Method for making plow blade stiffeners for agricultural plow tools

A technology of reinforcing ribs and plows and shovels, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problems of high cost, high coal consumption, cracking, etc., to prevent cracking tendency and reduce heating area , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

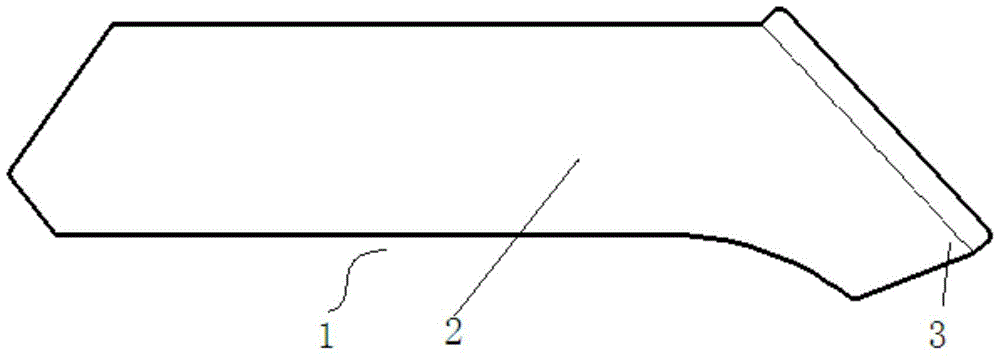

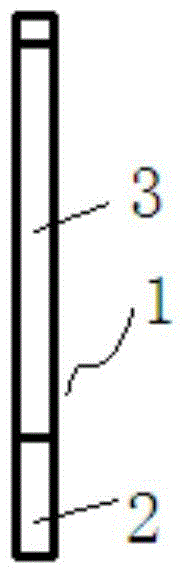

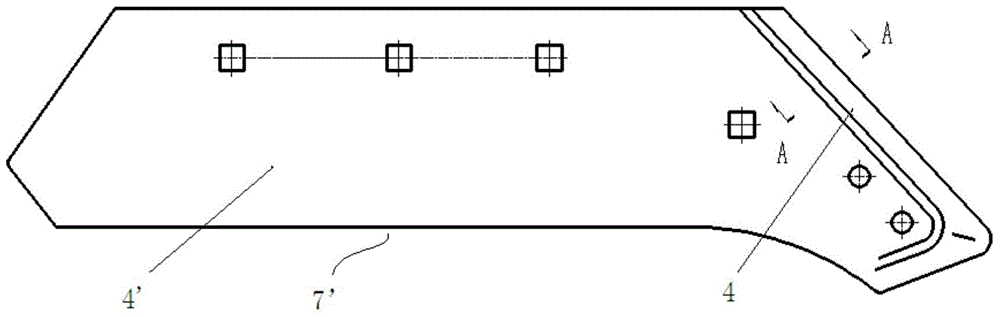

[0055] Such as Figure 5-Figure 7 Shown is a structural schematic diagram of the roughening mold used in the method for roughening the plow shovel blank of the agricultural plow tool in order to form the reinforcing rib according to the present invention.

[0056] Depend on Figure 5-Figure 7 It can be seen that the pier rough die of the present invention includes: a lower die set connected to the fixed worktable of the forging press, which has a fixed lower die 8 and a movable lower die 14 arranged side by side, and between the fixed lower die 8 and the movable lower die 14 Form a positioning station hole for positioning the non-pier thick part 2 of the plow shovel blank 1 (that is, the part used to form the shovel body 4'); the upper die set connected with the movable worktable of the forging press has a An upper mold 6 that is movable up and down for contacting with the plow shovel blank 1 to be thickened so that it is thickened, and the upper mold is aligned with the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com