, but to reject signals corresponding to undesired interfering signals at frequencies near the narrow bandwidth interrogation mode signals. A second IF channel has a wide band IF filter with a pass band sufficiently wide to pass second IF signals corresponding to the desired wide bandwidth interrogation mode signals. The receiver may be incorporated in a transponder for operation in narrow IFF Modes 1-4, C and S, and in wide IFF Mode 5, with optimum performance in all modes.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

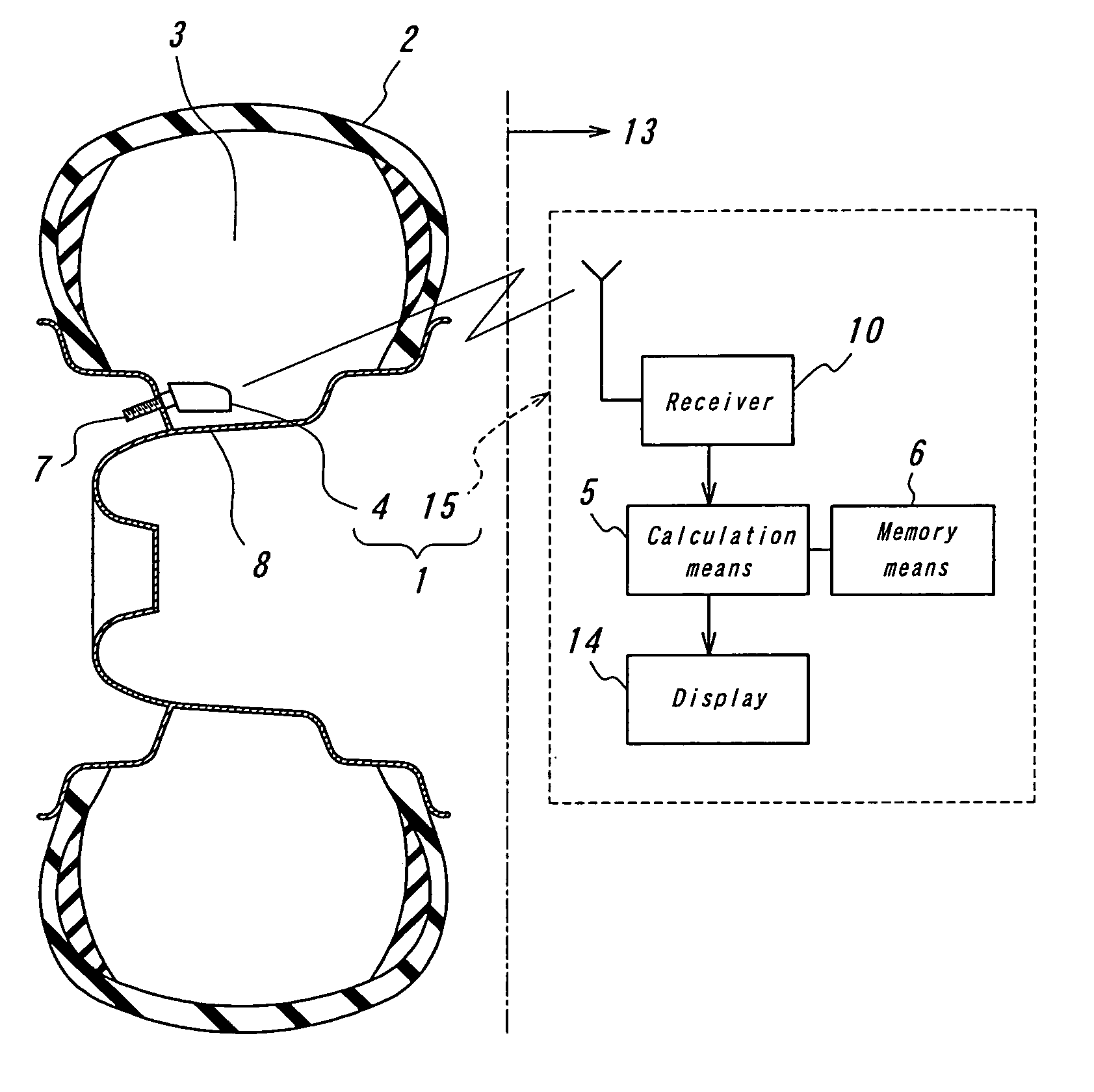

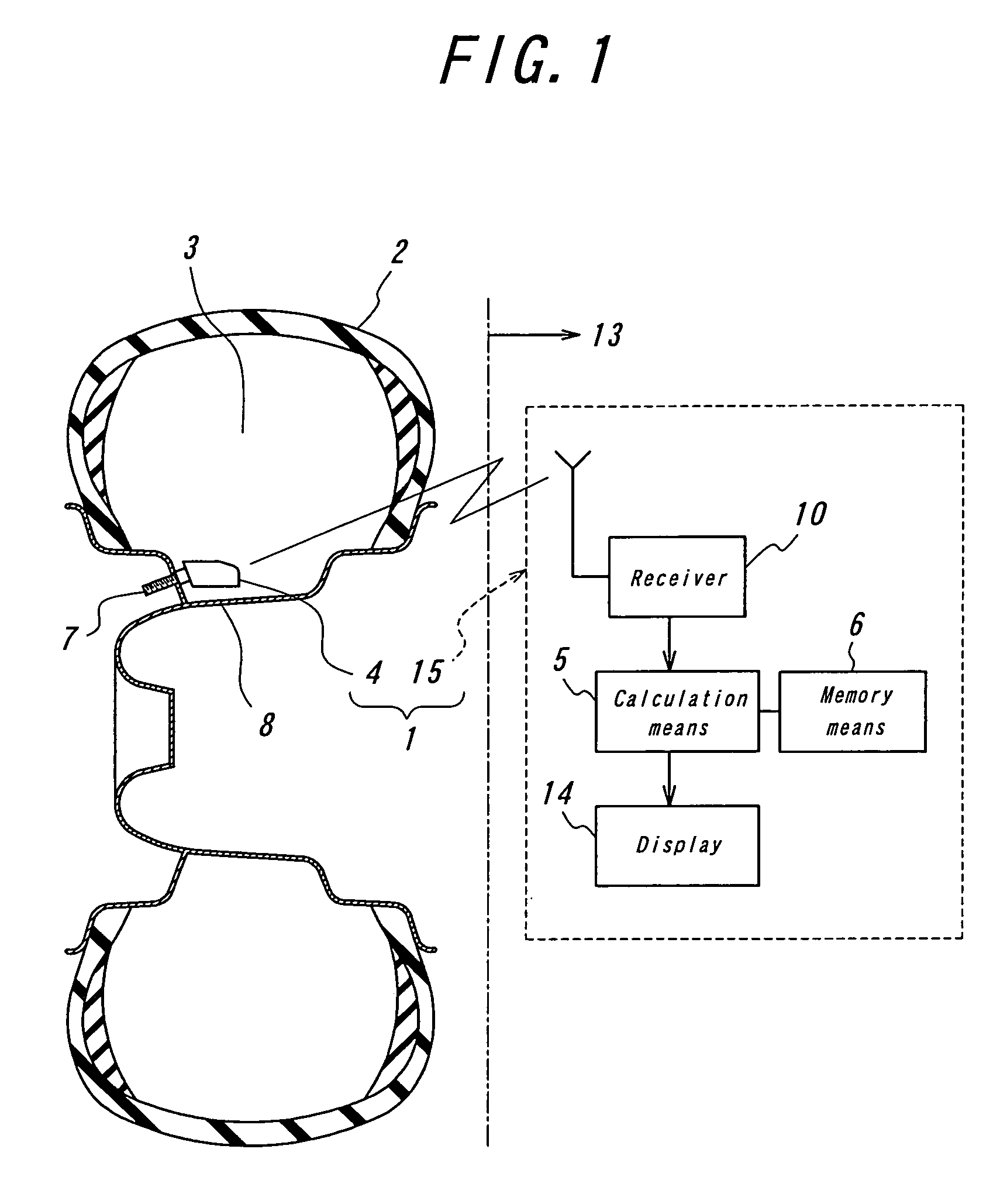

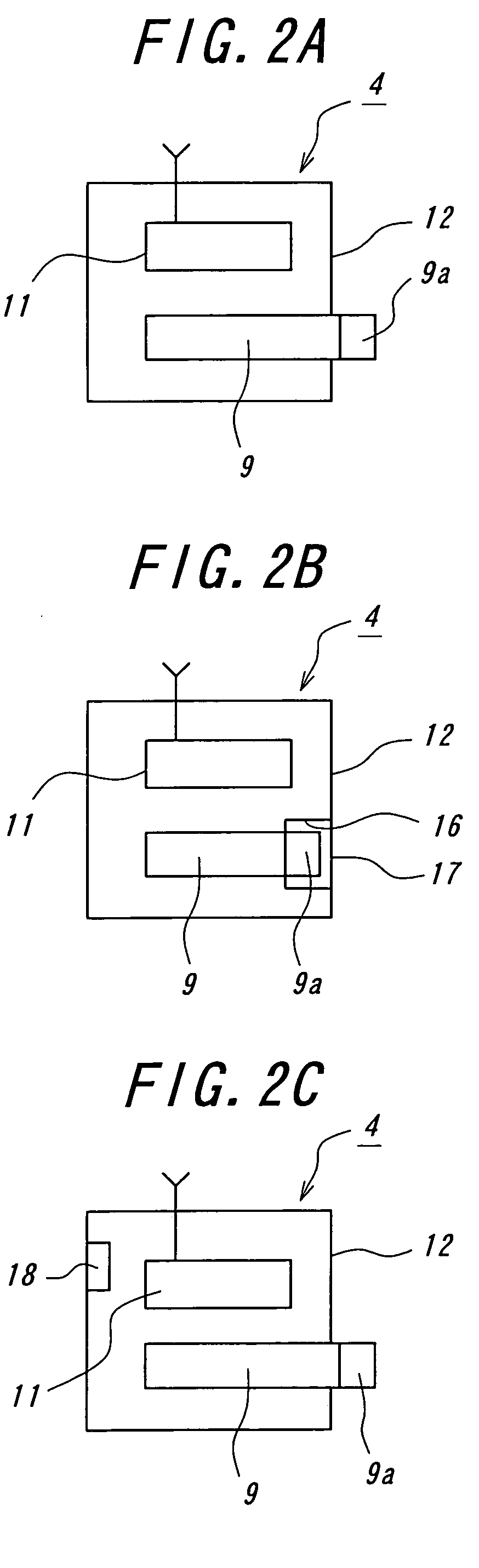

Method device and recording medium where program is recorded, for deciding residual travel life and end of life of run-flat tire that continues traveling in run-flat condition

InactiveUS20060093015A1Improve relationshipConvenient ArrangementThermometer detailsWeather/light/corrosion resistanceInternal pressureEnd stages

There are provided a process and the like for judging a residual lifetime of a run-flat tire and an end stage of the residual lifetime thereof during continuous running at a run-flat state. The process for judging the residual lifetime of the tire of the invention is characterized in that in a vehicle equipped with a run-flat tire system comprising run-flat tires 2 and detection units 4 each arranged in the respective tire 2 and capable of measuring an atmosphere temperature in at least an interior 3 of the tire 2, when the tire 2 is continuously run at the run-flat state by an extreme lowering of an internal pressure accompanied with the occurrence of puncture or the like, after a limit temperature being statistically an occurrence of trouble is previously set, the atmosphere temperature inside tire of the run-flat tire continuously running at the run-flat state is measured, and a runnable time and / or distance until the run-flat tire results in trouble is predicted by using the atmosphere temperature inside tire measured and data calculated therefrom.

Owner:BRIDGESTONE CORP

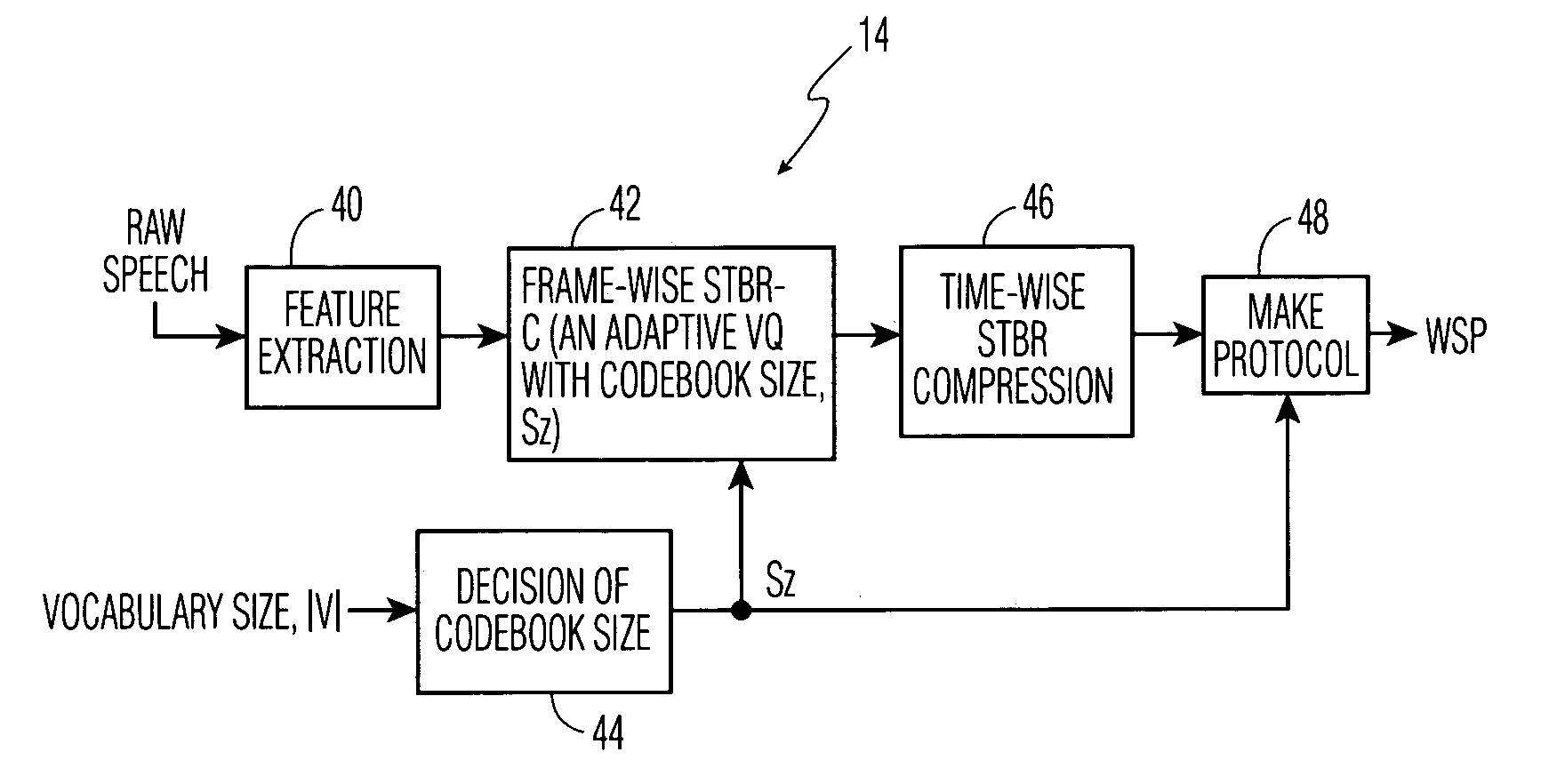

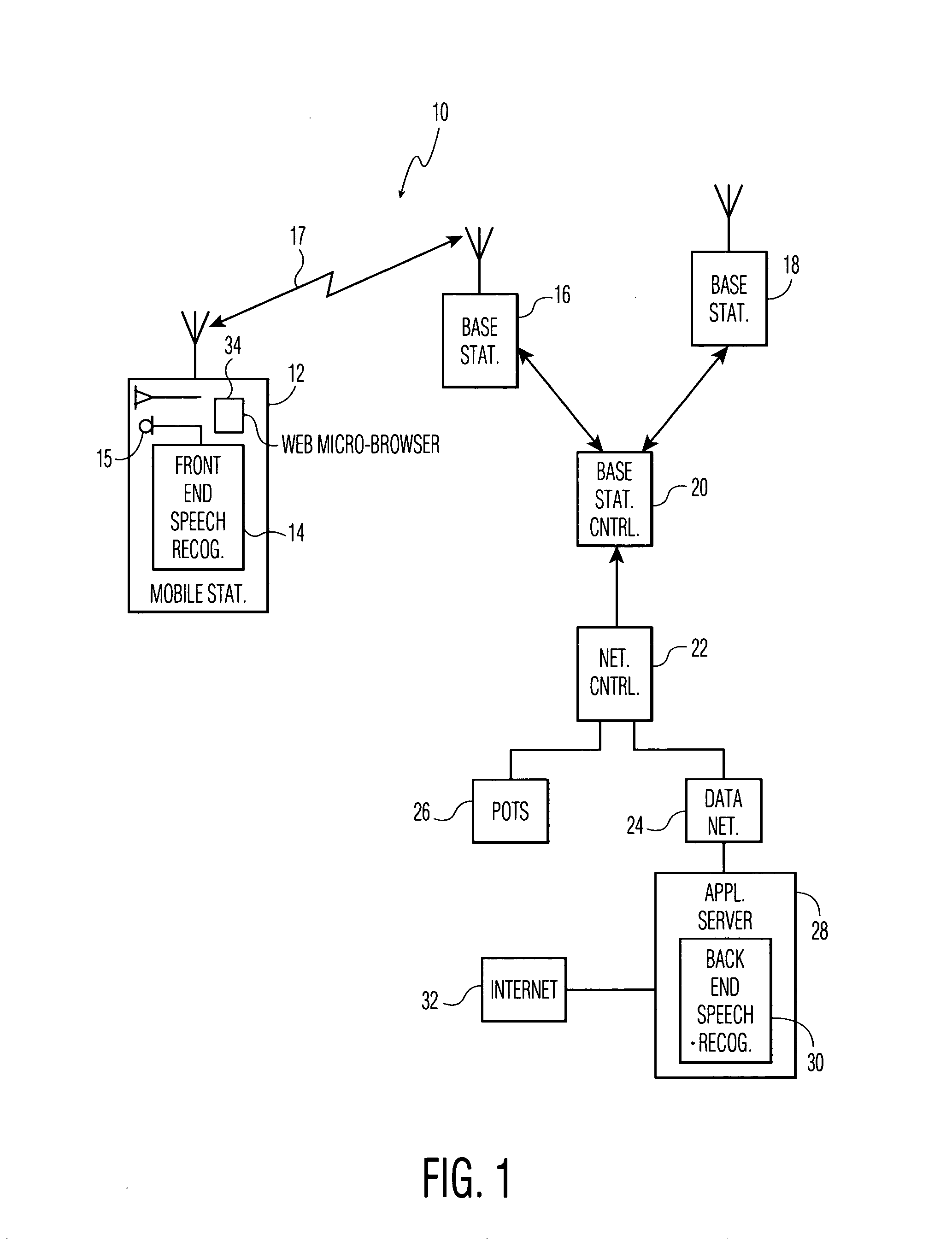

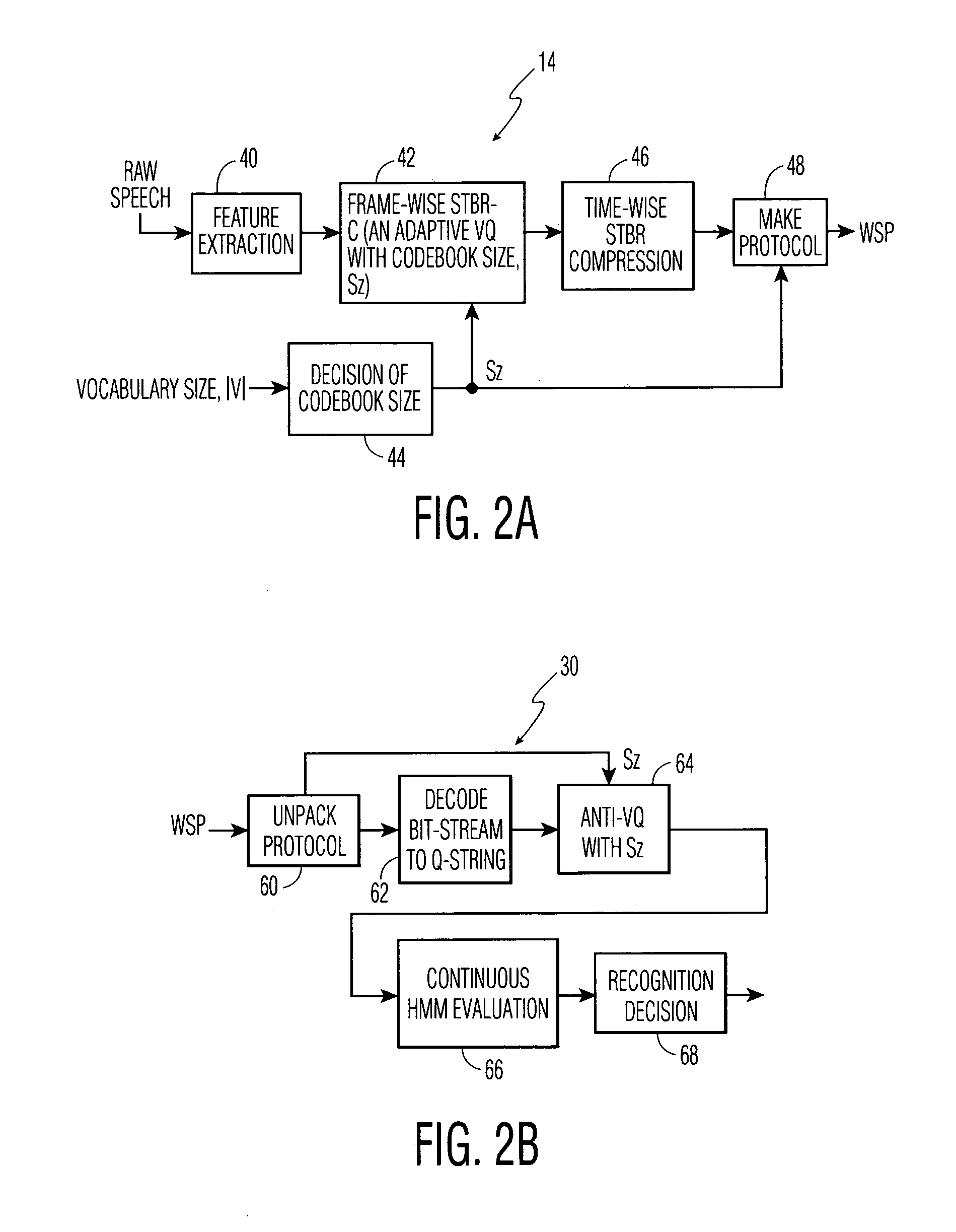

Device and method for coding speech to be recognized (STBR) at a near end

InactiveUS6934678B1Reduce capacityReduced ability to recognizeSpeech recognitionProximal pointMobile station

In a mobile wireless communication system automatic speech recognition is performed in a distributed manner using a mobile station based near or front end stage which extracts and vector quantizes recognition feature parameters from frames of an utterance and an infrastructure based back or far end stage which reverses the vector quantization to recover the feature parameters and subjects the feature parameters to a Hidden Markov Model (HMM) evaluation to obtain a recognition decision for the utterance. In order to conserve network capacity, the size (Sz) of the codebook used for the vector quantization, and the corresponding number of bits (B) per codebook index B, are adapted on a dialogue-by dialogue basis in relation to the vocabulary size |V| for the dialogue. The adaptation is performed at the front end, accomplishes a tradeoff between expected recognition rate RR and expected bitrate BR by optimizing a metric which is a function of both.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

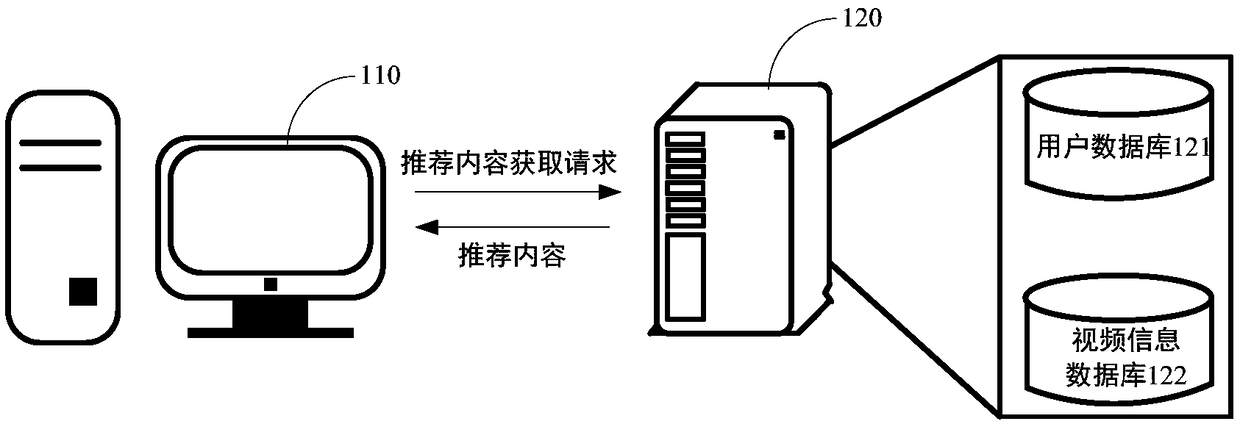

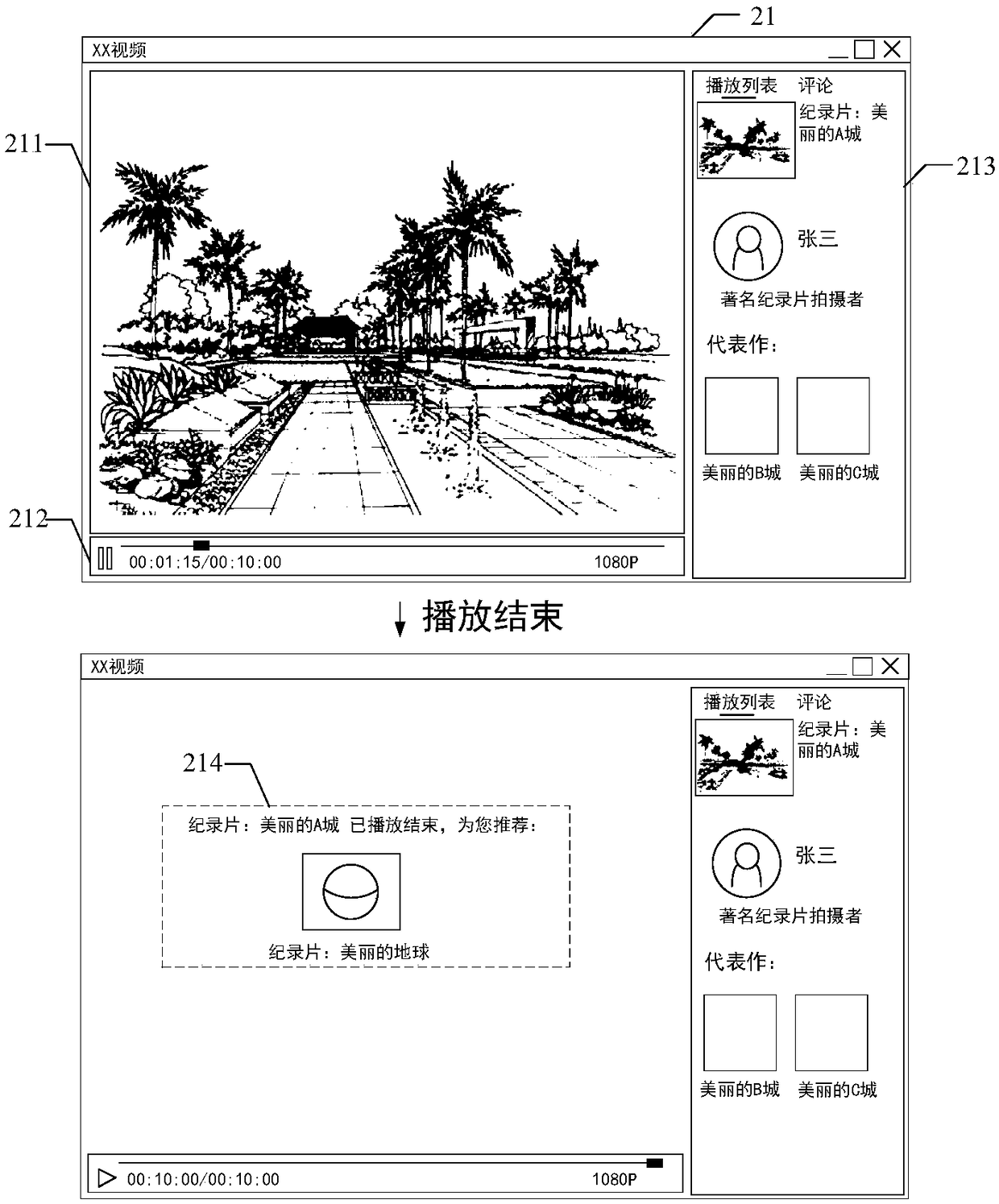

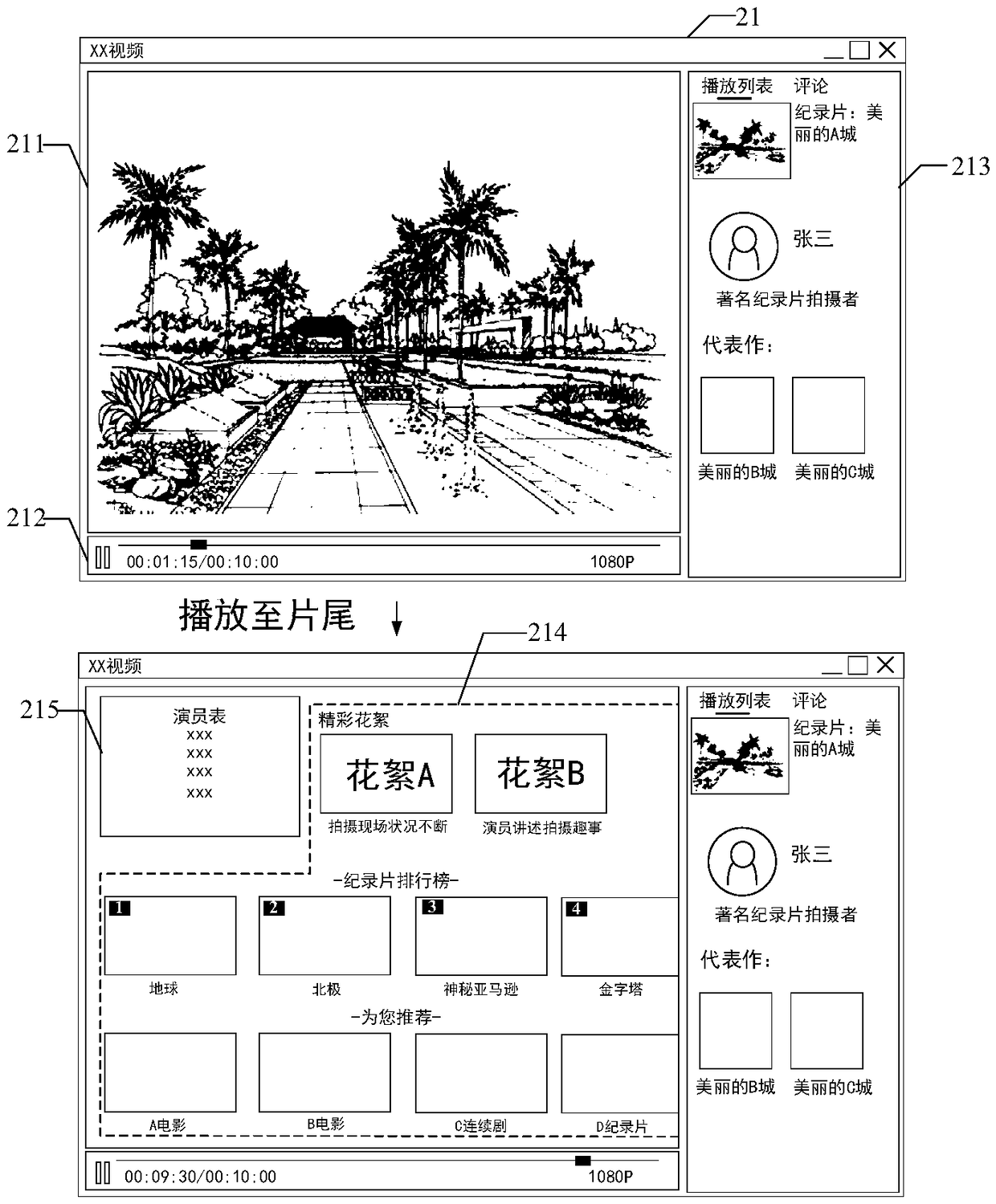

Recommended content display method, device, terminal and storage medium

The application discloses a recommended content display method and device, a terminal and a storage medium, and belongs to the field of the content recommendation. The method comprises the following steps: playing a target video in a video playing region of a video player; when the target video is played to the end, scaling down the size of the video playing region; and displaying the scaled-downvideo playing region and recommended content in the video player, wherein the scaled-down video playing region is used for continuously playing the target video. Compared with condition that the recommended content can be displayed after the video is completely played in the related technology, a user can check the recommended content at the end stage of the video by adjusting the size of the video playing region and performing content recommendation in the video player in the premise of not affecting the normal video watching of the user, and then the exposure rate of the recommended contentis improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

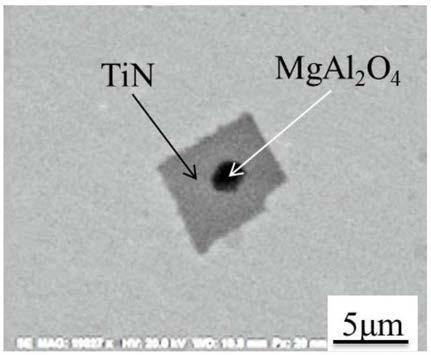

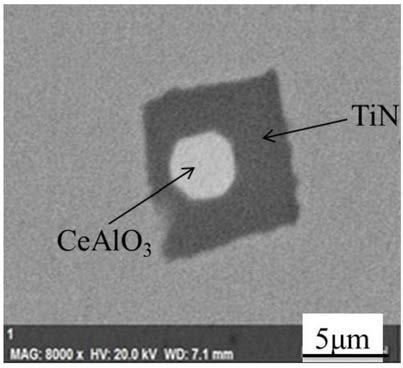

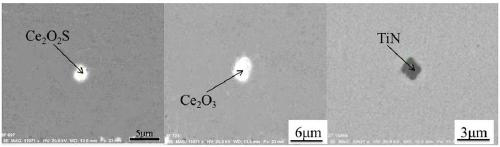

Alloy technology of adding Ce into bearing steel for inhibiting formation of TiN compound inclusion

The invention relates to the technical field of rare earth alloy, and provides an alloy technology of adding Ce into bearing steel for inhibiting formation of TiN compound inclusion. The alloy technology comprises the following steps: when a primary smelting furnace carries out steel tapping, making pre-smelted slags; in an LF (Ladle Furnace) refining process, making refining slags; at the end stage of vacuum smelting, adding rare earth Ce of which the adding amount is 0.15-0.75kg / (ton of steel); after the rare earth Ce is added, carrying out steel ladle bottom blowing Ar for soft stirring. According to the alloy technology, the rare earth Ce is added into bearing steel, MgAl2O4 in the steel is modified into a specific type of rare earth oxide (Ce2O3) or rare earth oxysulfide (Ce2O2S), andthe separation of the heterogeneous nucleation of TiN on MgAl2O4 in a solidification process is inhibited, the generated rare earth oxide or rare earth oxysulfide has a small size, and the hardness is far lower than that of MgAl2O4 inclusion. The obtained simple substance TiN inclusion has the advantages of small size and even distribution, and a new method is provided for improving the fatigue life of bearing steel.

Owner:UNIV OF SCI & TECH BEIJING

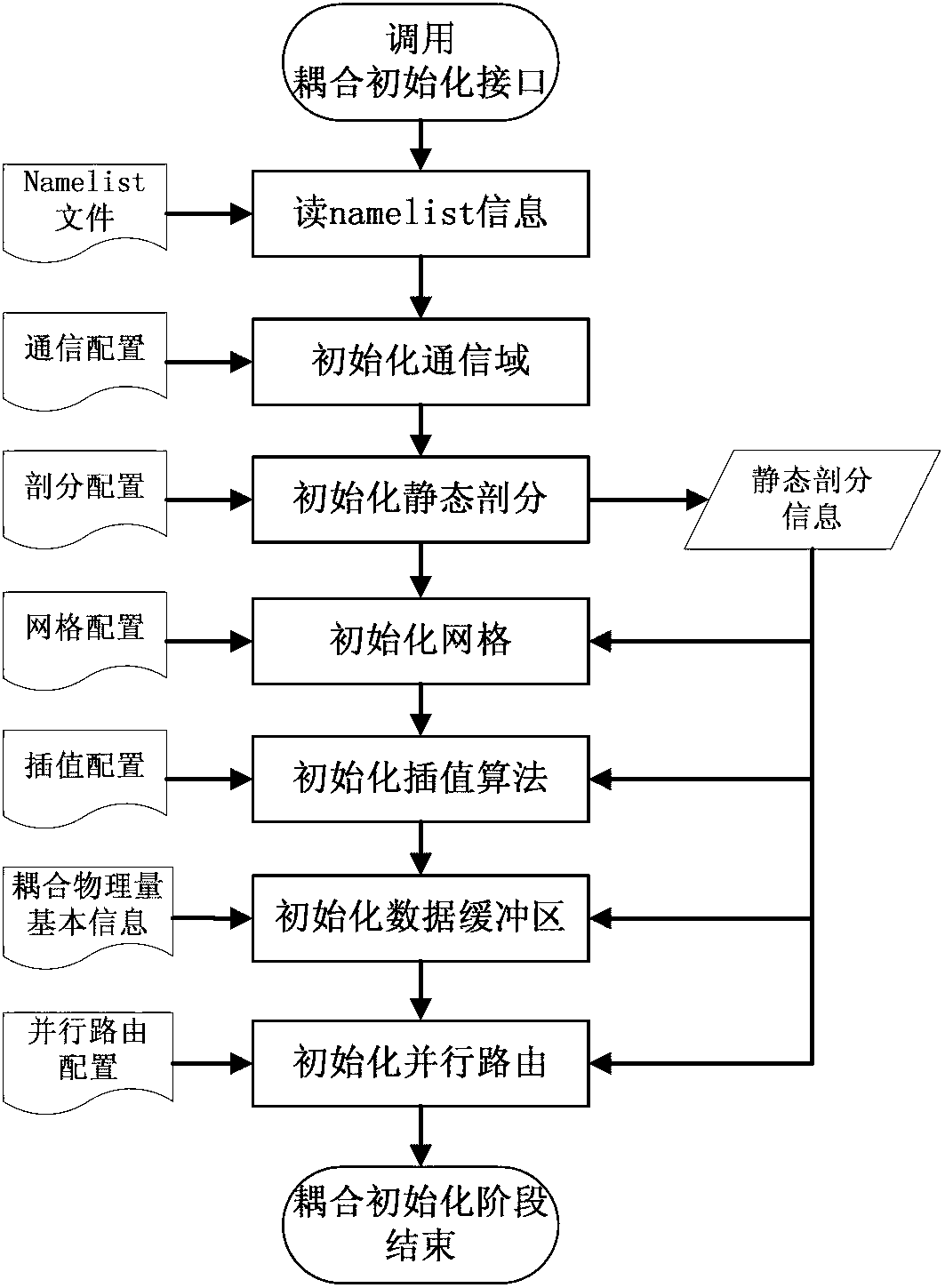

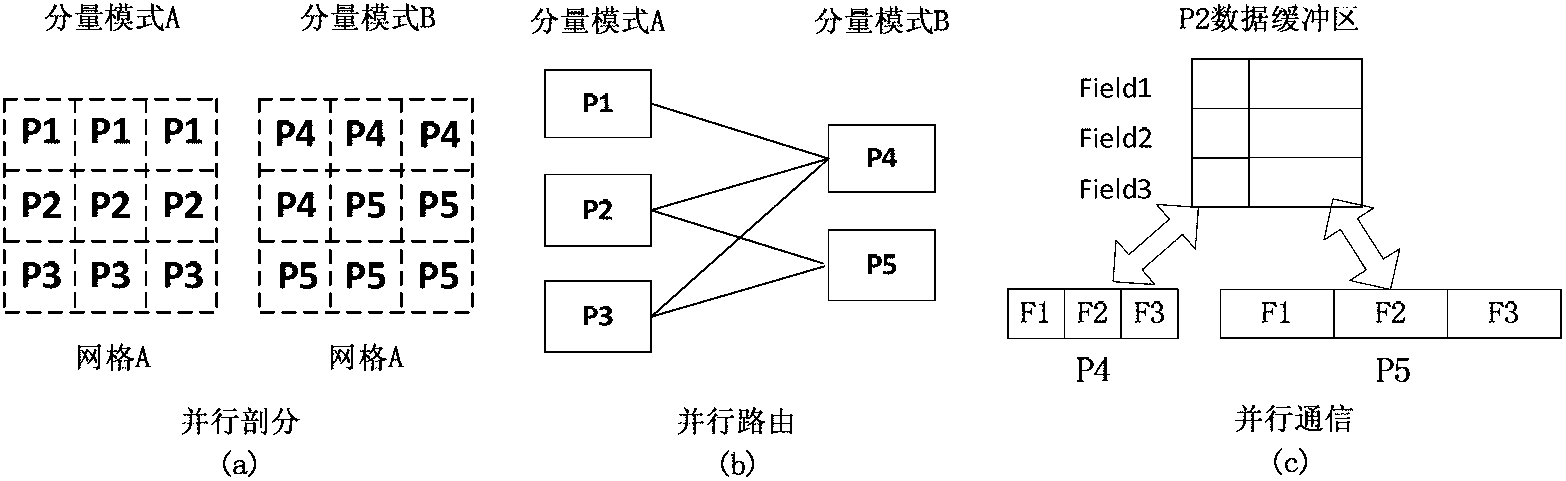

Parallel coupling method for global system mode

ActiveCN102707932AEliminate communication operationsReduce the number of communicationsInterprogram communicationConcurrent instruction executionEnd stagesCoupling

Owner:TSINGHUA UNIV

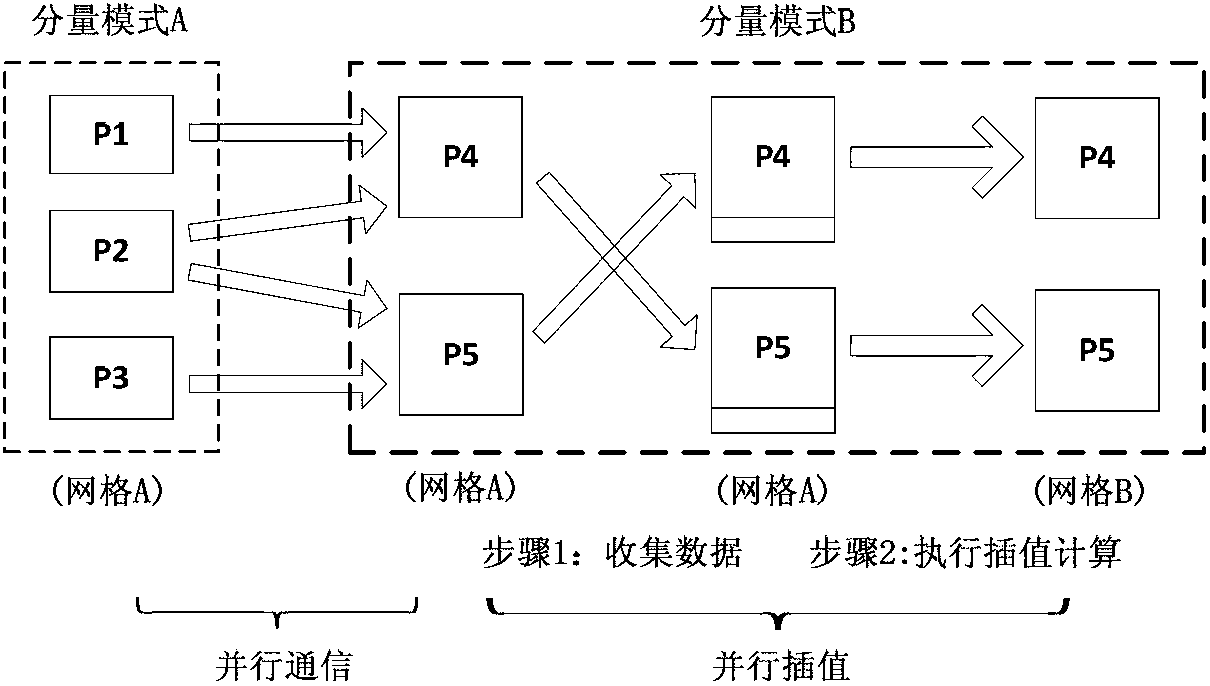

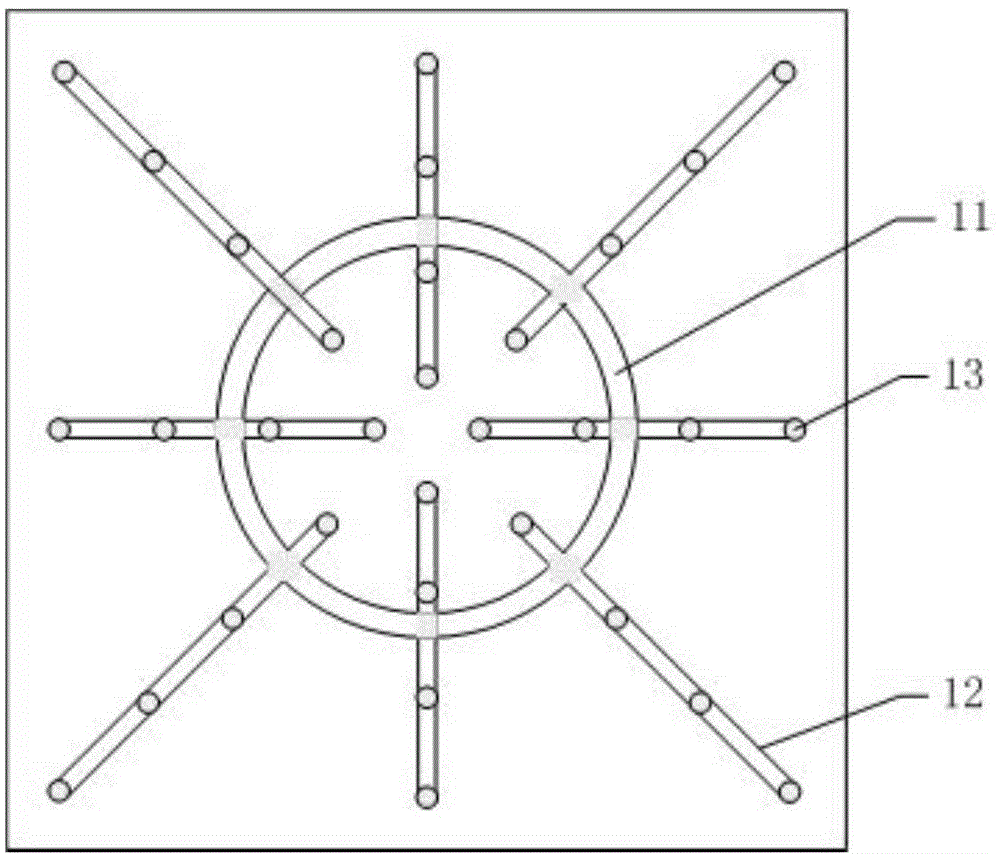

Sequencing batch sludge deep dewatering equipment and method adopting electroosmosis

ActiveCN104671632AReduce consumptionExtend anode lifeSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentEnd stagesDrive wheel

The invention relates to sequencing batch sludge deep dewatering equipment and method adopting electroosmosis. The equipment comprises a closed frame, wherein an anode assembly and a cathode assembly are arranged in the frame; the cathode assembly comprises a driving wheel set supported at the lower part of the frame, the driving wheel set is sleeved with annular cathode filter cloth connected end to end, and cathode plates are arranged on the inner side of the cathode filter cloth; the anode assembly comprises a group of anode plates opposite to the cathode plates and a fixed seat supported at the upper part of the frame, and the anode plates are supported on the fixed seat respectively through driving pieces; anode filter cloth is arranged on one side, back to the corresponding driving piece, of each anode plate; sludge treatment space is formed between the anode plates and the cathode plates; and a middle layer and a surface active layer are arranged on the surface of each anode plate sequentially. The method comprises a start stage, a normal circulation work stage and an end stage. The service life of an anode can be prolonged, the electric energy consumption can be reduced, and biochemical sludge with the moisture content of 80%-85% can be dewatered until the moisture content reaches 55%-60%.

Owner:南京赛佳环保实业有限公司

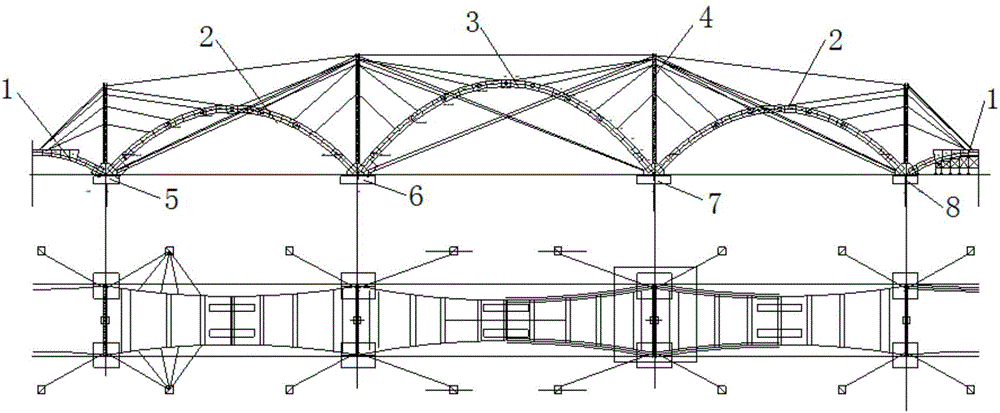

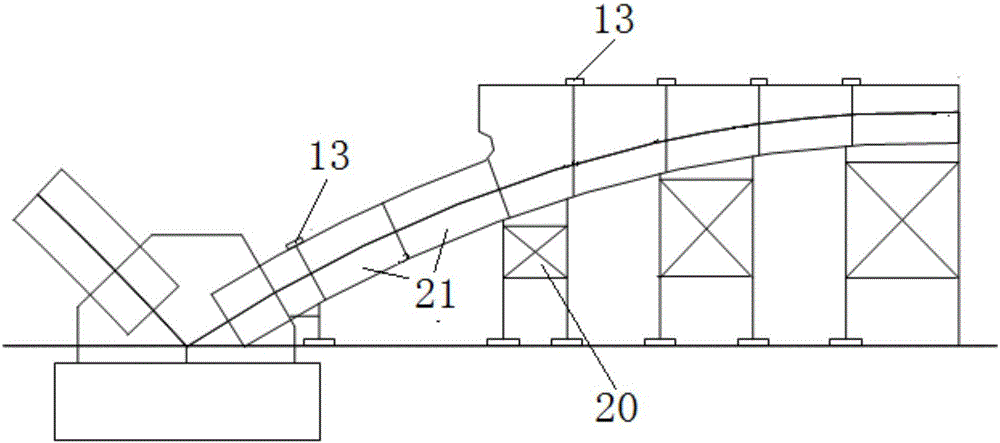

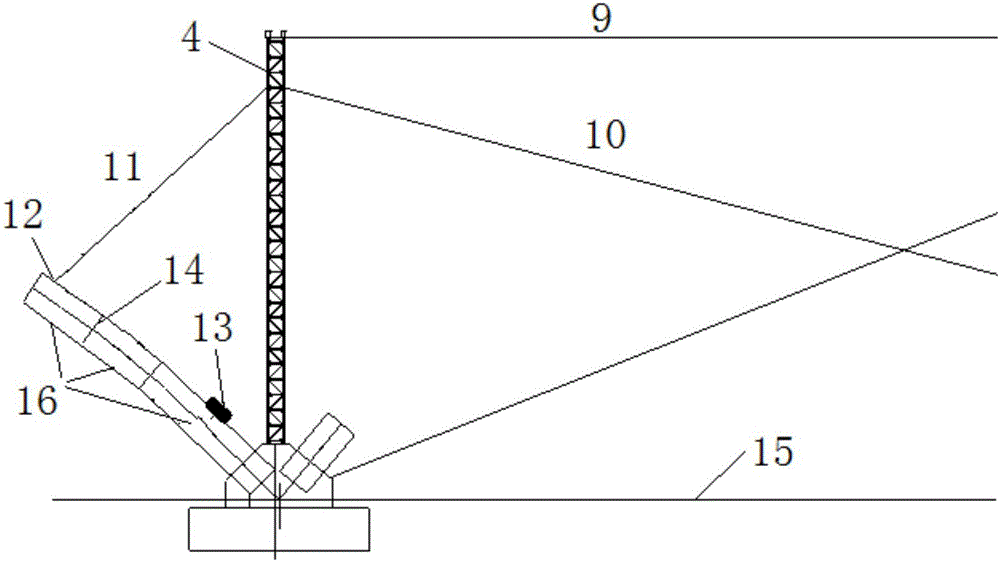

Construction method for multi-span basket type arch bridge

ActiveCN106087752AImprove construction progressSave materialBridge erection/assemblyArch-type bridgeEnd stagesMechanical models

The invention discloses a construction method for a multi-span basket type arch bridge and belongs to the technical field of bridge constructing methods. The construction method for the multi-span basket type arch bridge comprises a construction preparation stage, an arch foot installation stage, a side span and cable tower synchronous installation stage, a subsidiary side span and middle span arch rib installation stage and a construction ending stage. Side spans are installed through a support method. Subsidiary side spans and a middle span are installed through a self-balancing buckling method. Further, a mechanical model for the whole construction process is established by use of finite element calculation software MIDAS CIVIL, so that mechanical analysis is conducted on each construction stage. According to the construction method for the multi-span basket type arch bridge, the self-balancing buckling method is created besides the adopted conventional support method; defects of an inclined pulling and buckling installation technique are overcome; anchor cable materials are omitted; large-scale temporary building amount is decreased; the construction face of bridge installation is further expanded; the working efficiency is improved; the construction method has a decisive effect for speeding up the construction progress; the construction cost is greatly lowered; and the construction method adapts to construction of large multi-span bridges.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

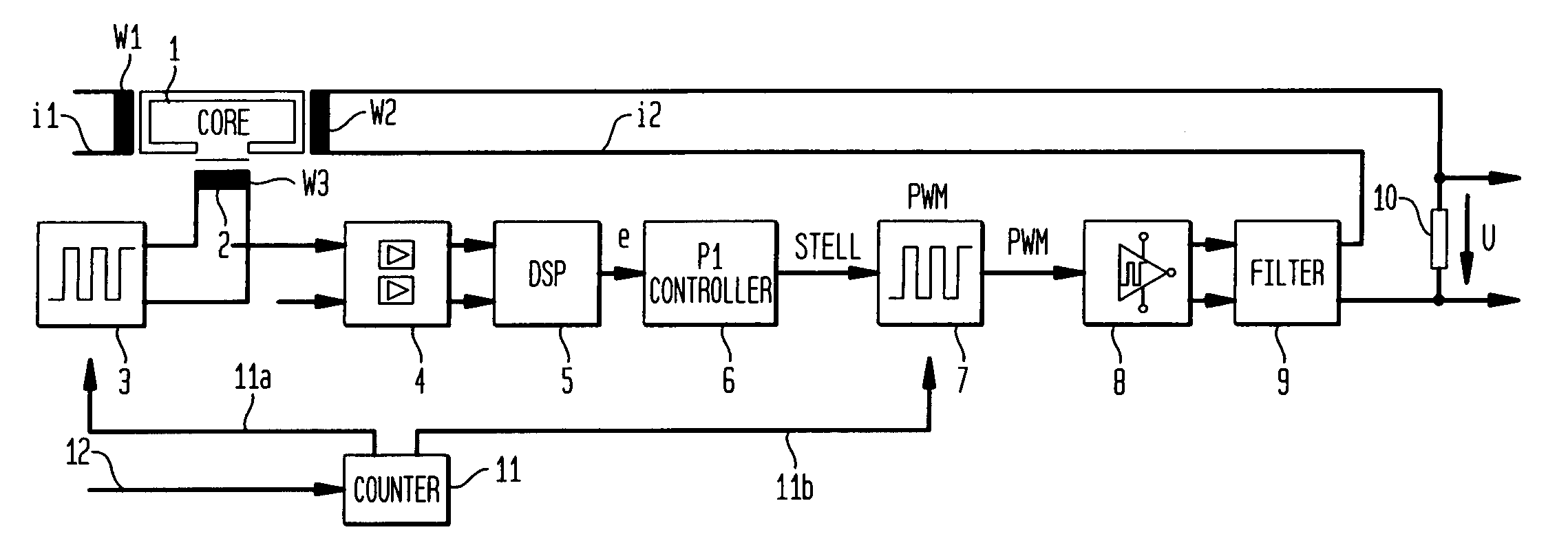

Evaluation circuit for a current sensor using the compensation principle, in particular for measuring direct and alternating currents, and a method for operating such a current sensor

InactiveUS6990415B2Eliminate biasHigh resolutionCurrent/voltage measurementElectrical testingCurrent sensorProcess measurement

A current sensor using the compensation principle, in particular for measuring direct and alternating currents, includes an entirely digital evaluation circuit for signal processing. This substantially lowers the cost of the control electronics, in particular through integration in an ASIC. The magnetic field probe is, for example, supplied with a square wave voltage of a predetermined frequency, the probe signal is recorded by one or two comparators and the pulse width is digitally measured by counters. Furthermore, the conventional analog final stage for the compensation current is replaced by a PWM end stage with a series connected sigma-delta modulator. The square wave can be synchronized with a defined synchronization signal, which can be derived, for example, from the processed measurement values.

Owner:SIEMENS AG

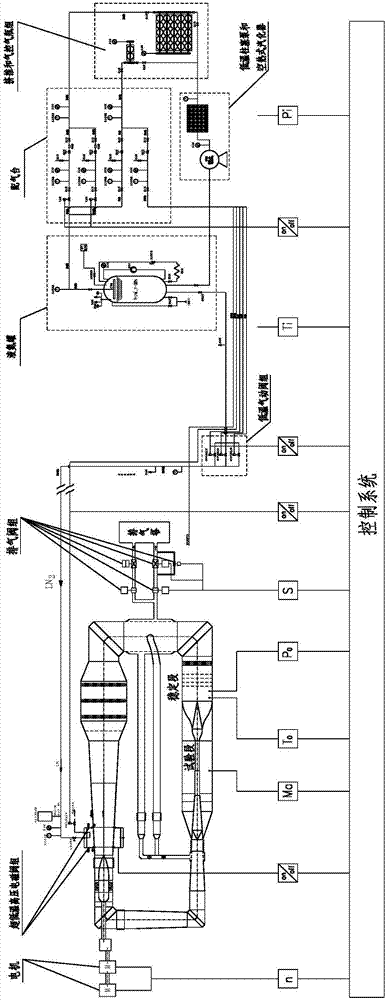

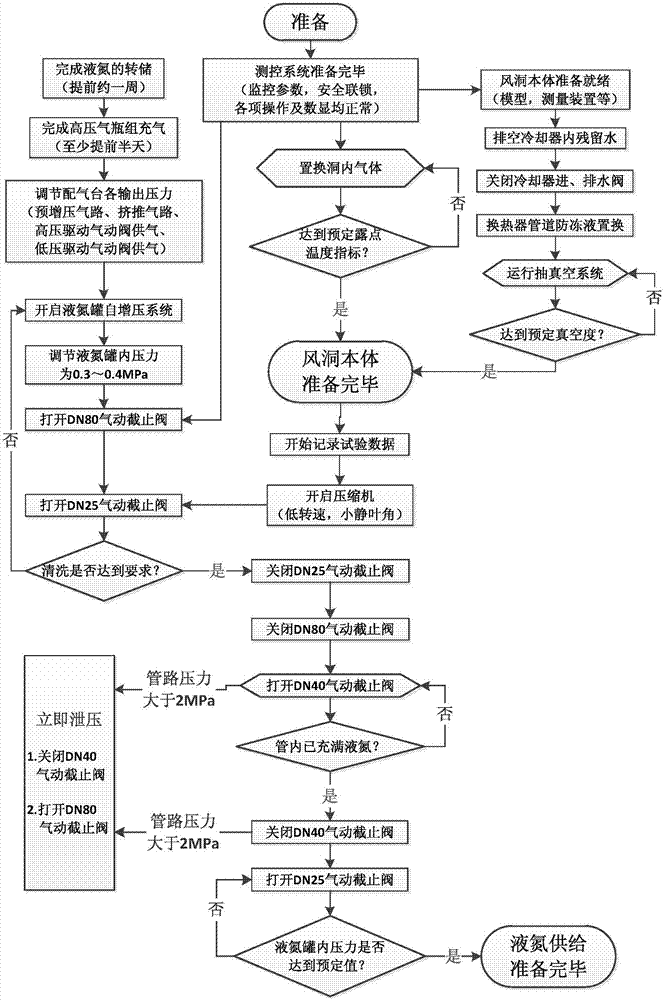

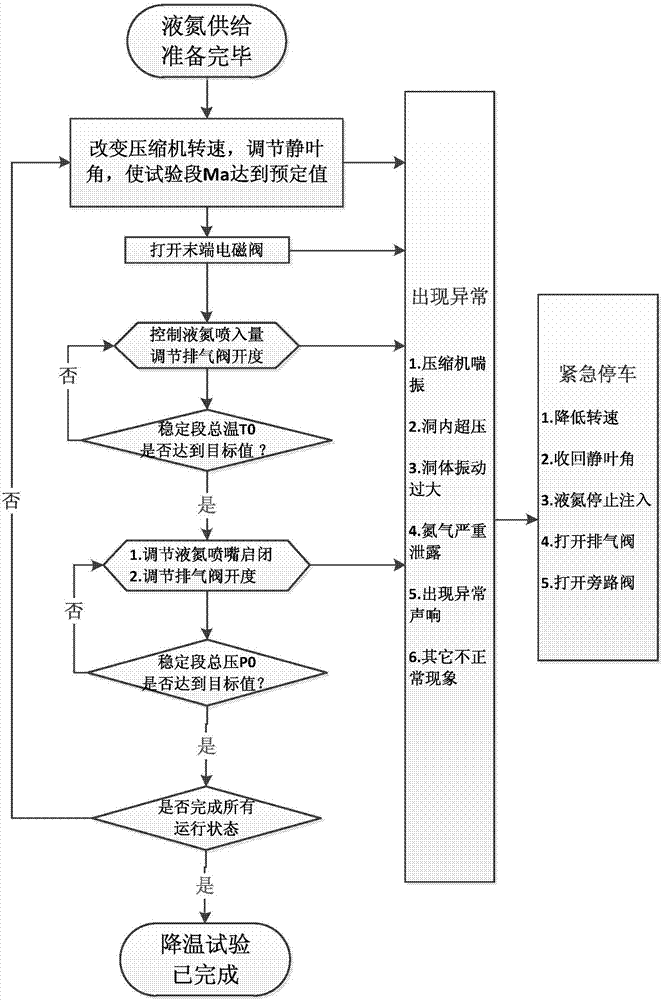

Continuous transonic speed wind tunnel spray liquid nitrogen cooling test operation method

InactiveCN107192531ASafe and effective liquid nitrogen spray cooling testAerodynamic testingEnd stagesLiquid nitrogen cooling

The invention provides a continuous transonic speed wind tunnel spray liquid nitrogen cooling test operation method. The method comprises three stages of work which includes preparation, operation and end. Preparation work comprises liquid nitrogen preparation, push and shove gas preparation, gas distribution bench preparation, wind tunnel preparation, measurement and control system preparation, liquid nitrogen conveying pipeline preparation, storage tank pre-pressurization and gas replacement in a wind tunnel. Operation stage work comprises wind tunnel cleaning, gas flow cooling, parameter transition and stable parameter testing. An end stage comprises steps that data recording is stopped; liquid nitrogen is stopped to be injected into the wind tunnel; through an exhaust system, wind tunnel decompression is performed; and a compressor continuously runs under a set work condition and heat released by the compressor is used to heat a gas flow and a wind tunnel body to a set temperature or to a normal temperature, and then the compressor stops running. By using the method of the invention, operation of a spray liquid nitrogen cooling system and operation of the wind tunnel are integrated into one body so that spray liquid nitrogen cooling testing can be safely and effectively performed in a continuous transonic speed wind tunnel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com