Electromagnetic thermal effect welding seam crack arresting and soldering structure strengthening device

A technology for weld cracks and welded structures, which is applied in the field of electromagnetic thermal effect weld crack arrest and welded structure strengthening devices, can solve the problem of not being able to achieve crack arrest at the same time, suppress the cracking trend, improve mechanical properties, and implementation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

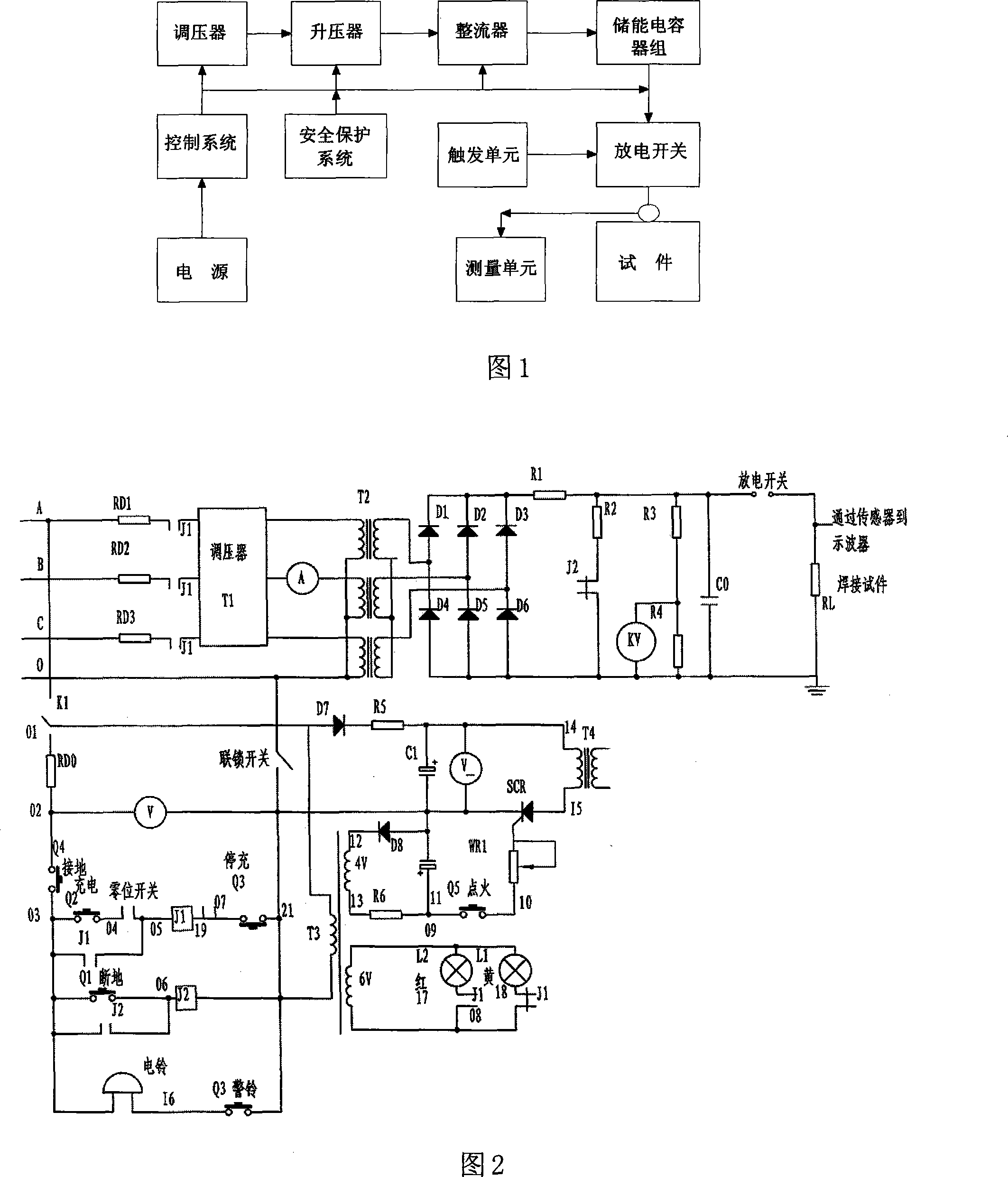

Method used

Image

Examples

experiment Embodiment 1

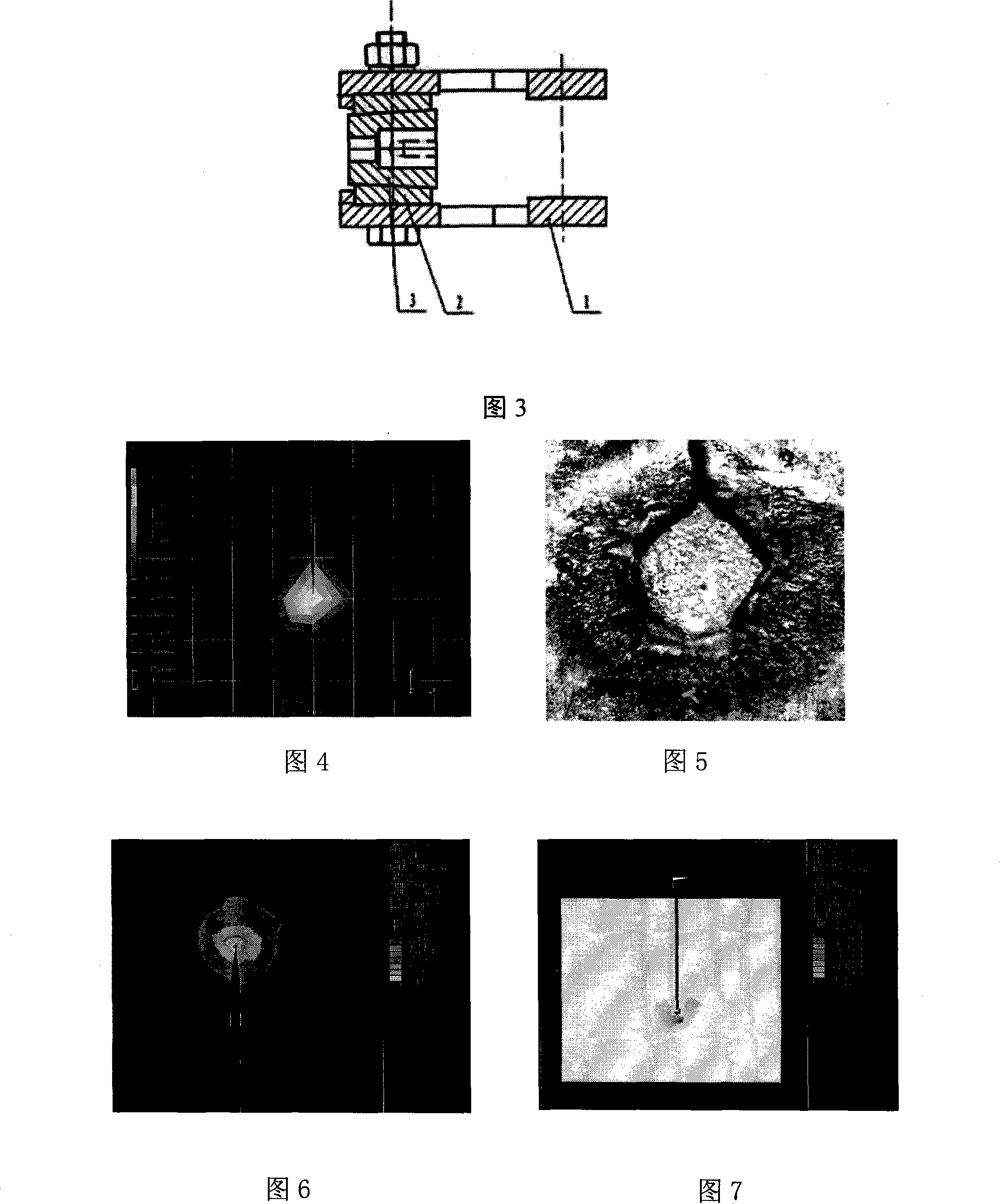

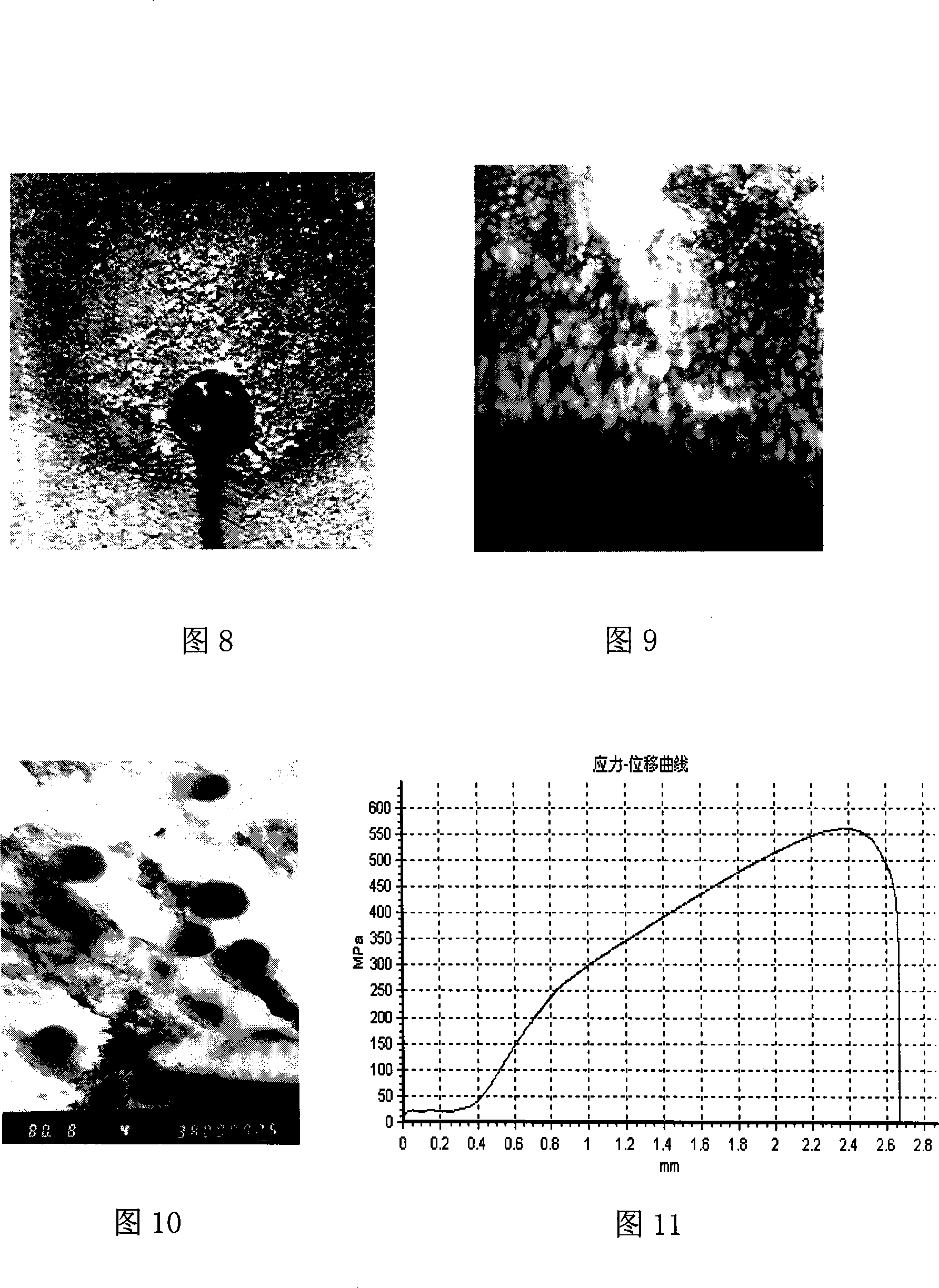

[0052] Common carbon steel weld crack arrest and welding structure strengthening: A132 austenitic stainless steel electrode is selected, the welding structure is the standard tensile test piece of No. 45 steel, and the intermediate welding method is adopted. Due to the small size of the tensile test piece, the weld crack arrest and structural strengthening are carried out by means of pulse discharge to the whole welded structure.

[0053] The numerical analysis method is used to study the temperature field at the instant of discharge when the micro-cracks are strengthened by electromagnetic heating effect. Due to the very short discharge time and the large heat release near the crack tip, the temperature changes drastically, and some materials melt, which is a highly nonlinear problem. The thermo-electric coupling analysis method is adopted in the numerical simulation.

[0054] The numerical simulation research of microcrack arrest strengthening was carried out by commercial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com