A kind of high temperature titanium alloy and preparation method thereof

A high-temperature titanium alloy and intermediate alloy technology, applied in the field of high-temperature titanium alloy and its preparation, can solve the problems of reducing the high-temperature creep and durability properties of materials, high-temperature creep properties, poor durability properties, and decreasing thermal stability of alloys, etc. The effect of improving high temperature durability and creep performance, good welding performance and excellent high temperature tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A preparation method of a high-temperature titanium alloy, the preparation method specifically comprising the following steps:

[0053] 1. Preparation materials:

[0054] Firstly, Ti is made of 0A--grade 1 sponge titanium, and the alloy elements Nb, Mo, and Si are added in the form of master alloy; Zr and C are added in the form of sponge Zr and carbon powder respectively; the Al part is brought in by the master alloy, and the insufficient part is added as pure Al ;

[0055] 2. Preparation of high temperature titanium alloy:

[0056] Continuing from the previous step, after the intermediate alloy and titanium sponge are batched and mixed, they are pressed into electrodes with a press, and then the electrode groups are welded together, and smelted 2 to 3 times in the smelting equipment. The smelting equipment is vacuum self-consumption arc furnace or vacuum induction furnace; alloy ingots are made, and the alloy ingots are vacuum poured into mechanical test bars throug...

Embodiment 1

[0076] The chemical content (wt%) of the high-temperature titanium alloy materials in Examples 1# to 7# is shown in the table below.

[0077] The chemical content (wt%) of embodiment 1#~7# high temperature titanium alloy material

[0078]

Al

Zr

Nb

Mo

Si

C

Example 1

6.3

4.0

1.6

0.6

0.4

0.10

Example 2

6.2

4.0

1.6

0.6

0.3

0.06

Example 3

6.6

3.9

1.7

0.6

0.3

0.08

Example 4

6.0

4.5

1.0

0.8

0.2

0.14

Example 5

6.6

3.5

2.0

0.4

0.7

0.06

Example 6

5.5

5.0

0.5

1.0

0.1

0.15

Example 7

7.0

2.0

2.5

0.2

0.8

0.03

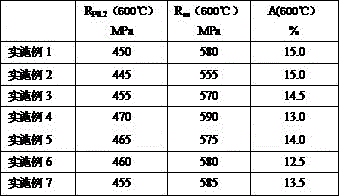

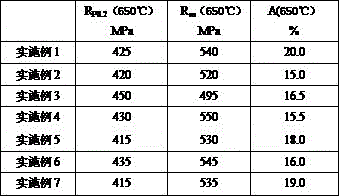

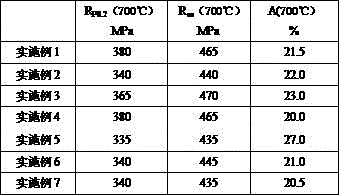

[0079] The tensile properties at room temperature of the high-temperature titanium alloy materials of Examples 1# to 7# are shown in the table below.

[0080] Example 1#~7# Tensile properties at room temperature

[0081]

R P0.2 (MPa)

R m (MPa)

A(%)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com