Method for reducing cracks of cladding coating on surface of stainless steel under high-temperature service

A high-temperature service, stainless steel technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of reducing the service life of stainless steel, failure of stainless steel components, and accelerated corrosion of stainless steel parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

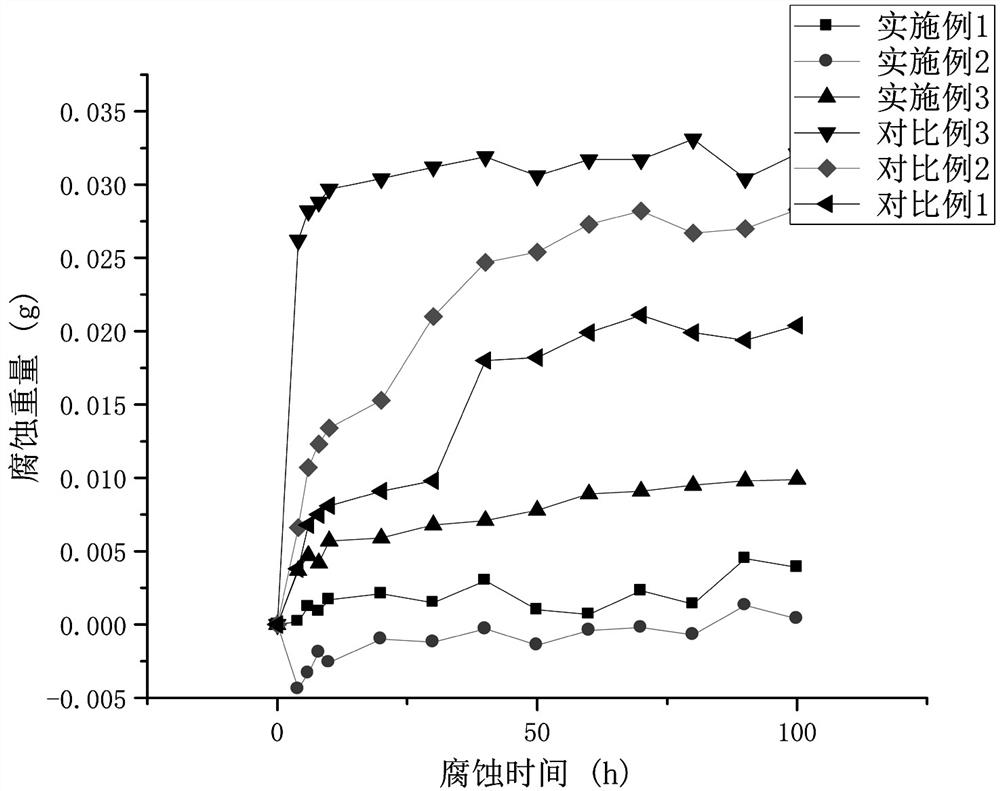

Examples

Embodiment 1

[0036] Cut 17-4PH stainless steel into small pieces of 20×20×10mm to obtain stainless steel matrix.

[0037] After polishing the surface of stainless steel substrate with sandpaper of 150, 400, 800 and 1500 meshes in turn, clean it with absolute ethanol, then put it in an ultrasonic cleaner for cleaning, take it out and blow dry it to remove the residual oil, oxide and other impurities on the surface of stainless steel substrate.

[0038] The stainless steel substrate is placed in a muffle furnace, heated to 500℃ and preheated for 30min.

[0039] The laser cladding process parameters are set as follows: laser power 1800W, spot diameter 4mm, scanning speed 5mm / s, carrier pressure of alloy powder 0.8MPa, powder feeding rate 35mg / s, and scanning lap ratio 50%. Ni625 alloy powder with 150 meshes is loaded in the powder cavity of laser cladding device, and the preheated stainless steel substrate is placed on the laser cladding workbench. Under the action of powder feeder, the coaxial p...

Embodiment 2

[0045] The laser cladding process parameters are set as follows: laser power 1700W, spot diameter 4mm, scanning speed 8mm / s, carrier pressure of alloy powder 0.8MPa, powder feeding rate 35mg / s, scanning lap ratio 50%. Other operations are the same as in Example 1, and the protective layer is clad on the surface of stainless steel substrate.

[0046] After testing, the hardness of the stainless steel surface coating prepared above is 465HV. 0.1 .

Embodiment 3

[0048] The laser cladding process parameters are set as follows: laser power 1600W, spot diameter 4mm, scanning speed 7mm / s, carrier pressure of alloy powder 0.8MPa, powder feeding rate 35mg / s, scanning lap ratio 50%. Other operations are the same as in Example 1, and the protective layer is clad on the surface of stainless steel substrate.

[0049] After testing, the hardness of the stainless steel surface coating prepared above is 470HV. 0.1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com