Ni-based alloy for a forged part of a steam turbine, rotor blade of a steam turbine, stator blade of a steam turbine, screw member for a steam turbine, and pipe for a steam turbine

A nickel-based alloy, rotor blade technology, applied in the direction of blade support elements, engine elements, mechanical equipment, etc., can solve application problems, and achieve the effect of enhanced forgeability and weldability, excellent high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0025] A nickel-based alloy of a forged part of a steam turbine having excellent high-temperature strength, forgeability, and weldability according to an embodiment of the present invention has the following composition. The symbol "%" herein means "% by weight", unless otherwise specified.

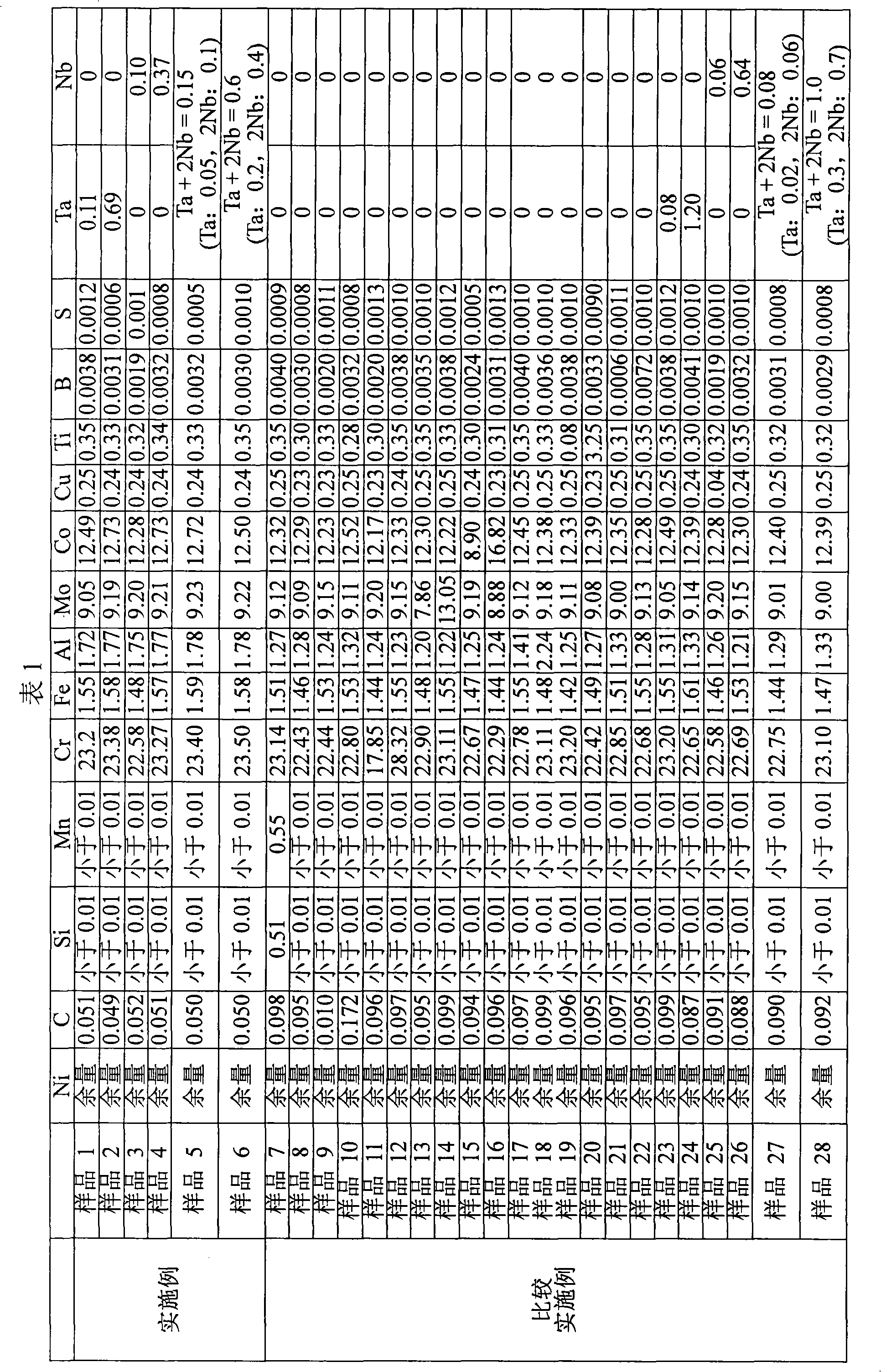

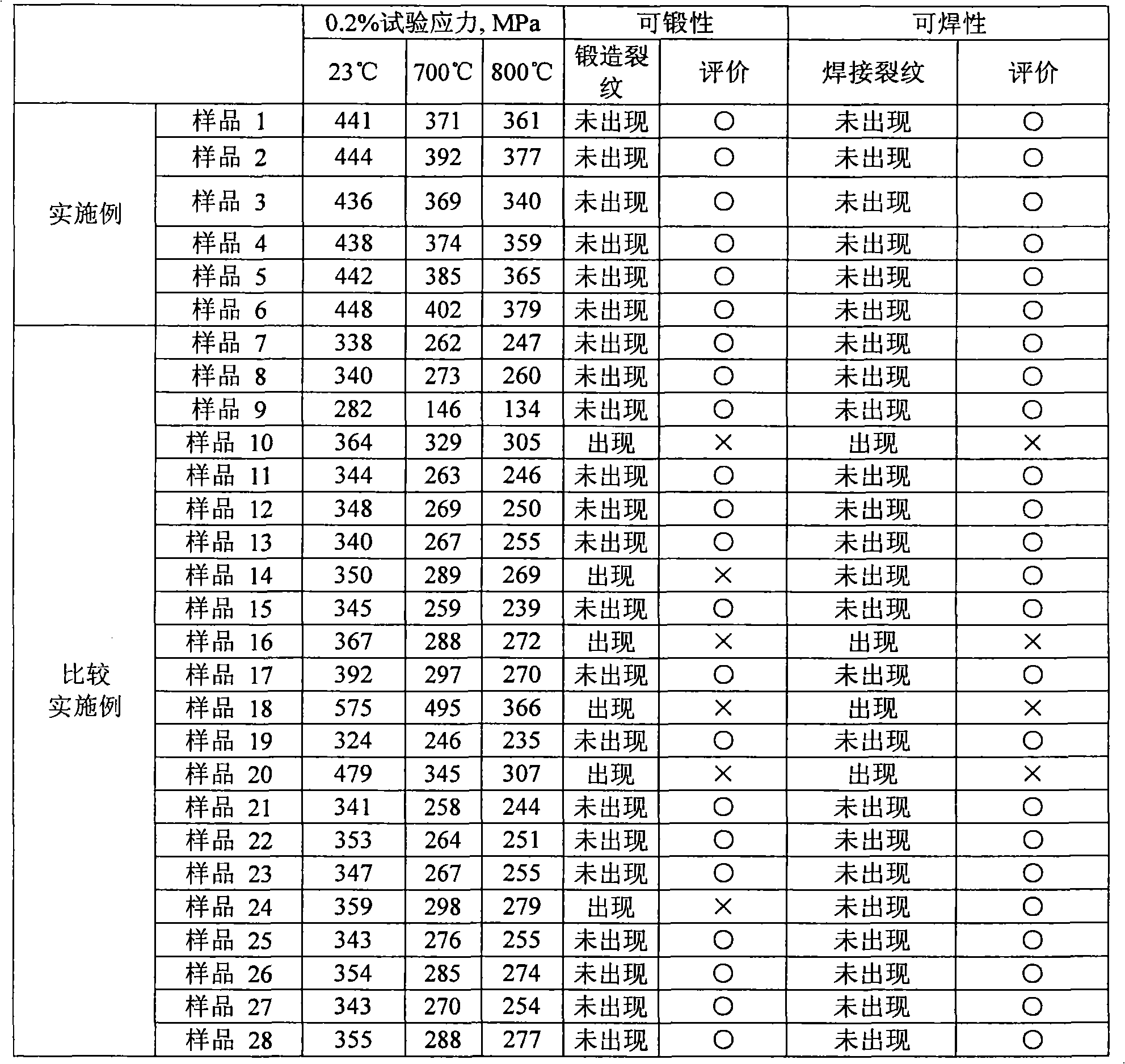

[0026] (M1) C: 0.01% to 0.15%, Cr: 18% to 28%, Co: 10% to 15%, Mo: 8% to 12%, Al: 1.5% to 2%, Ti: 0.1% to 3% , B: 0.001% to 0.006%, Ta: 0.1% to 0.7%, and the remainder thereof is Ni and unavoidable impurities.

[0027] (M2) C: 0.01% to 0.15%, Cr: 18% to 28%, Co: 10% to 15%, Mo: 8% to 12%, Al: 1.5% to 2%, Ti: 0.1% to 3% , B: 0.001% to 0.006%, Nb: 0.1% to 0.4%, and the remainder thereof is Ni and unavoidable impurities.

[0028] (M3) C: 0.01% to 0.15%, Cr: 18% to 28%, Co: 10% to 15%, Mo: 8% to 12%, Al: 1.5% to 2%, Ti: 0.1% to 3% , B: 0.001% to 0.006%, Ta+2Nb: 0.1% to 0.7%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com