Laser Selective Shock-Additive Composite Manufacturing Method for Three-dimensionally Reinforced Shape Memory Alloys

A technology for additive manufacturing and memory alloys, which is applied in the field of laser selective impact-additive composite manufacturing of three-dimensionally enhanced shape memory alloys. and other problems, to achieve the effect of inhibiting the initiation and expansion of pores and cracks, inhibiting the tendency of cracking, and reducing the tendency of alloy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

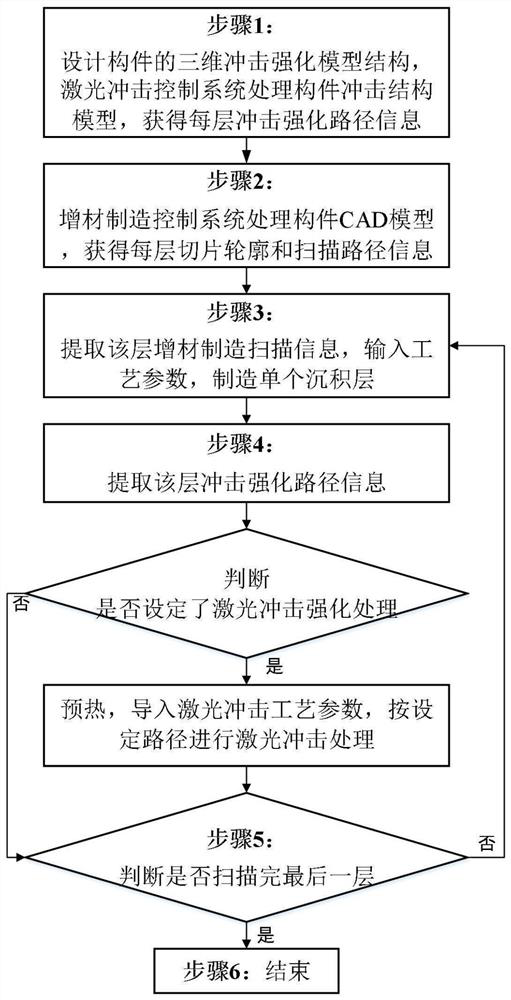

[0046] A method for composite manufacturing of NiTi shape memory alloy three-dimensional impact-reinforced structure by laser selective shock-laser selective melting, comprising the following steps,

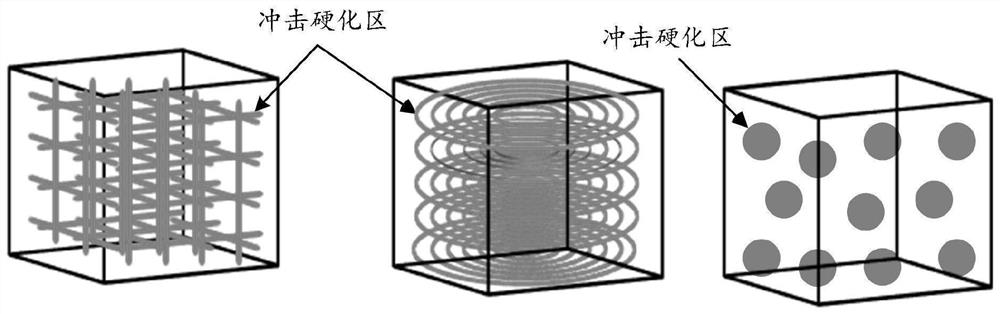

[0047] S1: Design as image 3 The spherical three-dimensional impact strengthening model structure, in which the diameter of the three-dimensional spherical structure is 1-10mm, the diameter of each three-dimensional sphere can be the same or different, the total area of the impact lattice accounts for 10-60% of the area of the sediment layer, and the three-dimensional sphere It is regularly and evenly distributed in the component, and the proportion of the martensite phase in the three-dimensional sphere is 10-50%. The laser shock strengthening control system processes the laser shock structure model designed above, and generates layer-by-layer shock strengthening path information of components according to the model;

[0048] S2: The laser selective melting control system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com